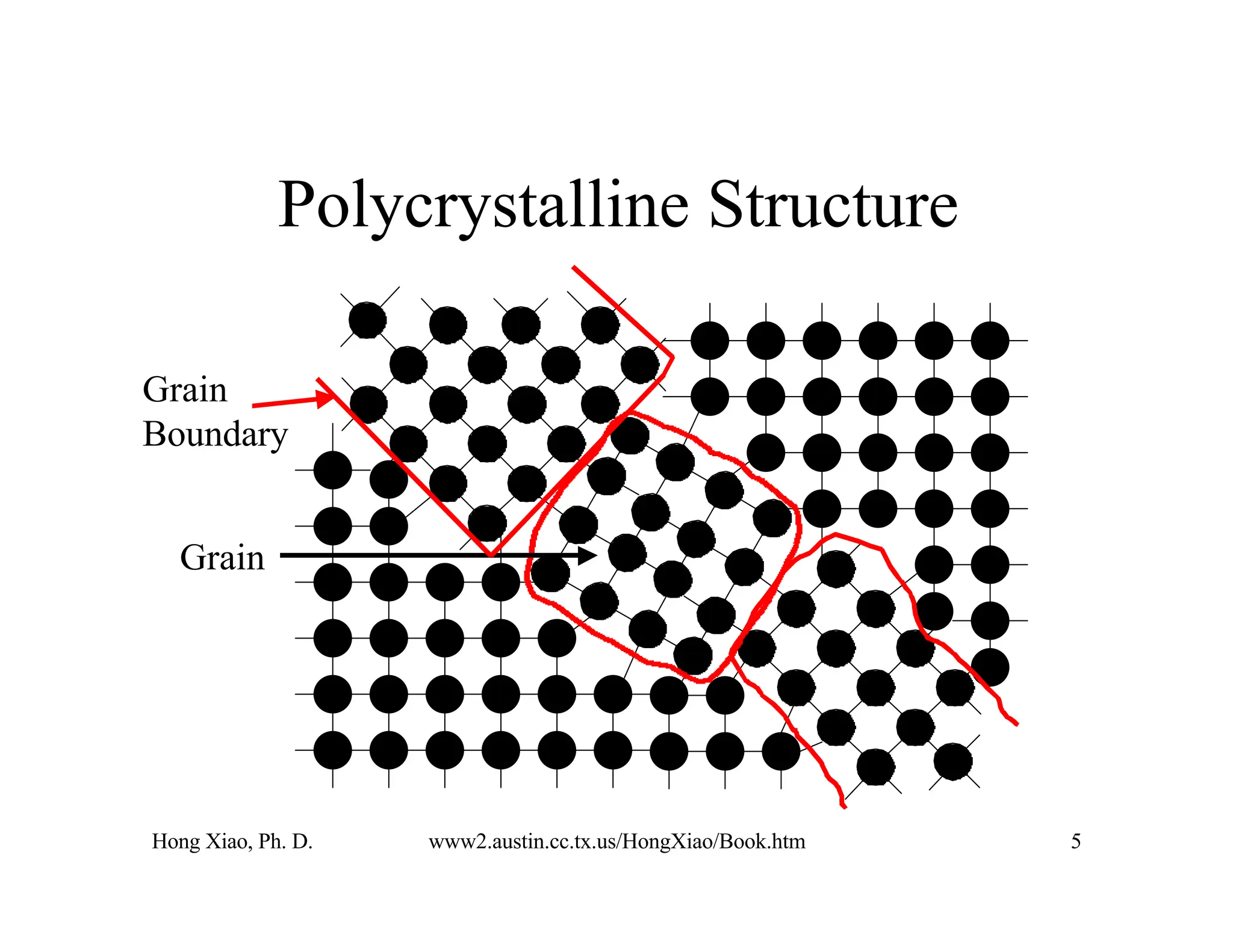

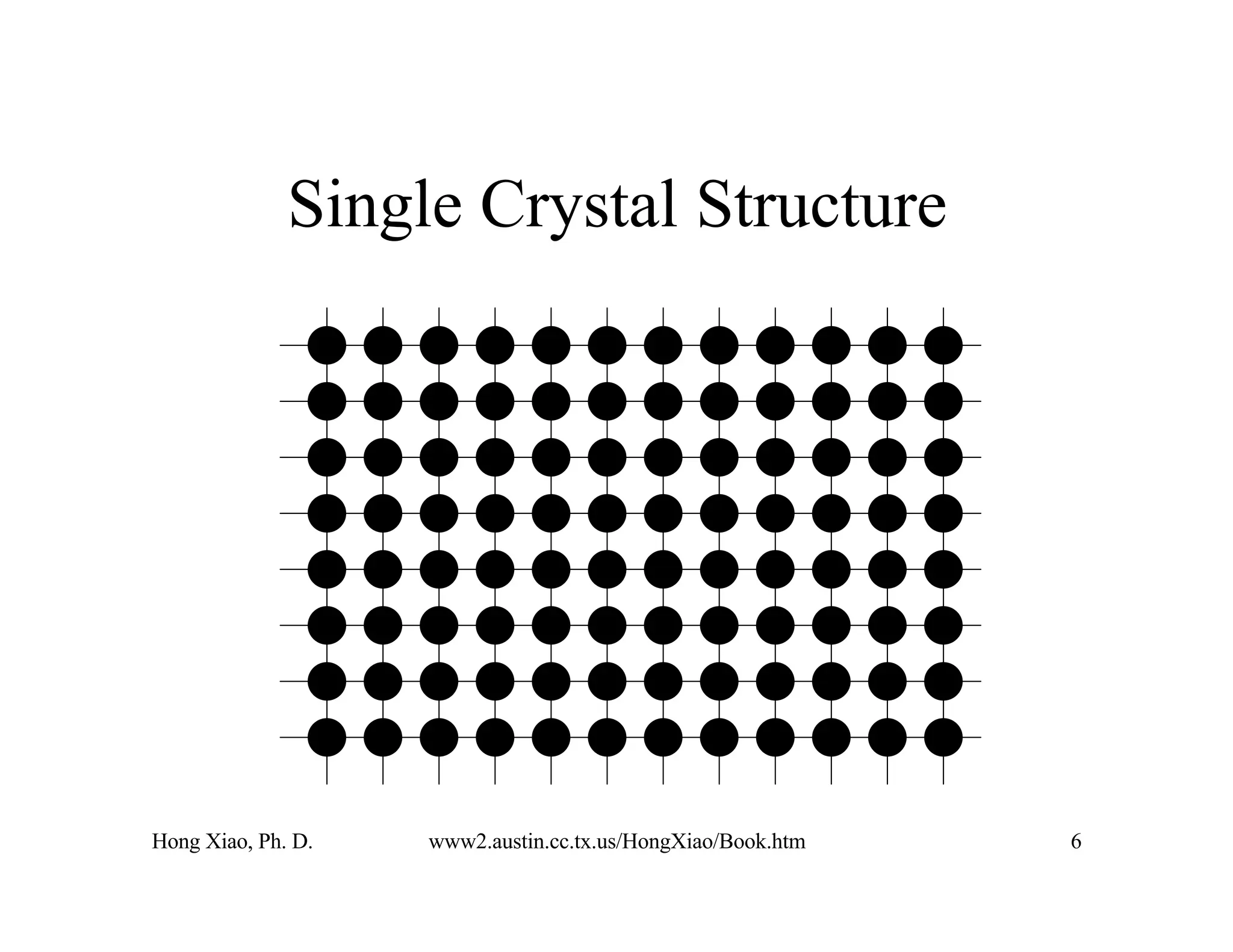

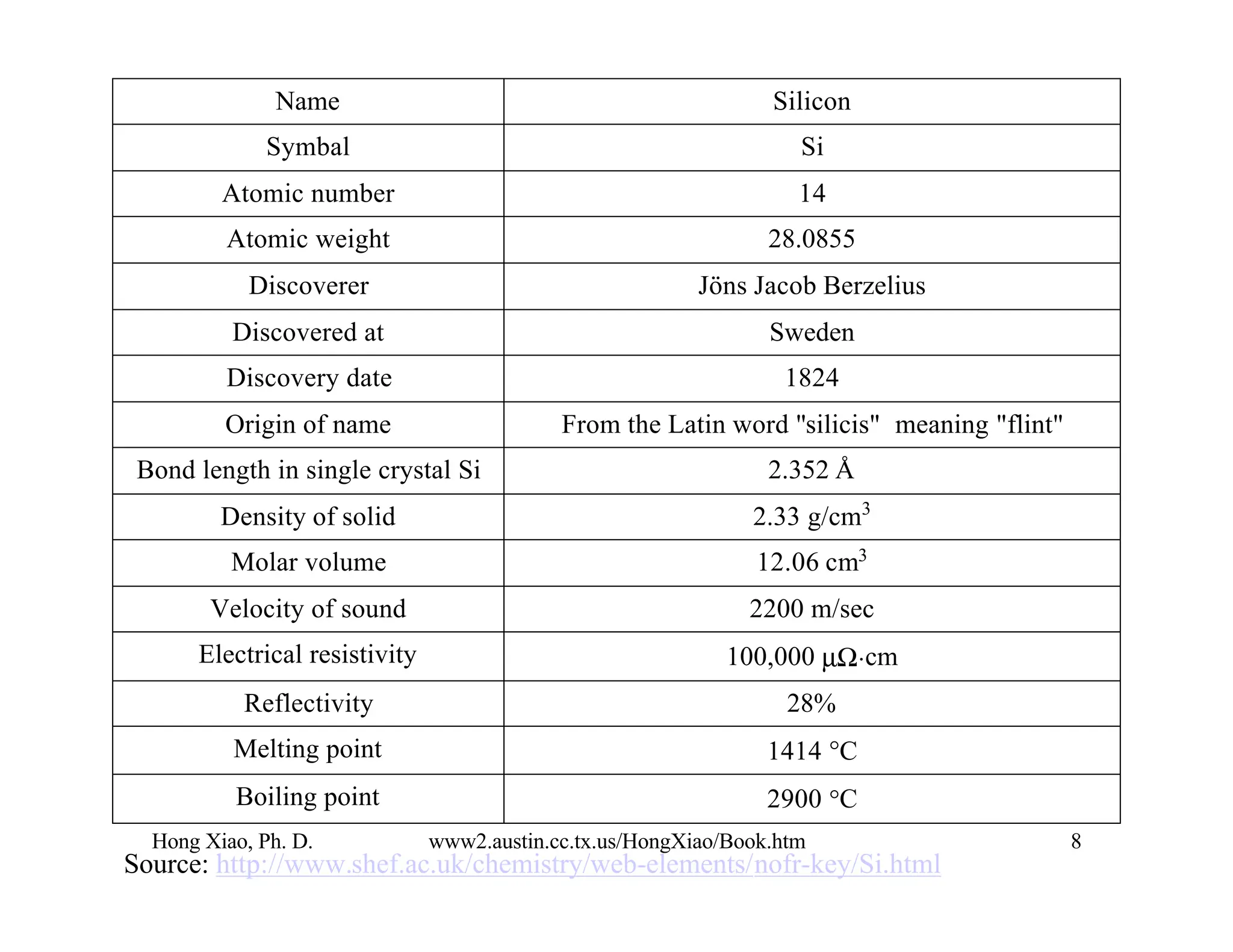

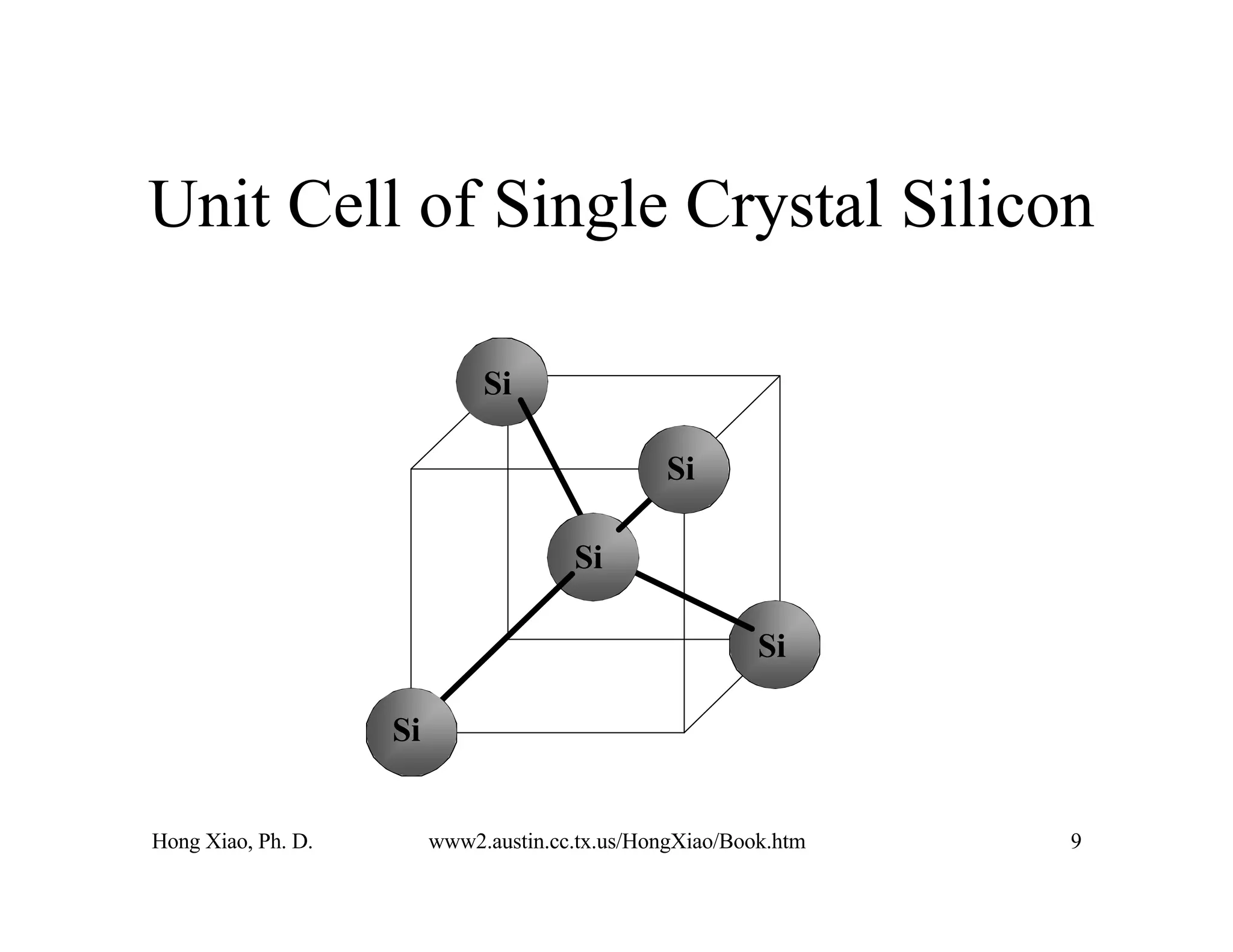

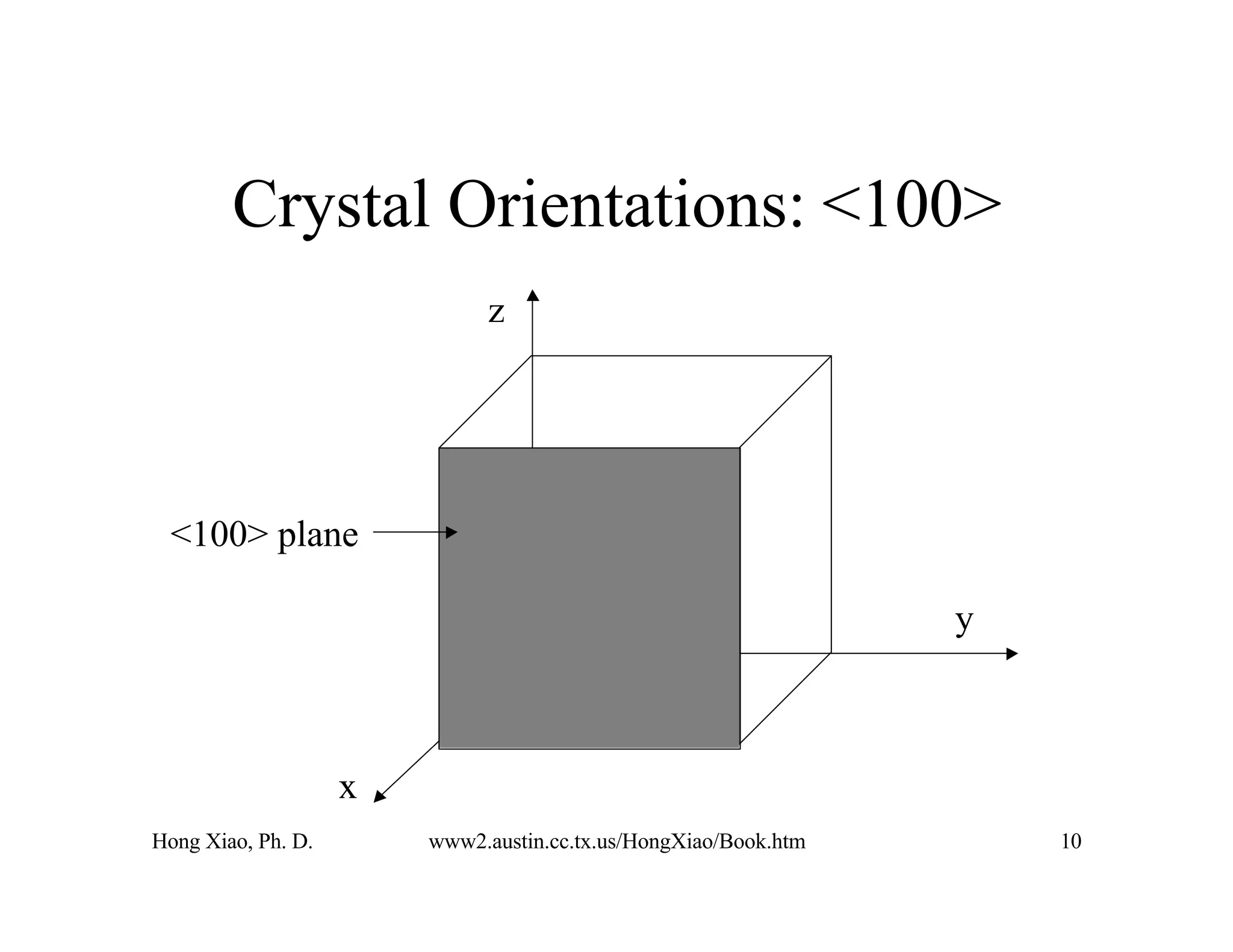

