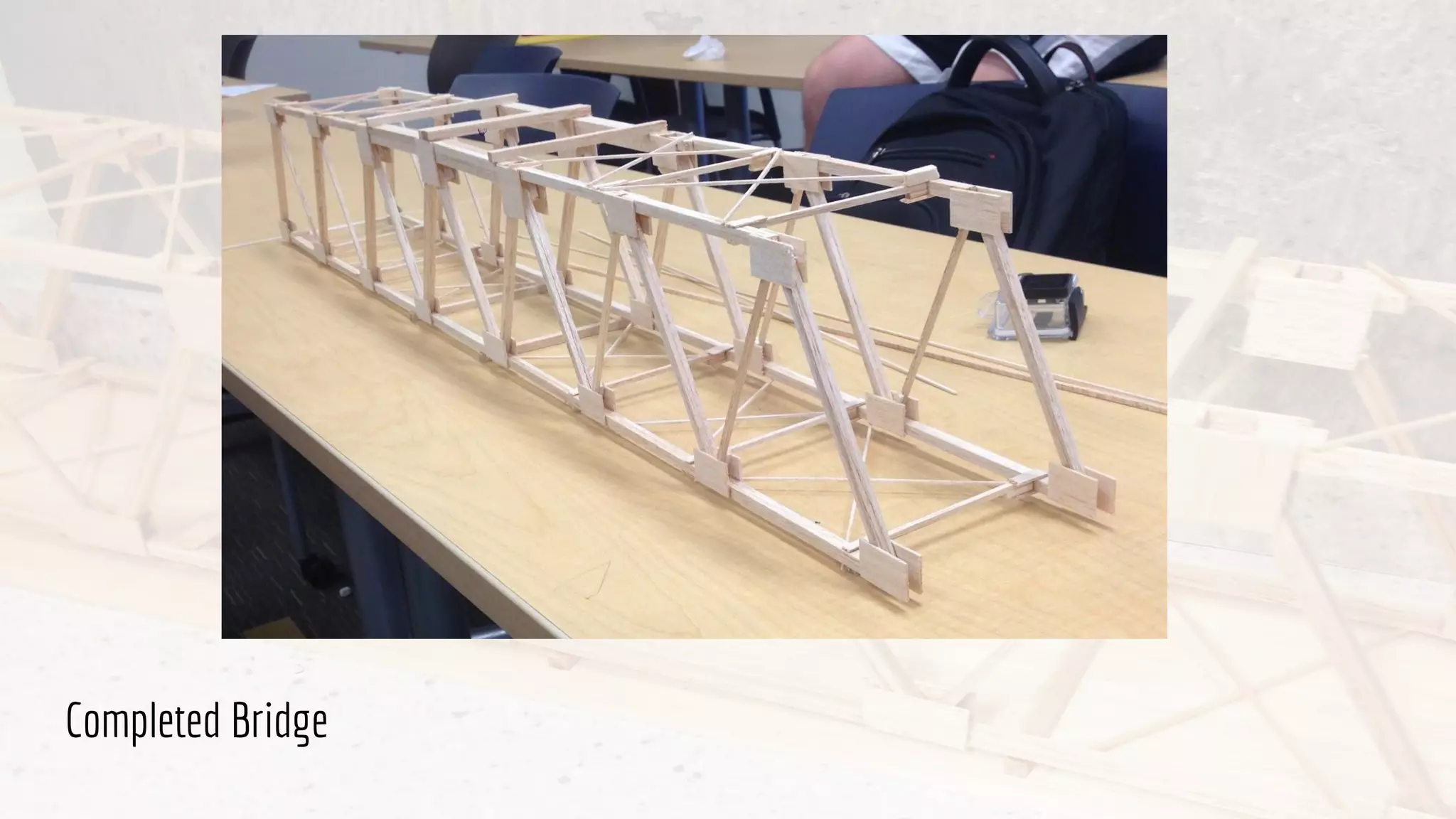

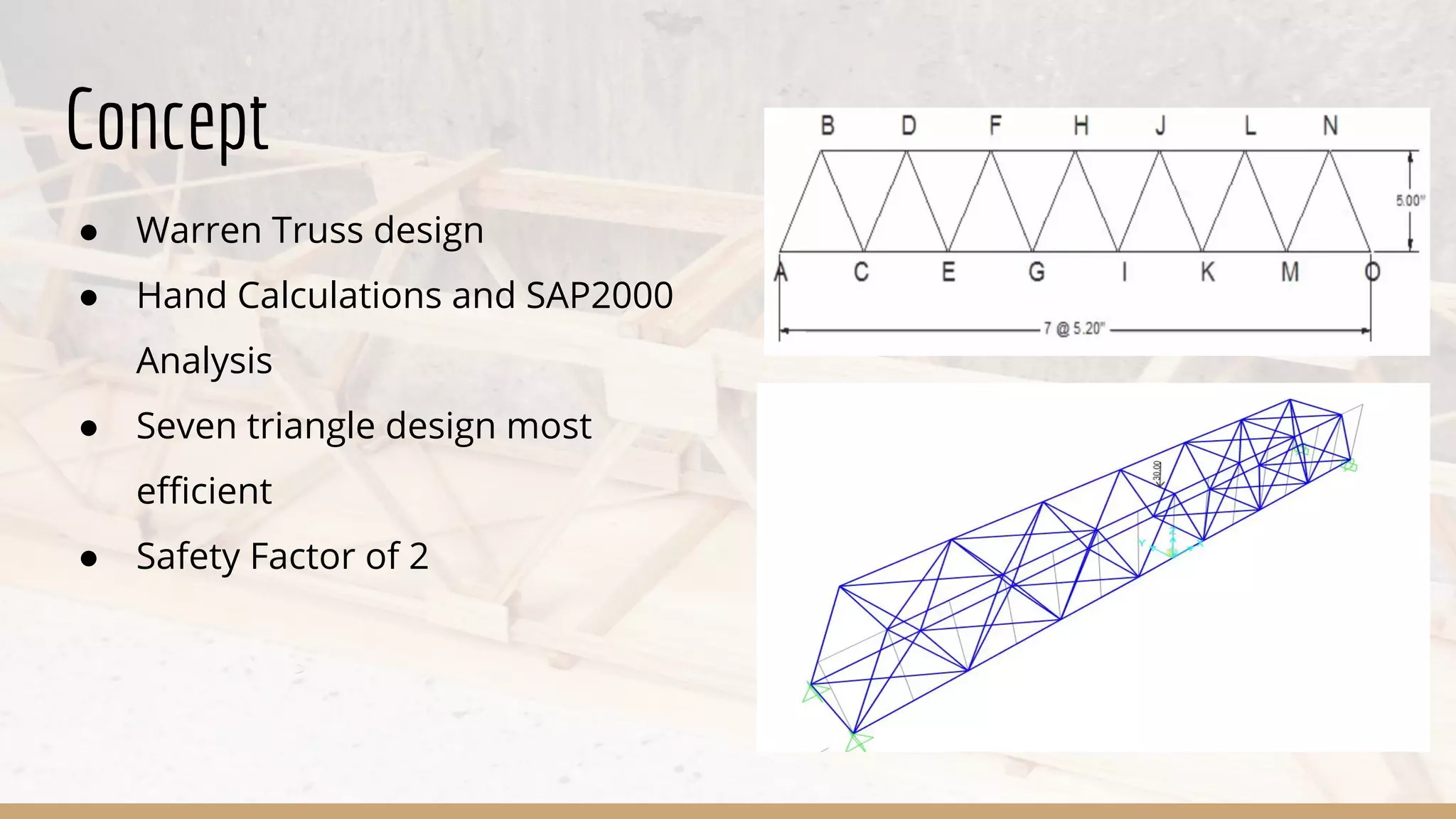

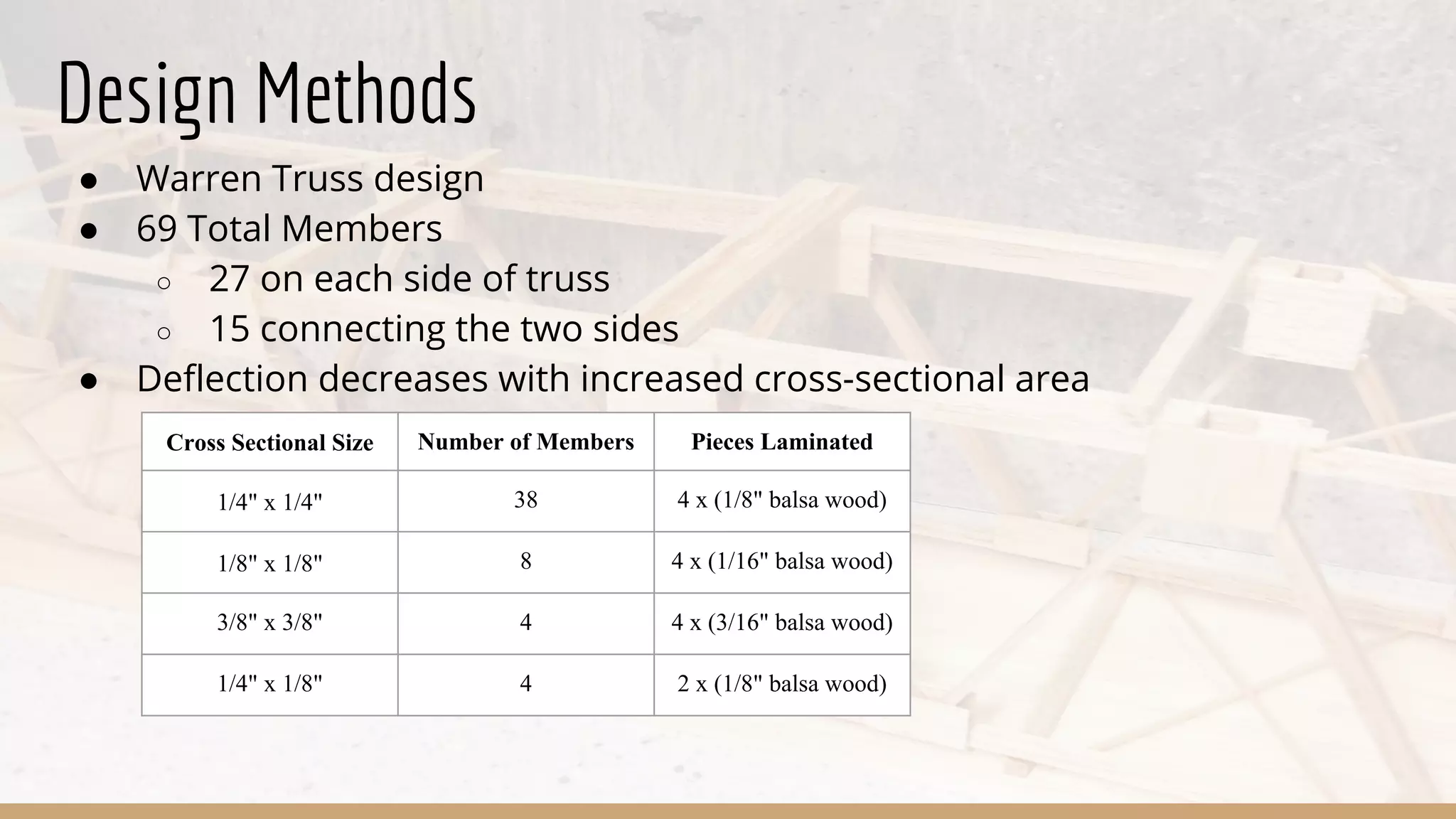

