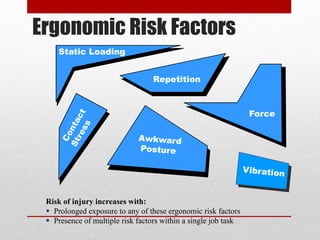

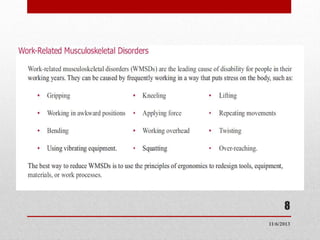

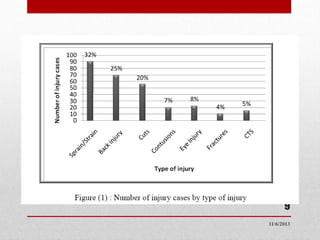

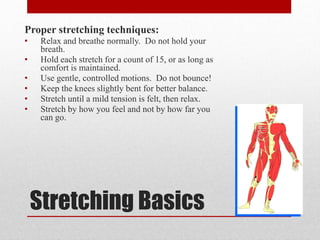

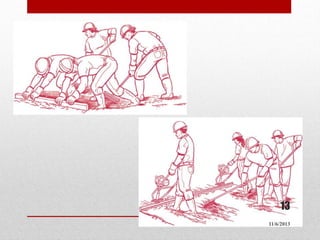

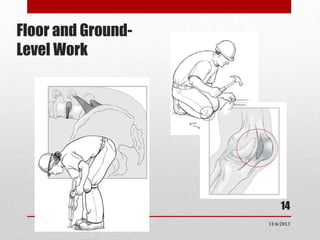

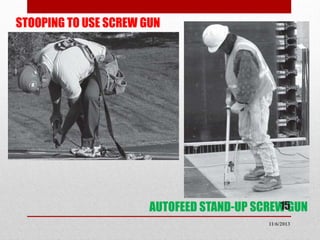

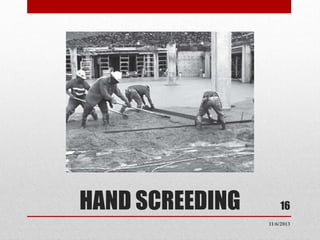

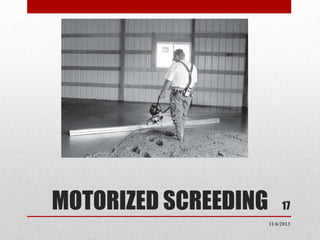

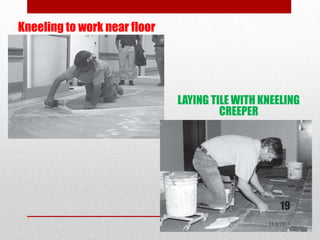

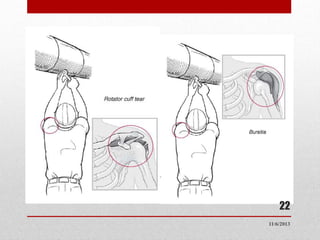

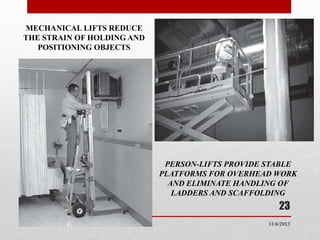

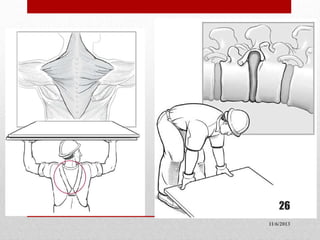

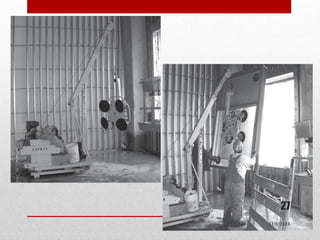

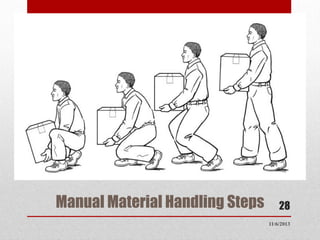

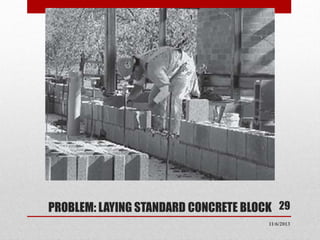

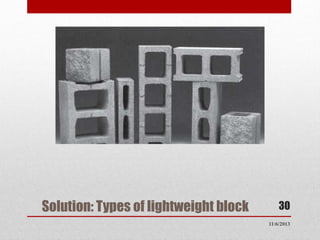

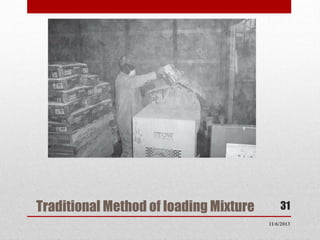

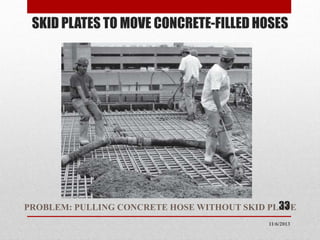

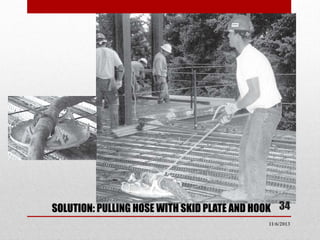

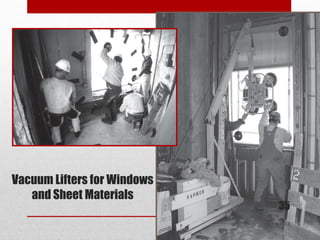

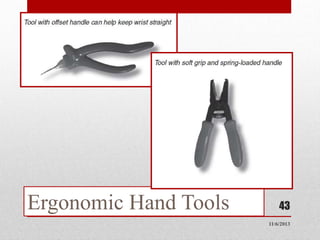

