- The document is a chemistry project submitted by a student named Tarun Malhotra analyzing samples of brass and bronze through qualitative analysis.

- It thanks various teachers and administrators for their support and contains an index of sections including introductions to alloys, common alloys like brass and bronze, how to prepare alloys, and descriptions of the qualitative analysis experiments performed on samples of brass and bronze.

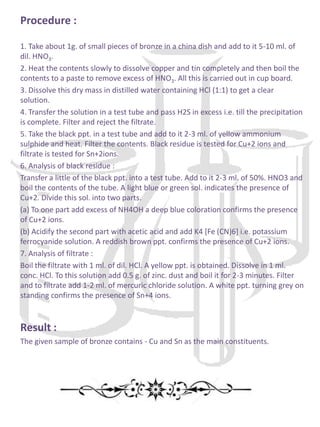

- The experiments aimed to identify the metal constituents in the samples through chemical tests to detect copper and zinc in brass and tests for copper and tin in bronze.