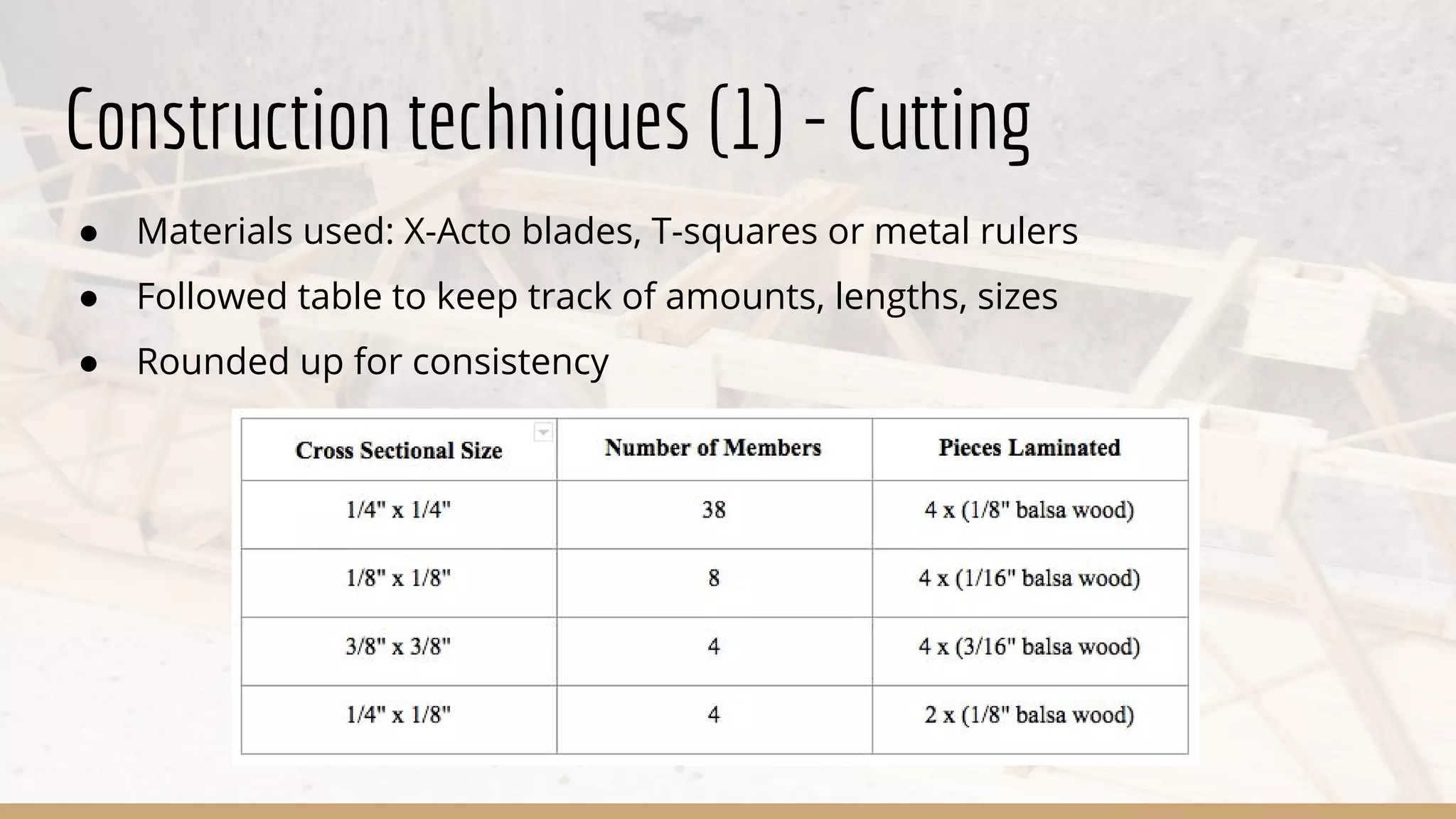

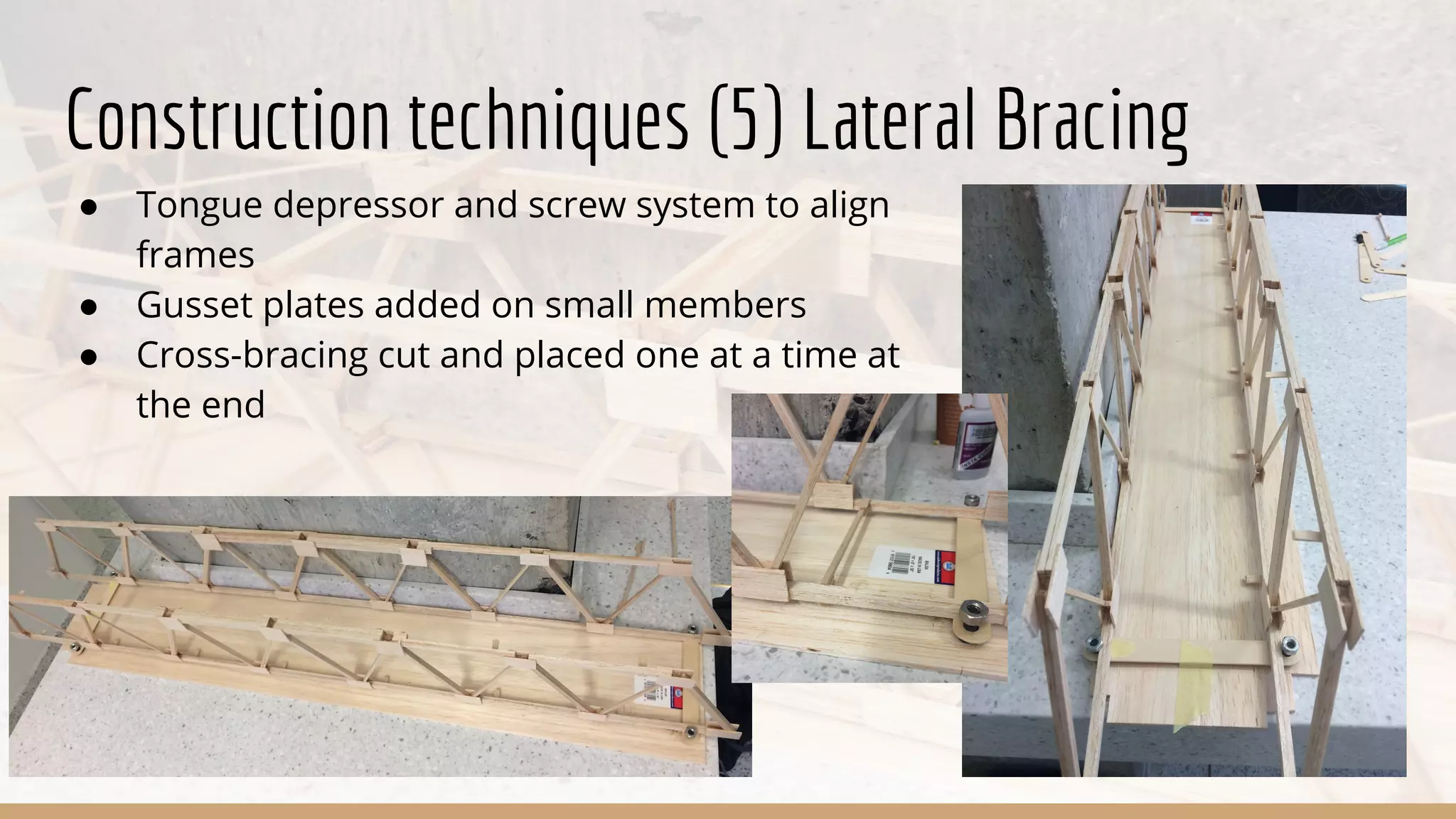

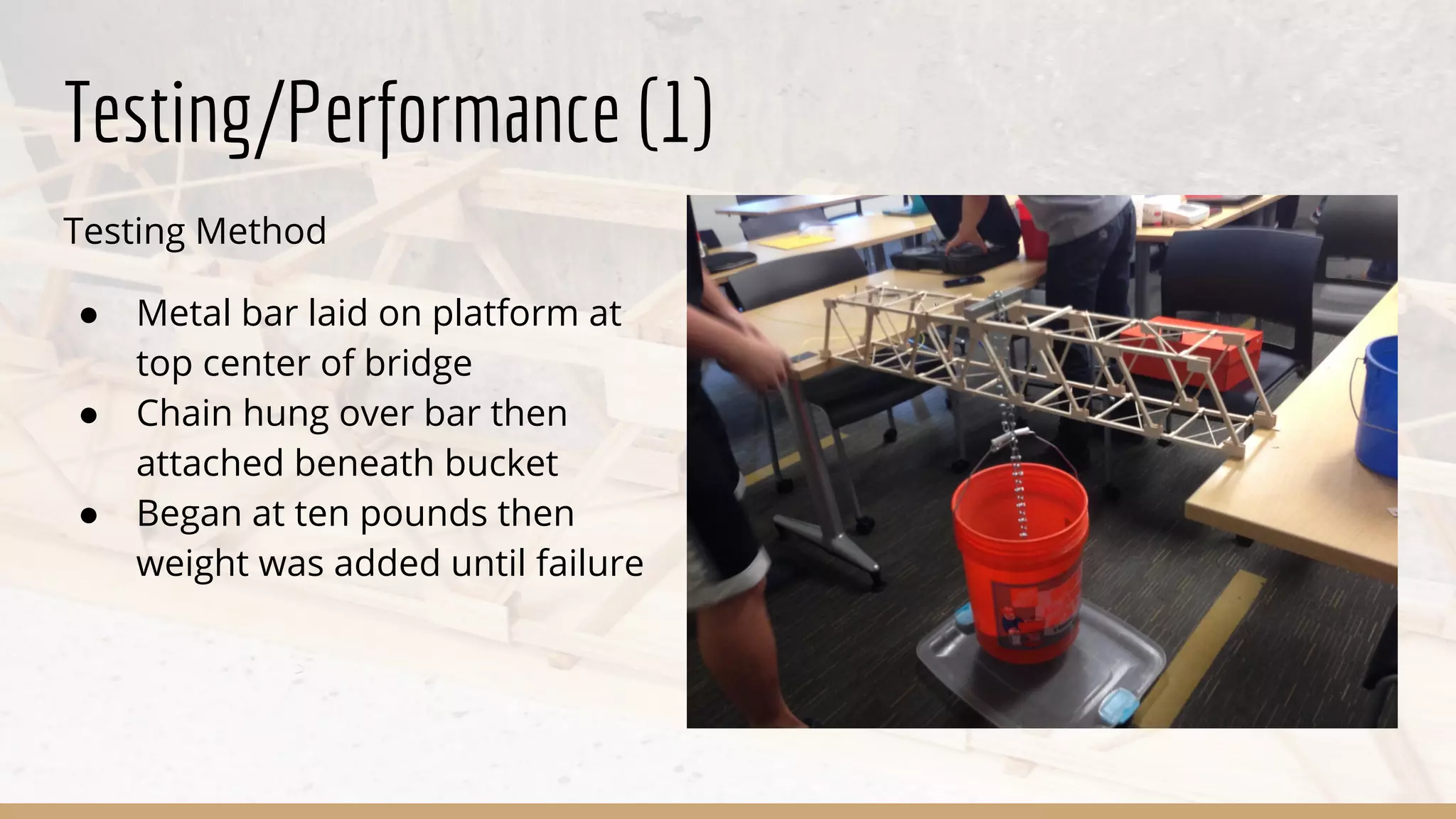

