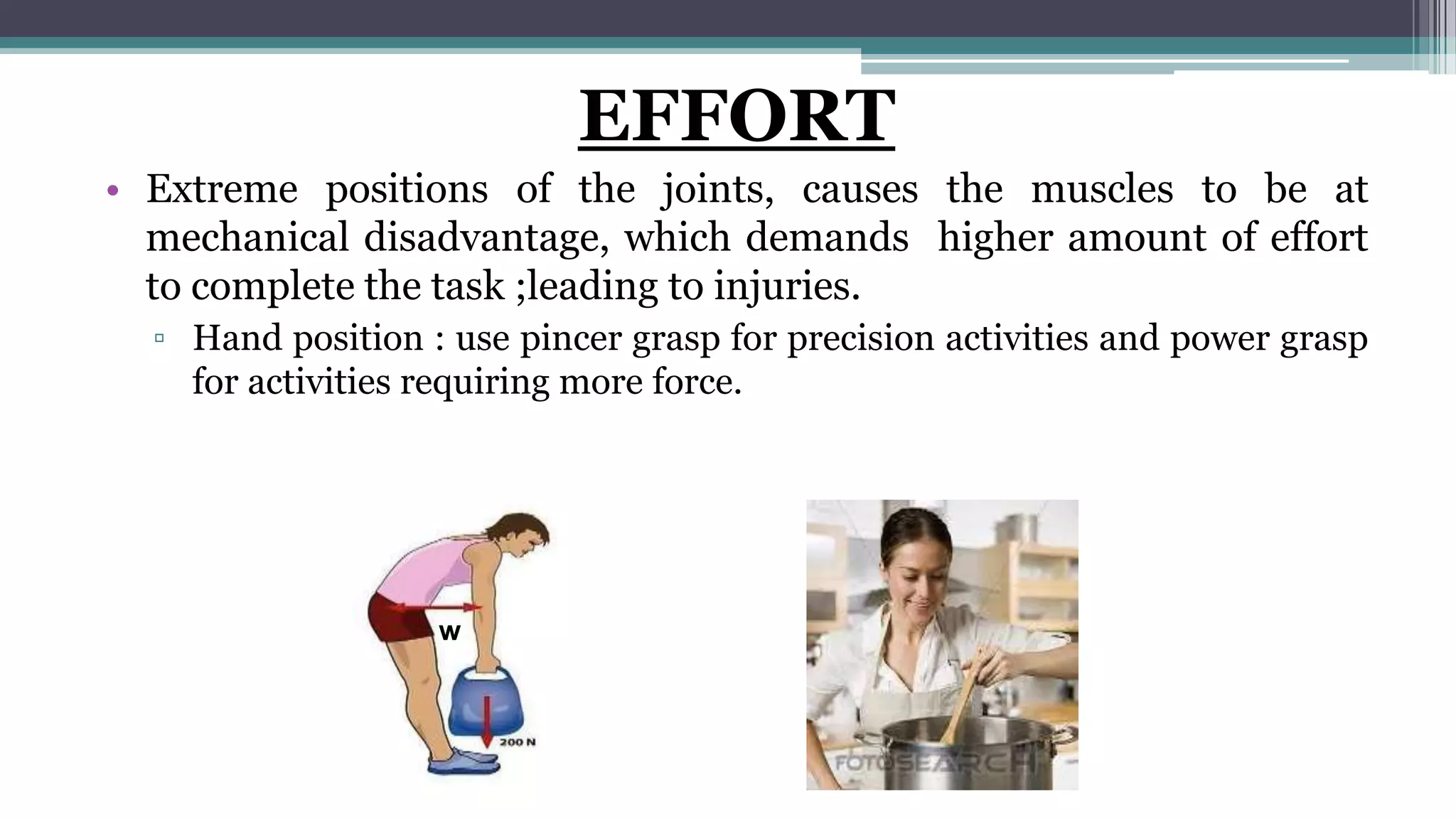

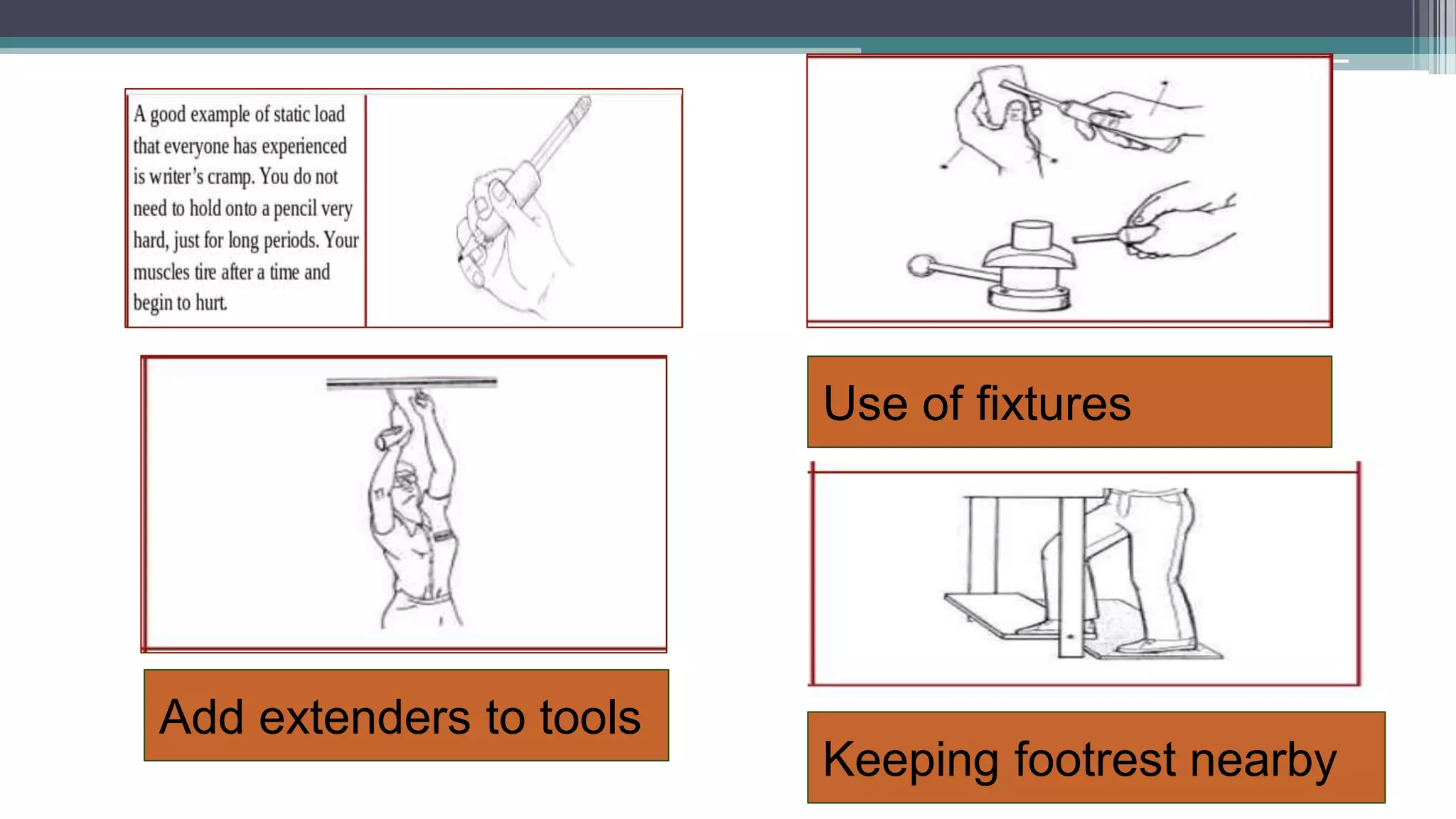

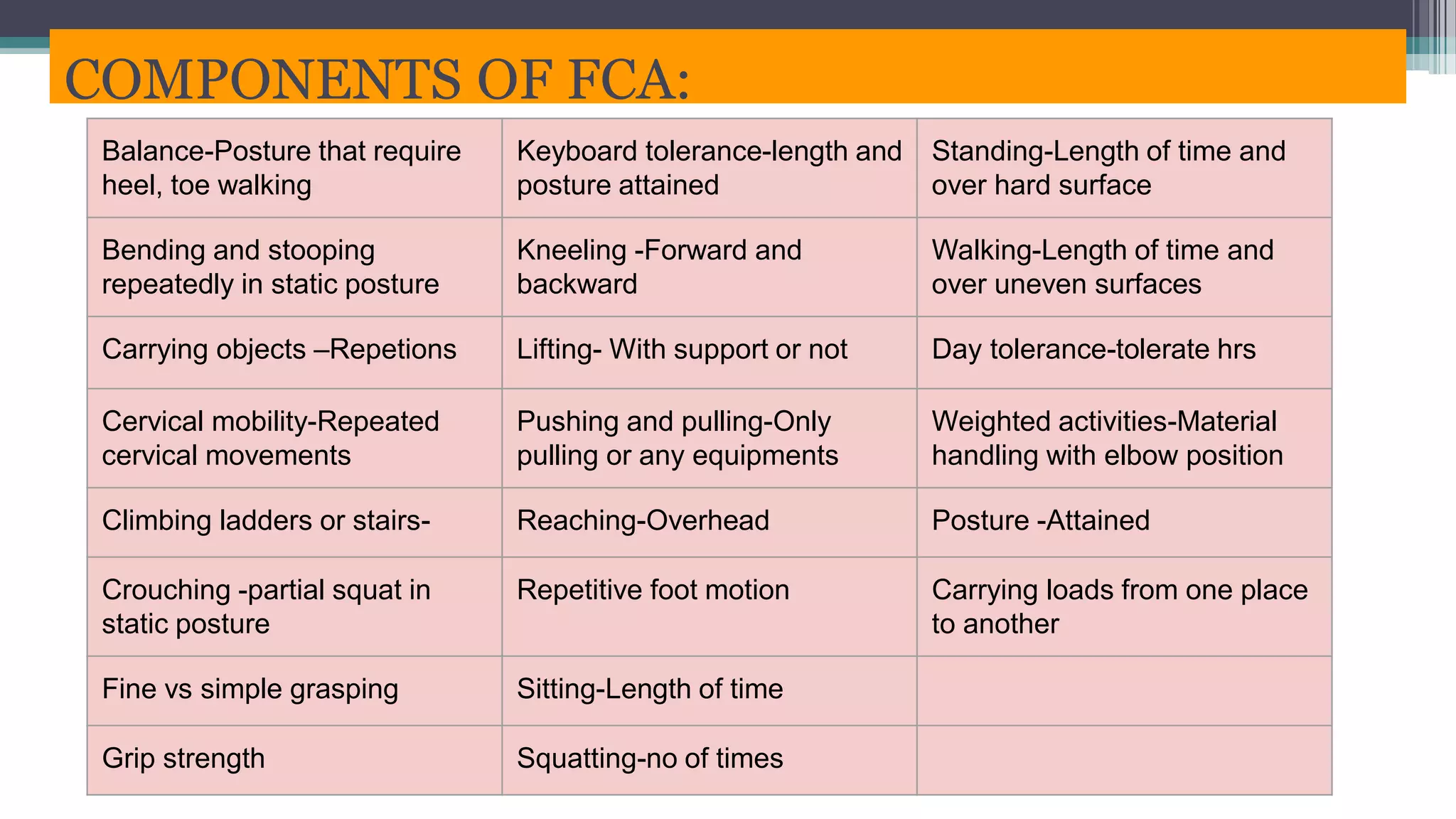

