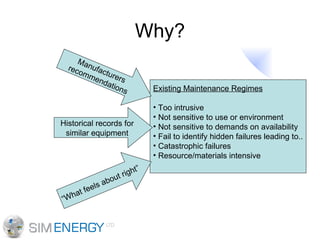

Reliability Centred Maintenance (RCM) is a structured approach aimed at enhancing maintenance effectiveness by focusing on reliability and cost efficiency. The process involves identifying equipment functions, analyzing potential failures, and prioritizing maintenance tasks based on data-driven insights. Opportunities from RCM implementation, such as the Airbridge RCM study, demonstrate significant reductions in maintenance tasks and faults, enhancing overall maintenance flexibility and technician productivity.