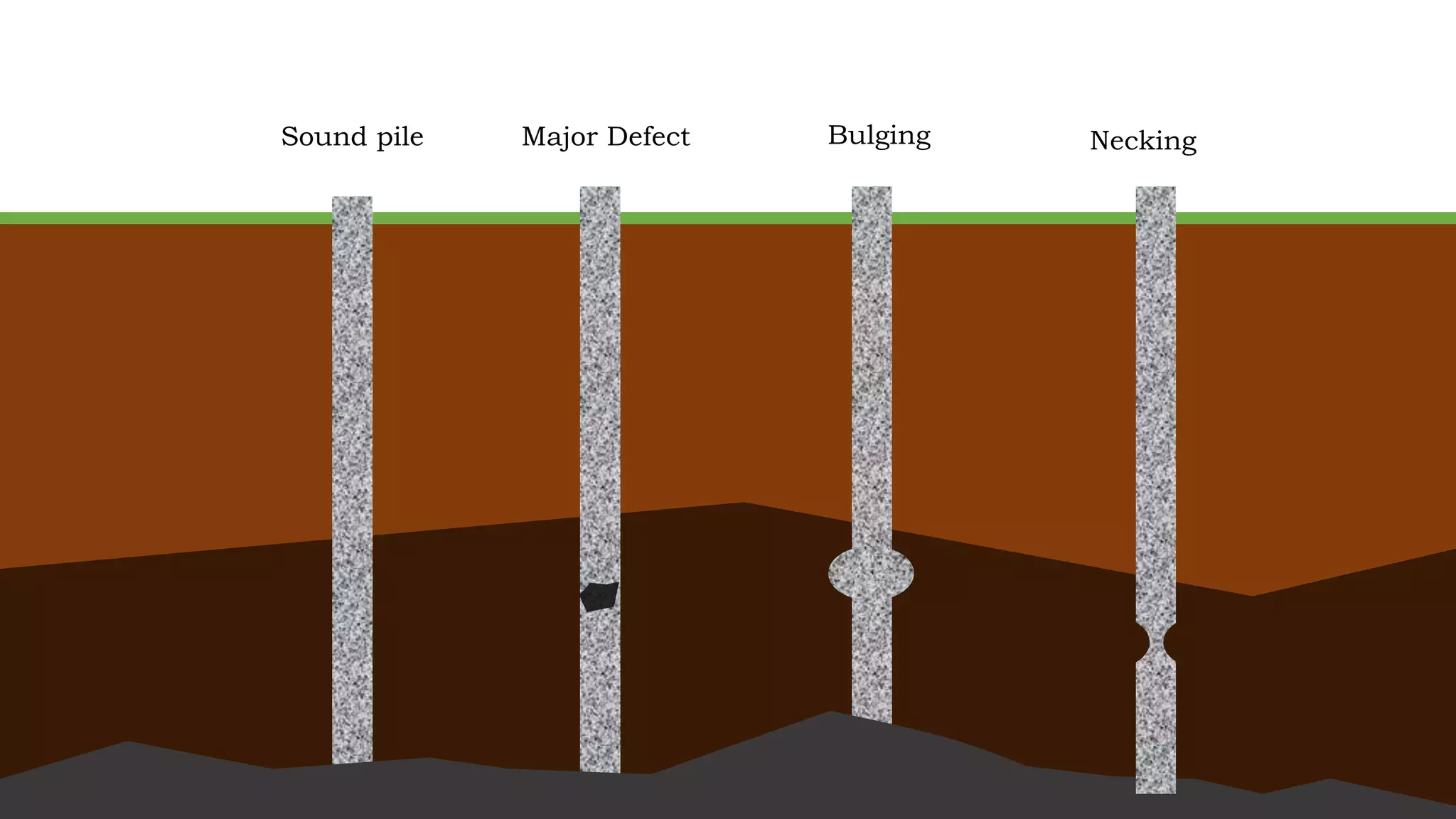

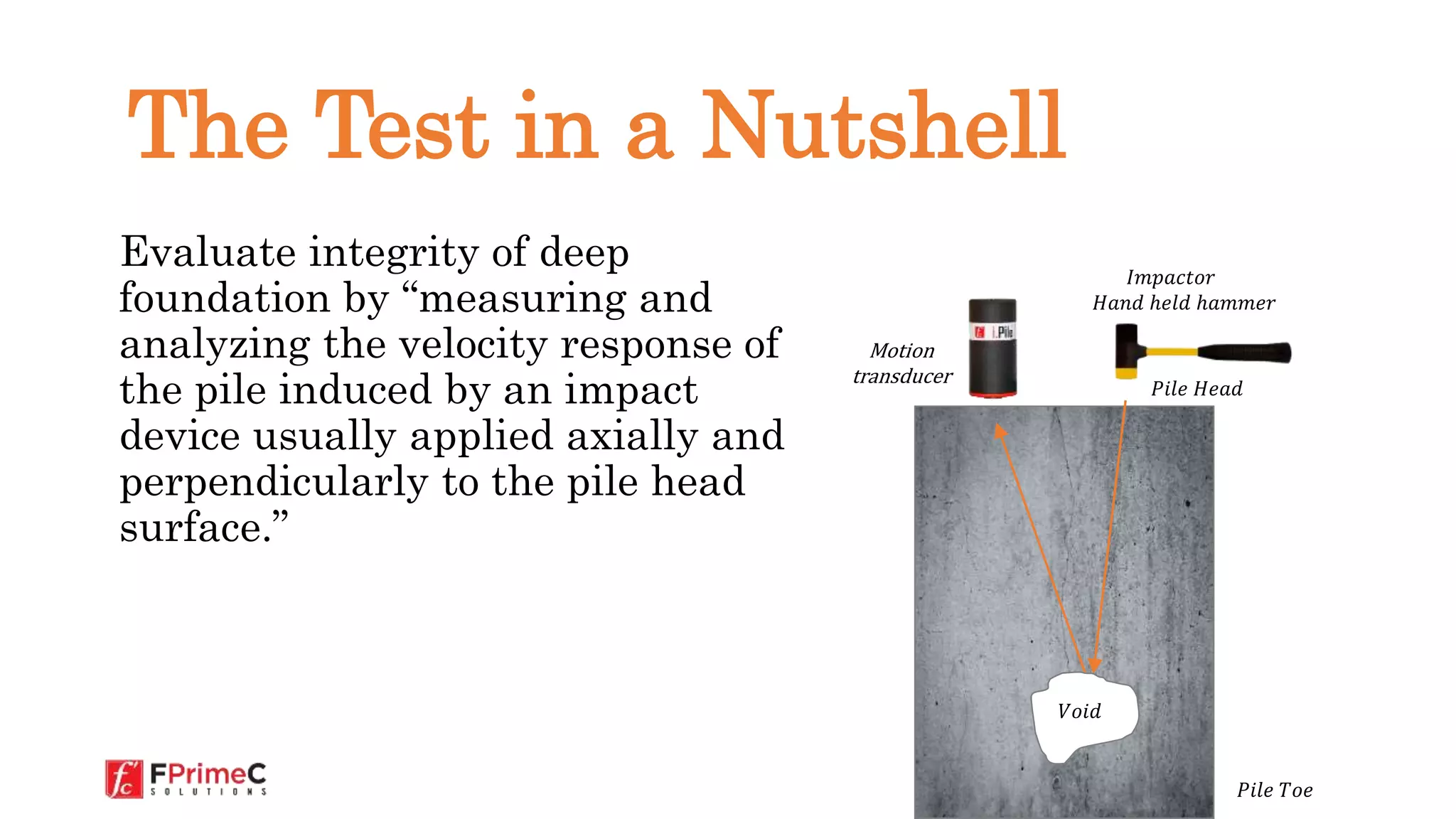

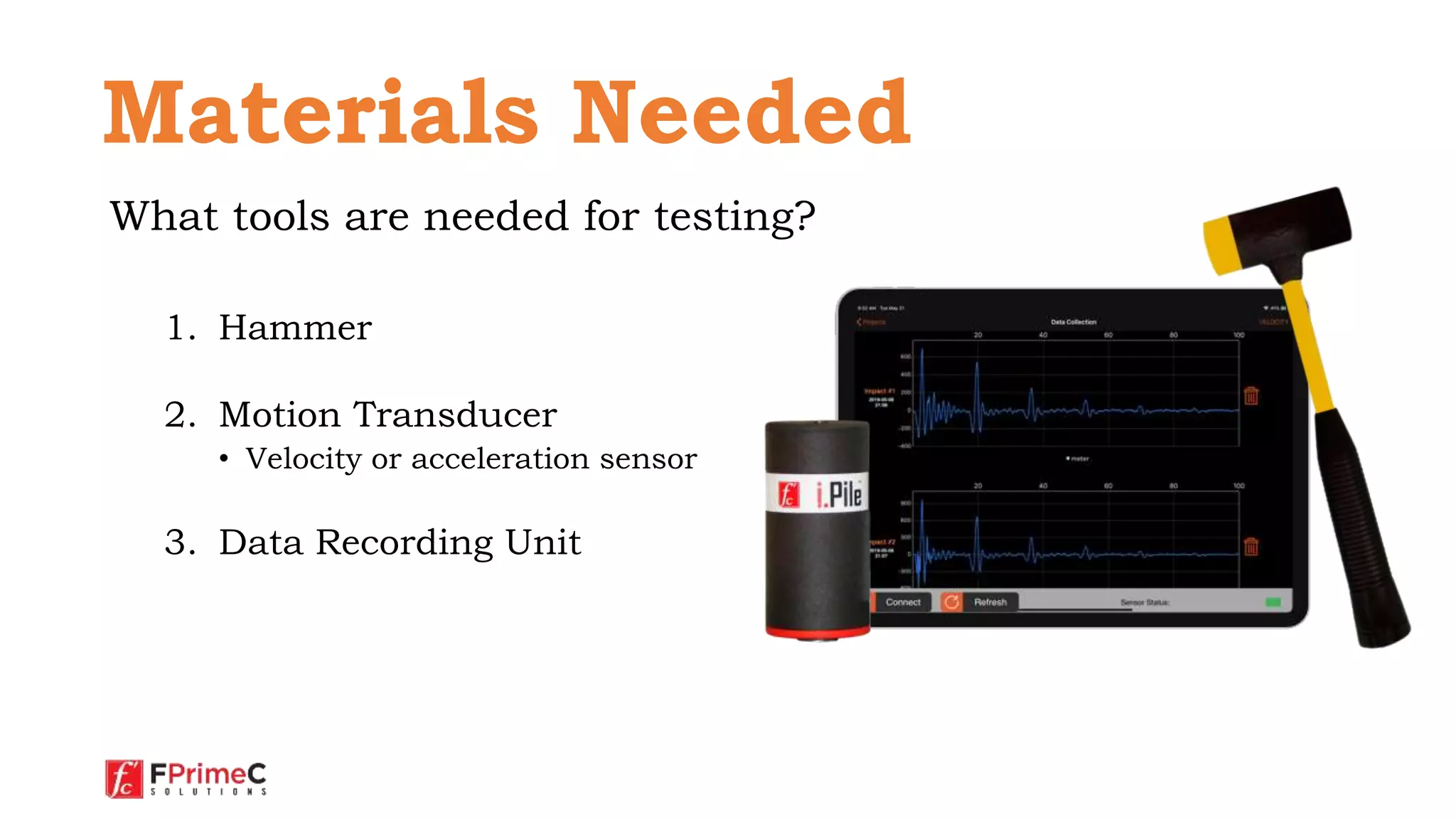

