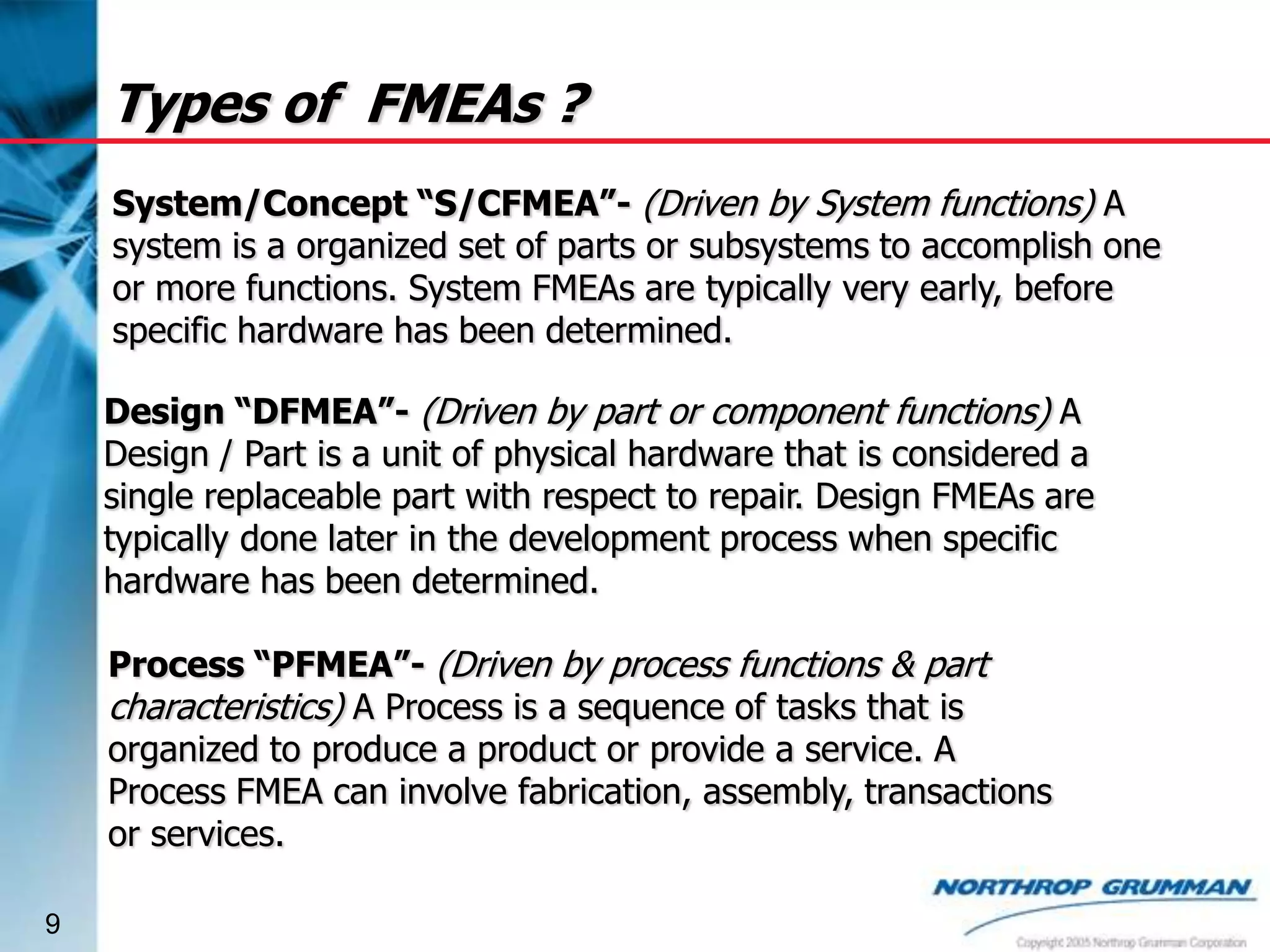

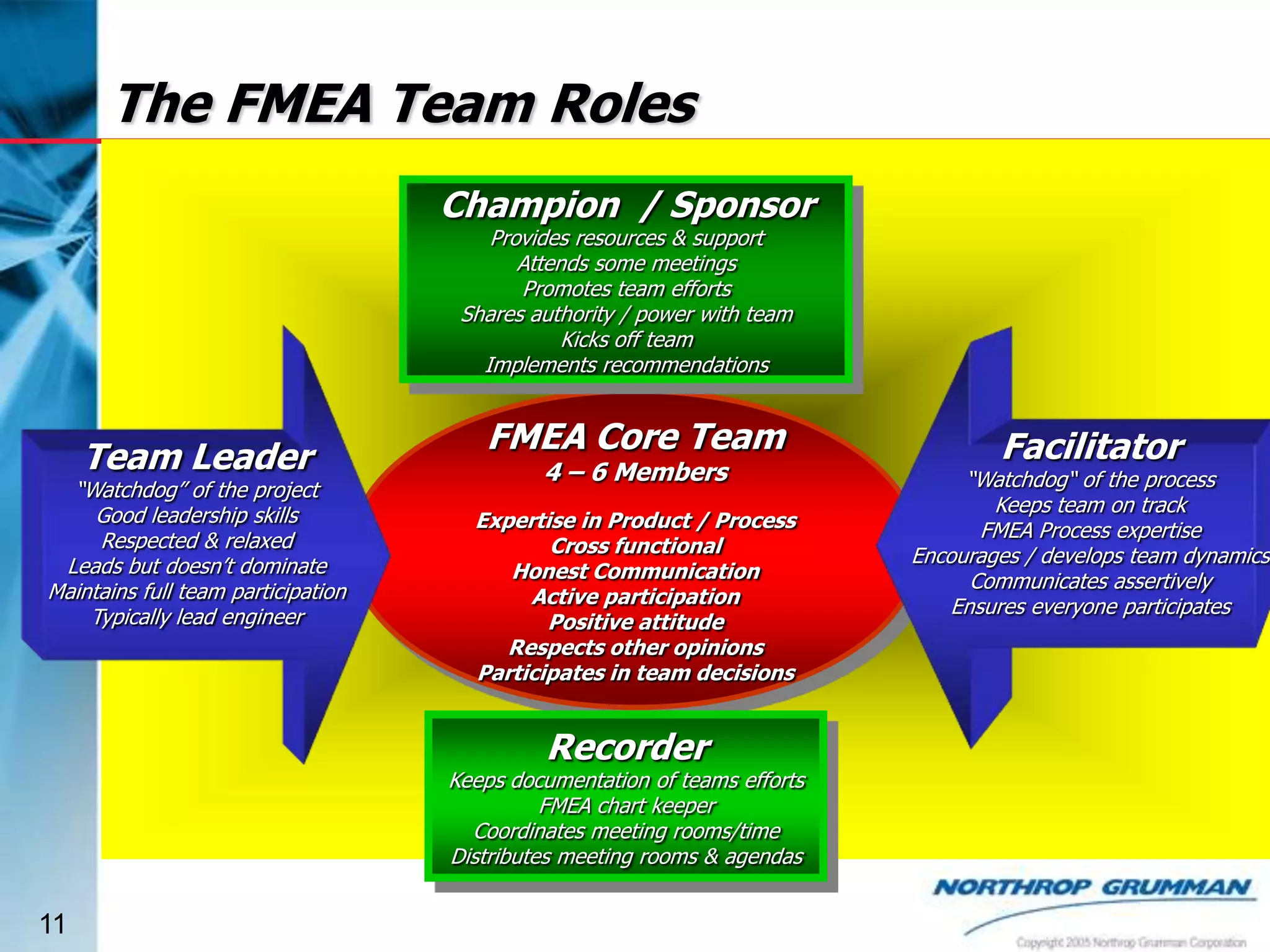

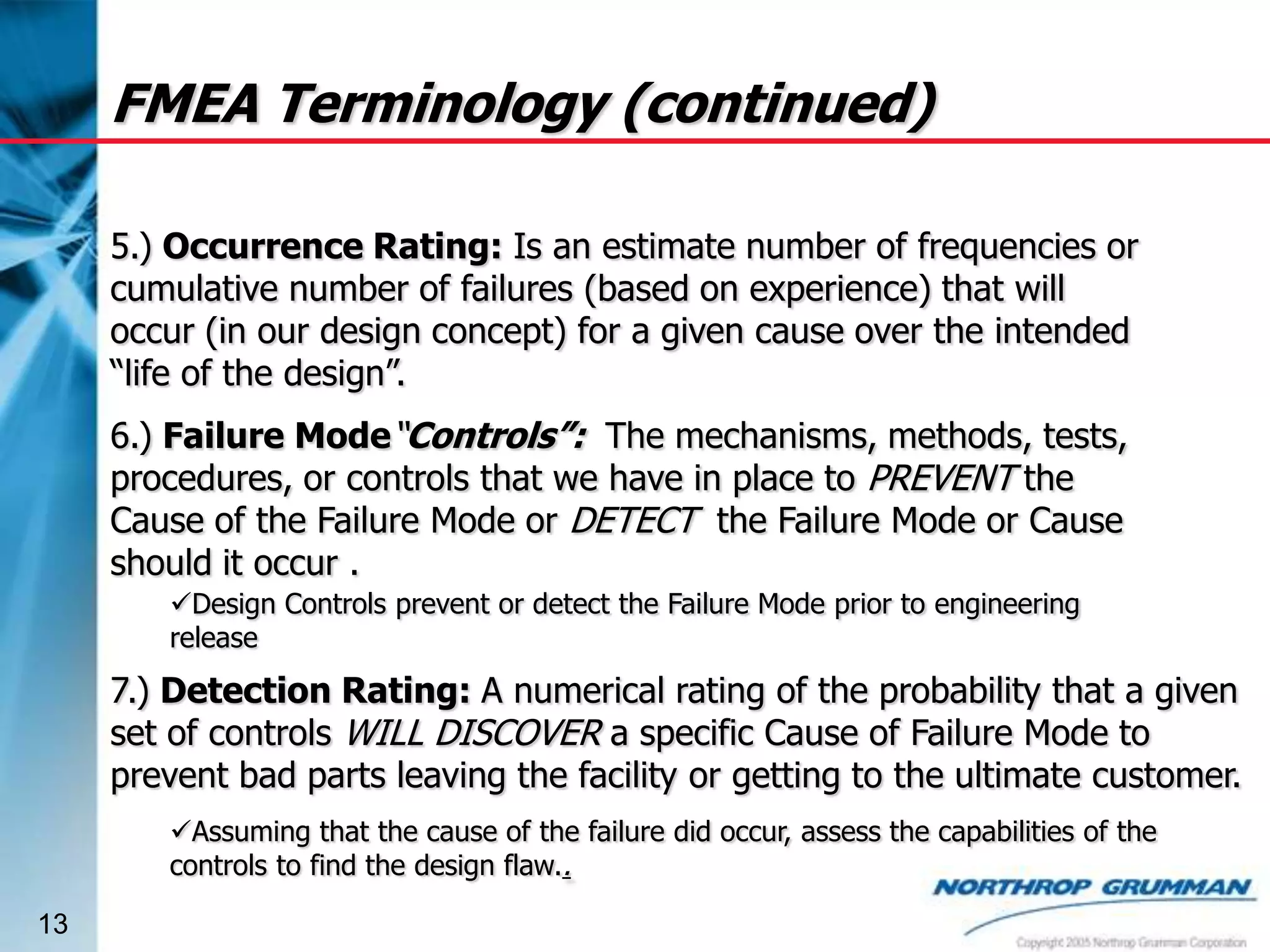