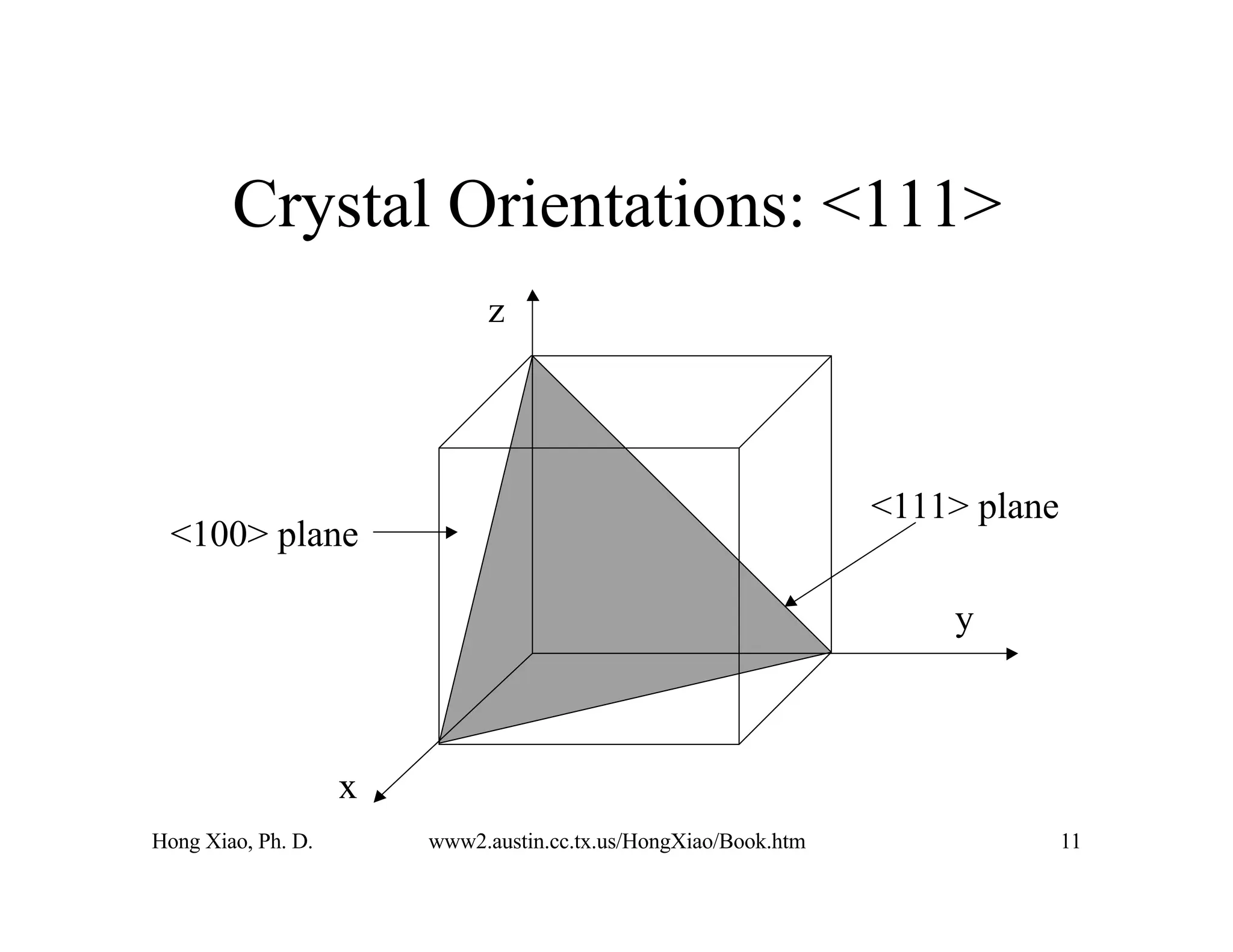

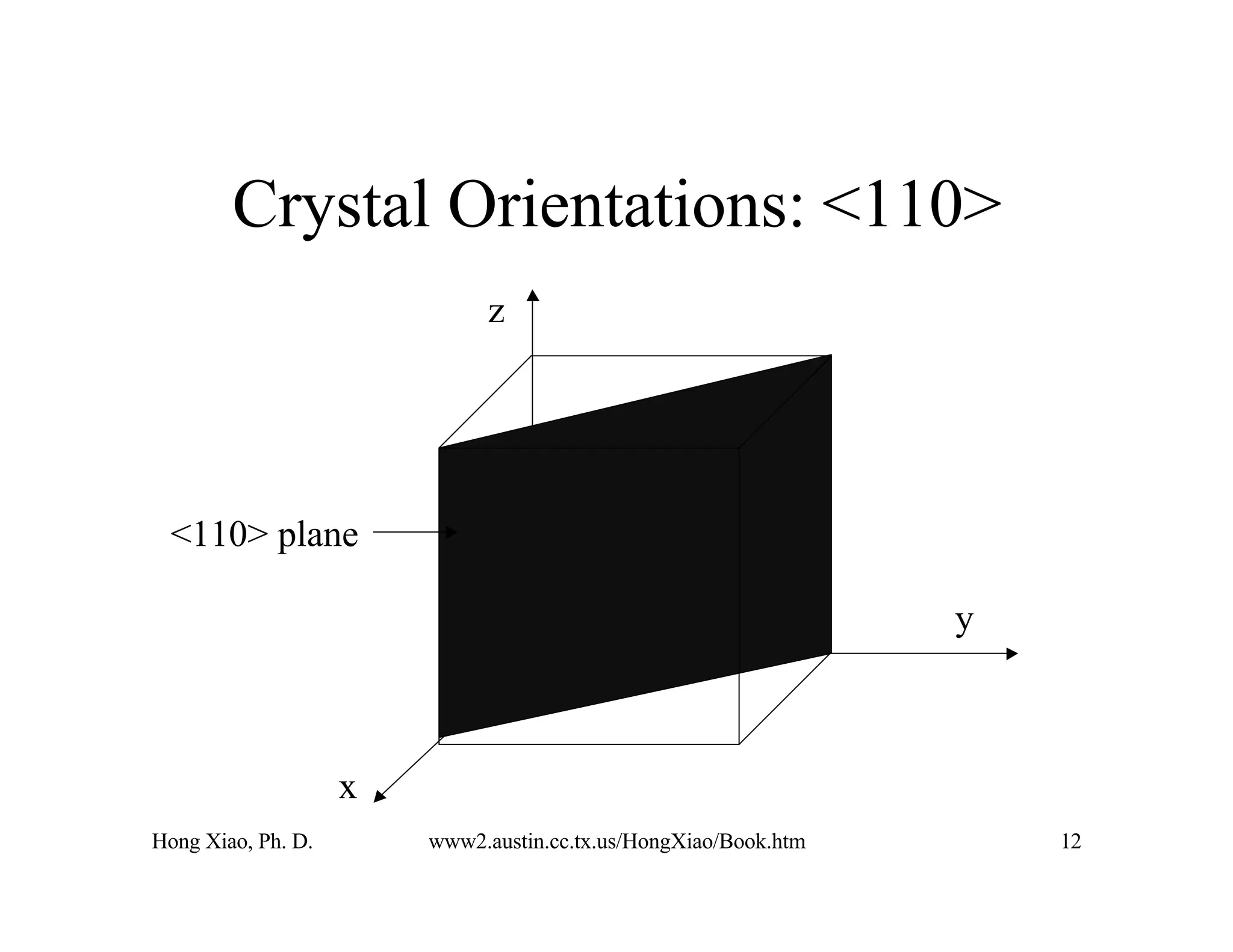

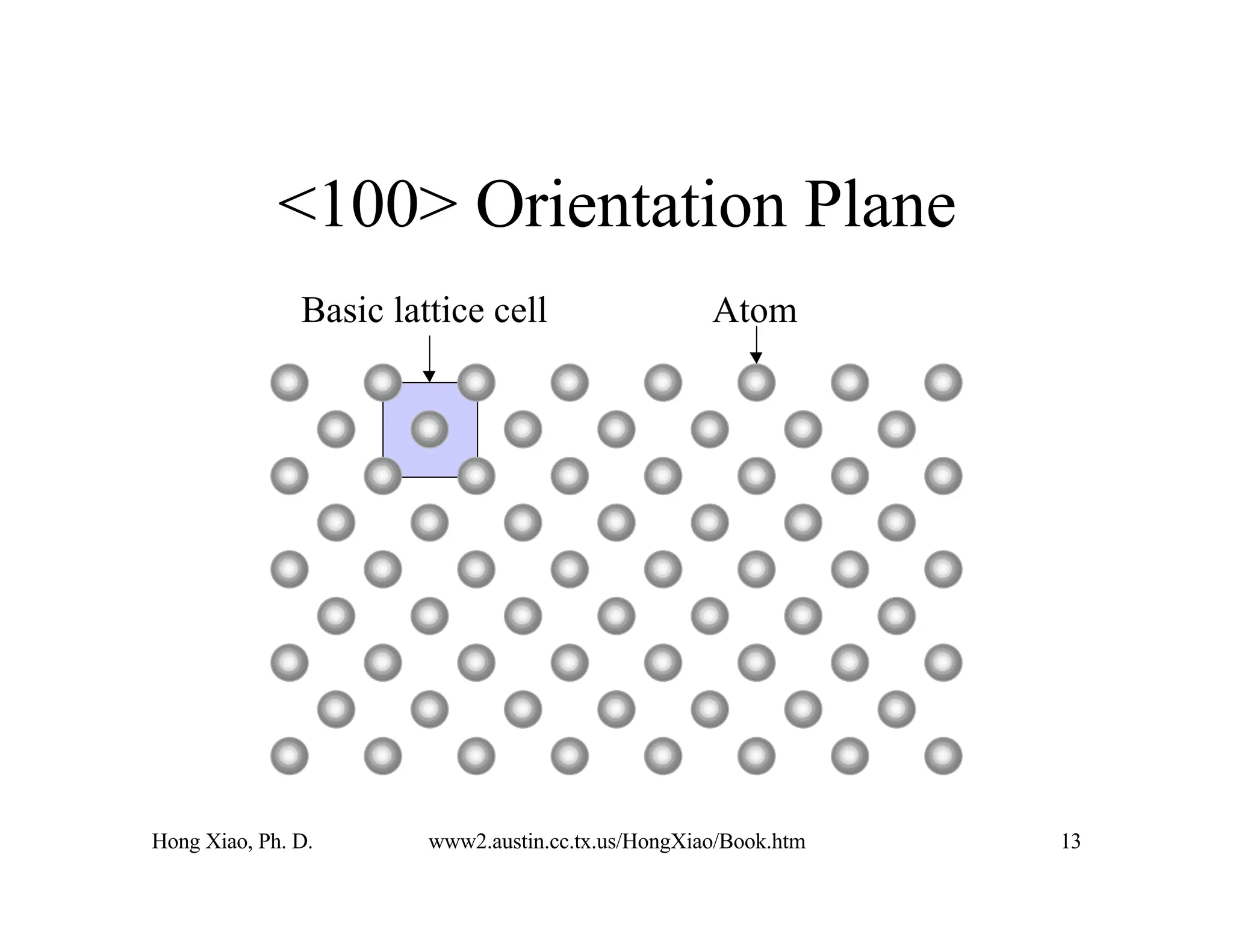

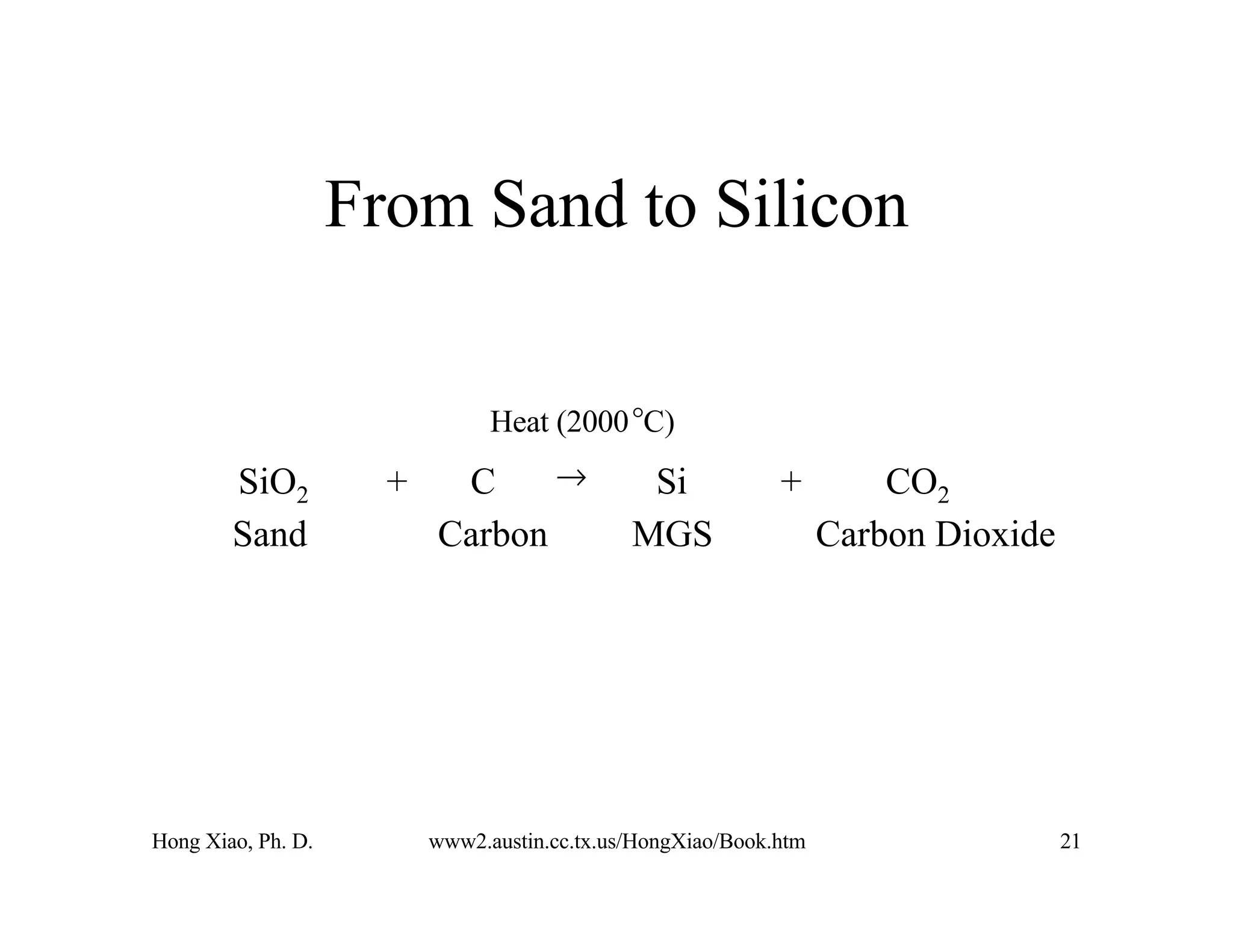

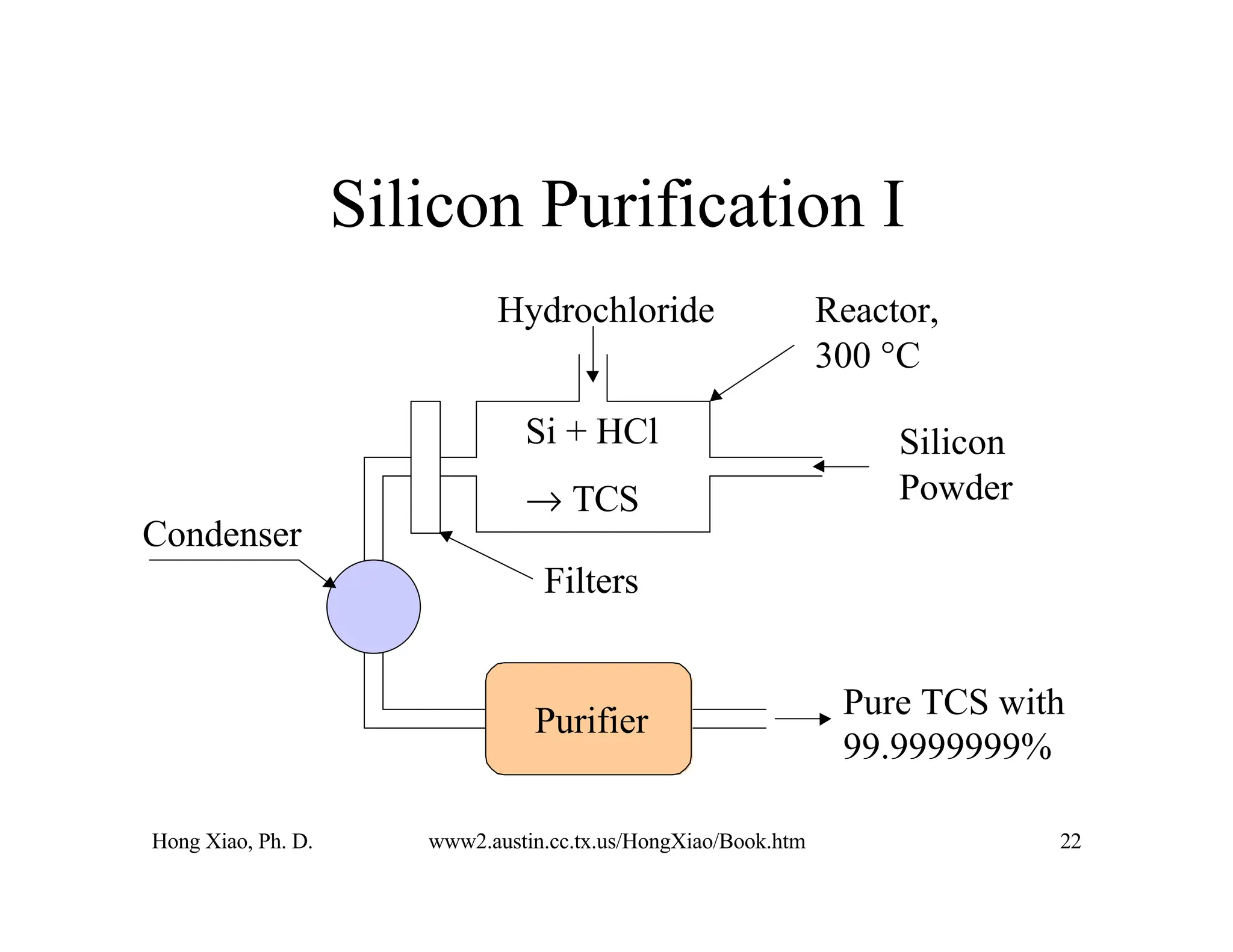

