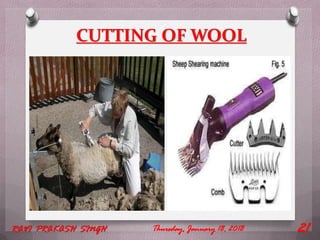

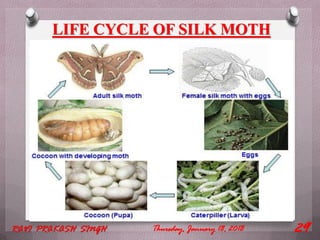

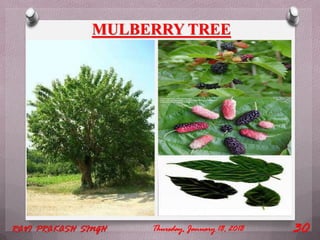

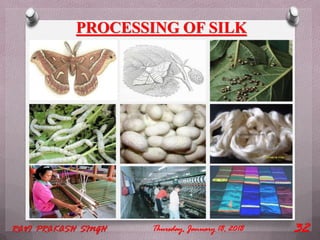

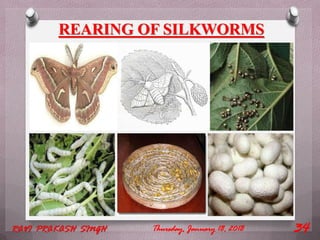

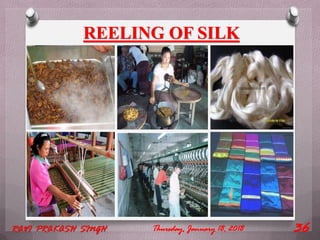

This document explains the importance of clothes and the types of fibers used to make them, which include natural fibers (like cotton, jute, silk, and wool) and man-made fibers (such as nylon and acrylic). It describes the processes involved in obtaining, processing, and using various natural fibers, detailing the life cycles of silkworms and sheep, as well as the methods for turning raw materials into textiles. Additionally, it covers the cultivation and processing of cotton and jute, highlighting their significance in the textile industry.