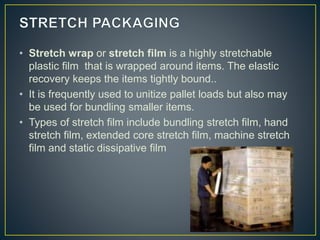

Shrink wrapping and stretch wrapping are two common packaging methods that use plastic film. Shrink wrapping involves wrapping an item and then applying heat to shrink the film tightly around the item. The process has four stages: wrapping, sealing, shrinking with hot air, and cooling. Stretch wrapping uses elastic plastic film that is stretched to wrap around items palletized on a pallet. When stretched, the film's elastic recovery keeps the items tightly bound. Stretch wrapping provides benefits like load stabilization, efficient handling and storage, and some protection from dust, moisture, and tampering. It also saves on energy compared to shrink wrapping.