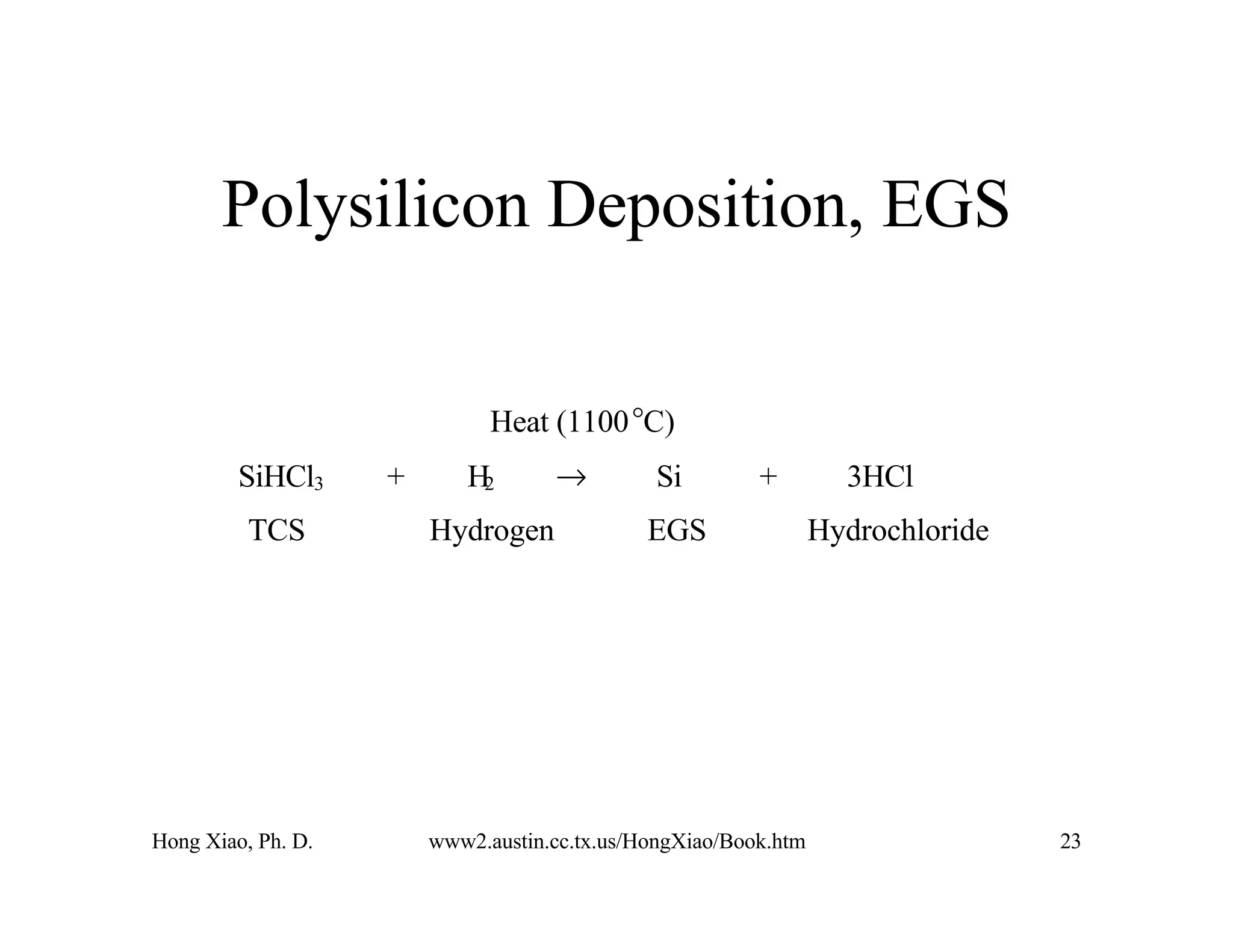

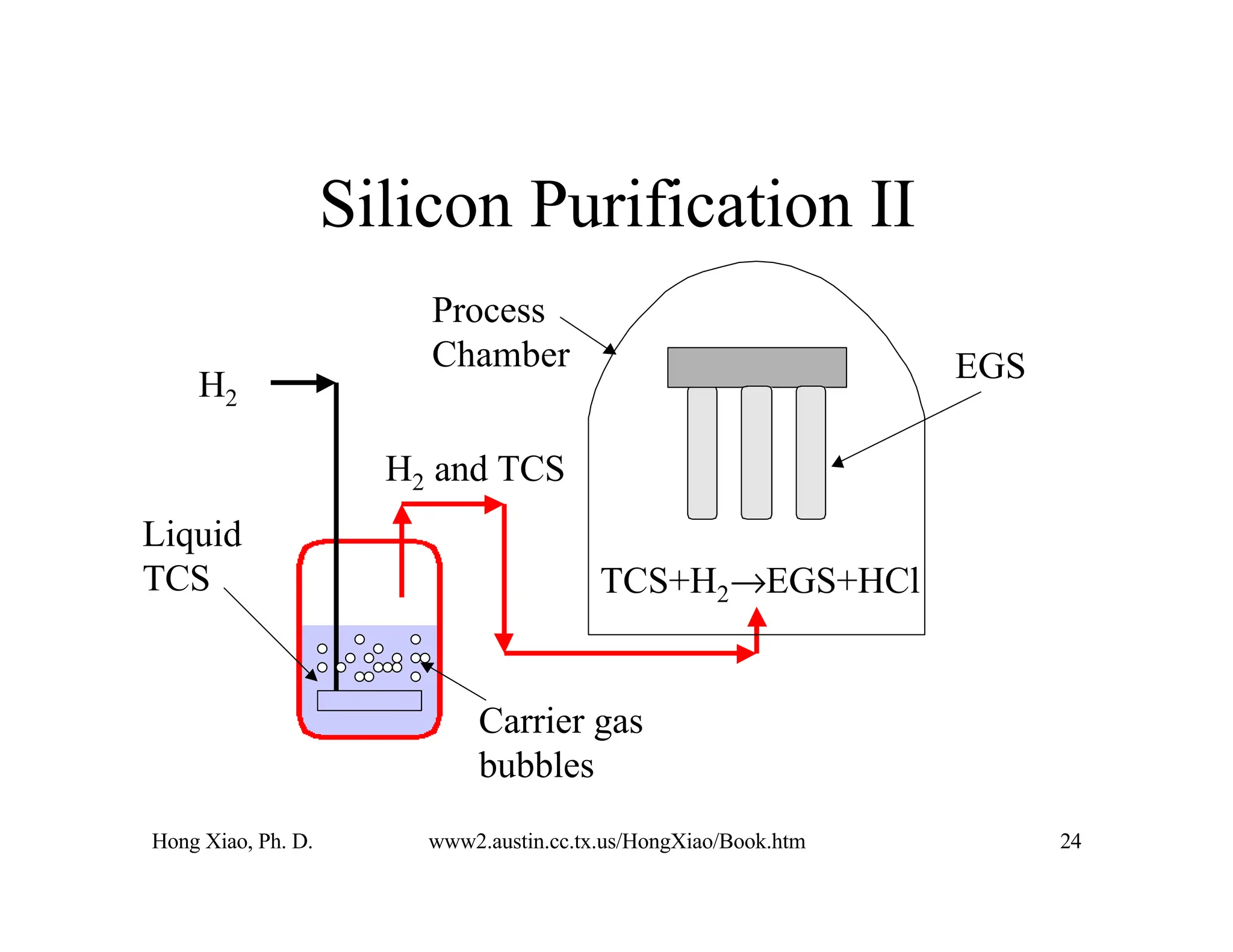

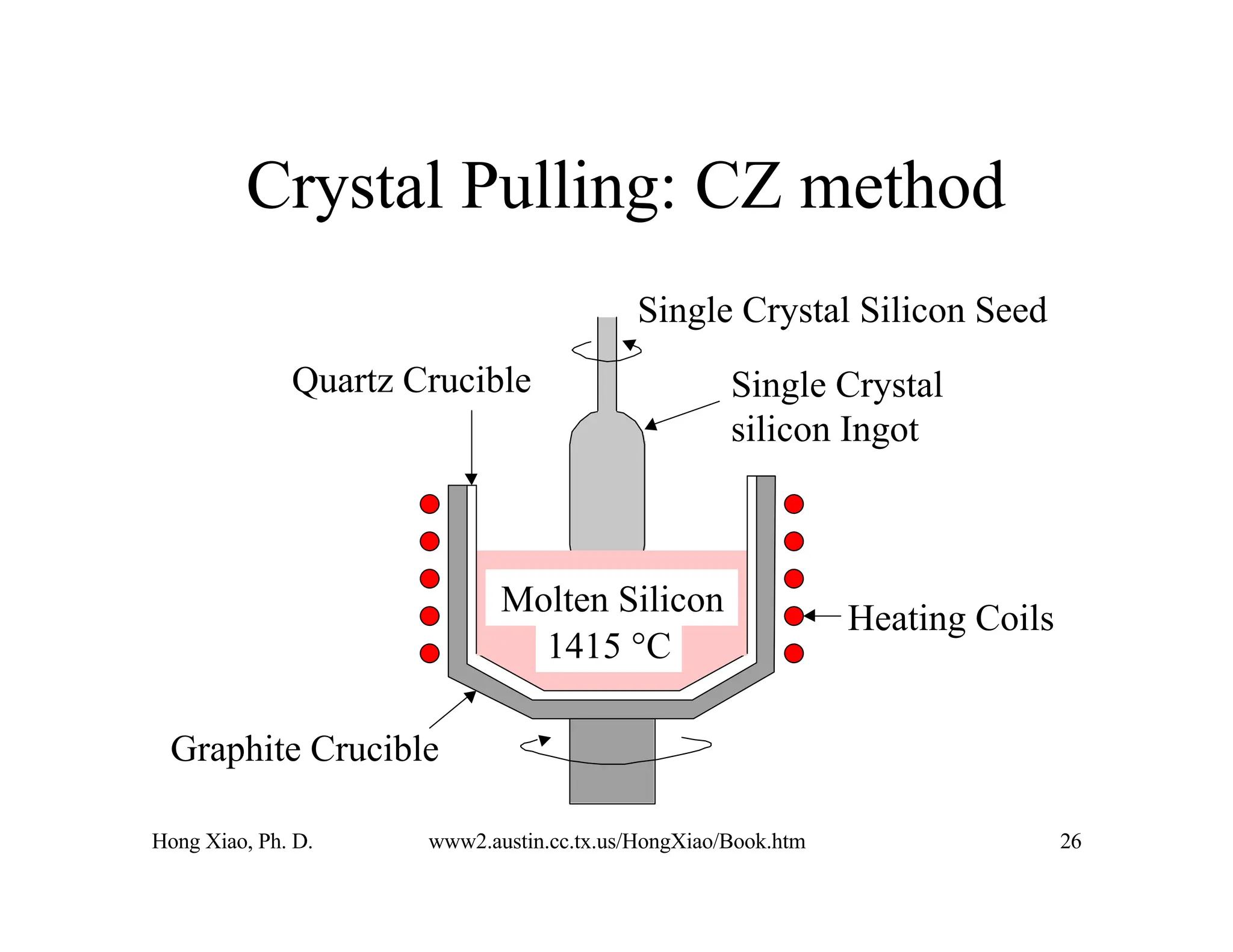

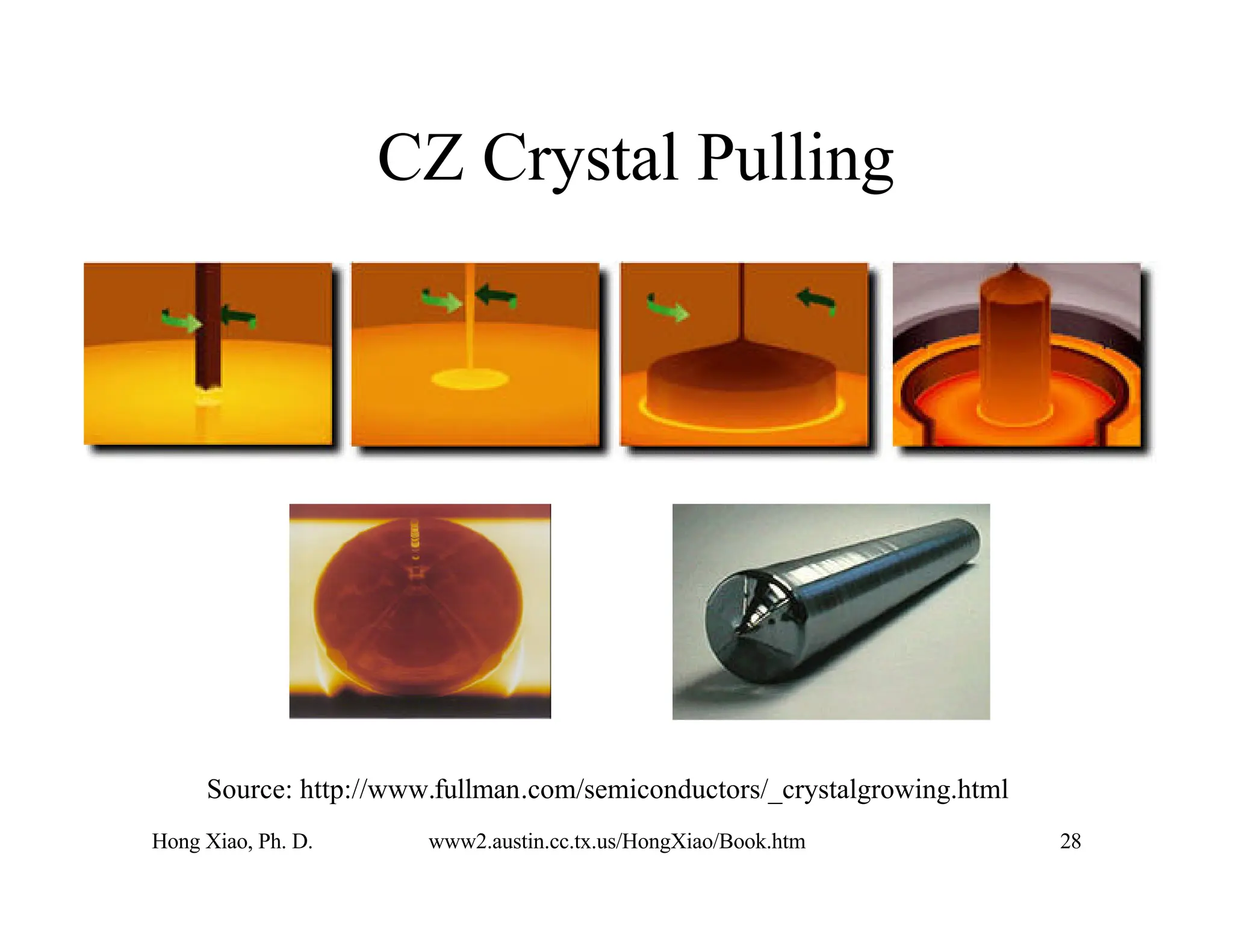

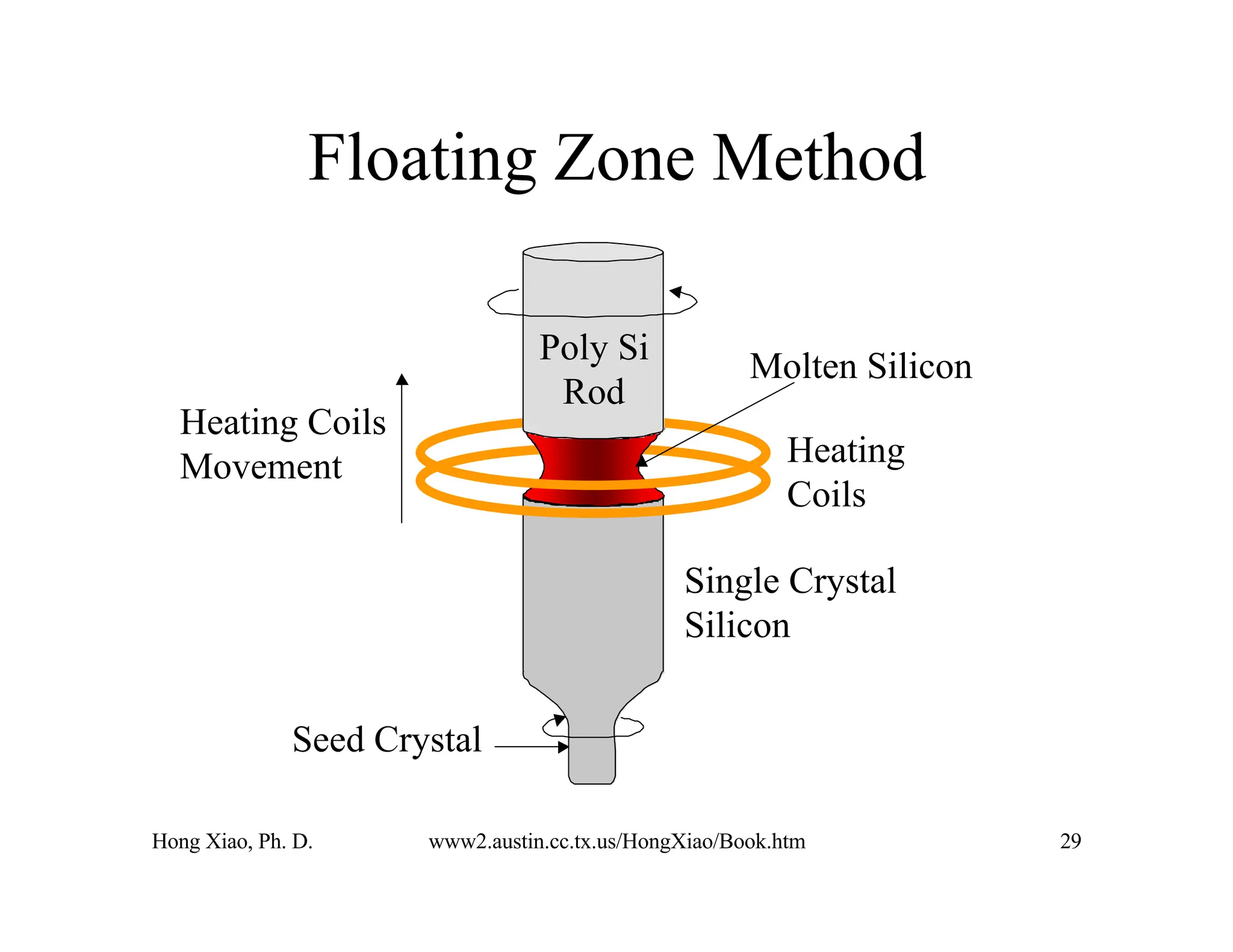

