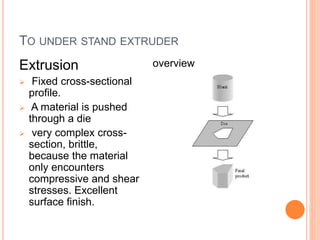

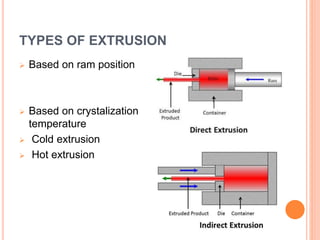

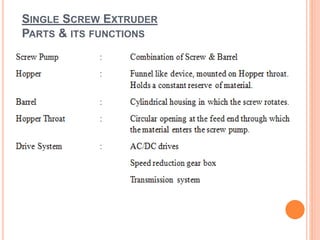

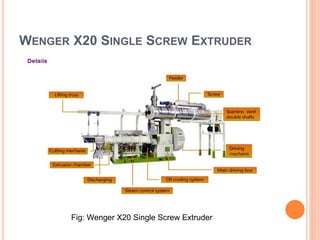

The document provides an overview of extruders, which are devices that transport molten materials into molds using screws to generate melt energy. It details the components and operation of a single screw extruder, as well as parameters like capacity and efficiency, and highlights the historical evolution and benefits of the technology in producing high-quality food products. Key advantages of using extruders include improved uniformity in flavoring and non-contamination of ingredients.