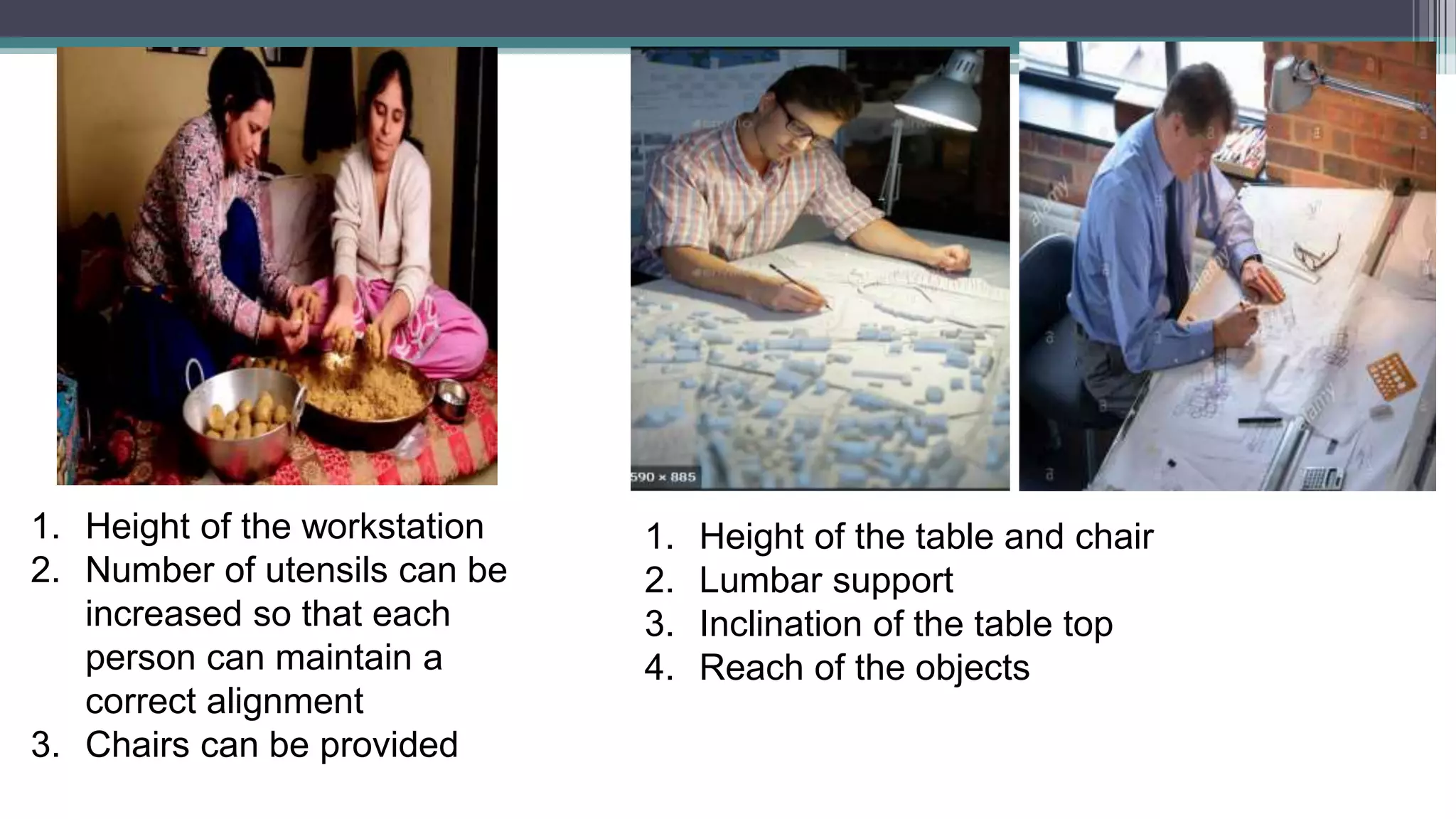

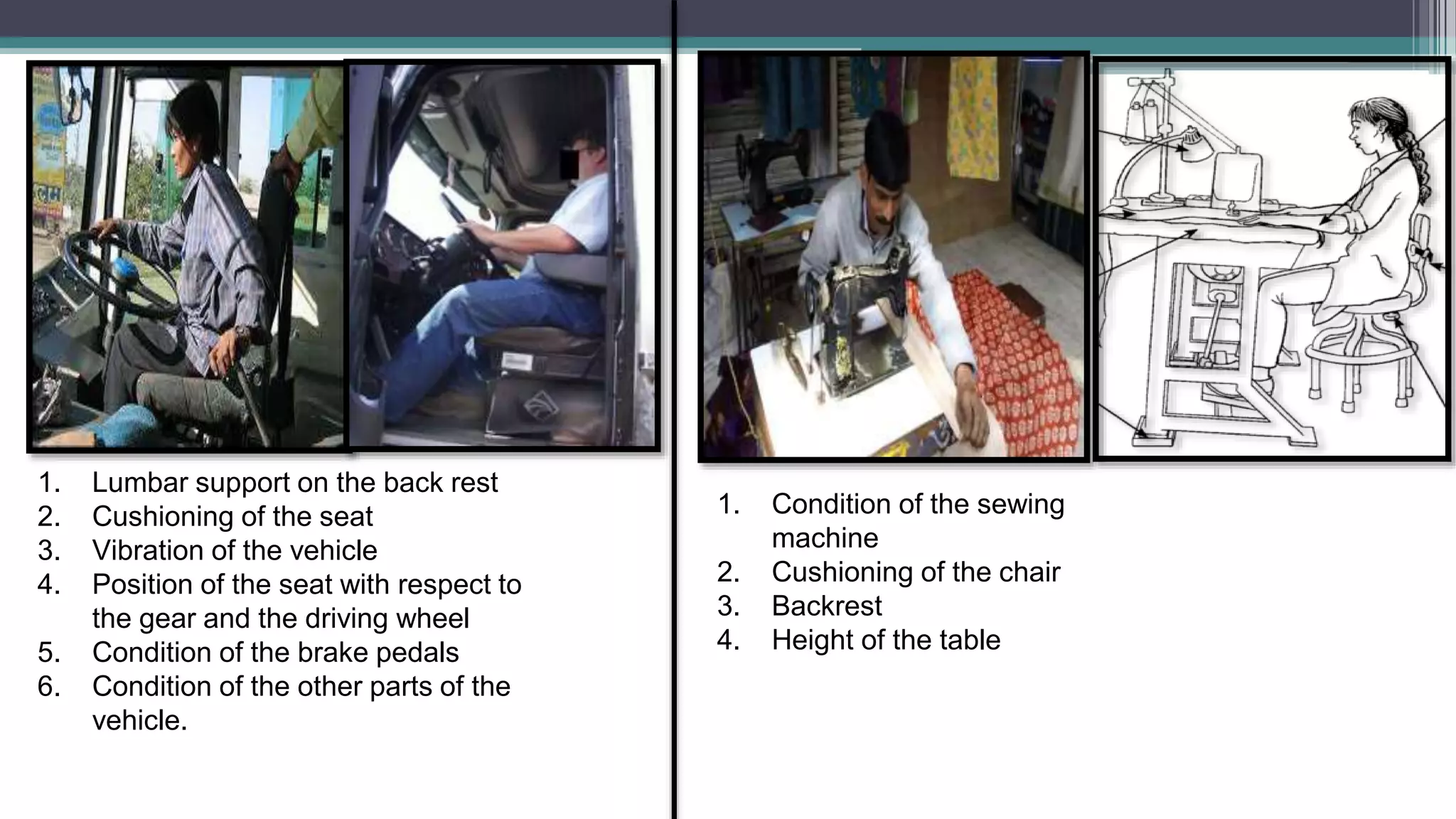

The document focuses on workplace ergonomics, highlighting its importance in preventing work-related injuries and enhancing safety and productivity. It discusses cumulative trauma disorders (CTDs) caused by repetitive stresses and outlines management strategies, including physiotherapy, workplace assessment, and engineering ergonomics. The document emphasizes the need for adapting jobs and work environments to optimize worker comfort and performance.