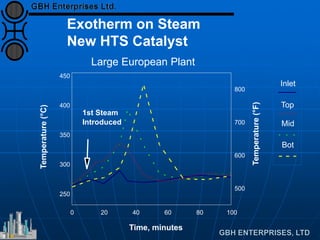

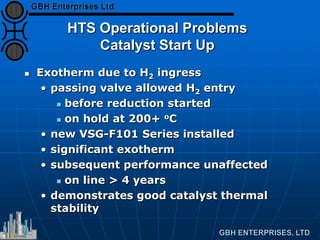

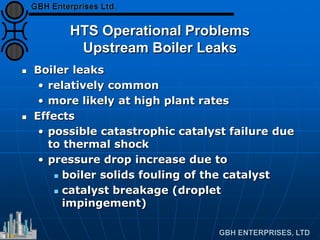

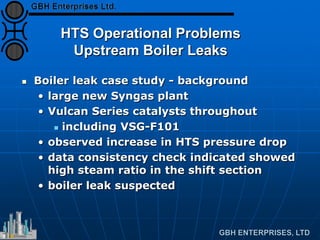

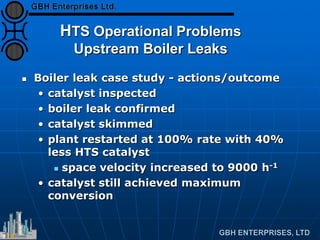

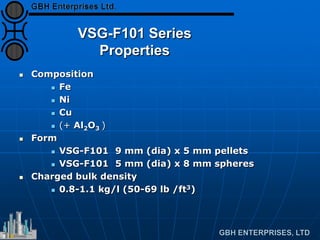

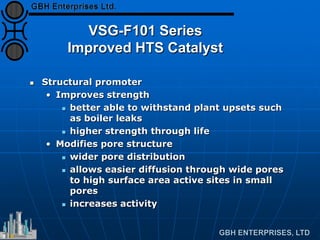

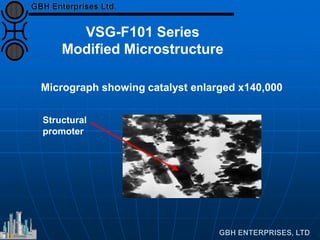

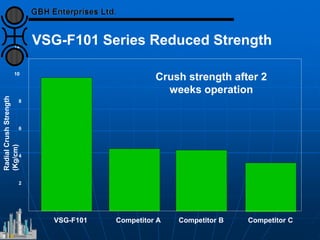

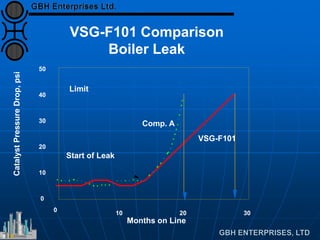

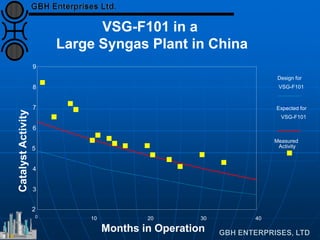

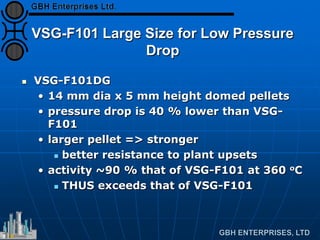

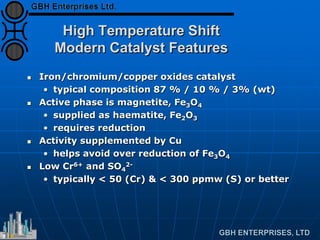

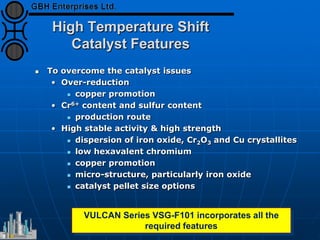

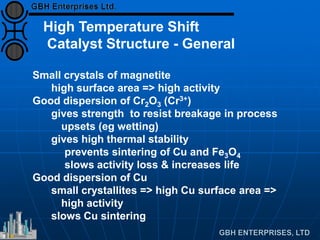

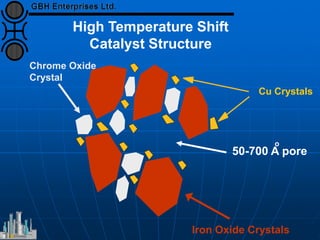

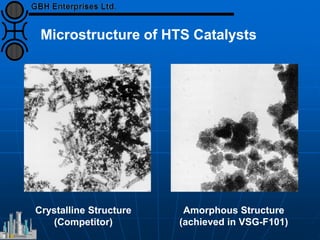

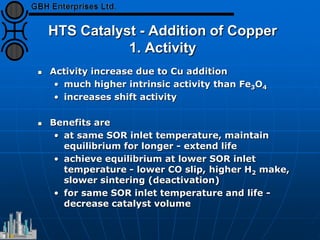

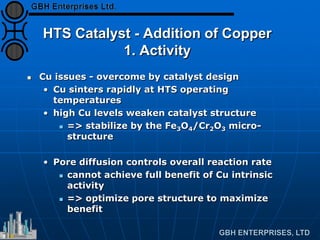

The document discusses improvements in high temperature shift catalysts. It describes the characteristics and operational issues of traditional HTS catalysts and how the new VULCAN Series VSG-F101 catalyst has addressed these issues through modifications to its microstructure and composition. The VSG-F101 has shown improved activity, strength, and resistance to thermal and mechanical stresses during plant upsets compared to previous catalysts.

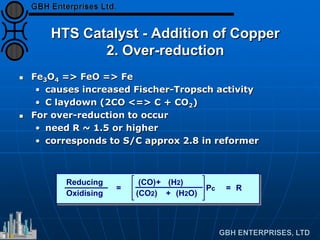

![HTS Catalyst - Addition of Copper

2. Over-reduction

CO2/CO phase equilibrium

Cu increases activity

• rapidly increases p[CO2]/decreases p[CO]

300 350 400 450 500 550

0.5

0.7

0.9

1.1

1.3

1.5

1.7

1.9

Temperature (oC)

P[CO2]/P[CO]

Fe

Fe3O4](https://image.slidesharecdn.com/htshightemperatureshift-comprehensievoverview-130729110953-phpapp02/85/HTS-High-Temperature-Shift-Catalyst-VSG-F101-Comprehensiev-Overview-19-320.jpg)

![HTS Catalyst - Addition of Copper

2. Over-reduction

H2O/H2 phase equilibrium

• rarely close to boundary

• Cu tends towards lower temperature

operation

300 350 400 450 500 550

0.1

0.2

0.3

0.5

0.7

1

Temperature (oC)

P[H2O]/P[H2]

Fe

Fe3O4

FeO](https://image.slidesharecdn.com/htshightemperatureshift-comprehensievoverview-130729110953-phpapp02/85/HTS-High-Temperature-Shift-Catalyst-VSG-F101-Comprehensiev-Overview-20-320.jpg)