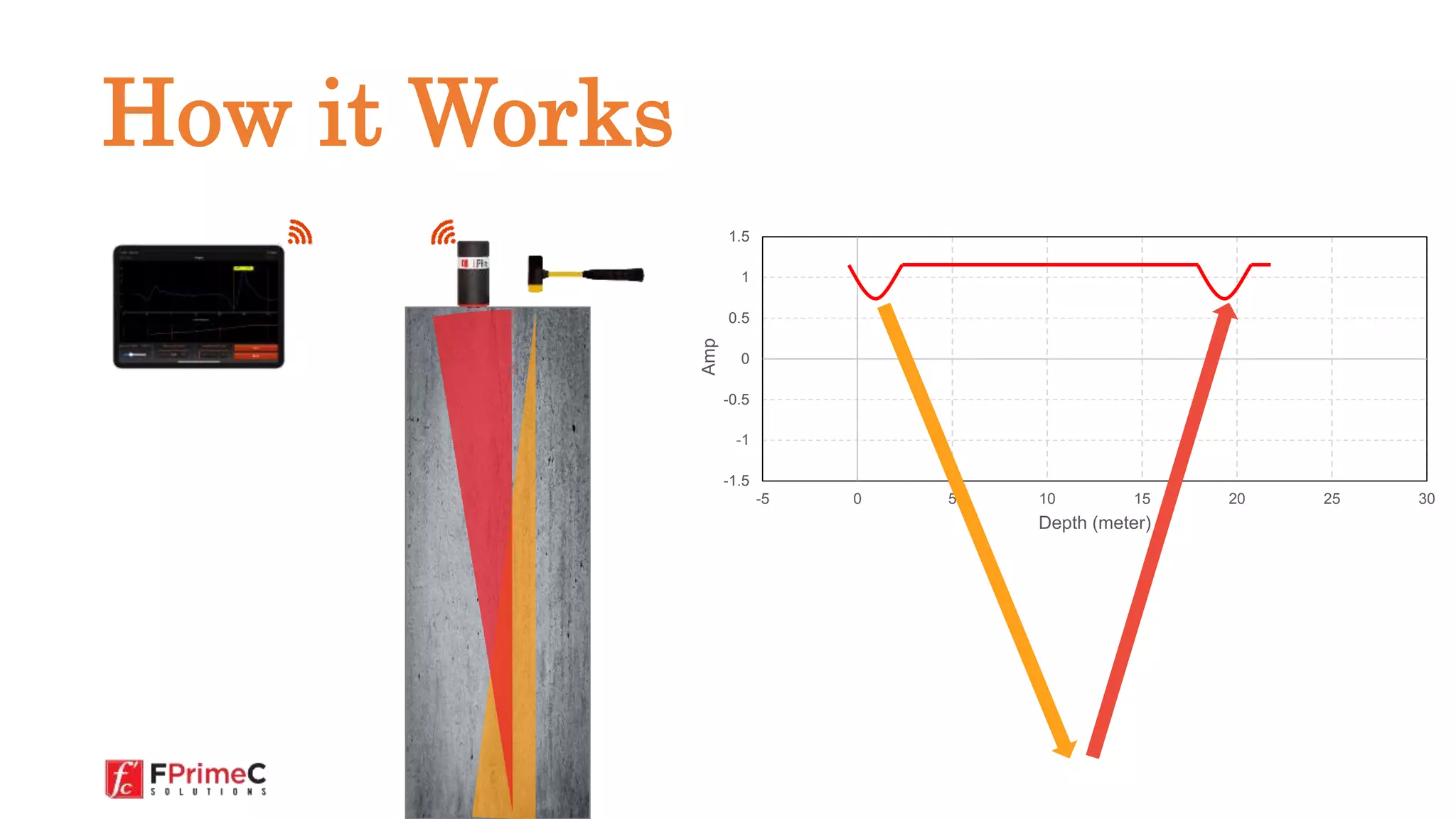

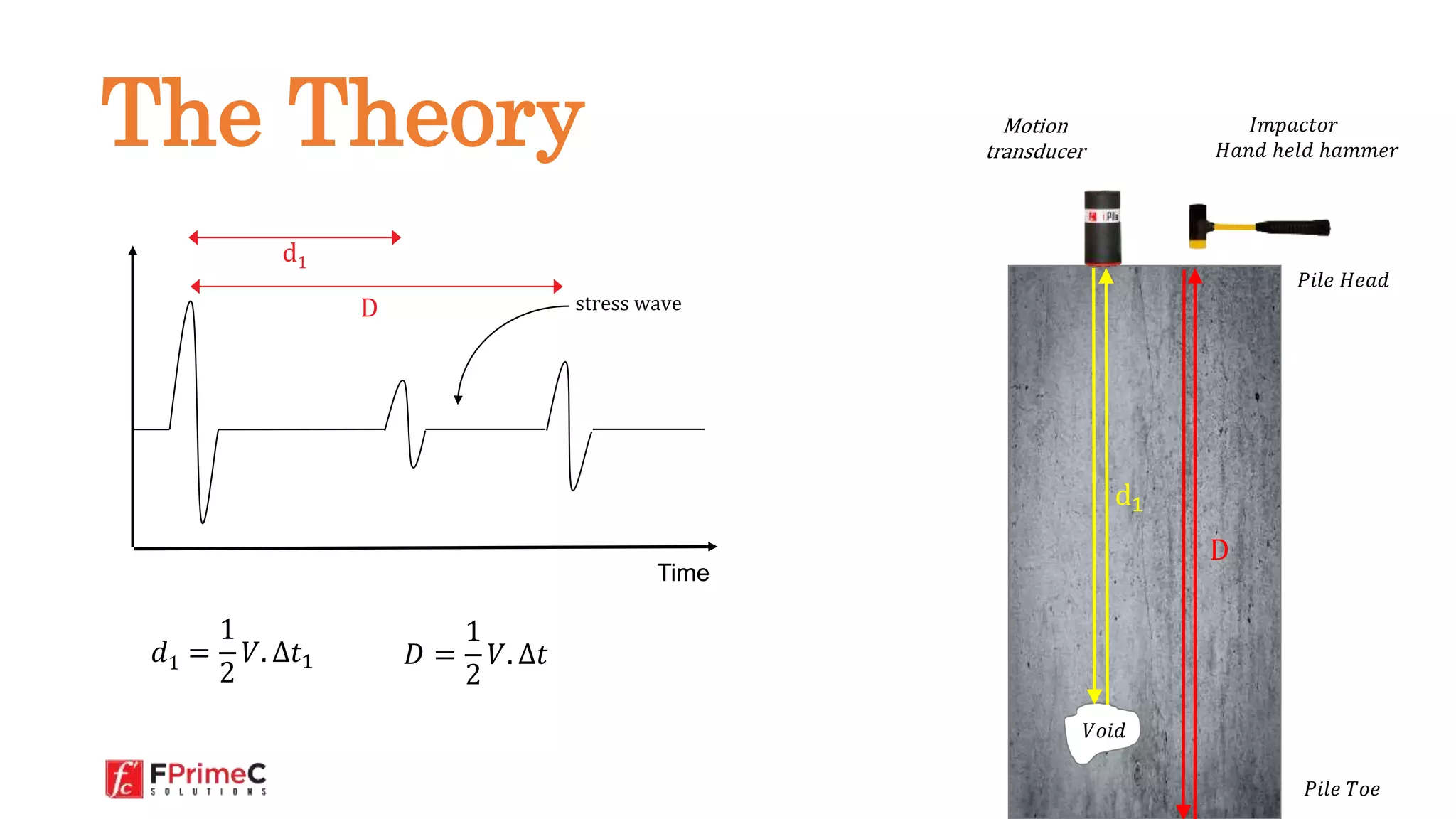

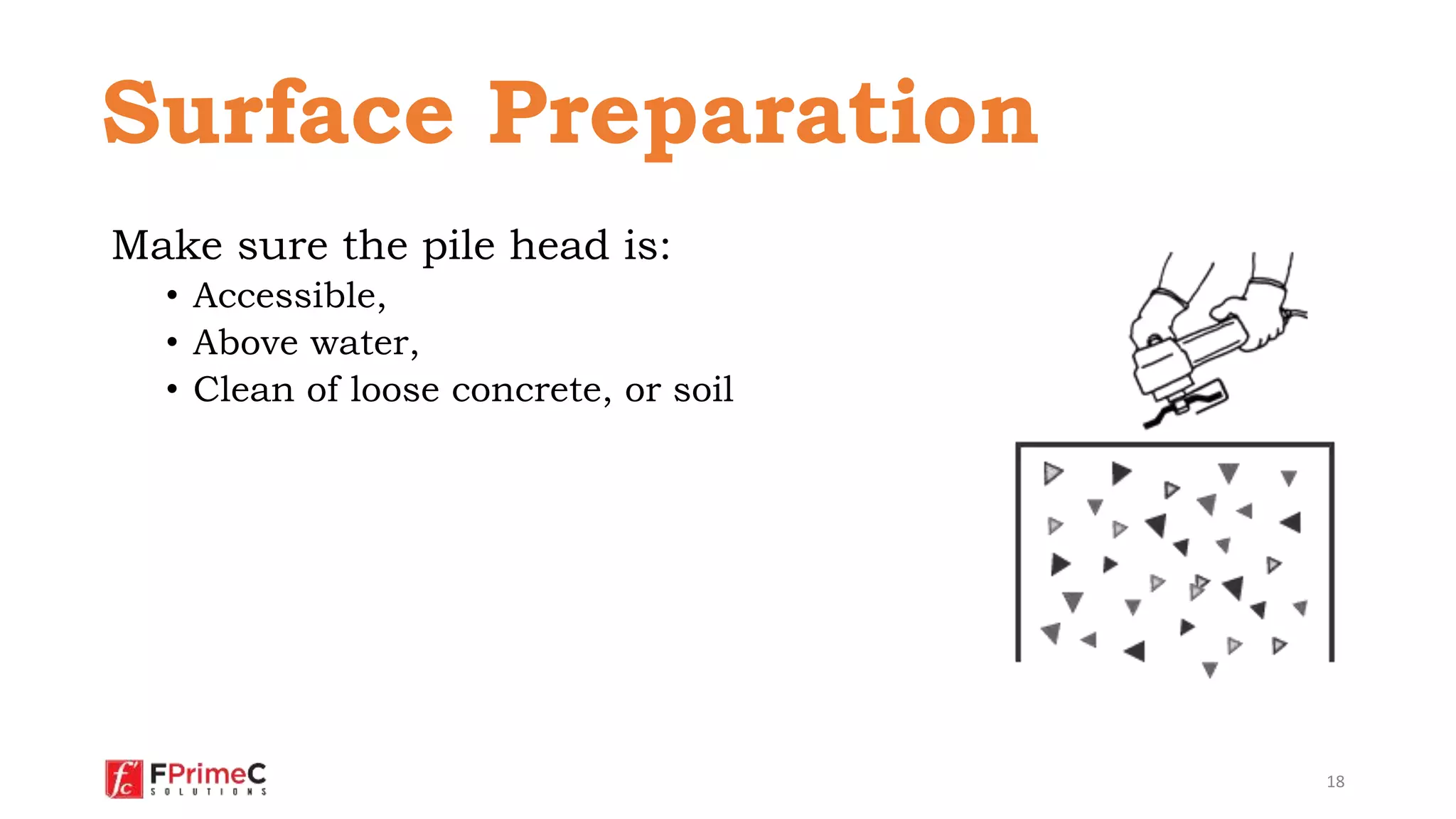