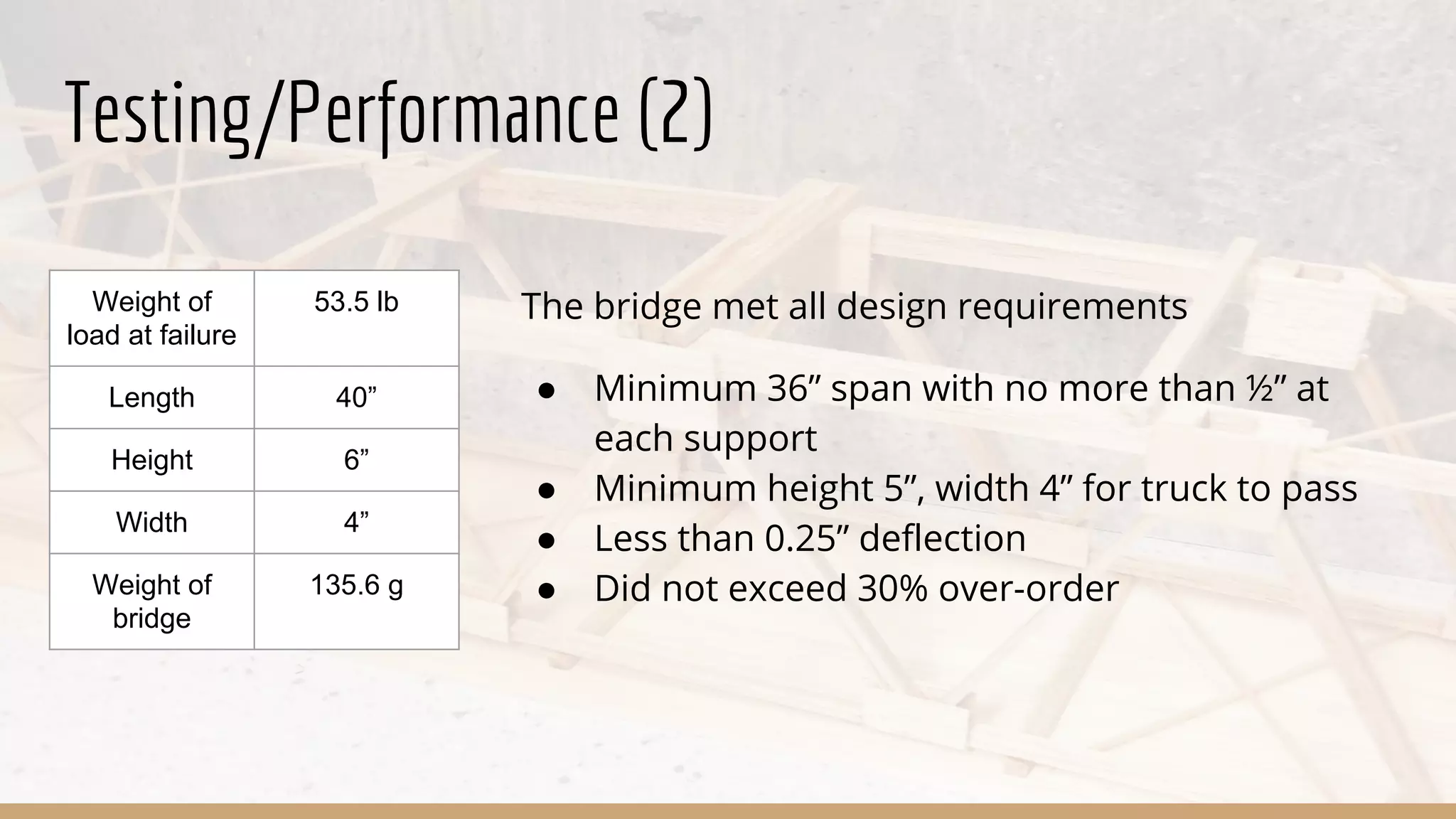

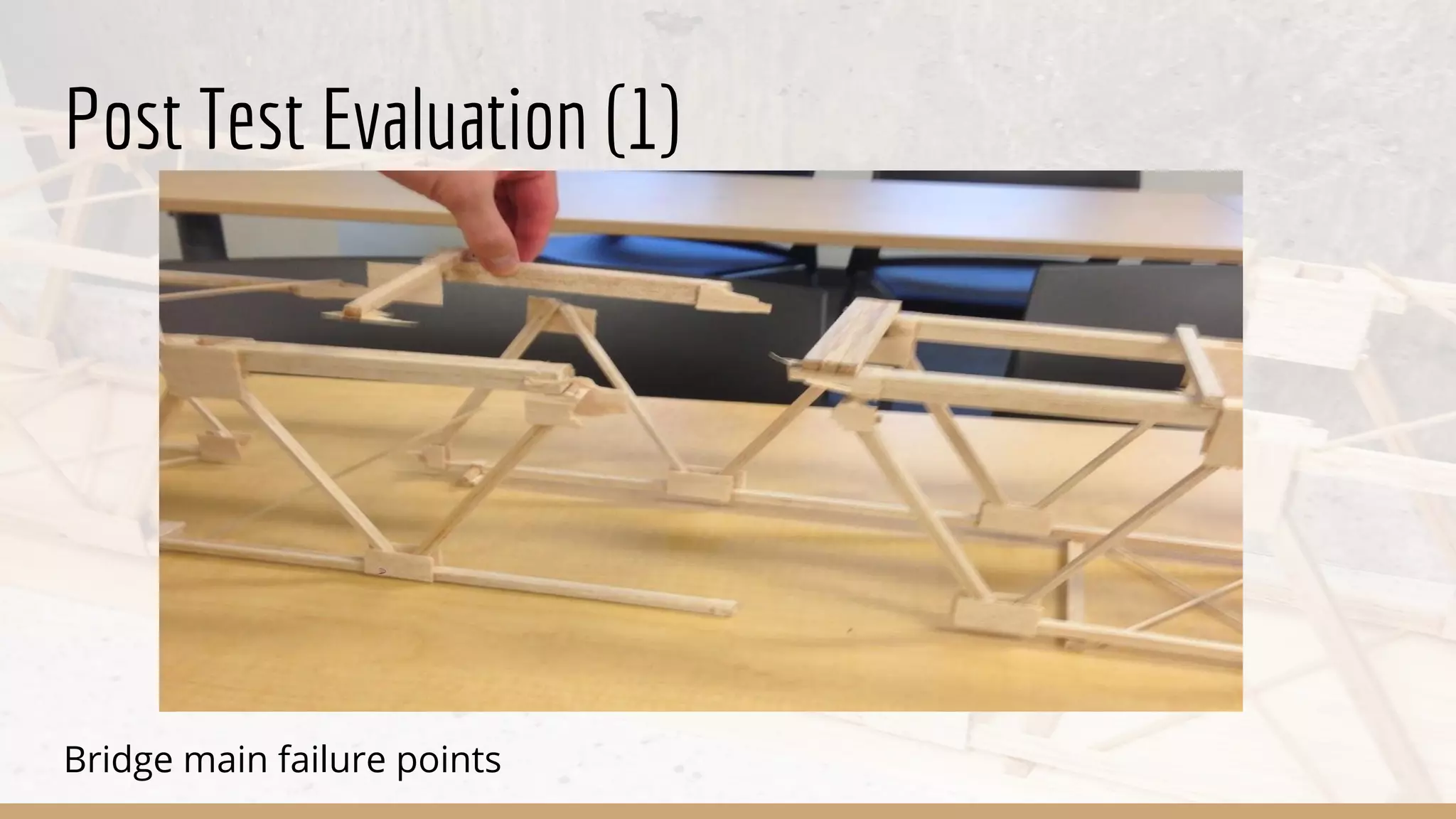

