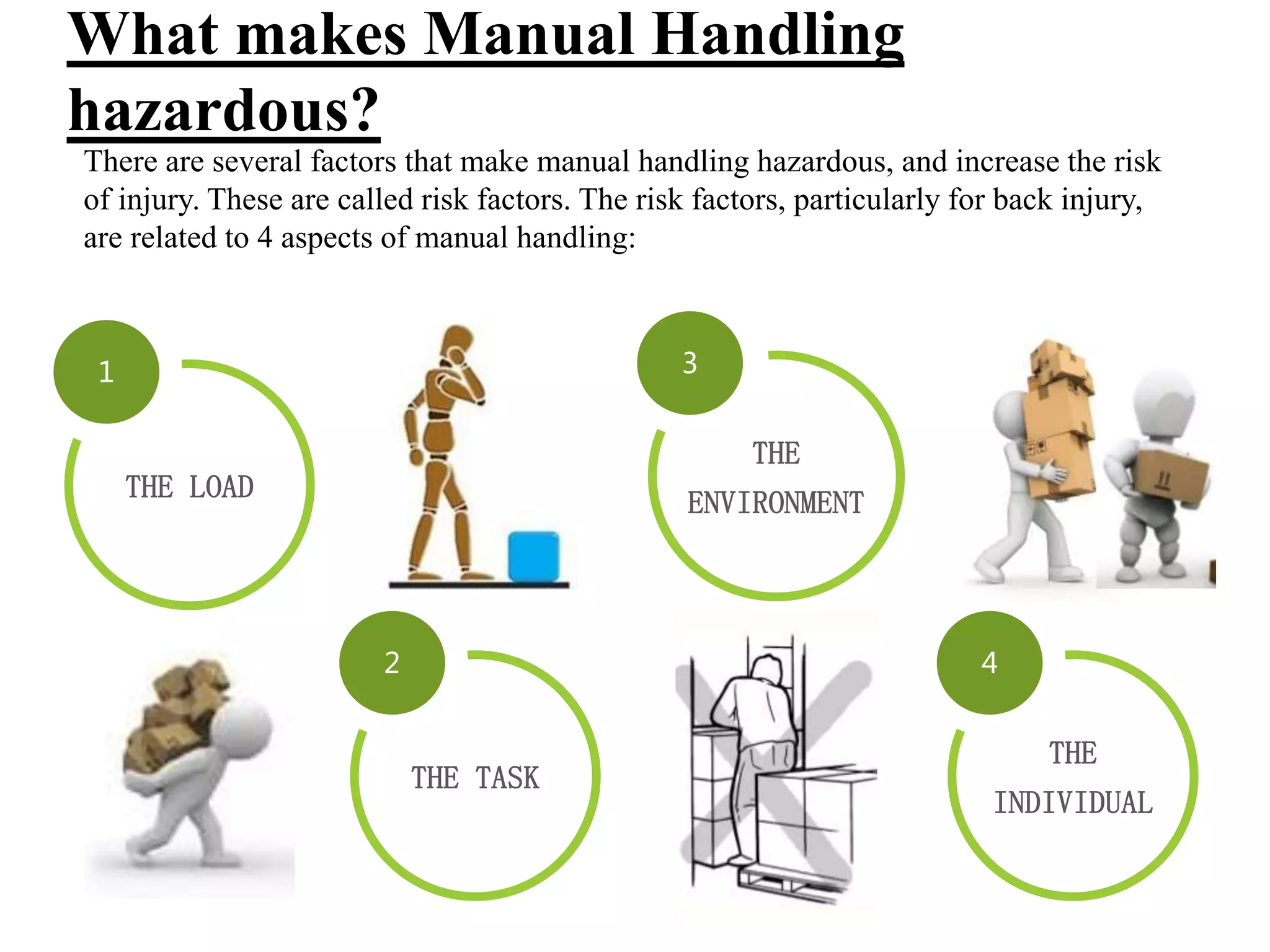