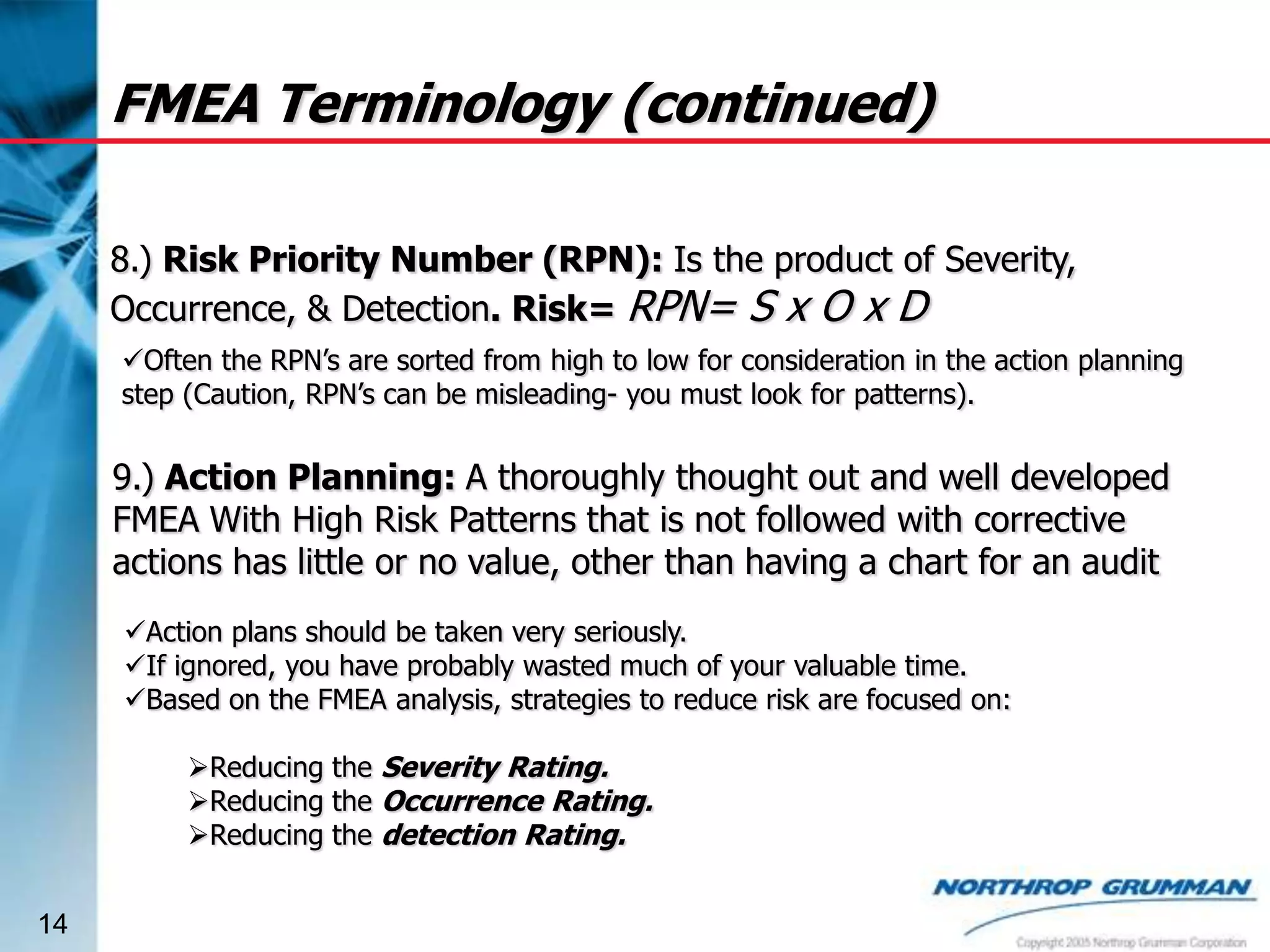

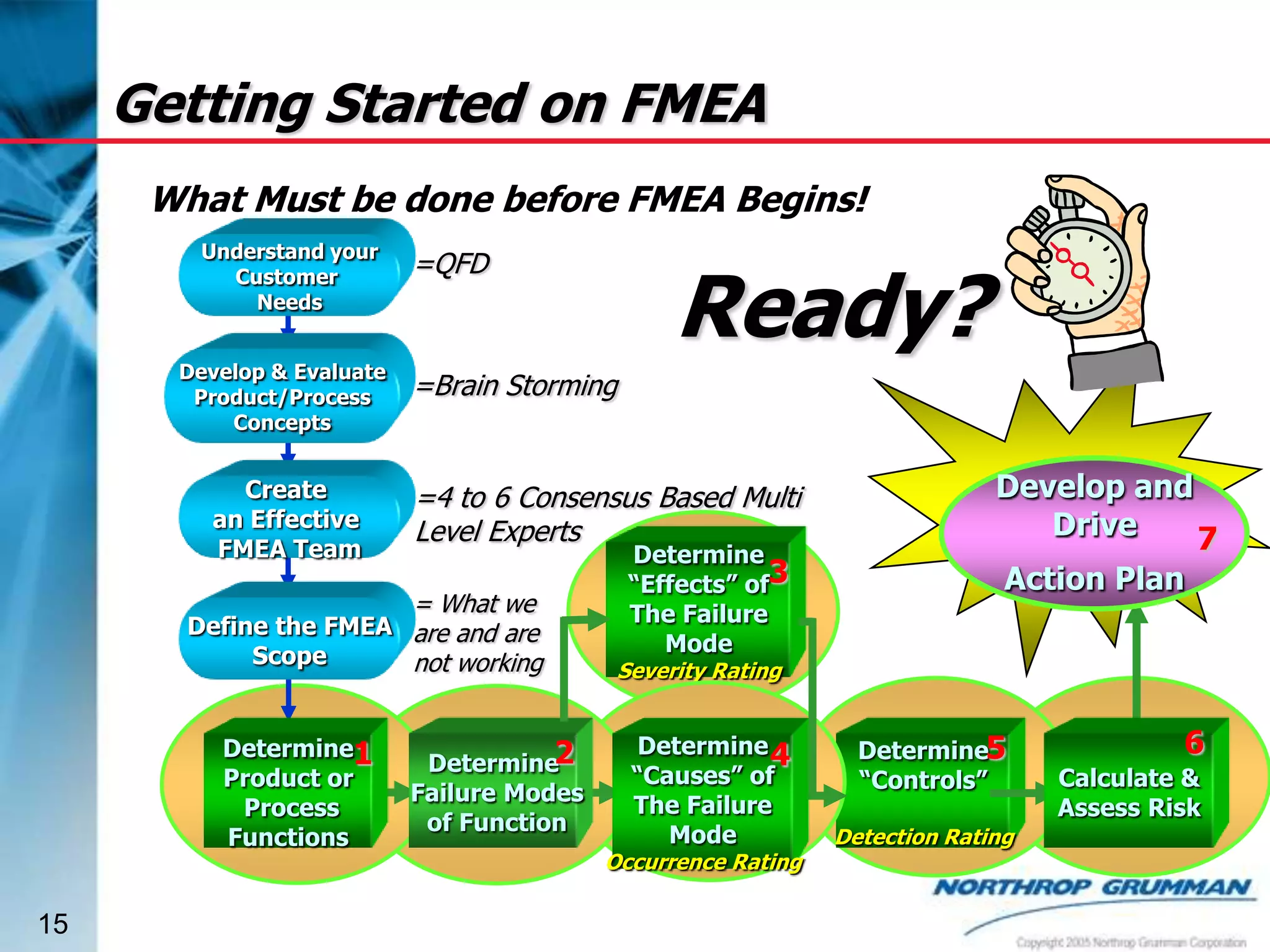

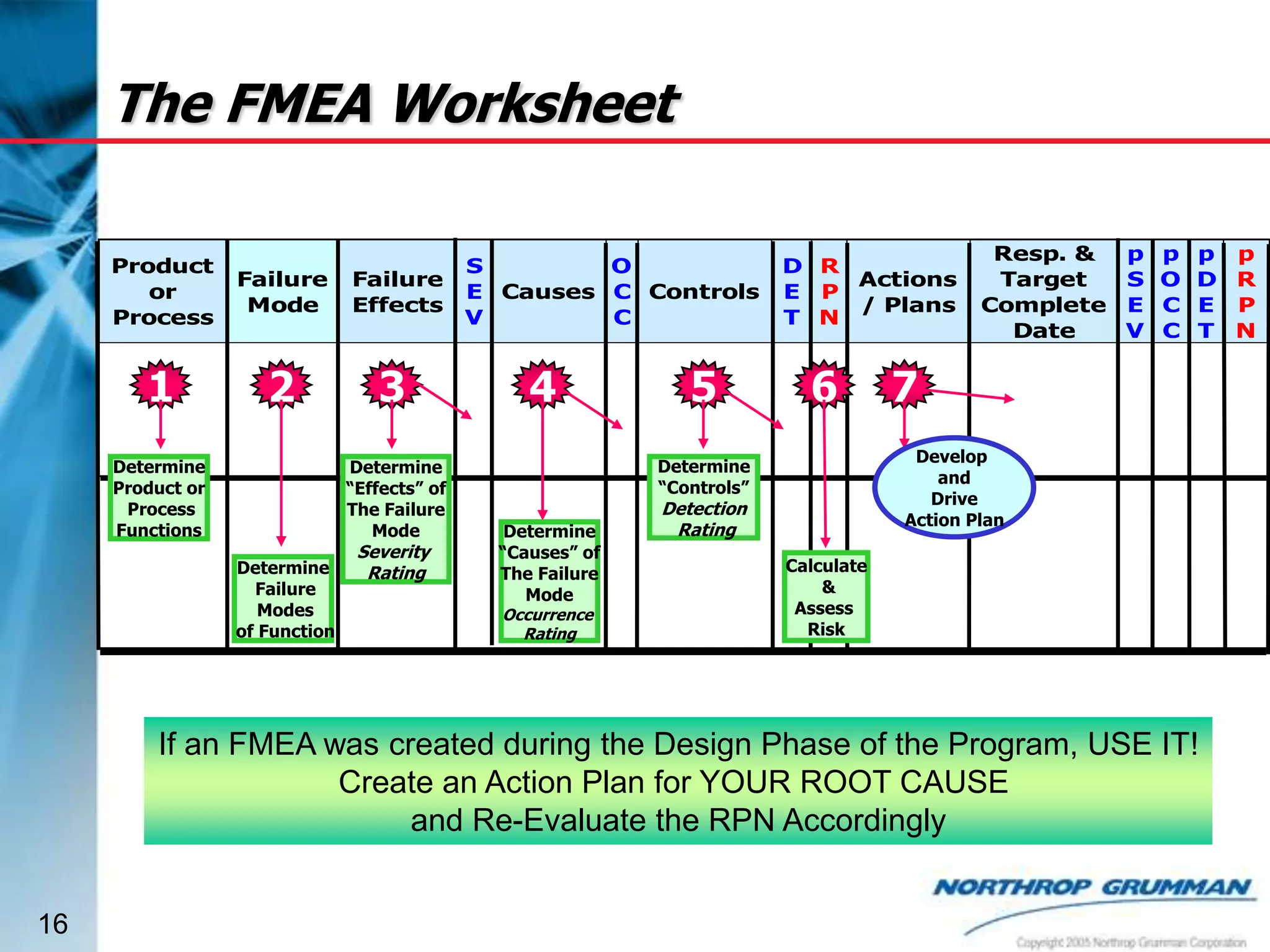

