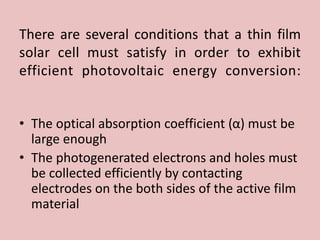

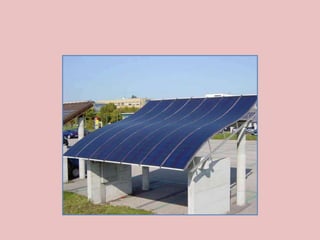

This document discusses thin film applications such as solar cells, thin film transistors, optical coatings, and thin film batteries. It provides details on how each of these applications uses thin films, including how solar cells convert light to electricity using electron-hole pairs, how thin film transistors act as switches in LCD displays, and how optical coatings can reduce reflections. Thin film batteries are also summarized as being solid-state and potentially flexible. In general, the document outlines the key uses and operating principles of several important thin film technologies.