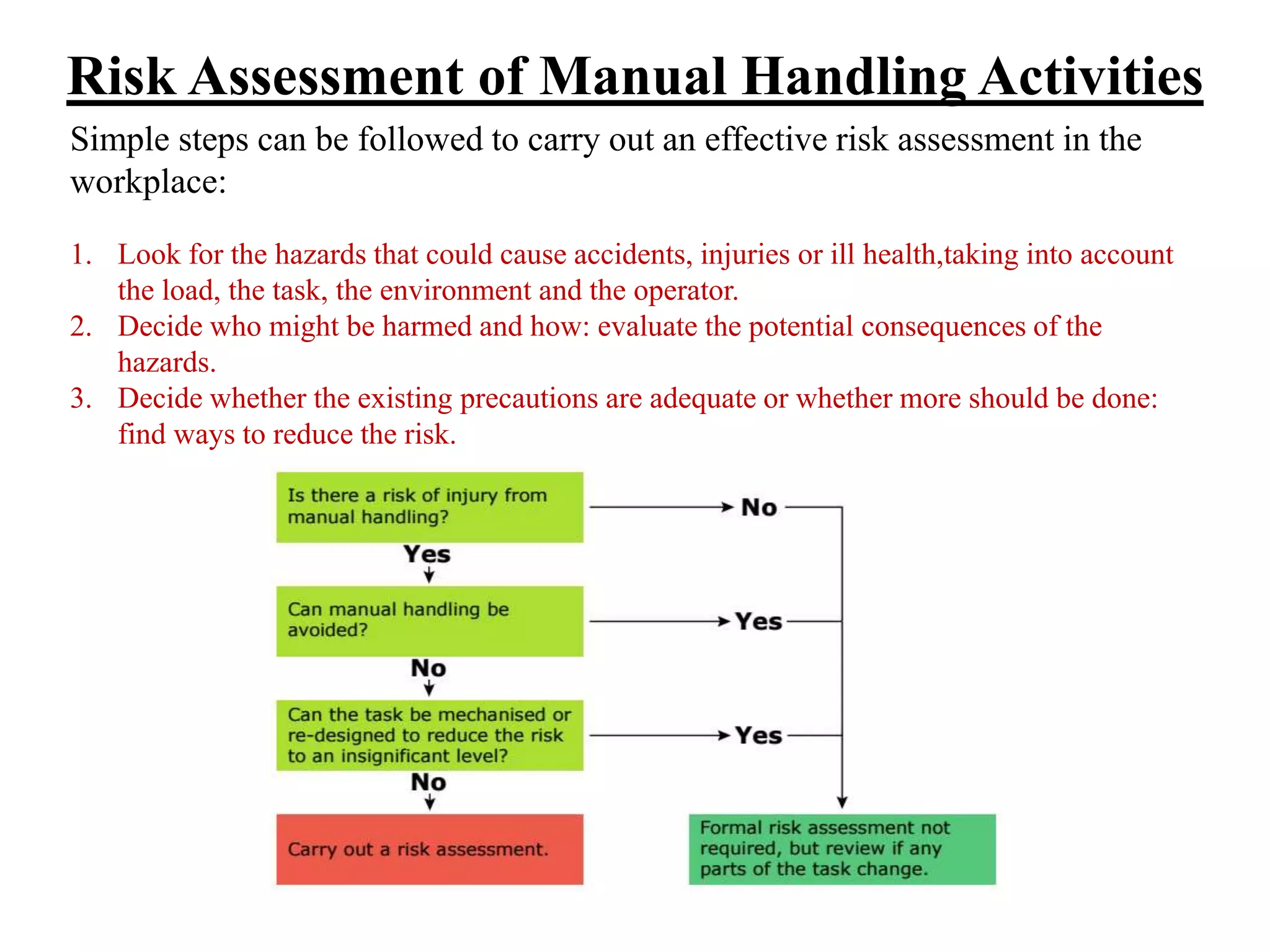