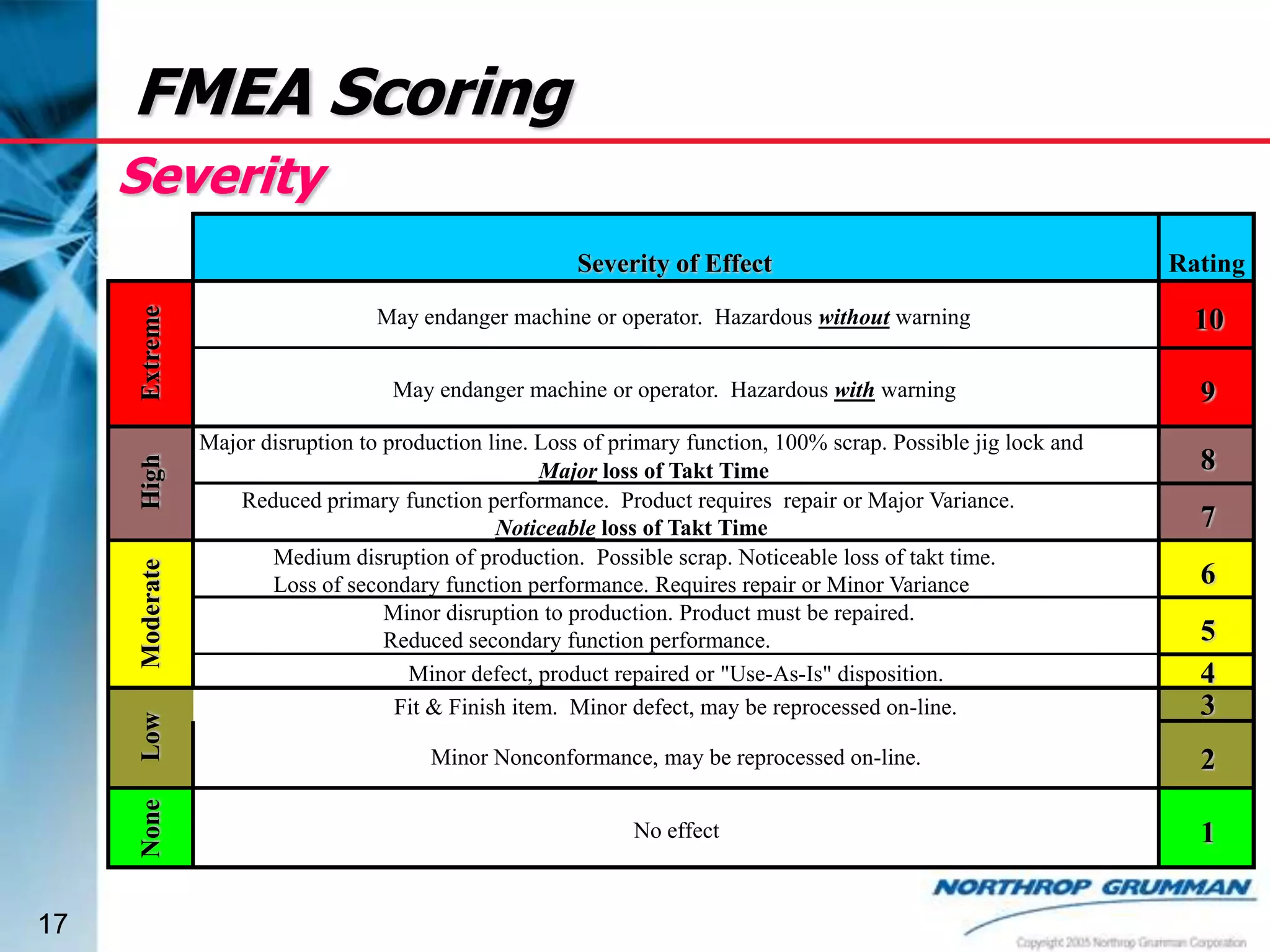

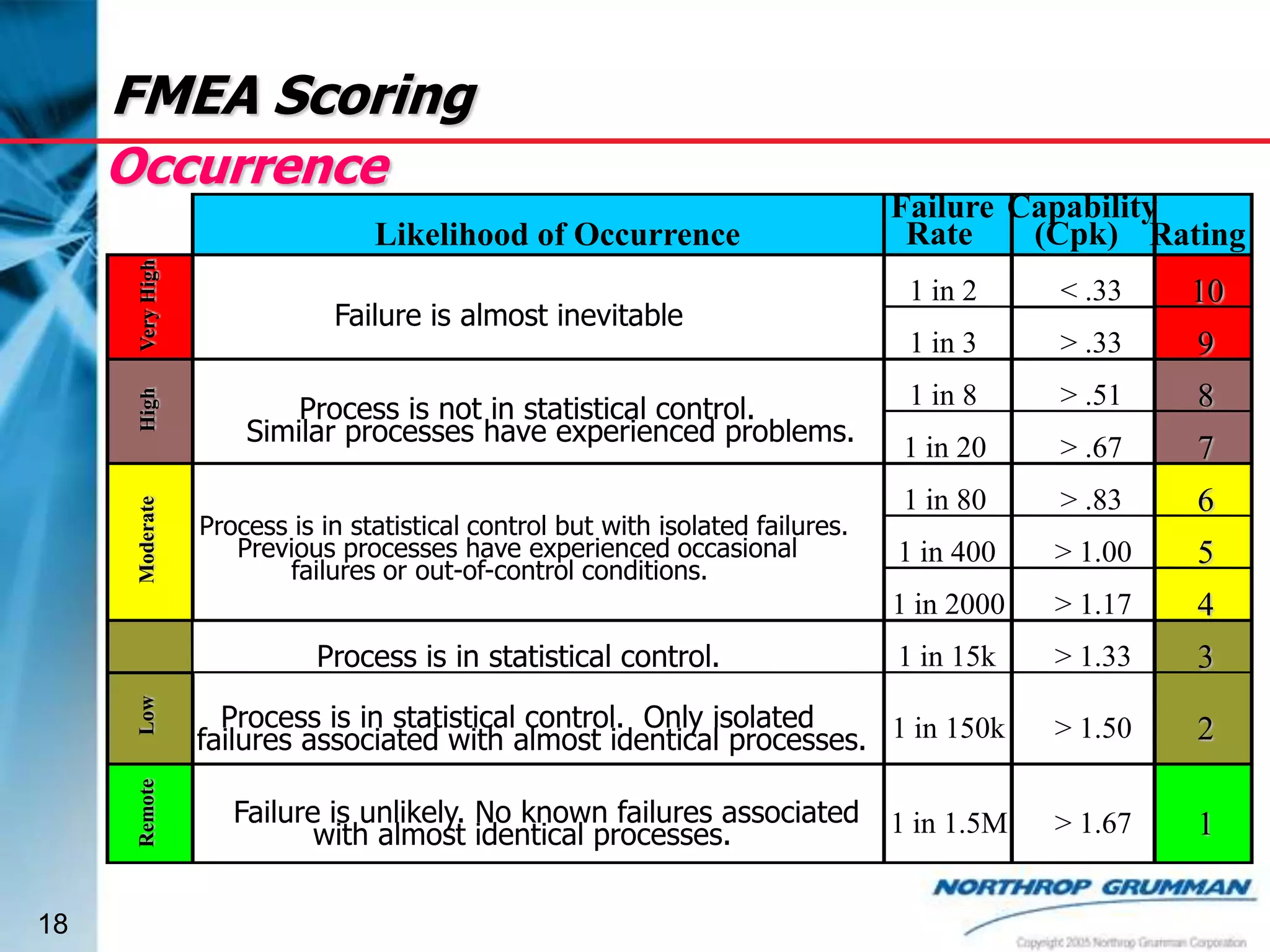

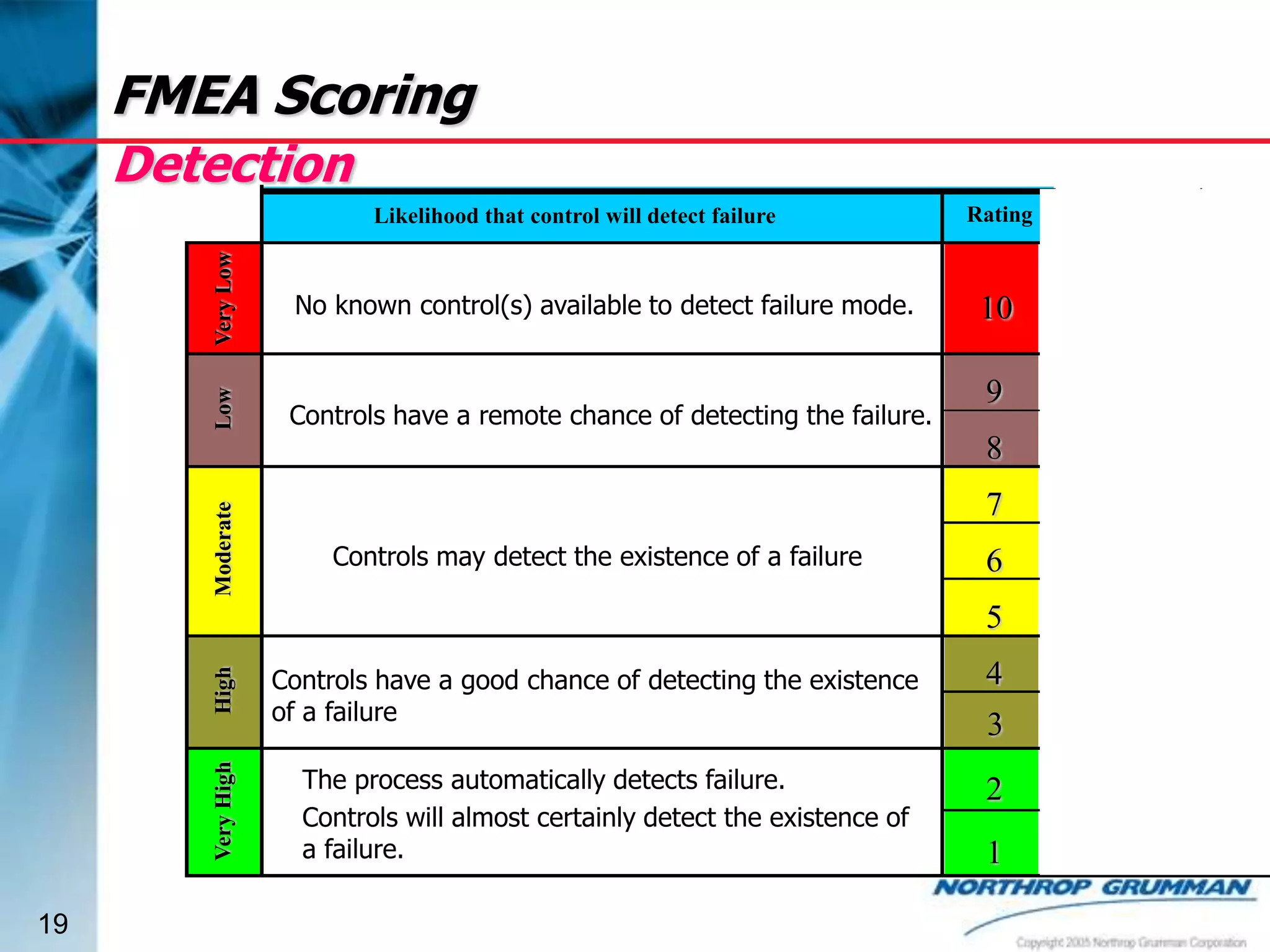