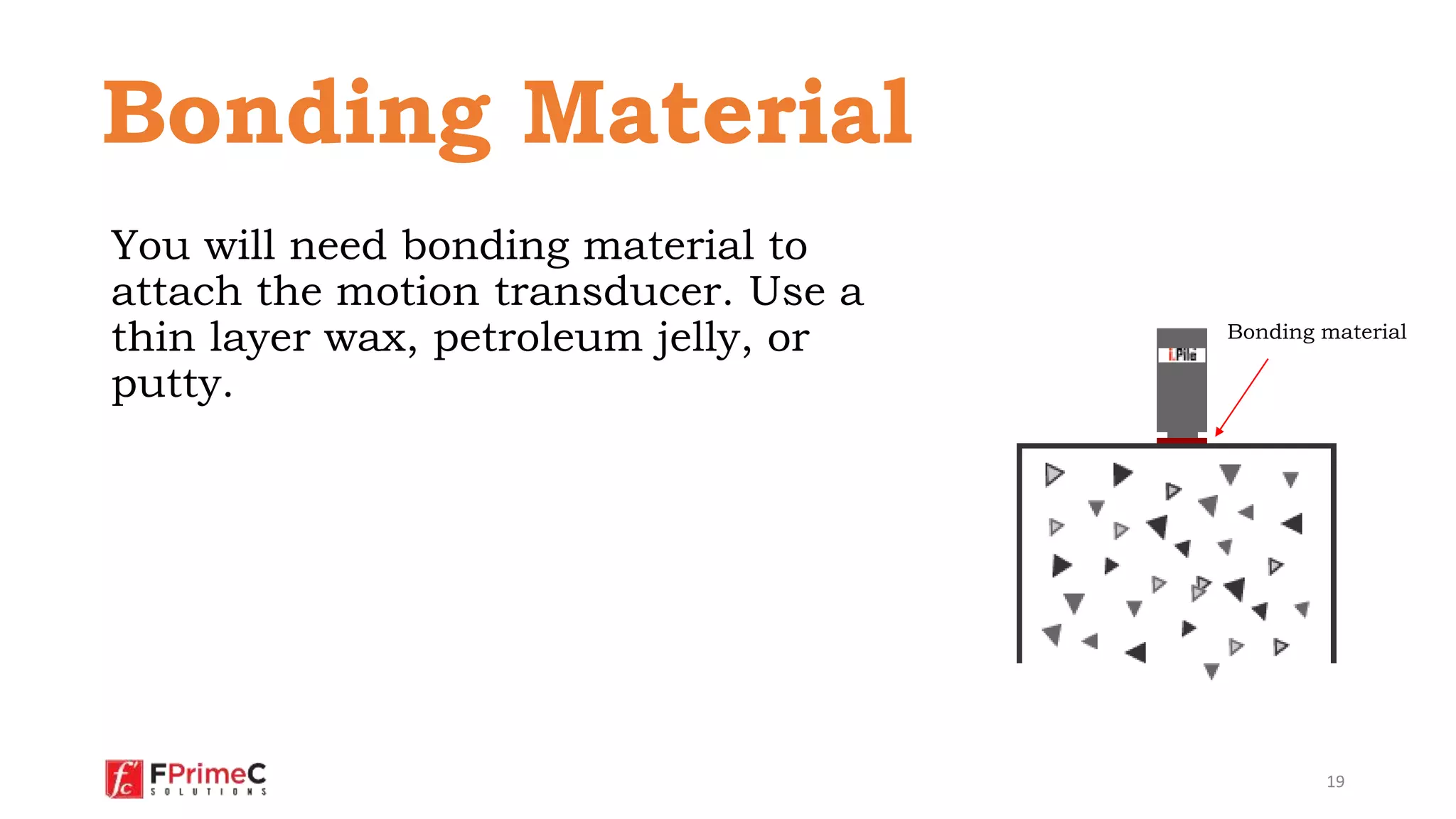

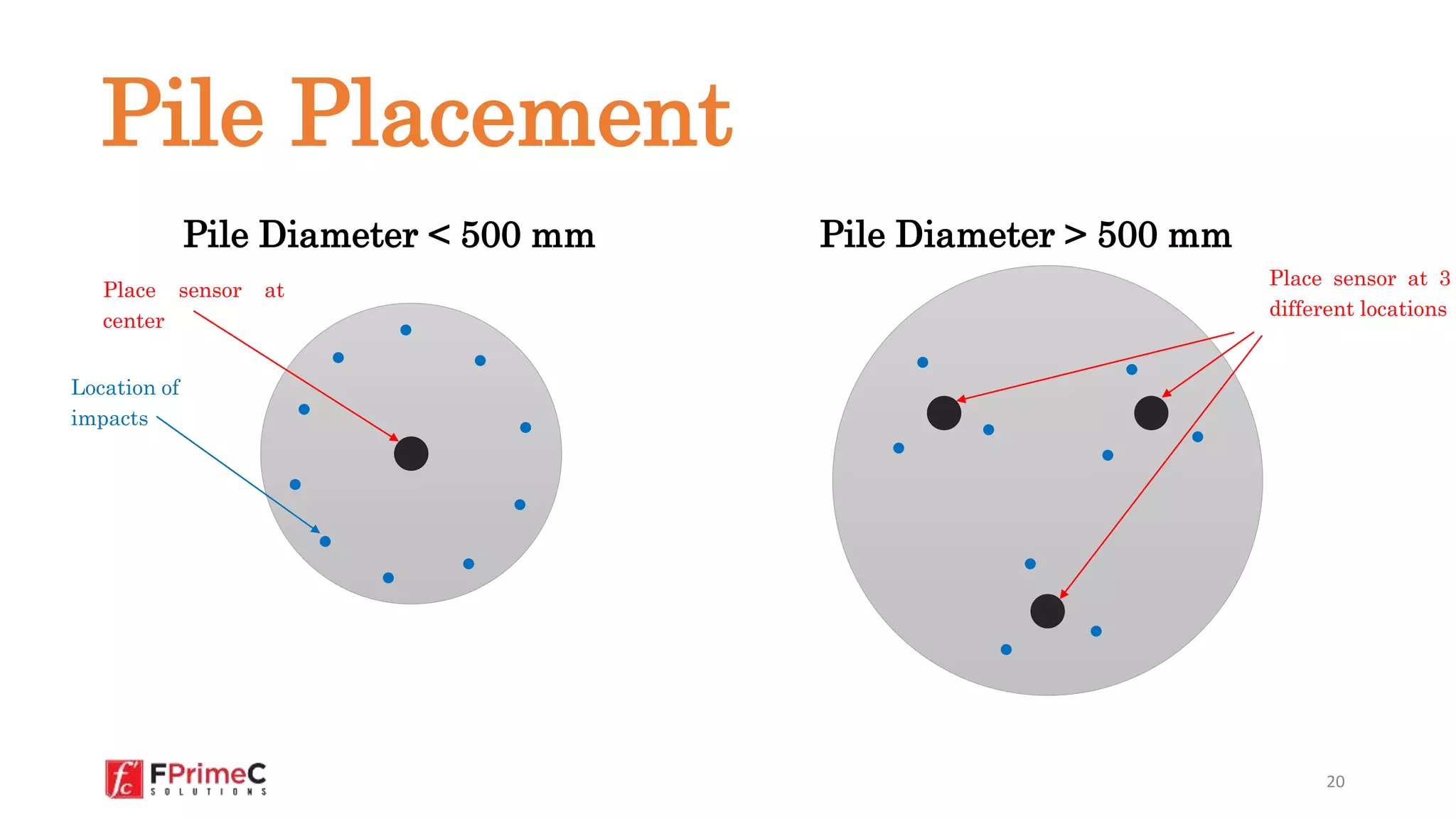

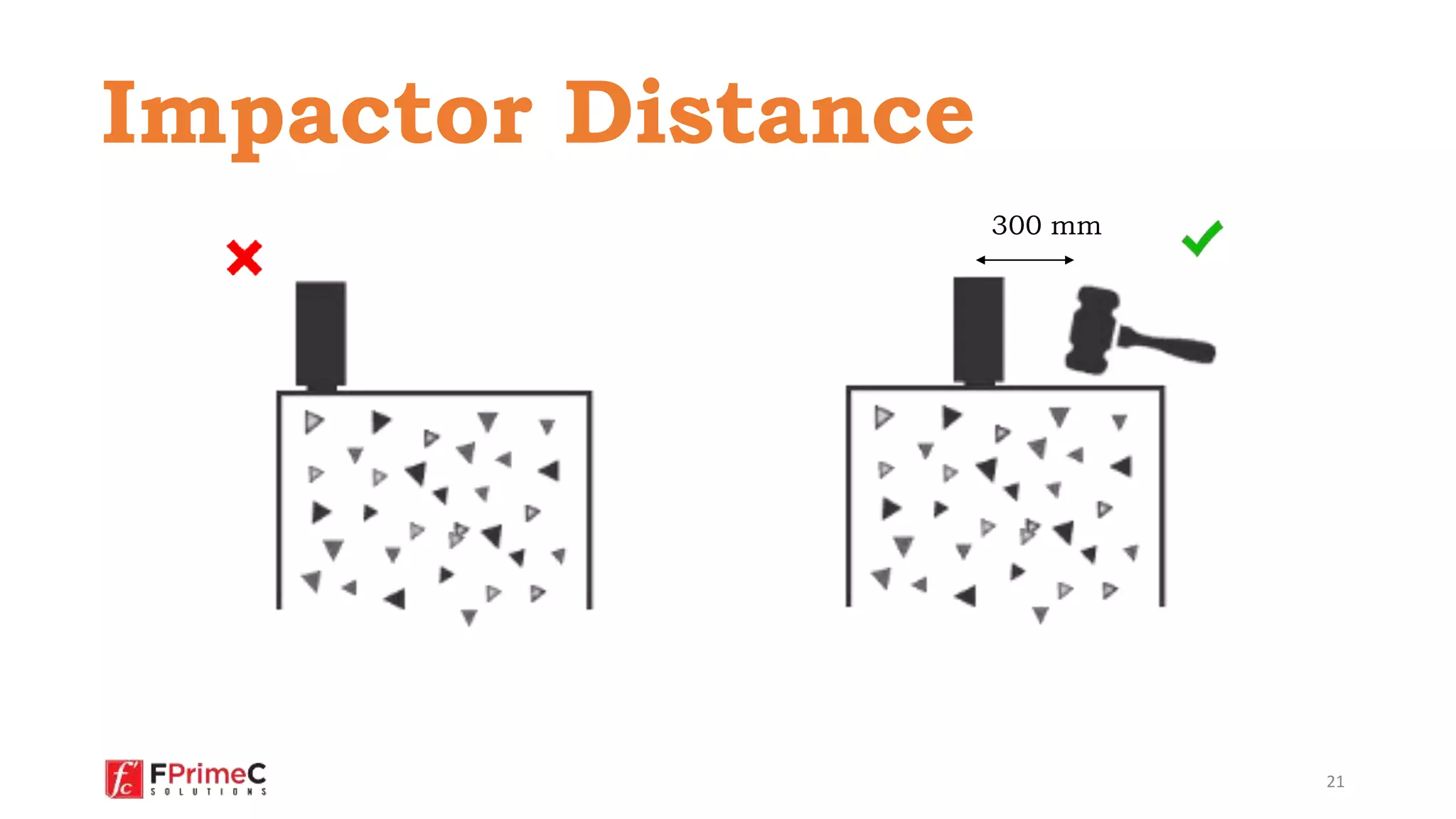

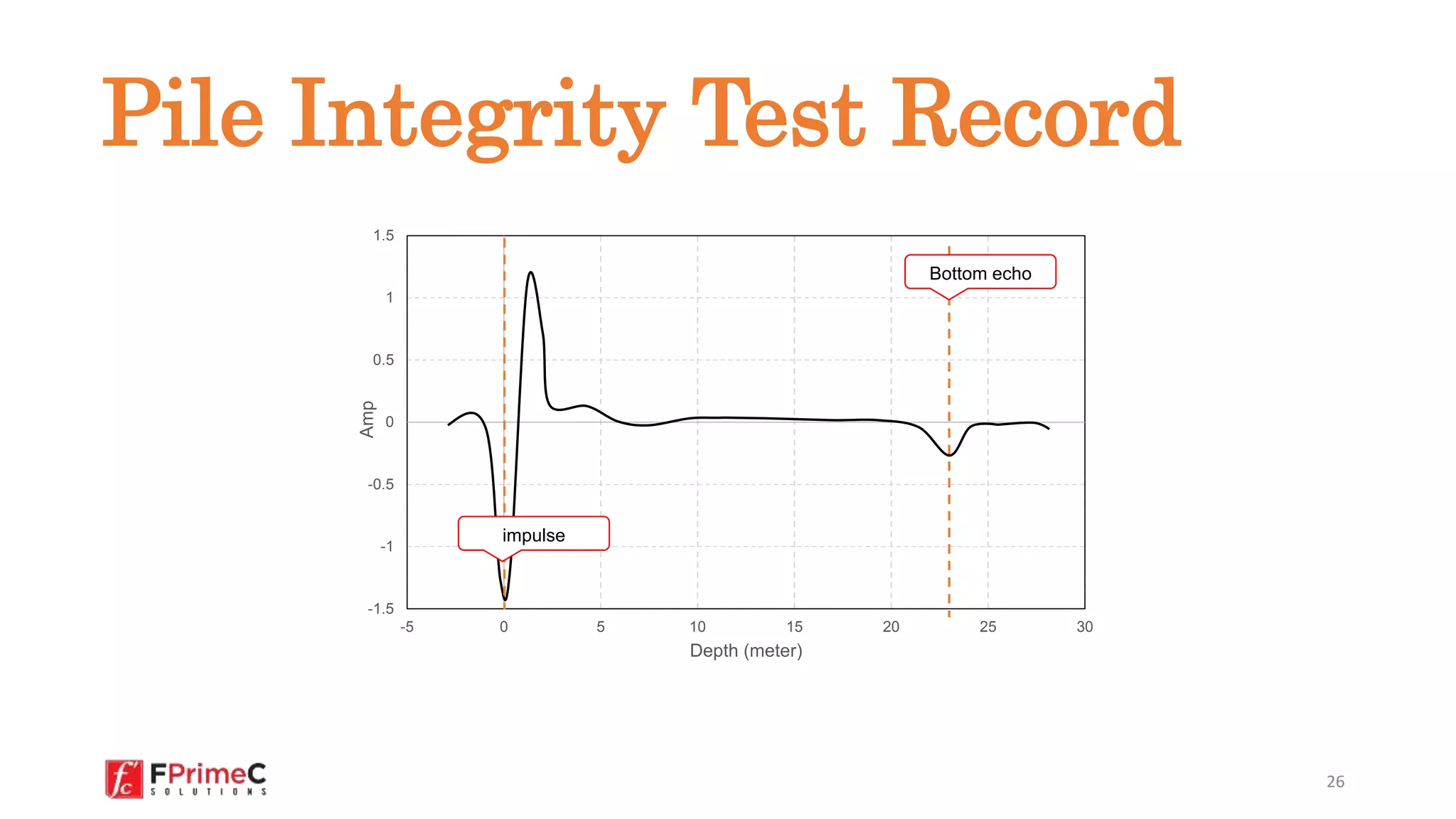