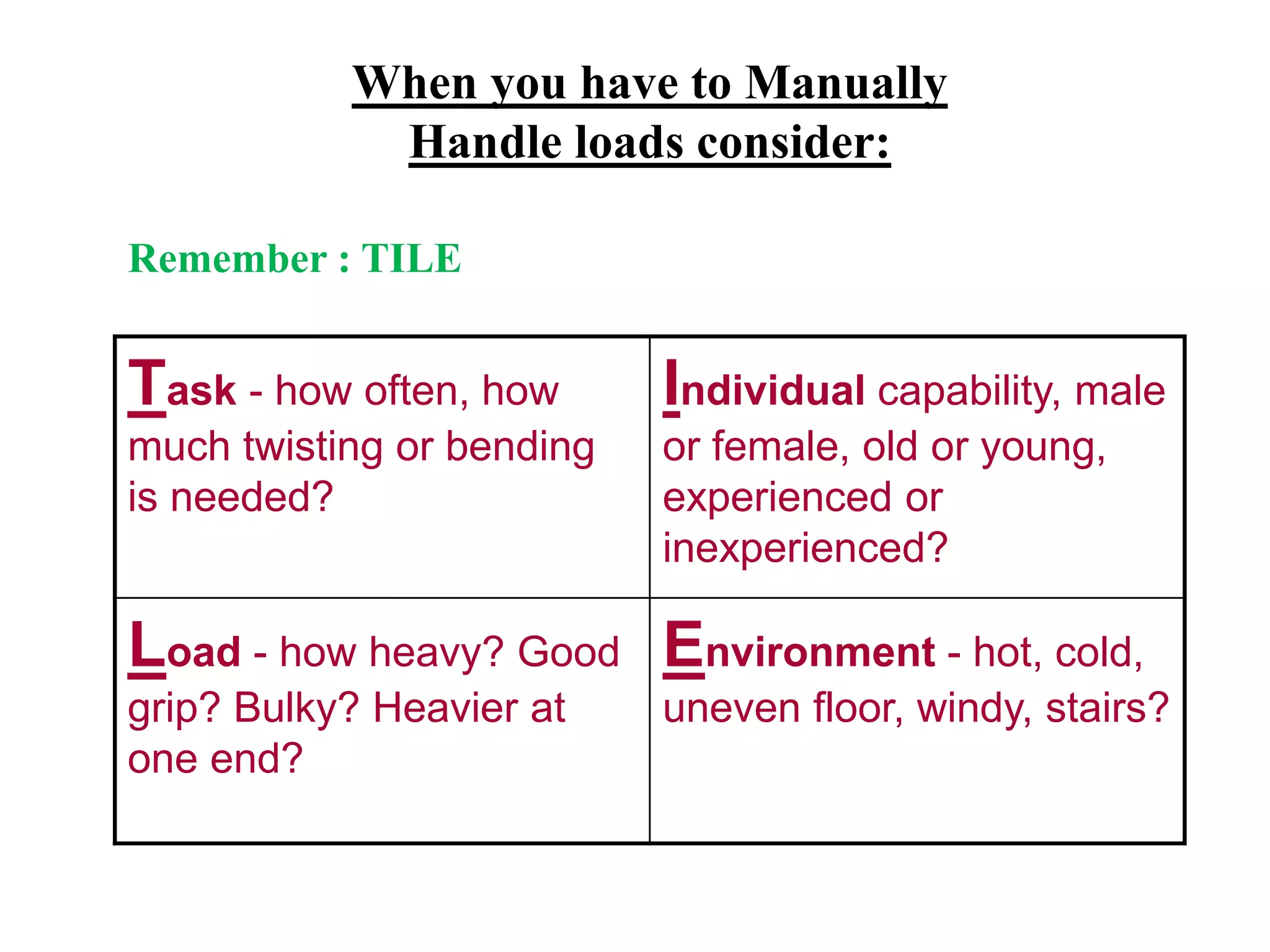

