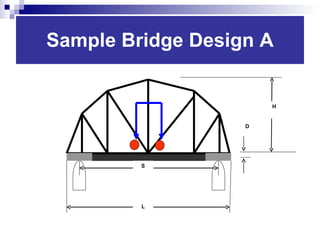

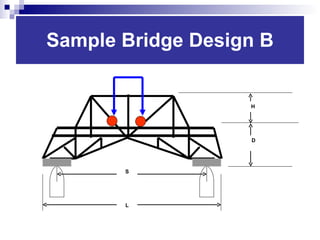

The document outlines the technical guidelines for a truss bridge competition held at DLSU-CES for the academic year 2009-2010, specifying various design requirements such as dimensions, weight limits, and material restrictions. Bridges must adhere to strict specifications, including using only popsicle sticks and all-purpose glue, and must have a smooth deck for a toy vehicle. A universal testing machine will evaluate the bridges based on strength and displacement, with awards given for creativity, design principles, and practicality.