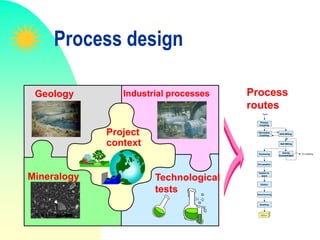

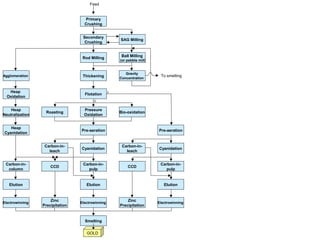

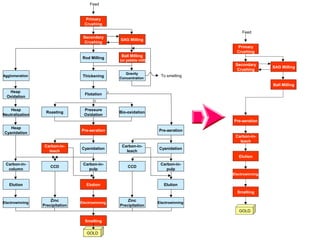

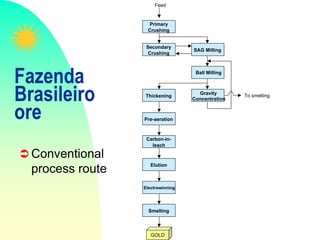

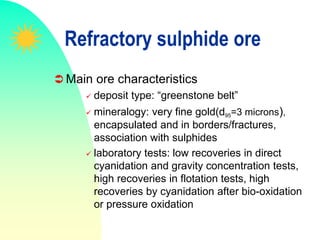

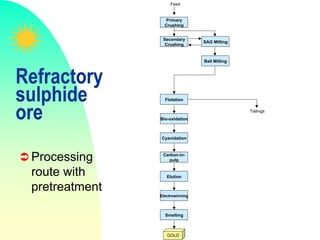

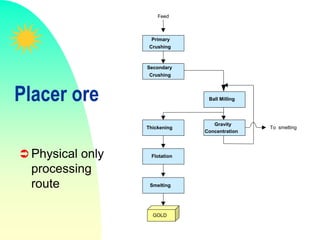

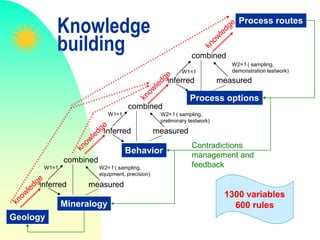

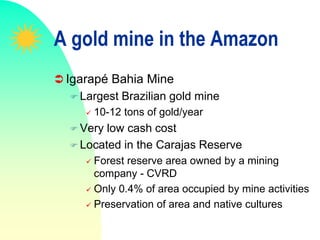

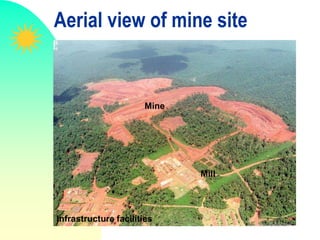

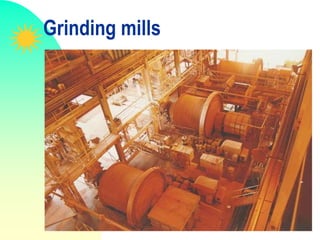

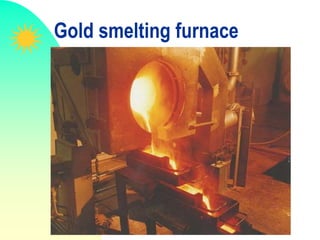

The document outlines various processes for gold ore processing, detailing methods such as crushing, milling, concentration, and extraction techniques tailored to different ore types. It emphasizes the importance of mineralogical characteristics in determining the most effective processing routes and highlights advancements in technology for improving operations in the gold mining industry. Furthermore, it provides context on significant gold mines, including their locations and operational efficiencies.