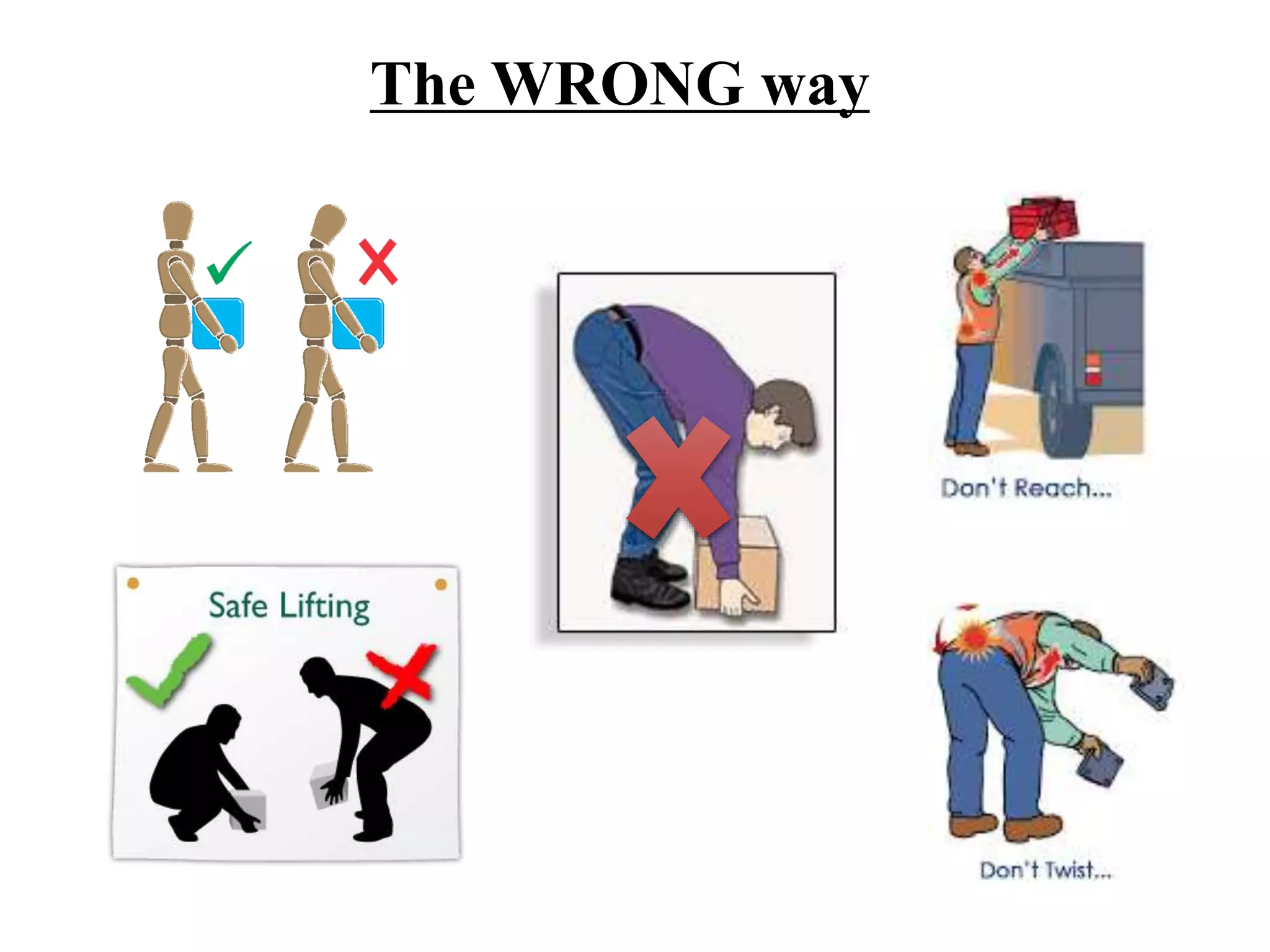