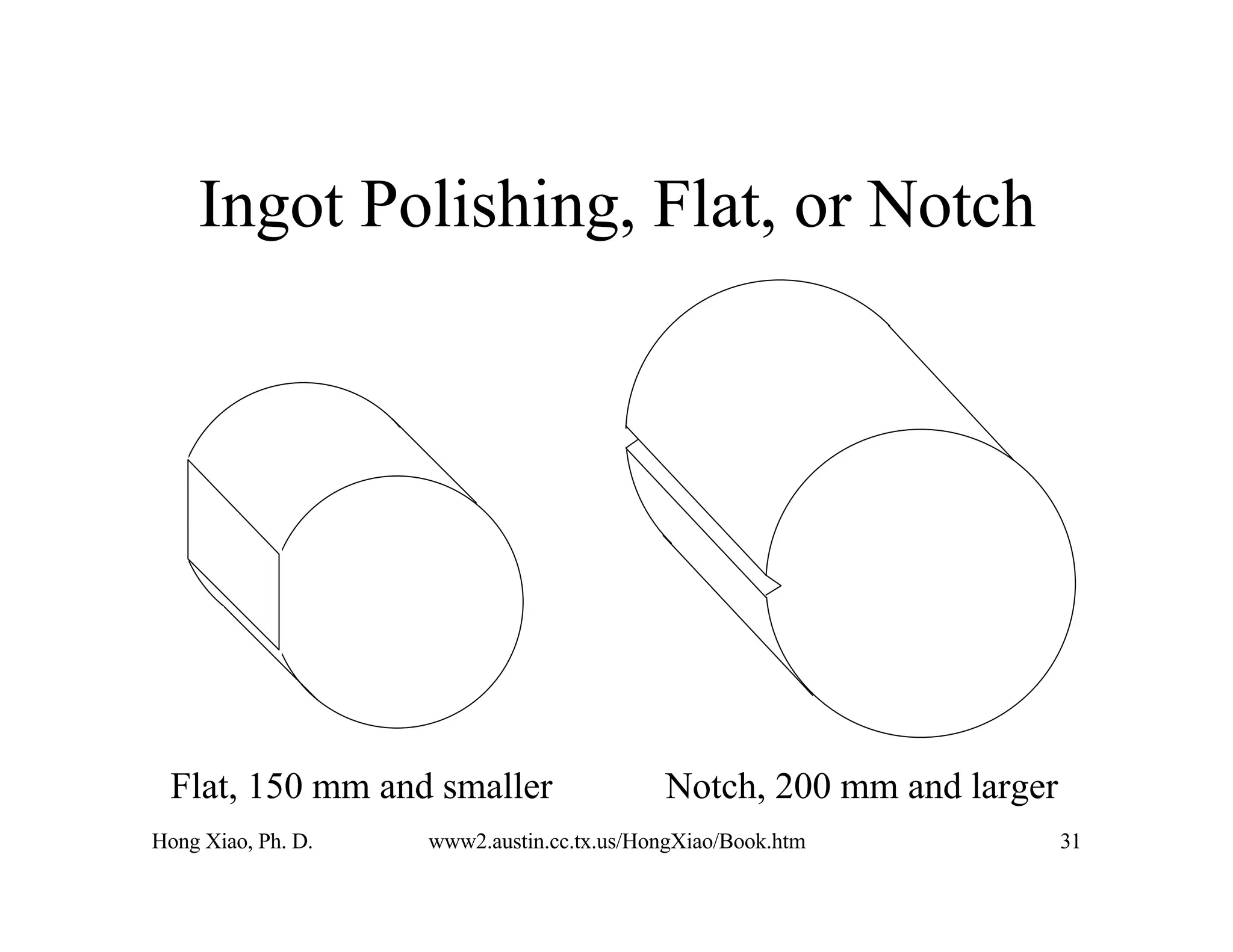

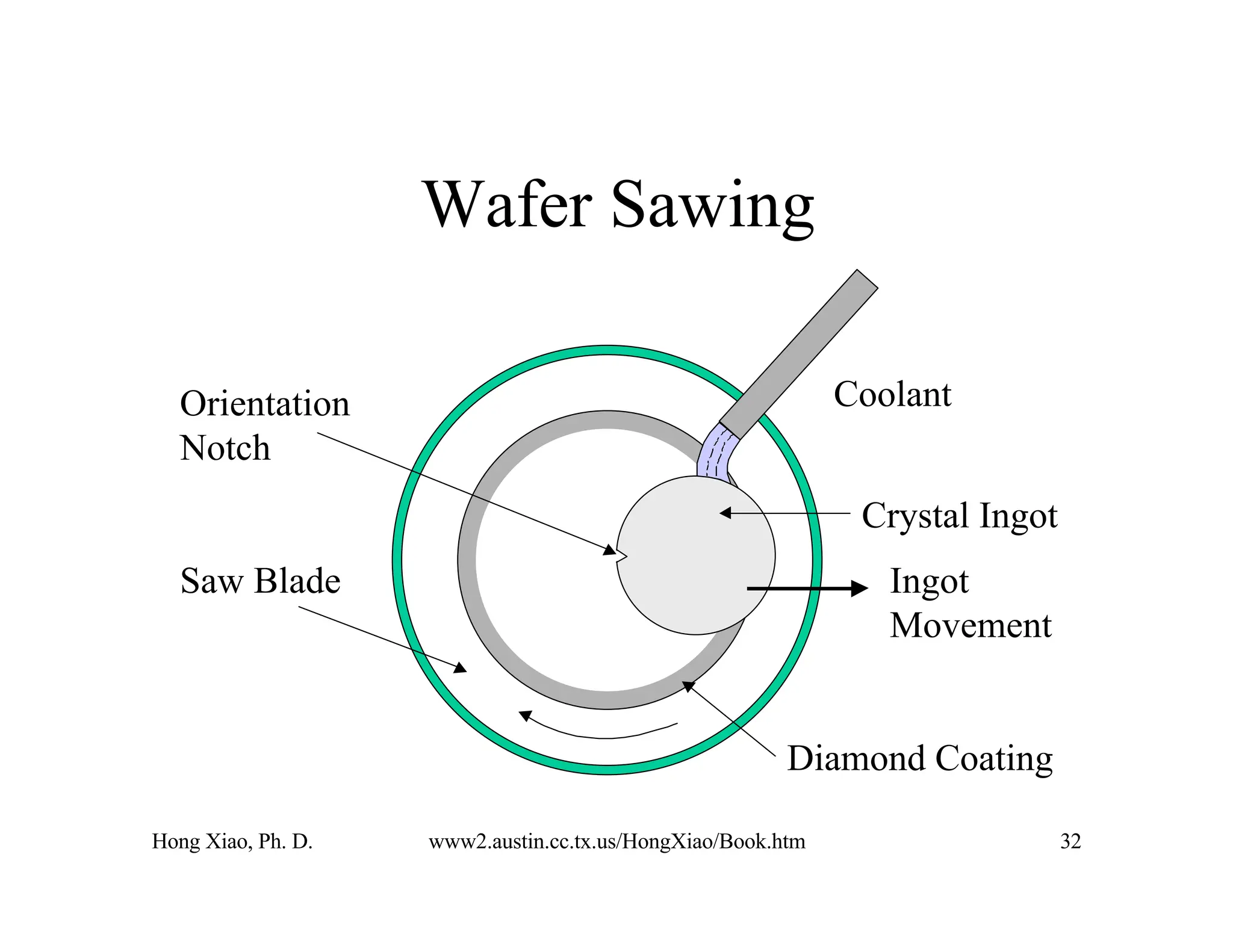

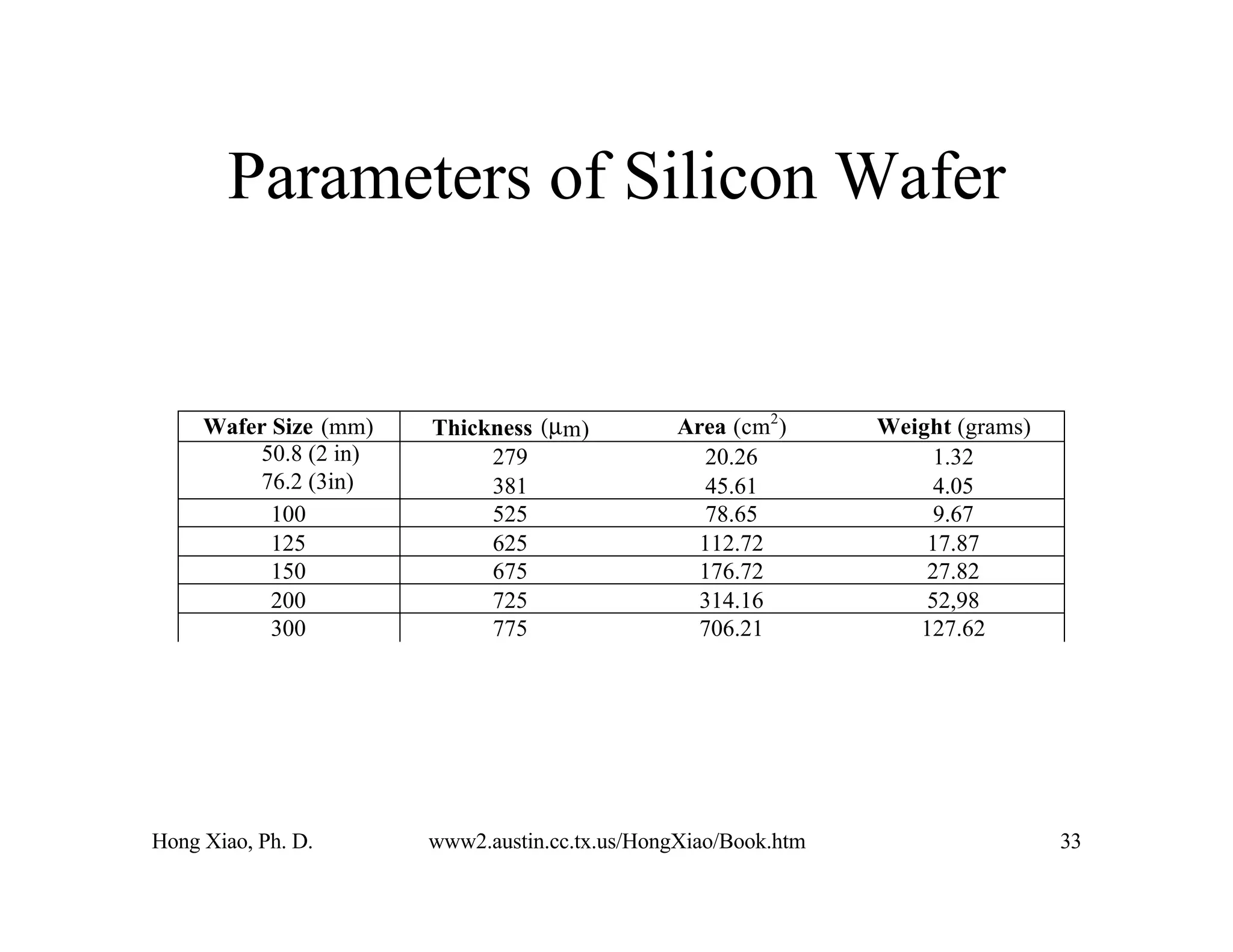

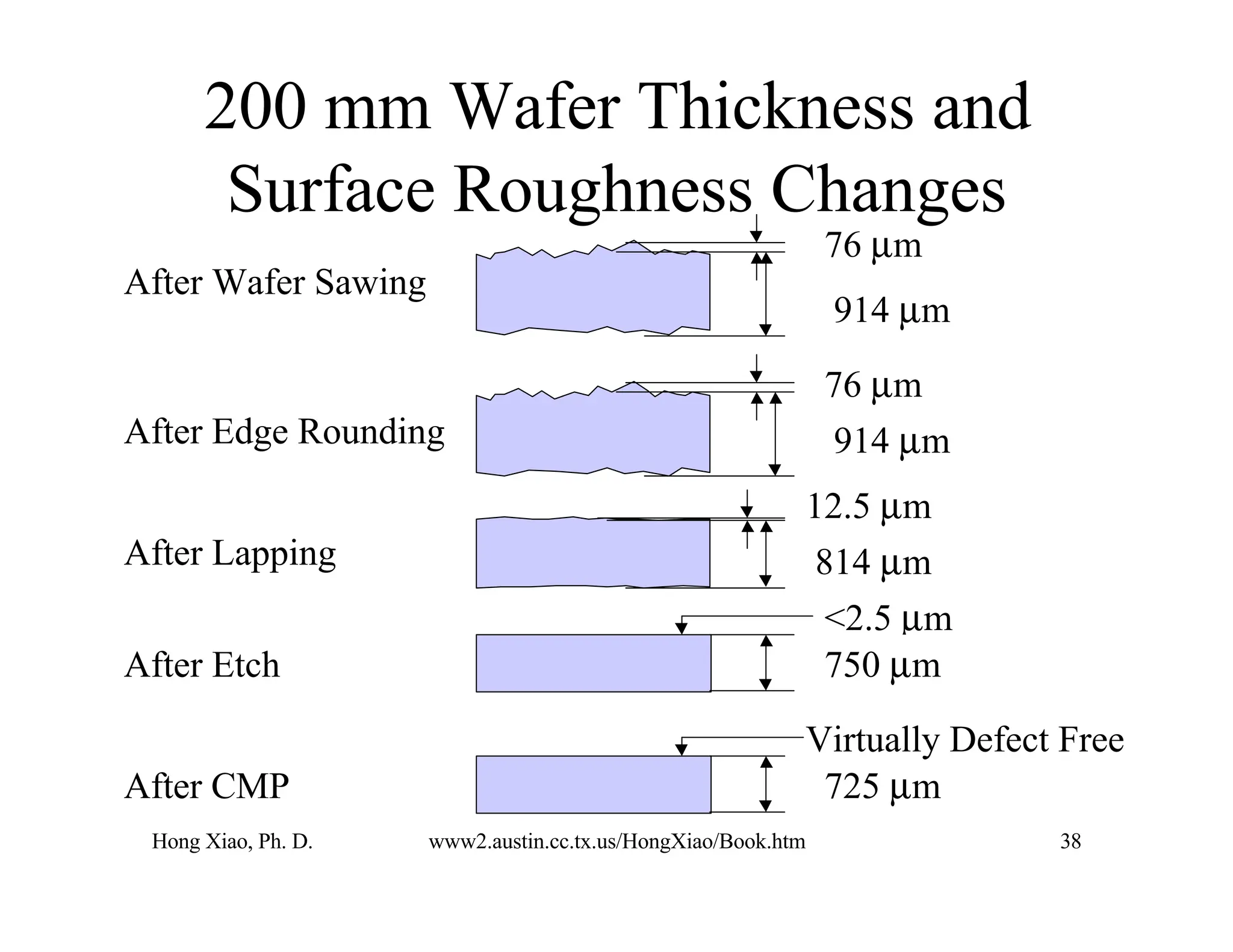

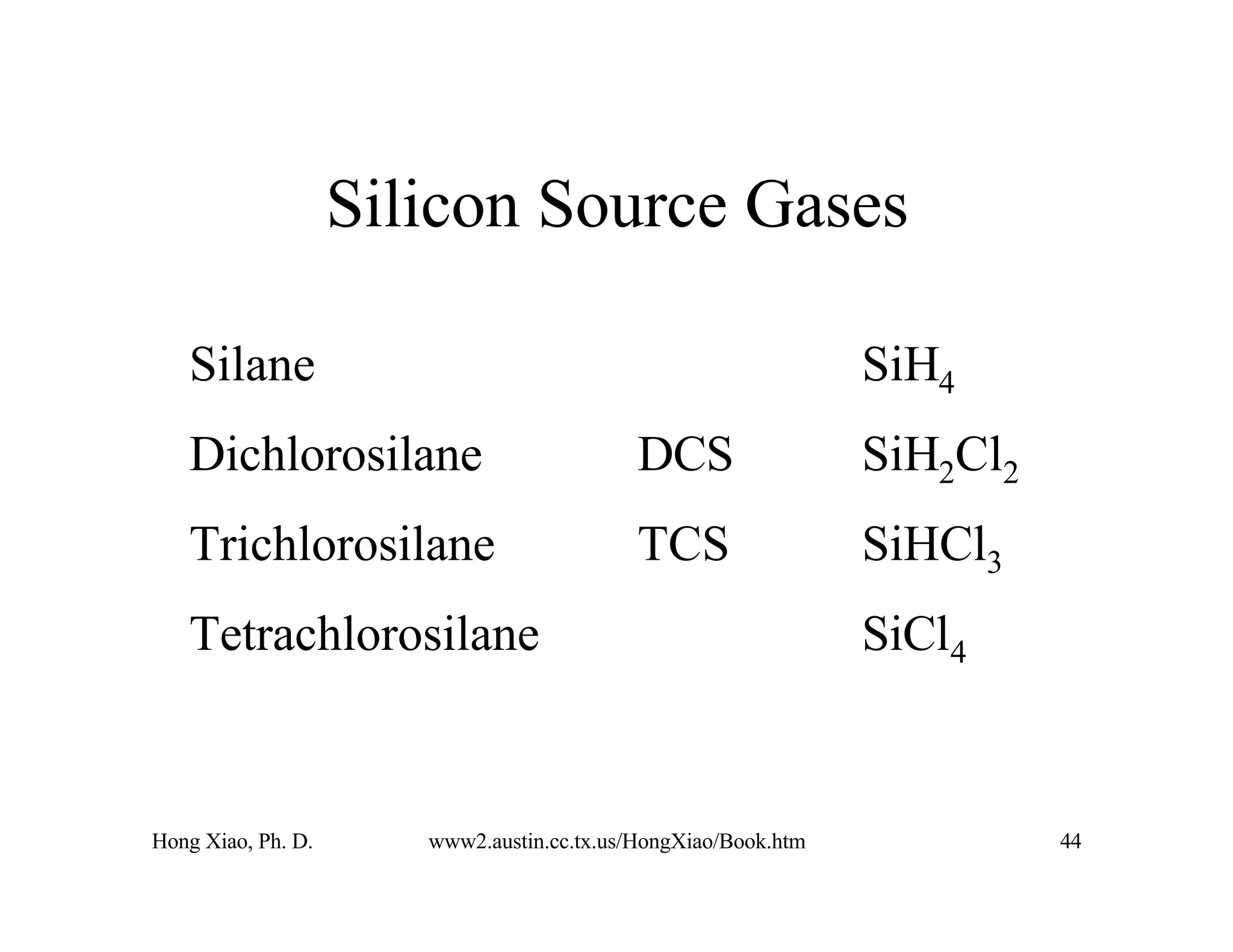