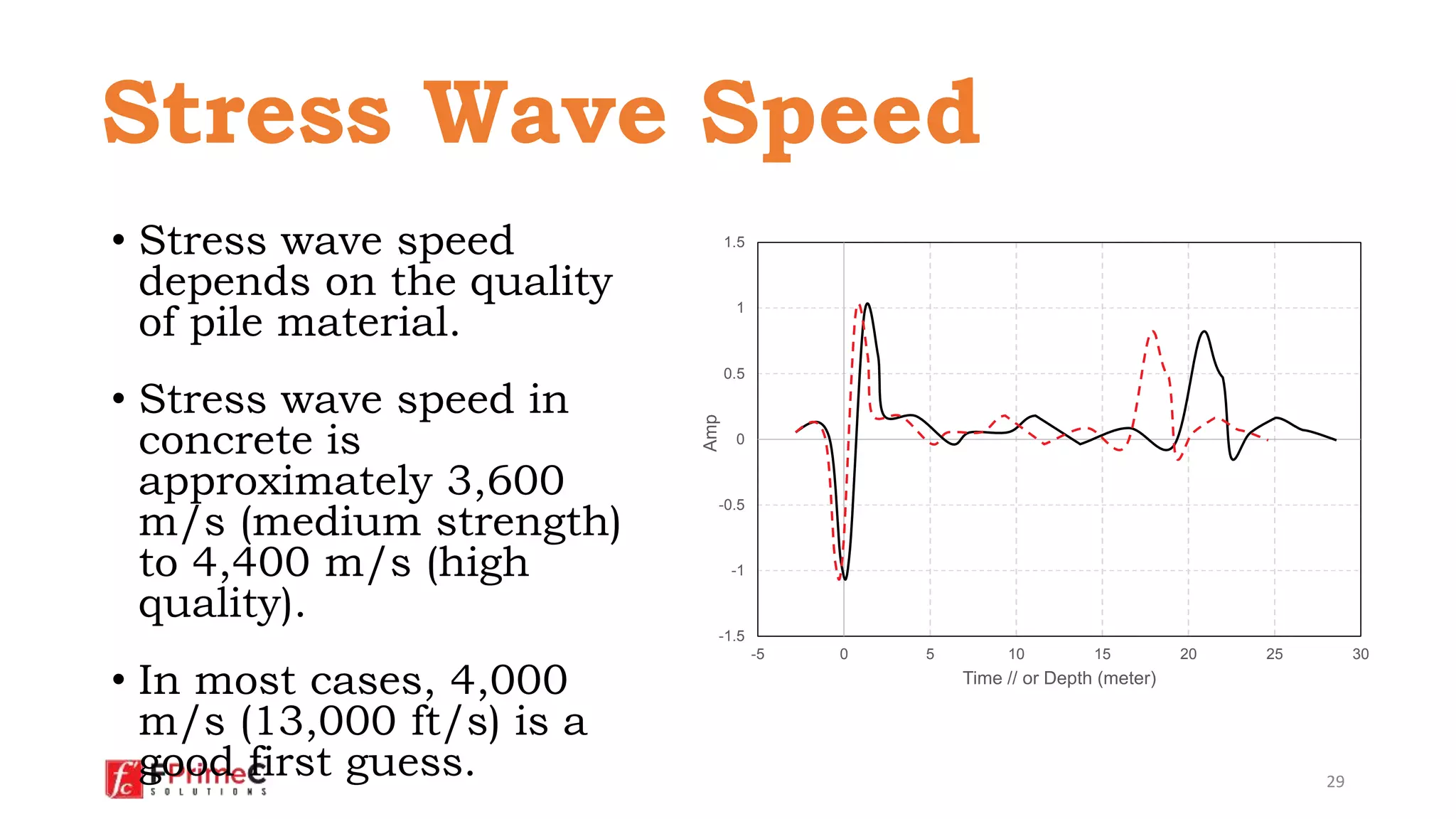

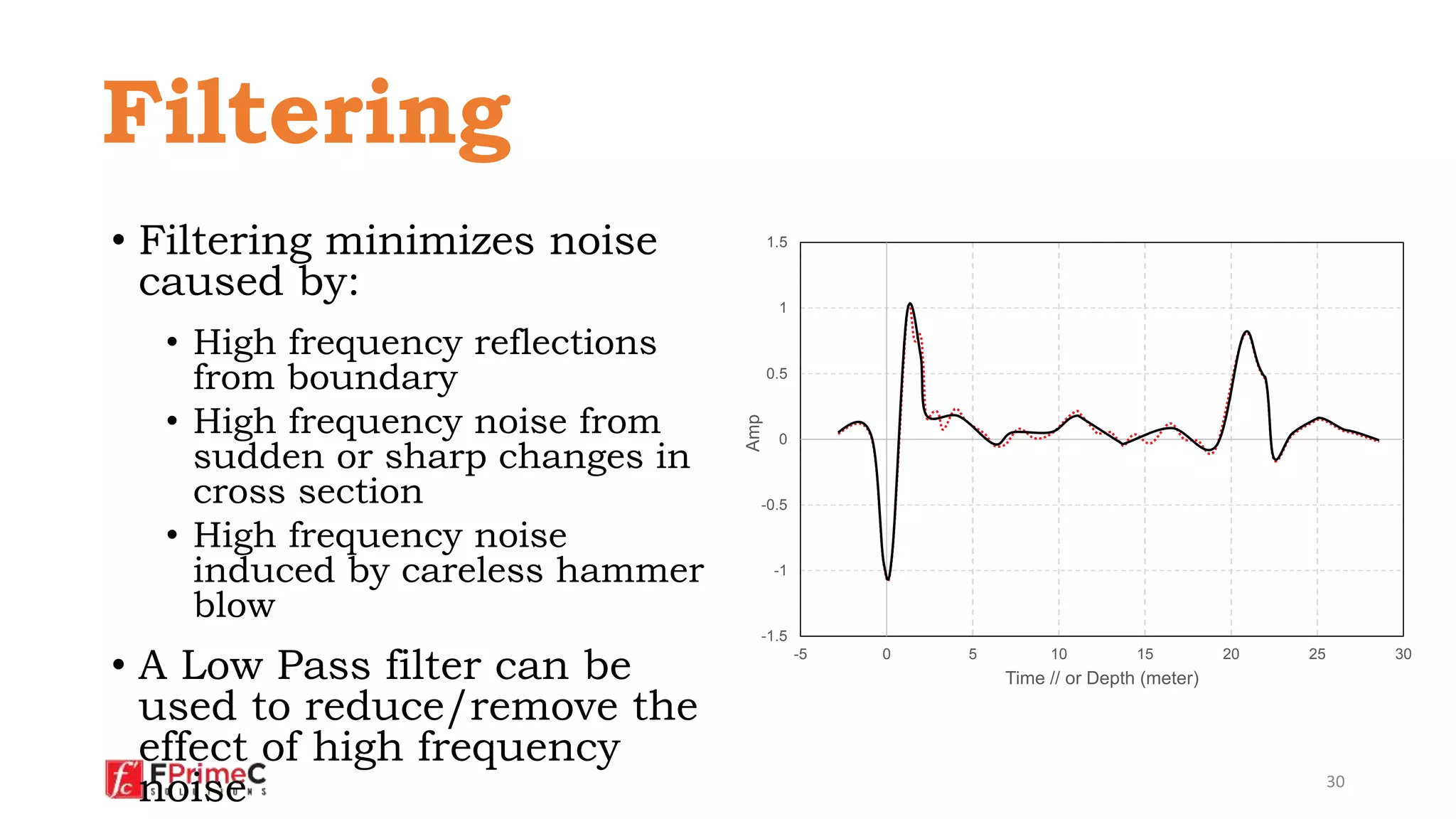

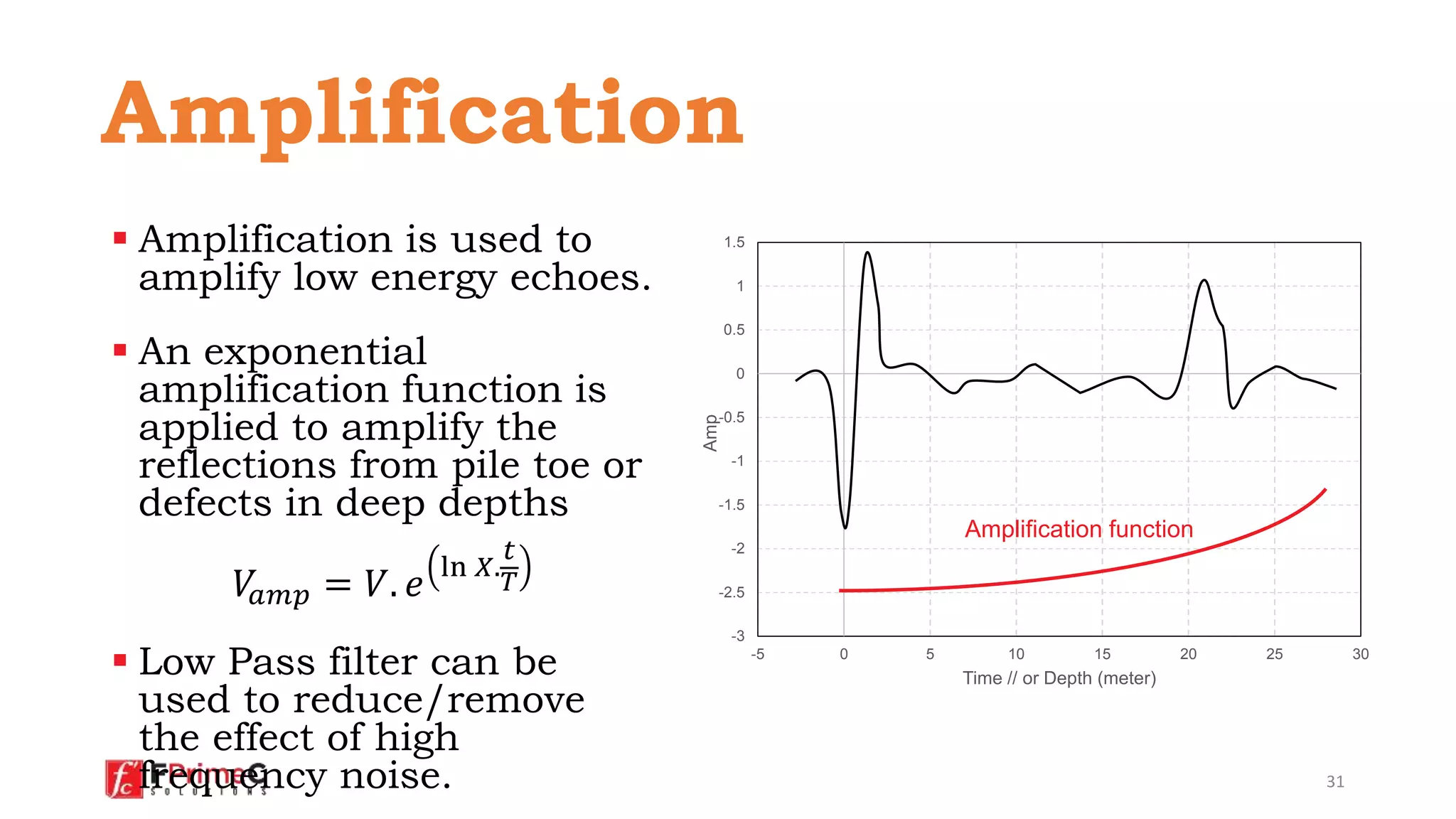