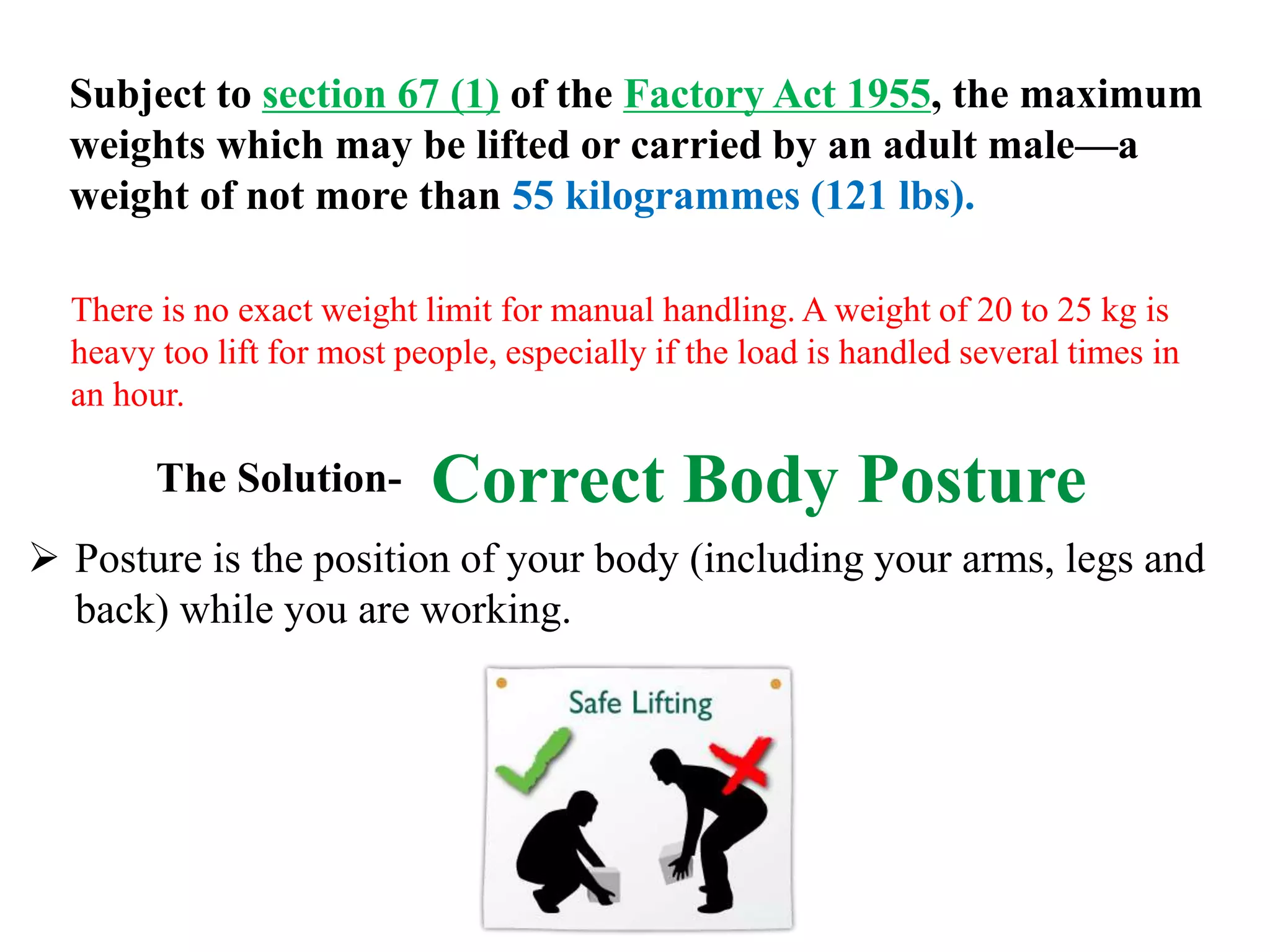