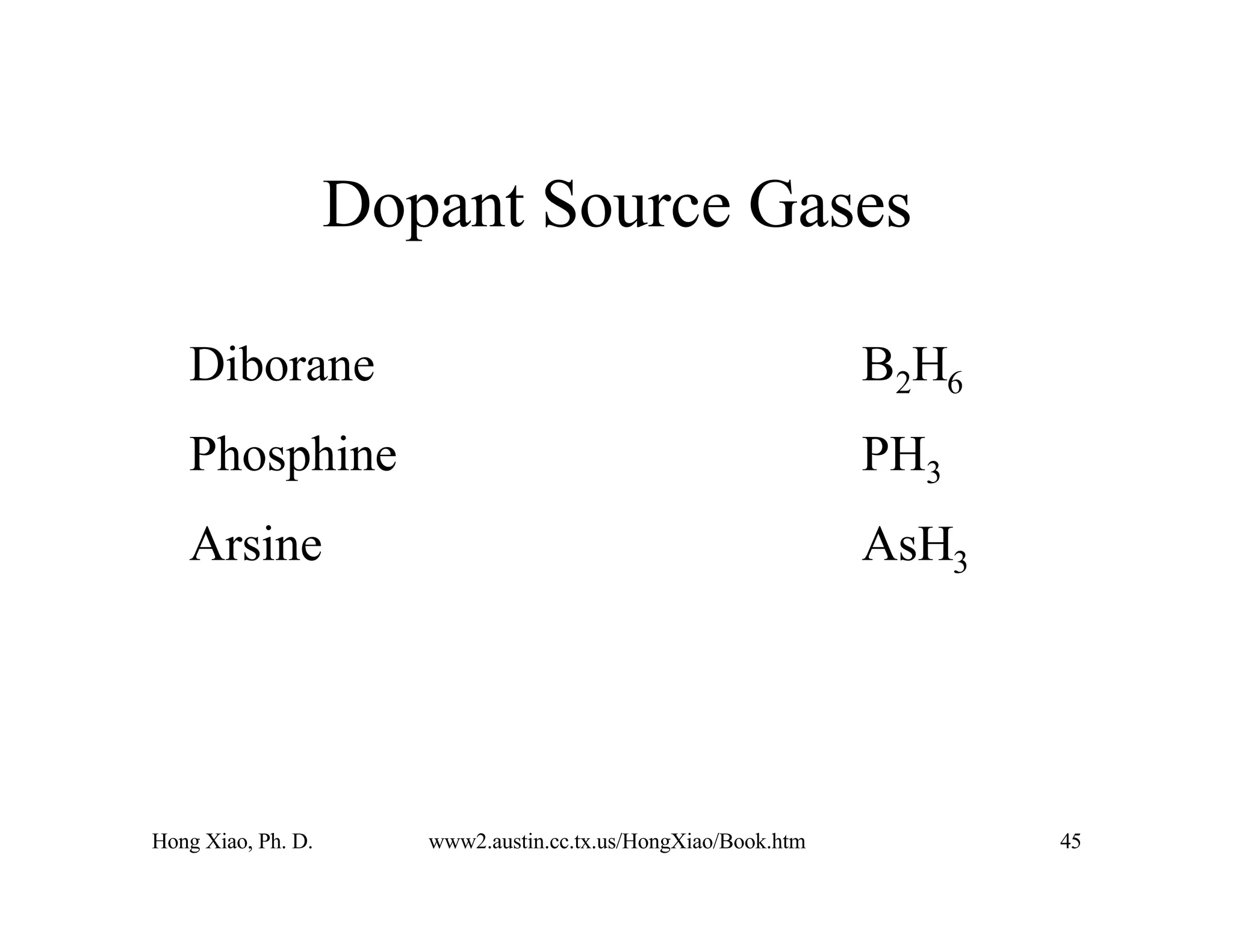

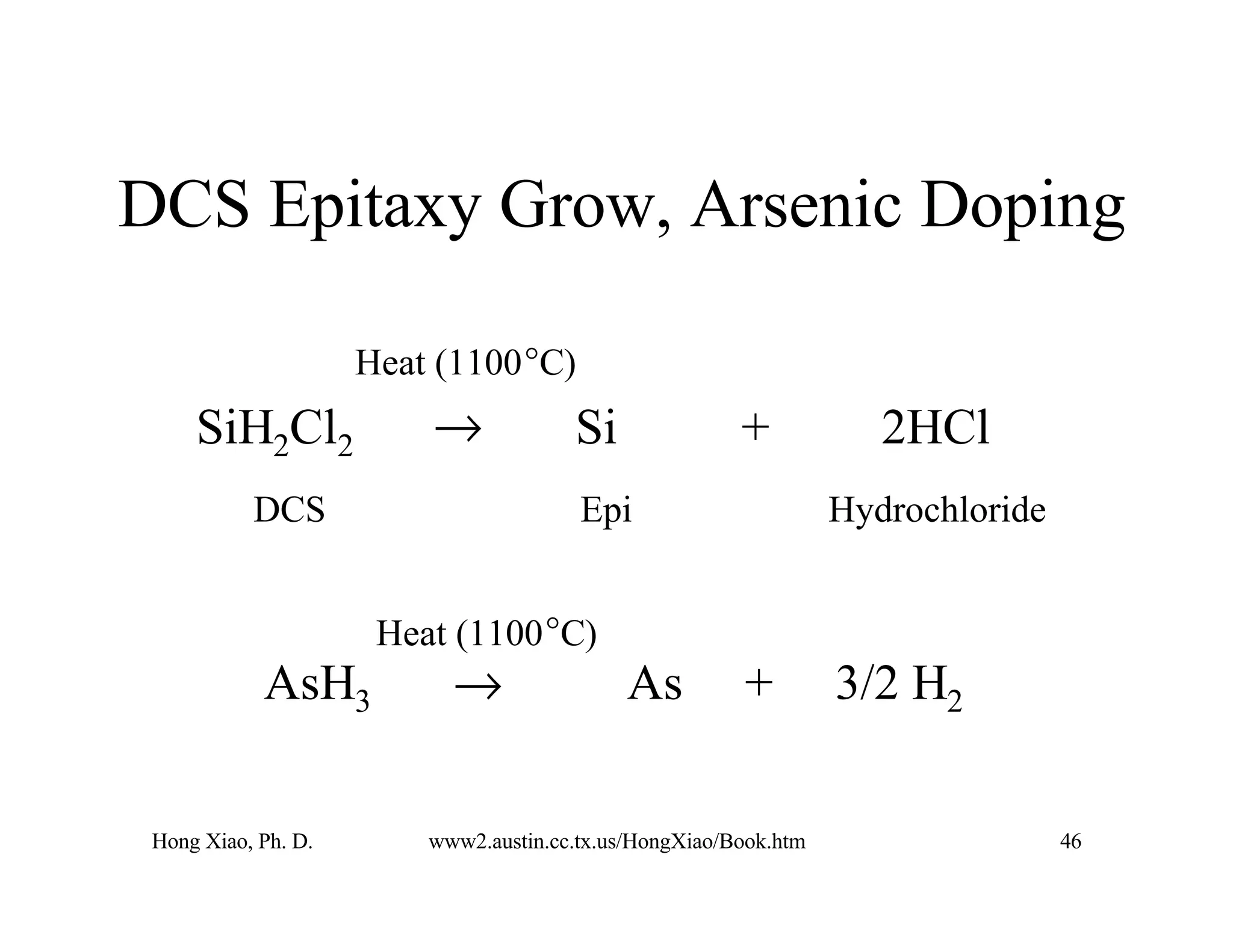

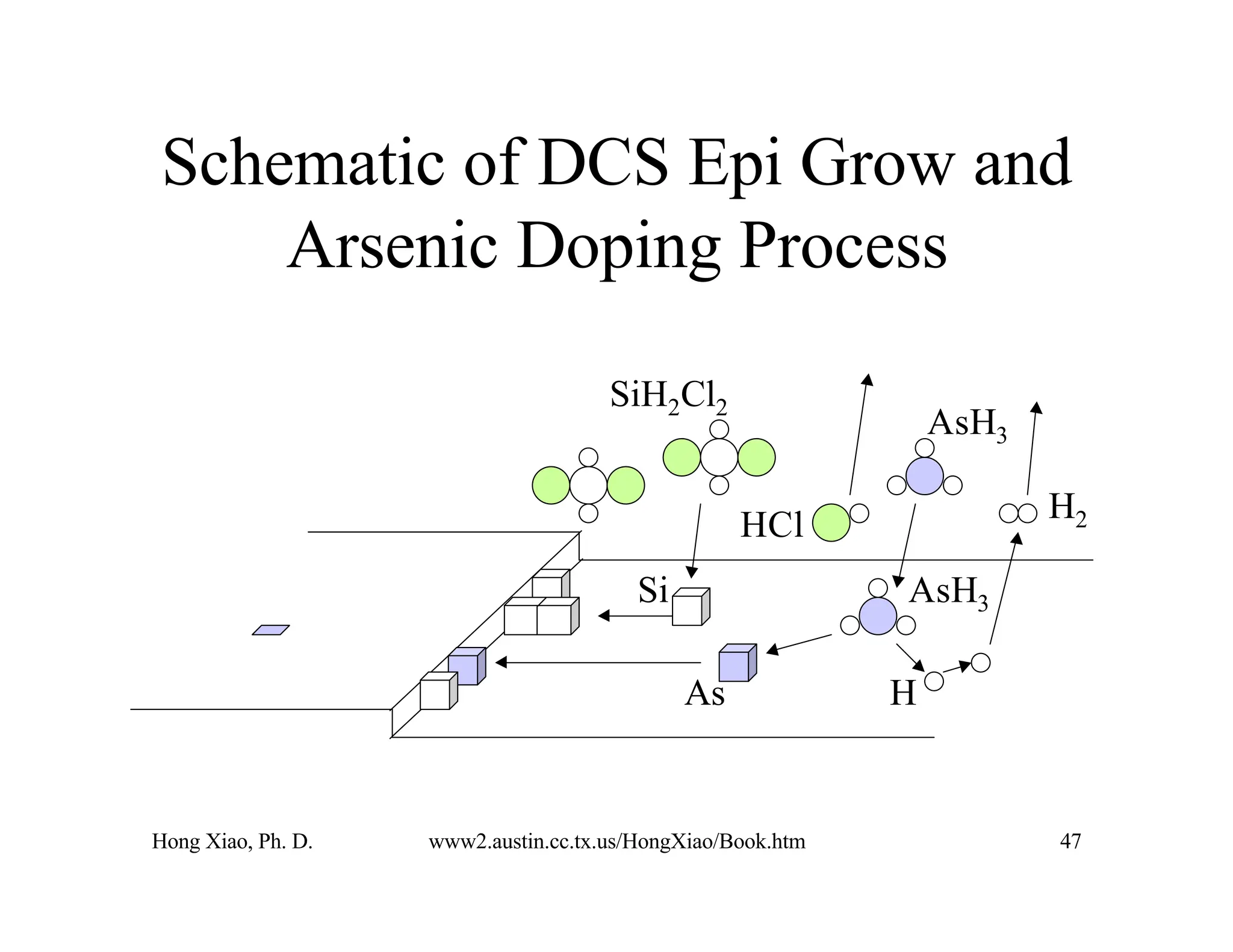

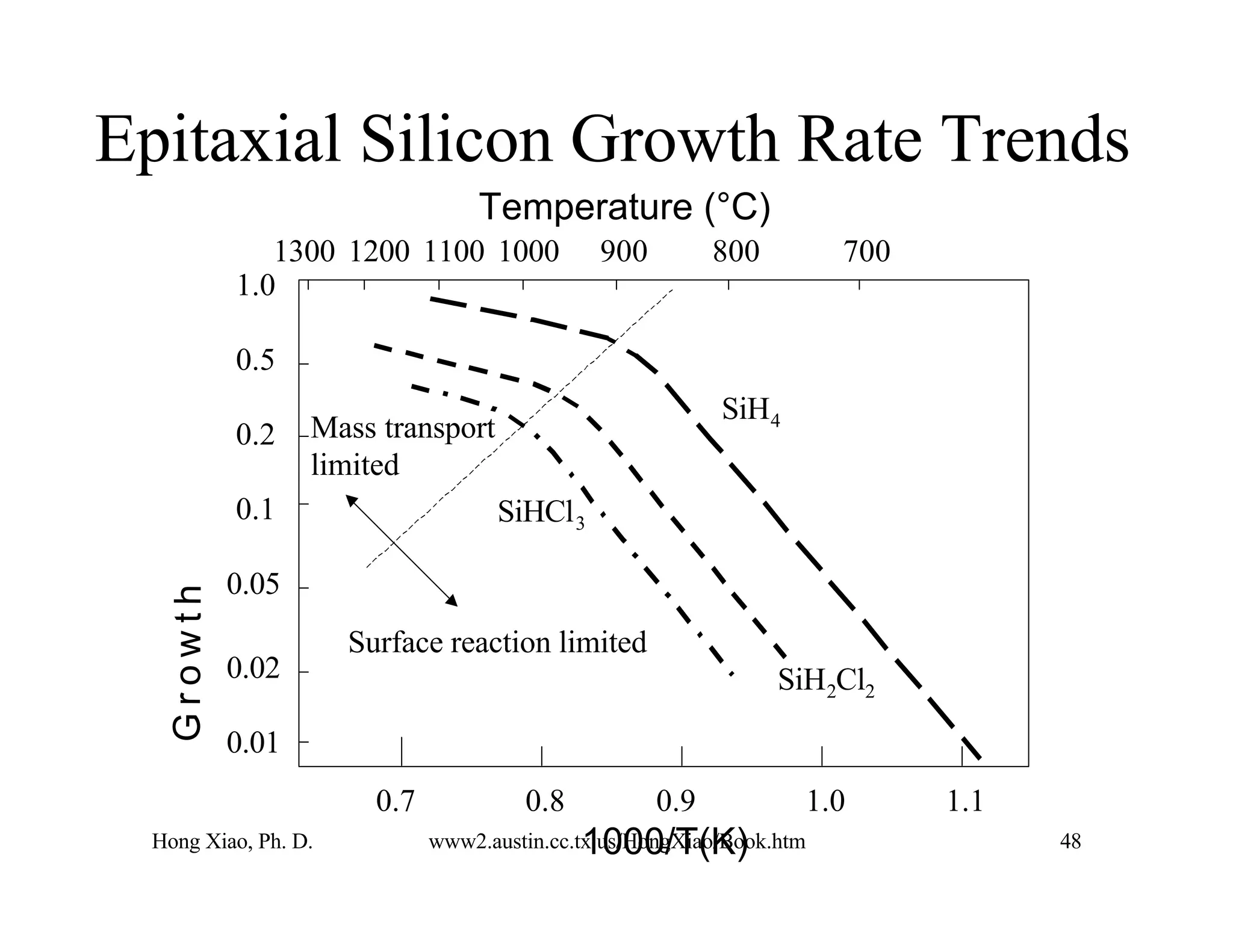

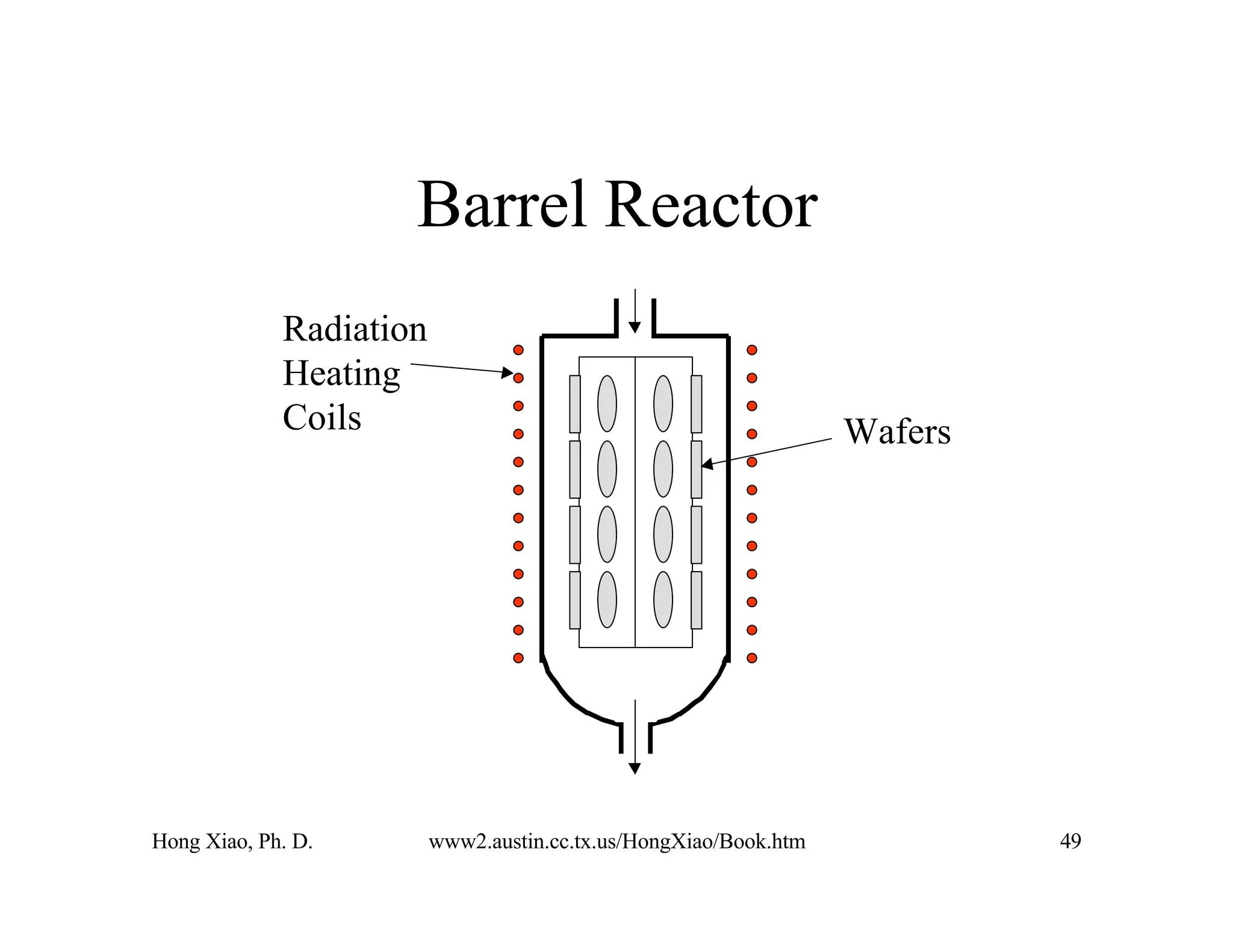

