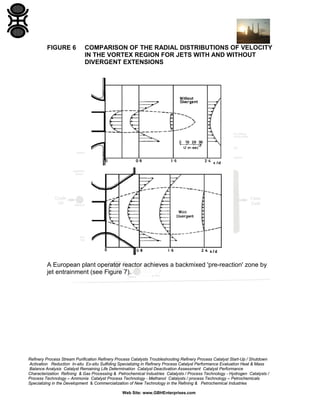

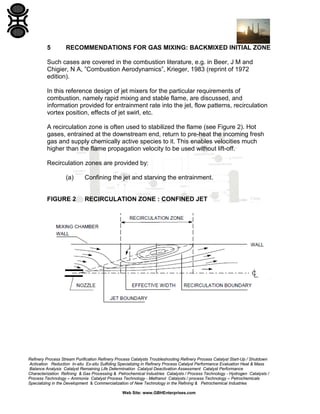

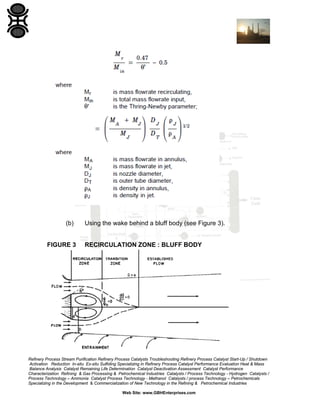

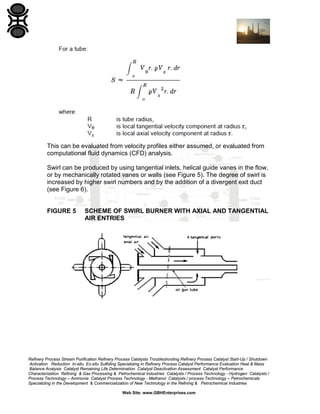

The document is a process engineering guide from GBH Enterprises outlining gas mixing techniques and recommendations for refining and petrochemical applications. It covers various aspects of gas mixing, including design procedures for different mixer types and specific contexts such as pre-reaction zones and recirculation flows. The guide serves as a technical resource for process engineers, emphasizing the importance of evaluating gas mixing methodologies to enhance performance and reliability in industrial applications.

![Static mixers can achieve good mixing in less than five pipe diameters regardless

of the density difference. Figure 1 shows the results obtained using a Sulzer

SMV mixer. Unless the densities are similar and the flow rates constant, a

minimum operating velocity, UG, is recommended. For the Sulzer SMV mixer,

this is obtained if the modified Froude number exceeds 20 [Ref 1 : Germain et

al., 1982]:

. The values of f and DH are obtained from the manufacturers' data;

Refinery Process Stream Purification Refinery Process Catalysts Troubleshooting Refinery Process Catalyst Start-Up / Shutdown

Activation Reduction In-situ Ex-situ Sulfiding Specializing in Refinery Process Catalyst Performance Evaluation Heat & Mass

Balance Analysis Catalyst Remaining Life Determination Catalyst Deactivation Assessment Catalyst Performance

Characterization Refining & Gas Processing & Petrochemical Industries Catalysts / Process Technology - Hydrogen Catalysts /

Process Technology – Ammonia Catalyst Process Technology - Methanol Catalysts / process Technology – Petrochemicals

Specializing in the Development & Commercialization of New Technology in the Refining & Petrochemical Industries

Web Site: www.GBHEnterprises.com](https://image.slidesharecdn.com/gasmixing-131017103934-phpapp02/85/Gas-Mixing-5-320.jpg)

![6

BIBLIOGRAPHY

Reference

Authors, Title and Source

[1]

Germain, E & Wetter, R. Mélange Statique de gaz, Informations

Chimie No. 232. Dec 1982, p 135 (referred to in Clause 4).

Refinery Process Stream Purification Refinery Process Catalysts Troubleshooting Refinery Process Catalyst Start-Up / Shutdown

Activation Reduction In-situ Ex-situ Sulfiding Specializing in Refinery Process Catalyst Performance Evaluation Heat & Mass

Balance Analysis Catalyst Remaining Life Determination Catalyst Deactivation Assessment Catalyst Performance

Characterization Refining & Gas Processing & Petrochemical Industries Catalysts / Process Technology - Hydrogen Catalysts /

Process Technology – Ammonia Catalyst Process Technology - Methanol Catalysts / process Technology – Petrochemicals

Specializing in the Development & Commercialization of New Technology in the Refining & Petrochemical Industries

Web Site: www.GBHEnterprises.com](https://image.slidesharecdn.com/gasmixing-131017103934-phpapp02/85/Gas-Mixing-11-320.jpg)