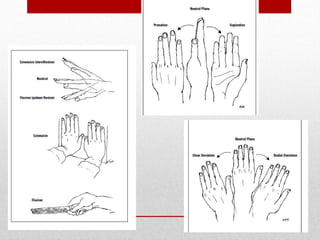

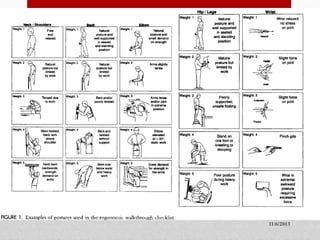

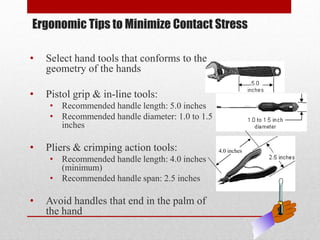

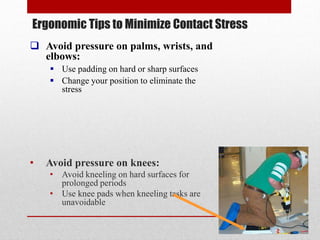

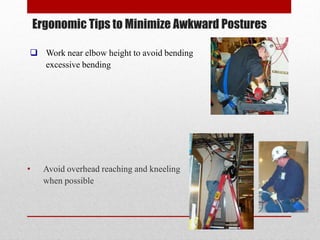

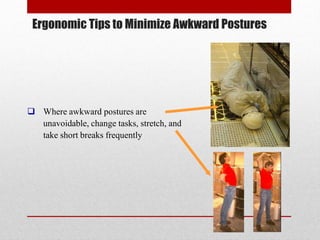

The document discusses ergonomics in construction and provides simple solutions to common ergonomic issues. It defines ergonomics as fitting the job to the employee rather than forcing the employee to fit the job. It then describes common ergonomic injuries in construction like cumulative trauma disorders and strains/sprains. The rest of the document provides examples of ergonomic issues in construction work and potential solutions through changes in tools, equipment, work processes and postures. It emphasizes the importance of stretching, taking breaks, job rotation and other measures to minimize ergonomic risk factors like force, repetition, awkward postures and static loading.