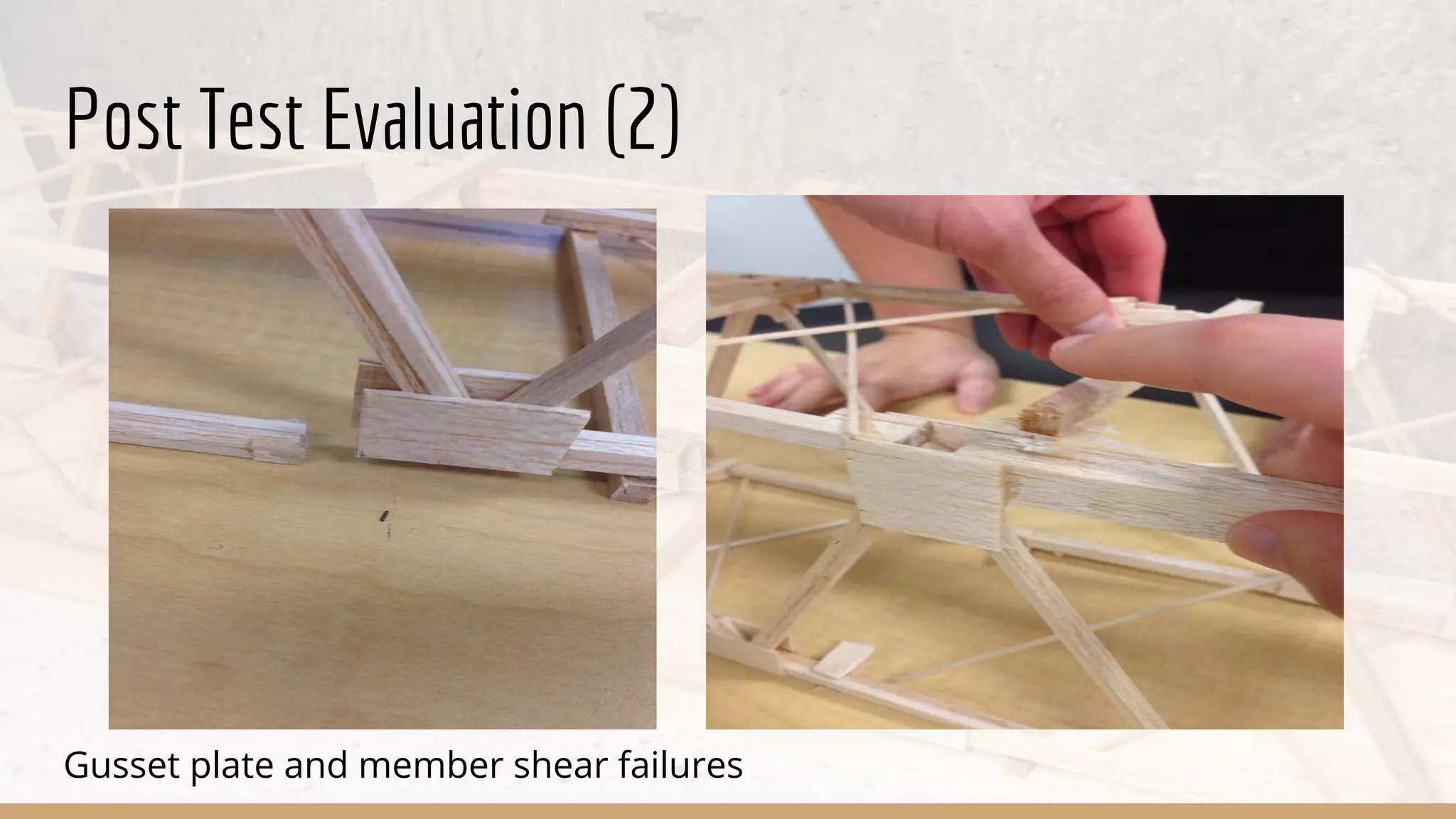

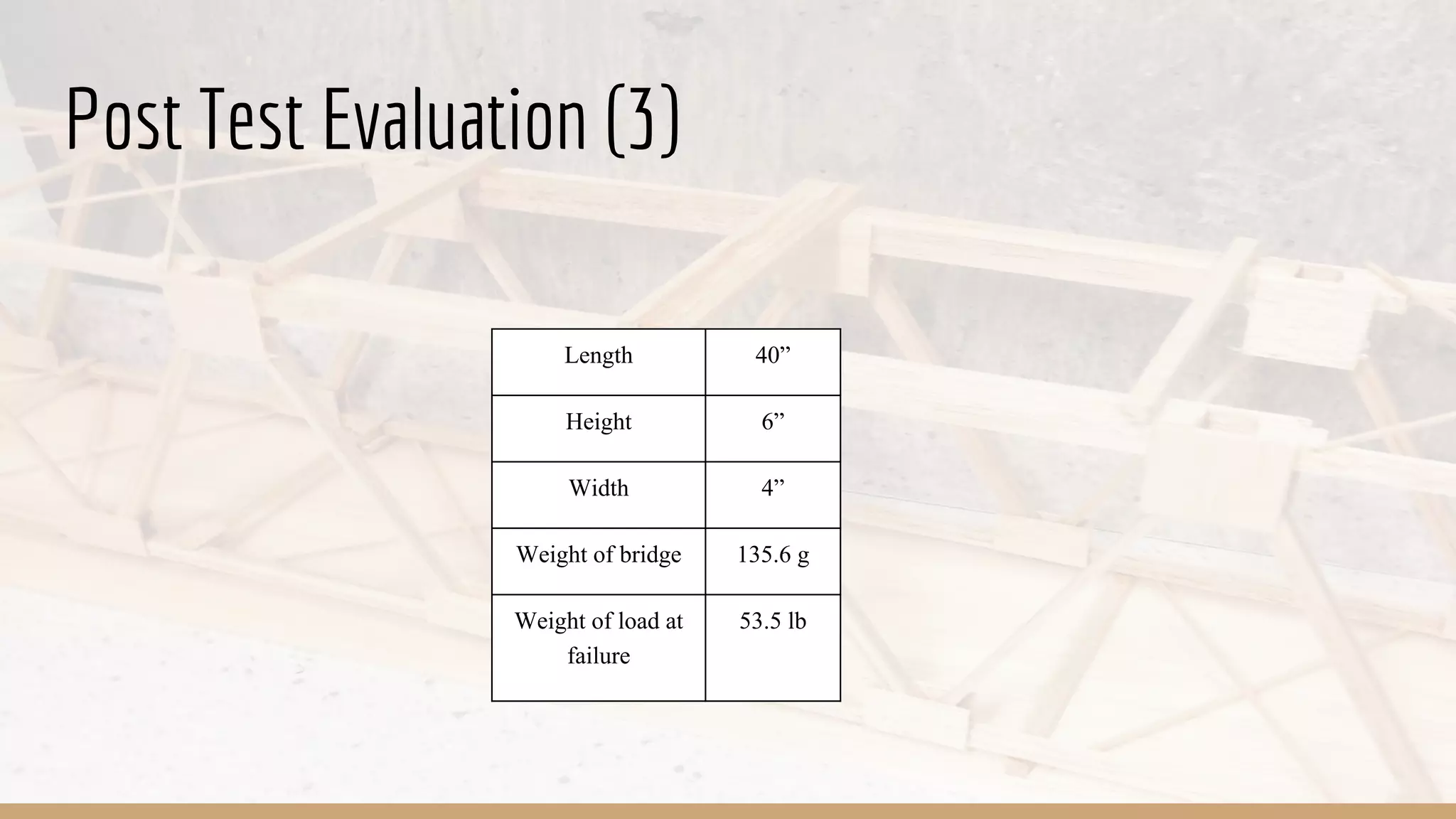

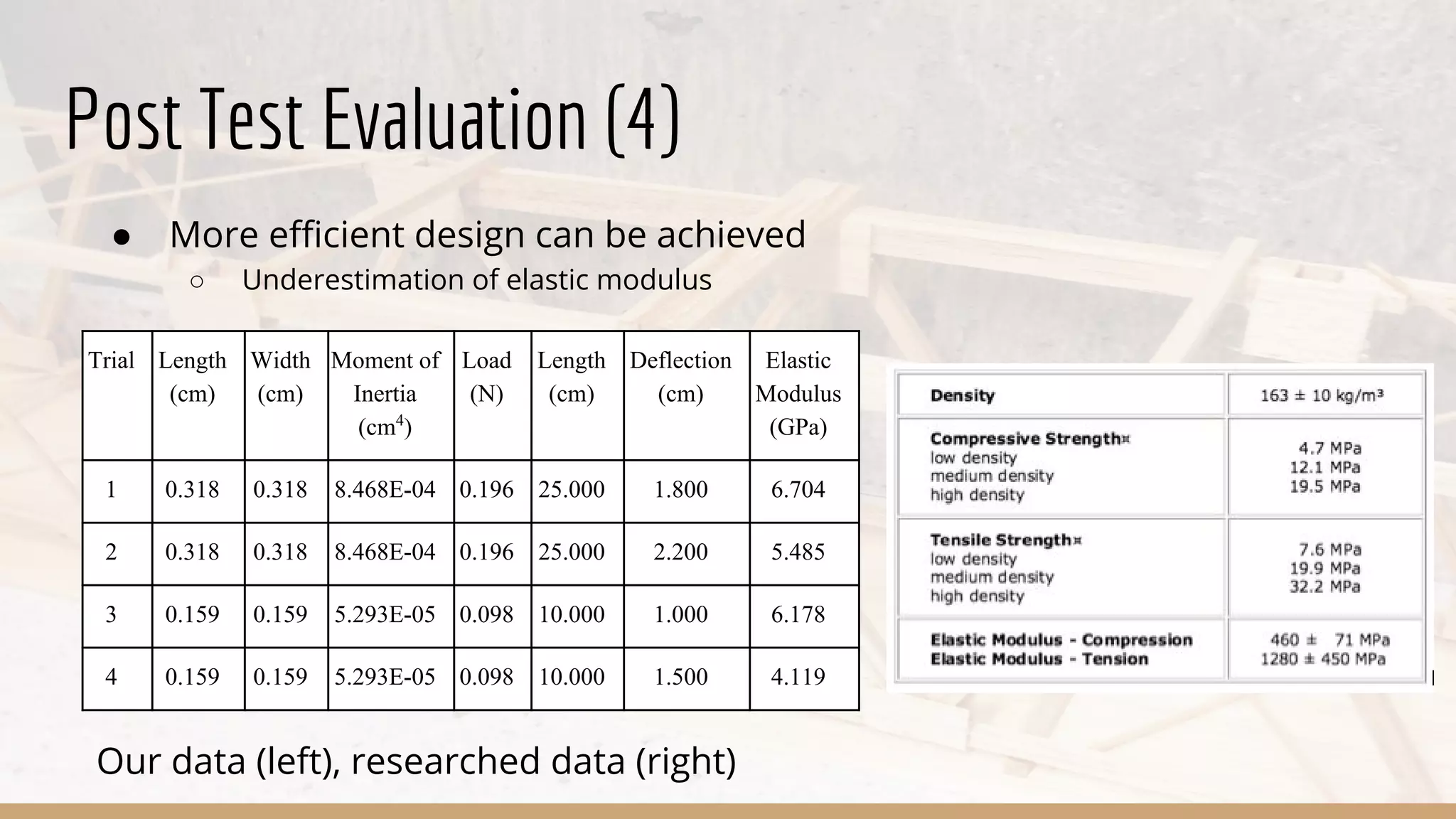

Group 3 designed and constructed a Warren truss bridge made of balsa wood with a total of 69 members. Through testing, the bridge met all requirements by supporting over 50 pounds without failing and having less than 0.25 inches of deflection. While the bridge was successful, post-evaluation found the design could be improved by using larger gusset plates and more accurately accounting for member thickness and the material's elastic modulus in the calculations.