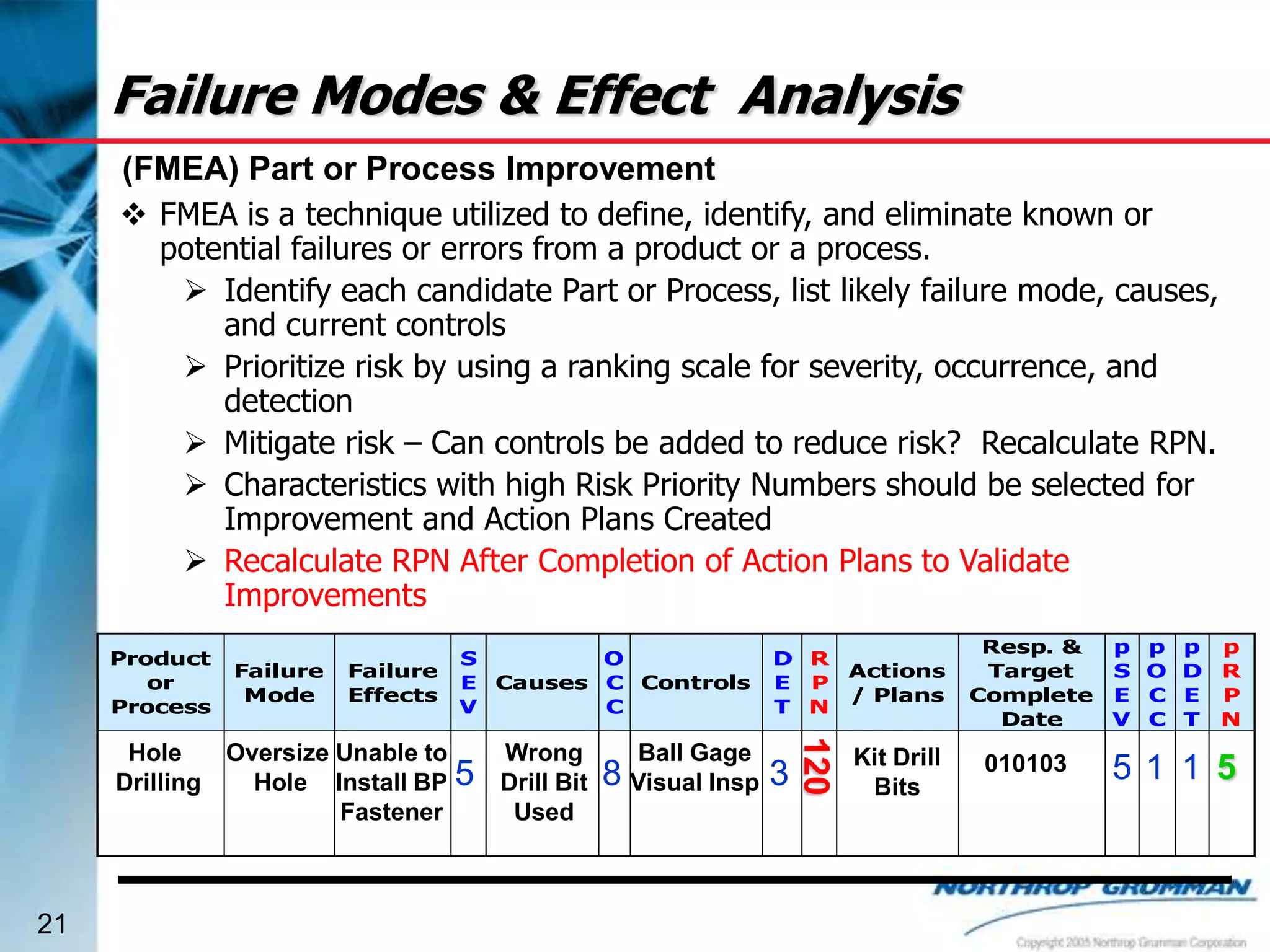

This document provides an overview of Failure Mode and Effects Analysis (FMEA). FMEA is a systematic method for evaluating potential failure modes within a design, identifying their causes and effects, and prioritizing risks. The document outlines the history and purpose of FMEA, defines key terms, and describes how to conduct an FMEA, including establishing a team, documenting the process on a worksheet, scoring risks, and developing action plans. FMEA is a useful tool for proactively identifying and mitigating risks within a product or process design to improve quality and prevent failures.