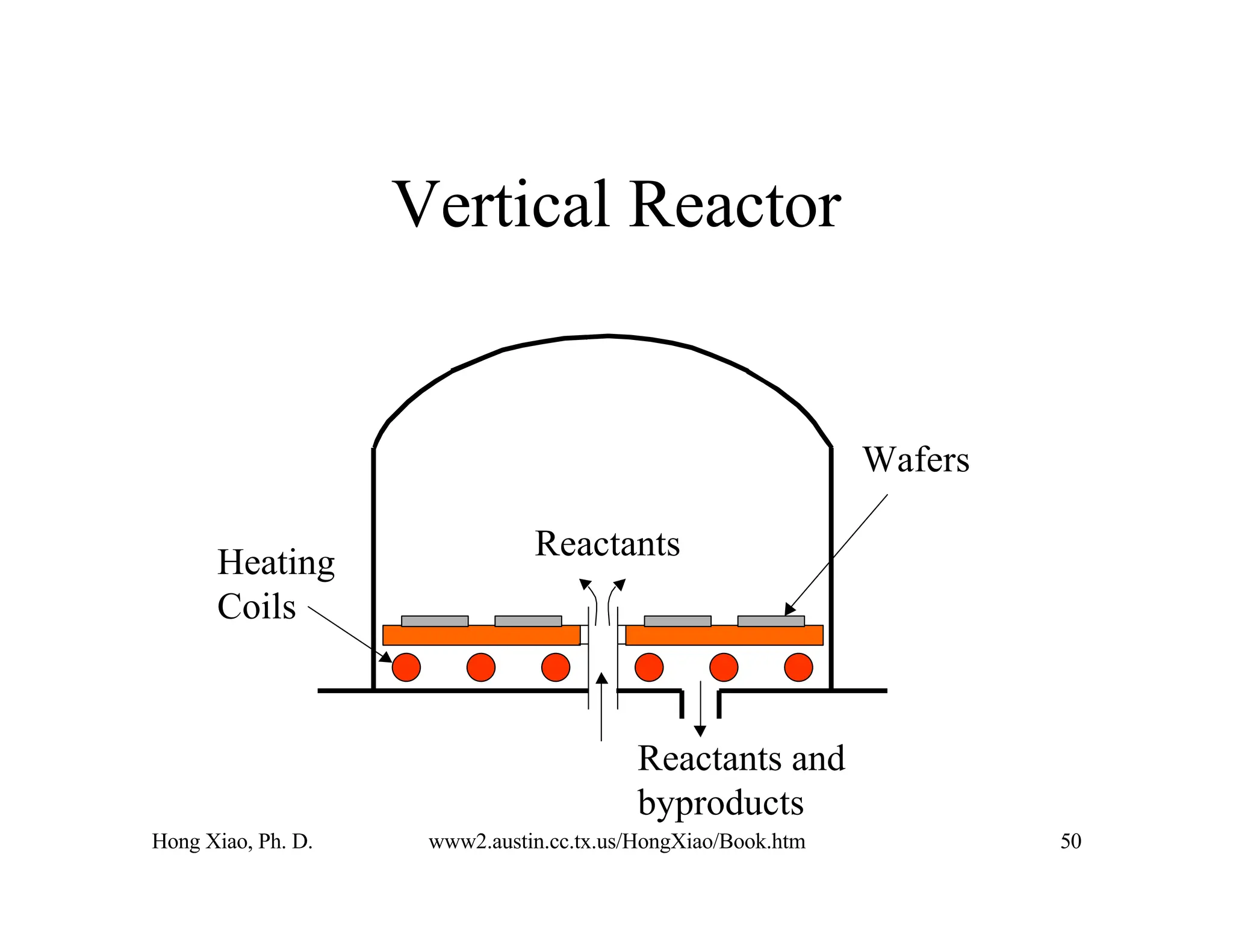

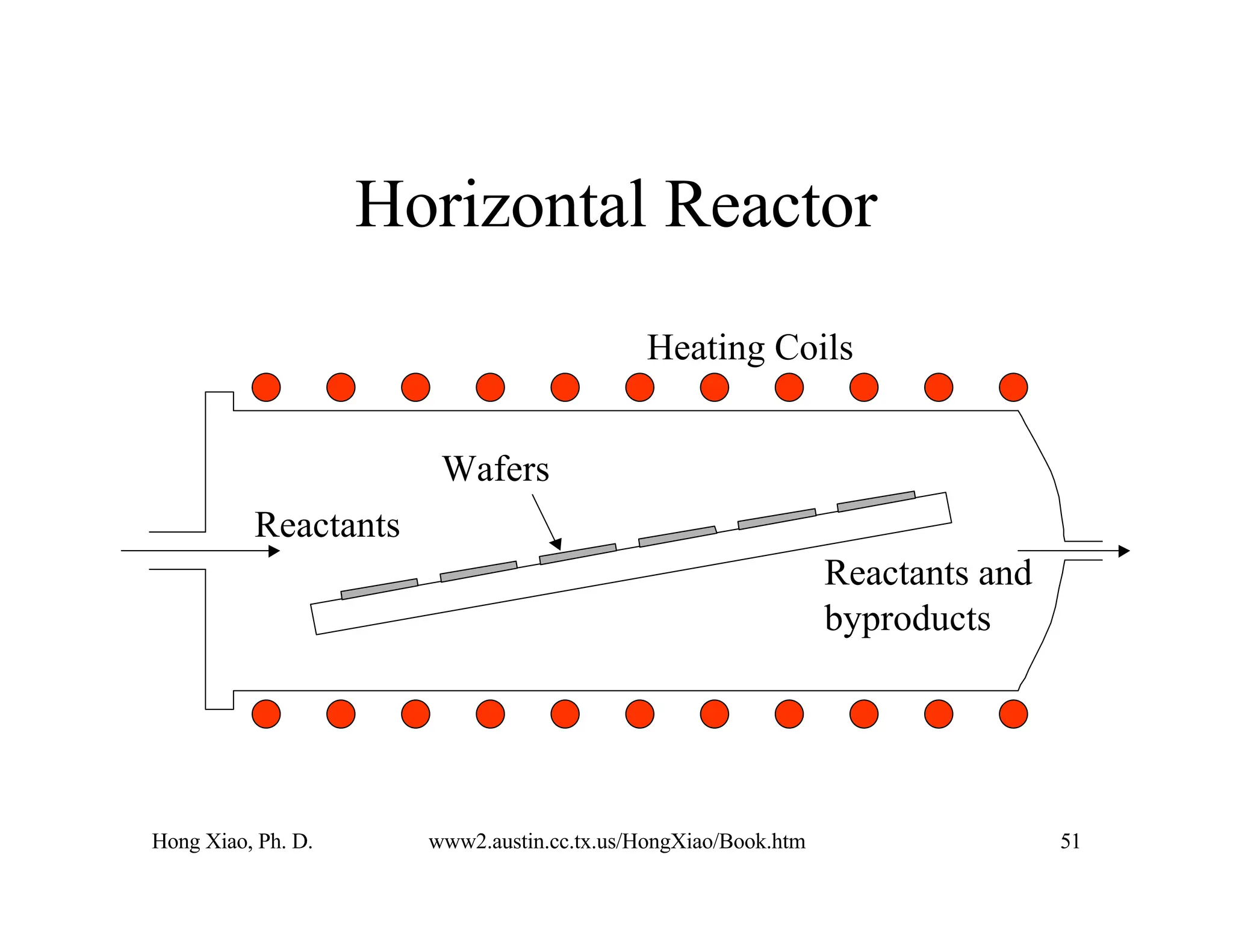

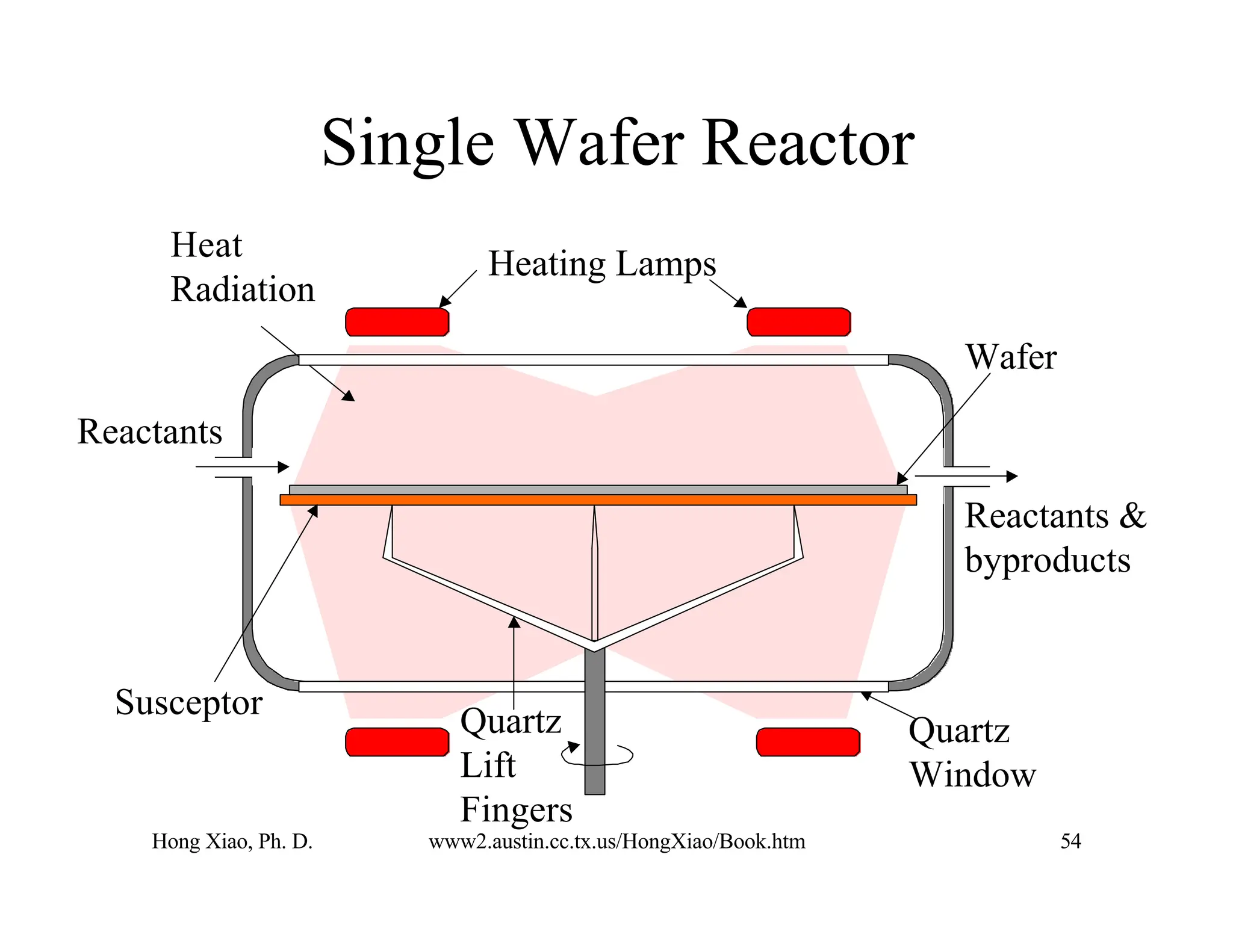

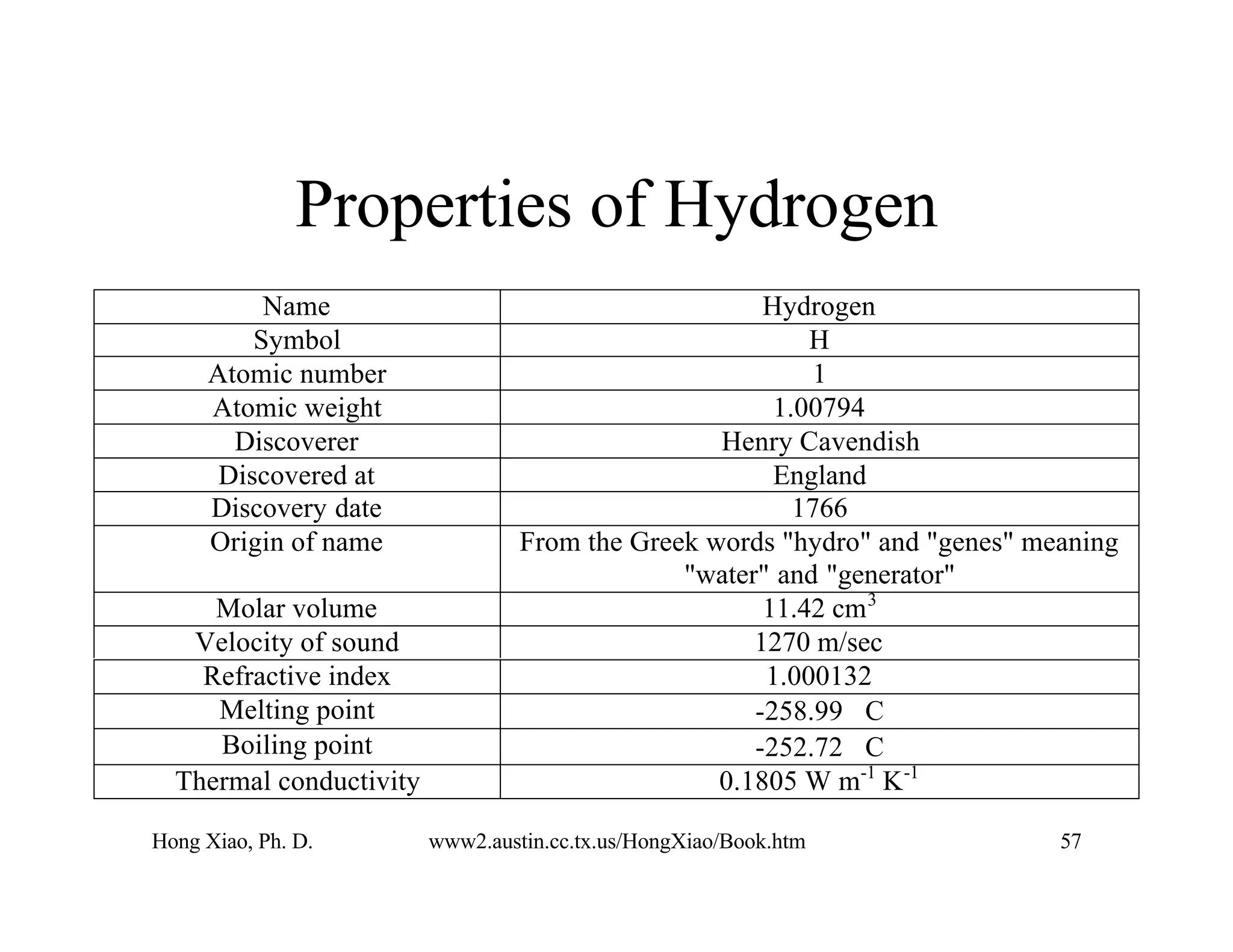

The document discusses the wafer manufacturing and epitaxy processes focusing on silicon, explaining its dominance due to its abundance and stable oxide. Key topics include crystal structures, the steps from sand to wafer, methods of silicon purification, and epitaxial growth processes essential for semiconductor applications. It also highlights the differences between the Czochralski (CZ) method and Floating Zone method for crystal pulling and various epitaxy systems.