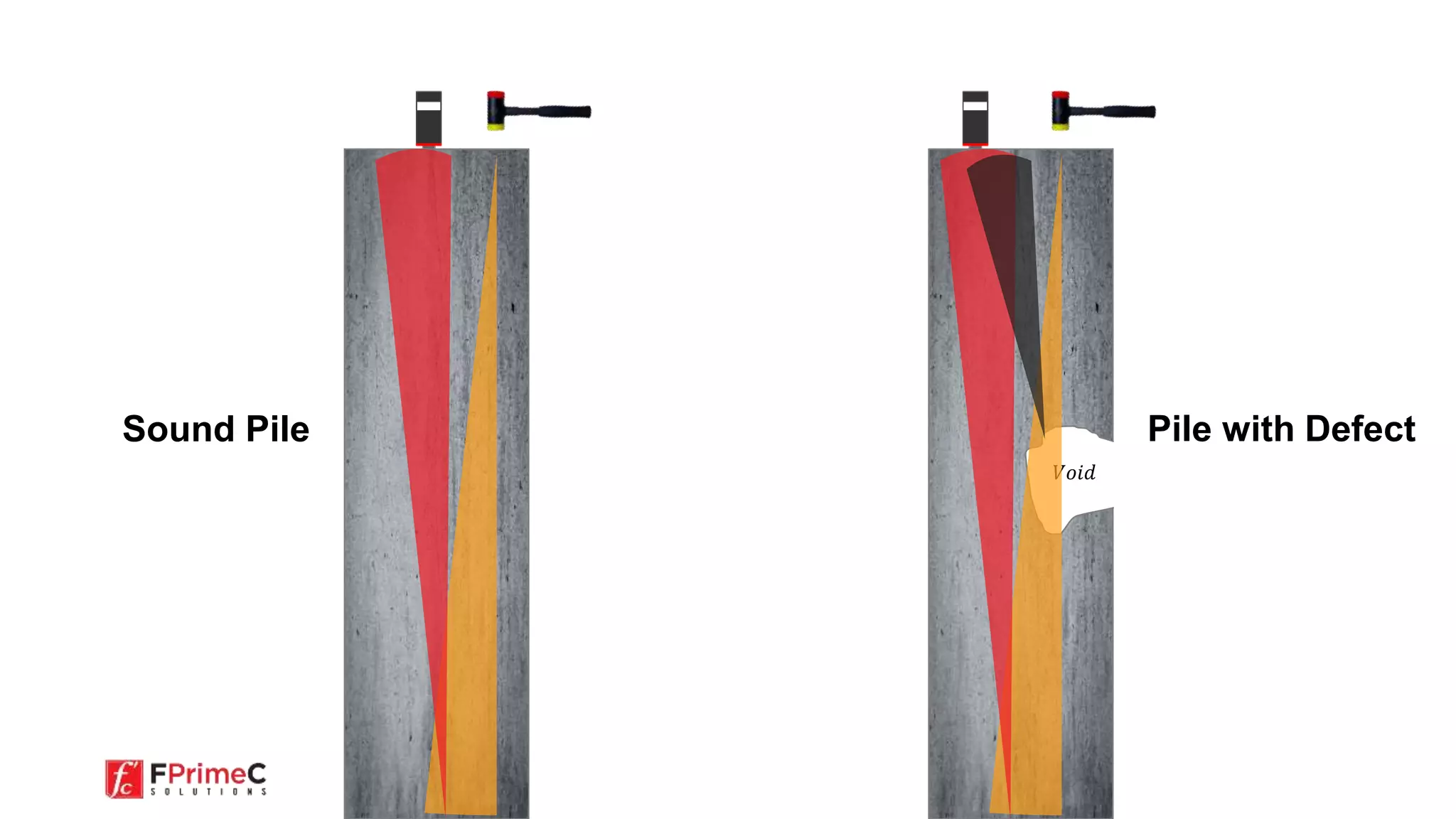

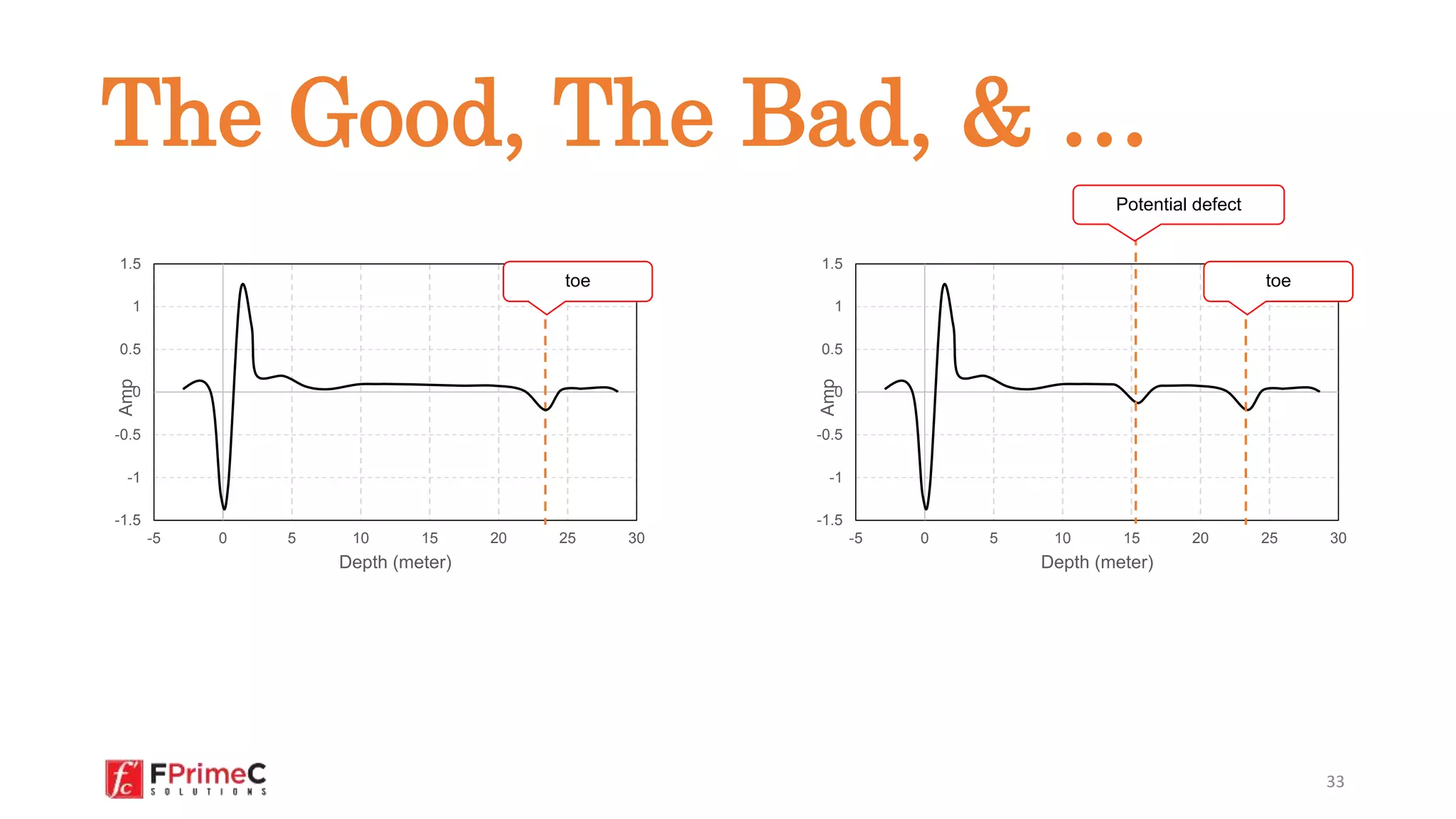

The document reviews low strain impact tests for evaluating pile integrity in deep foundations, highlighting the methods, tools, and practical considerations required for effective testing. It details the theory behind the low strain impact integrity test and outlines the advantages and disadvantages of this testing method. Key aspects include timing, surface preparation, and data analysis techniques necessary for accurate results.