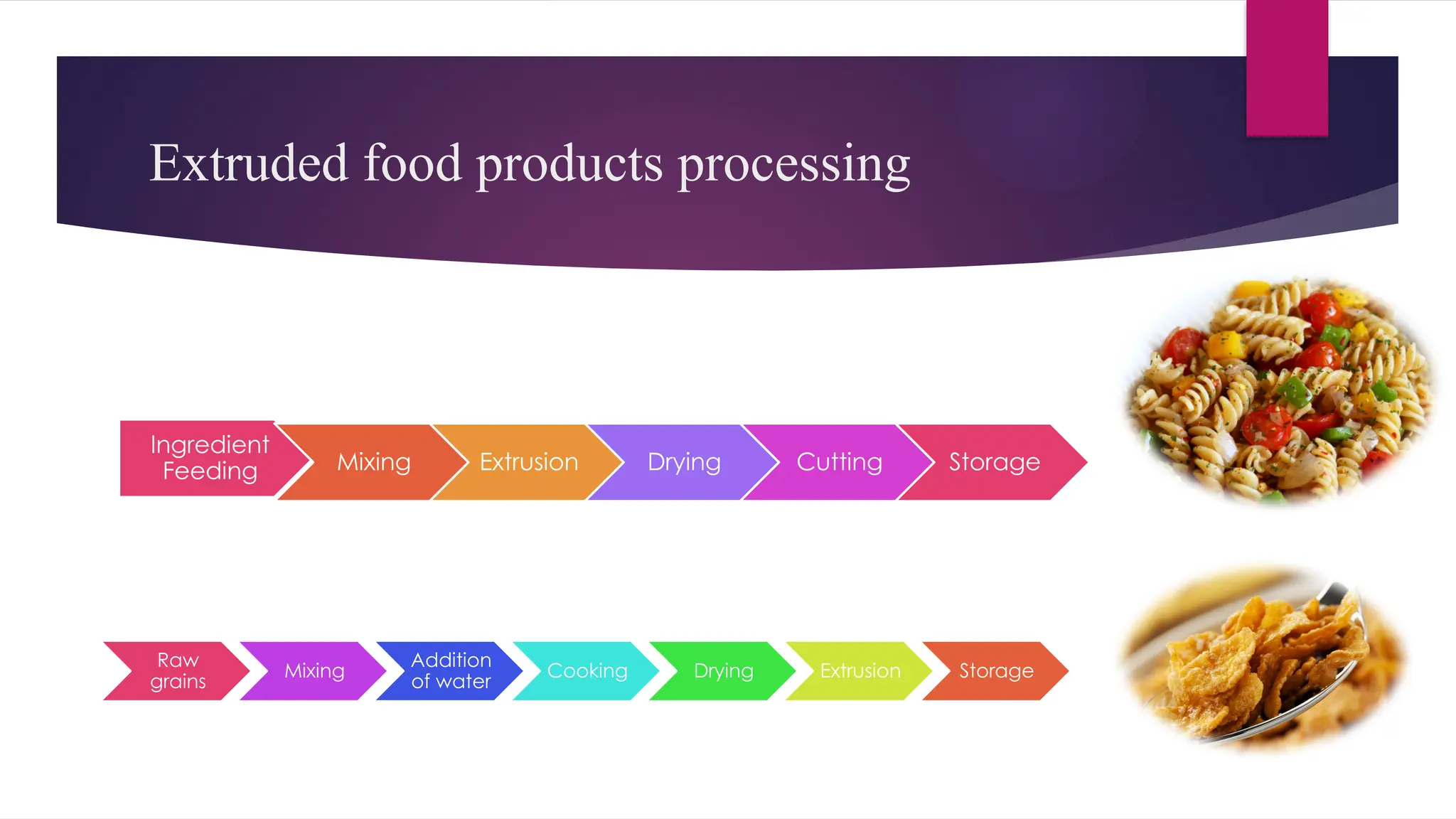

Extrusion technology, developed in the 1870s and advanced significantly since the 1950s, involves the processing of moistened food materials to create various products through a continuous combination of mixing, shearing, and heating. It produces versatile food items with favorable nutritional qualities while enabling the development of new products like 3D printed food. Despite its advantages, extrusion can lead to nutrient loss and product quality issues such as color fading.