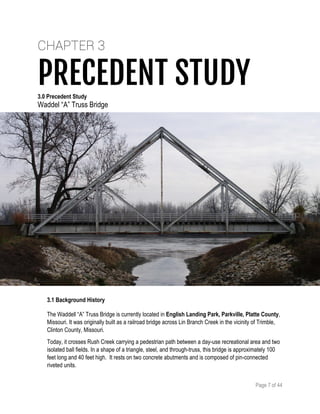

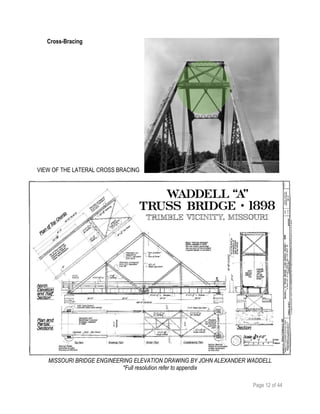

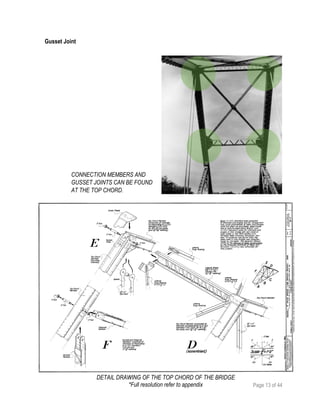

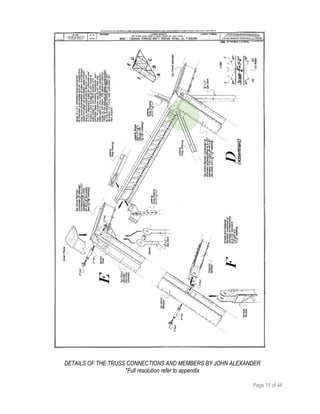

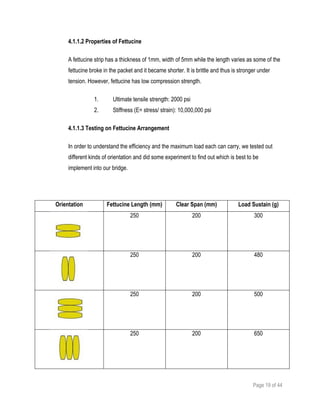

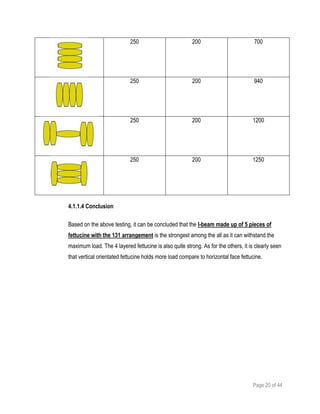

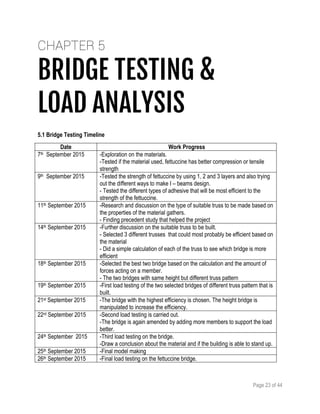

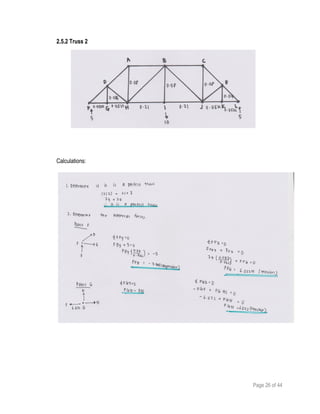

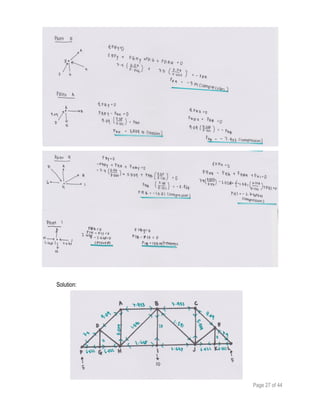

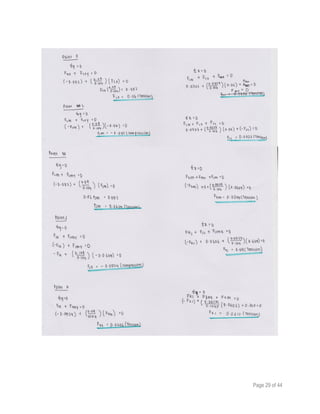

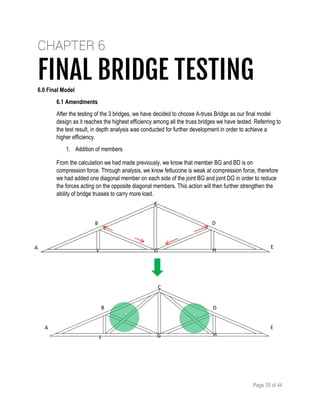

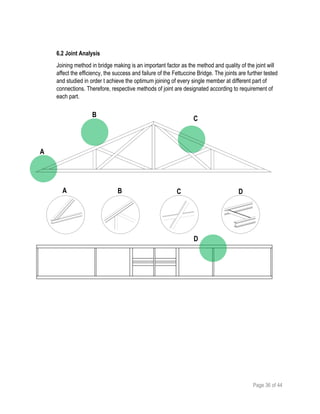

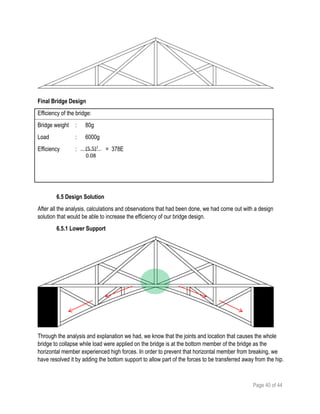

This document describes the process of designing and testing a fettuccine truss bridge. It begins with an introduction and methodology section outlining the goals and steps of the project. Materials testing is conducted to select the strongest type of fettuccine and adhesive. Multiple bridge designs are constructed and load tested, with improvements made based on results. A precedent truss bridge is studied for inspiration. The final optimized bridge design is load tested and calculations are performed to determine efficiency.