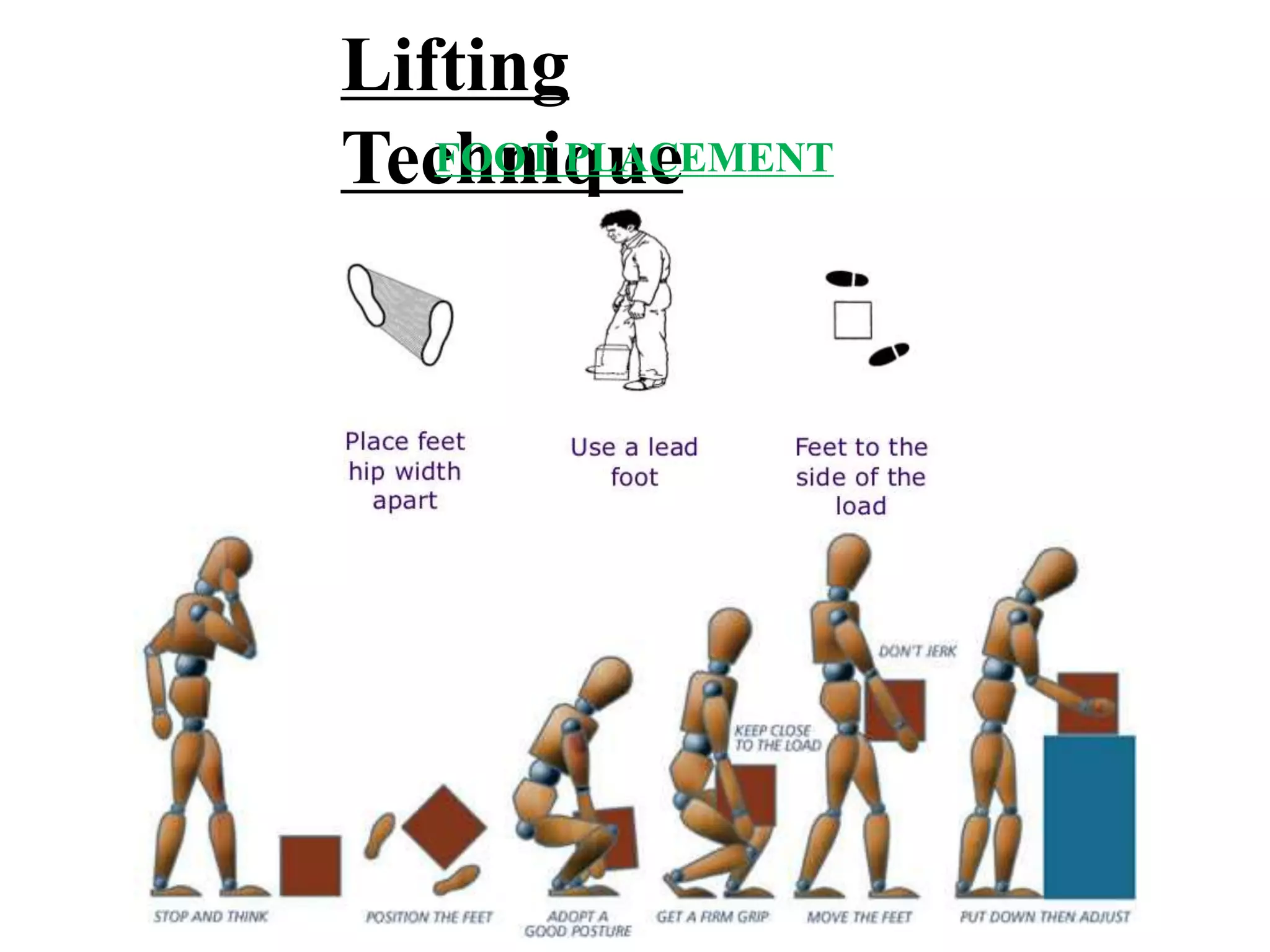

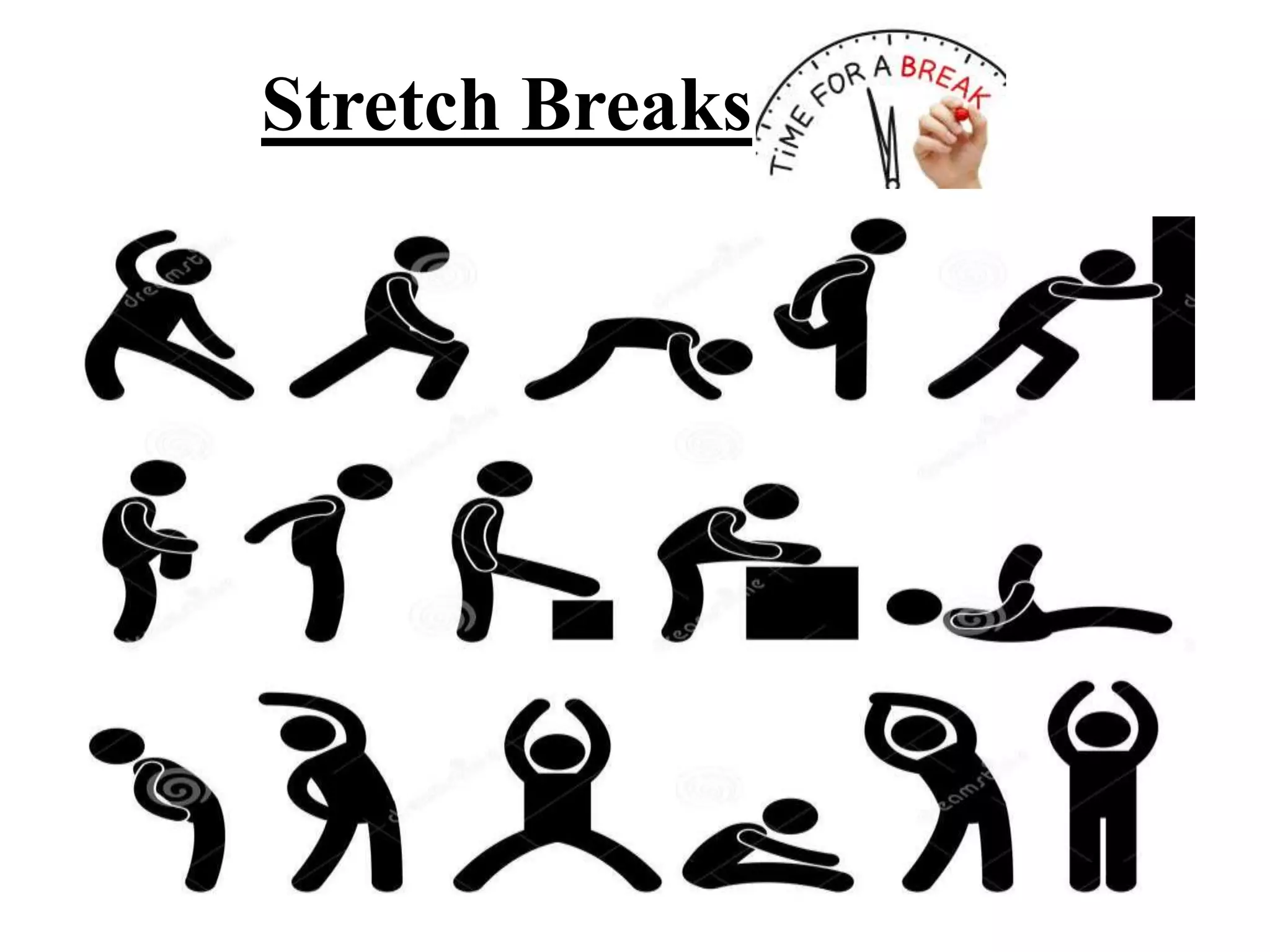

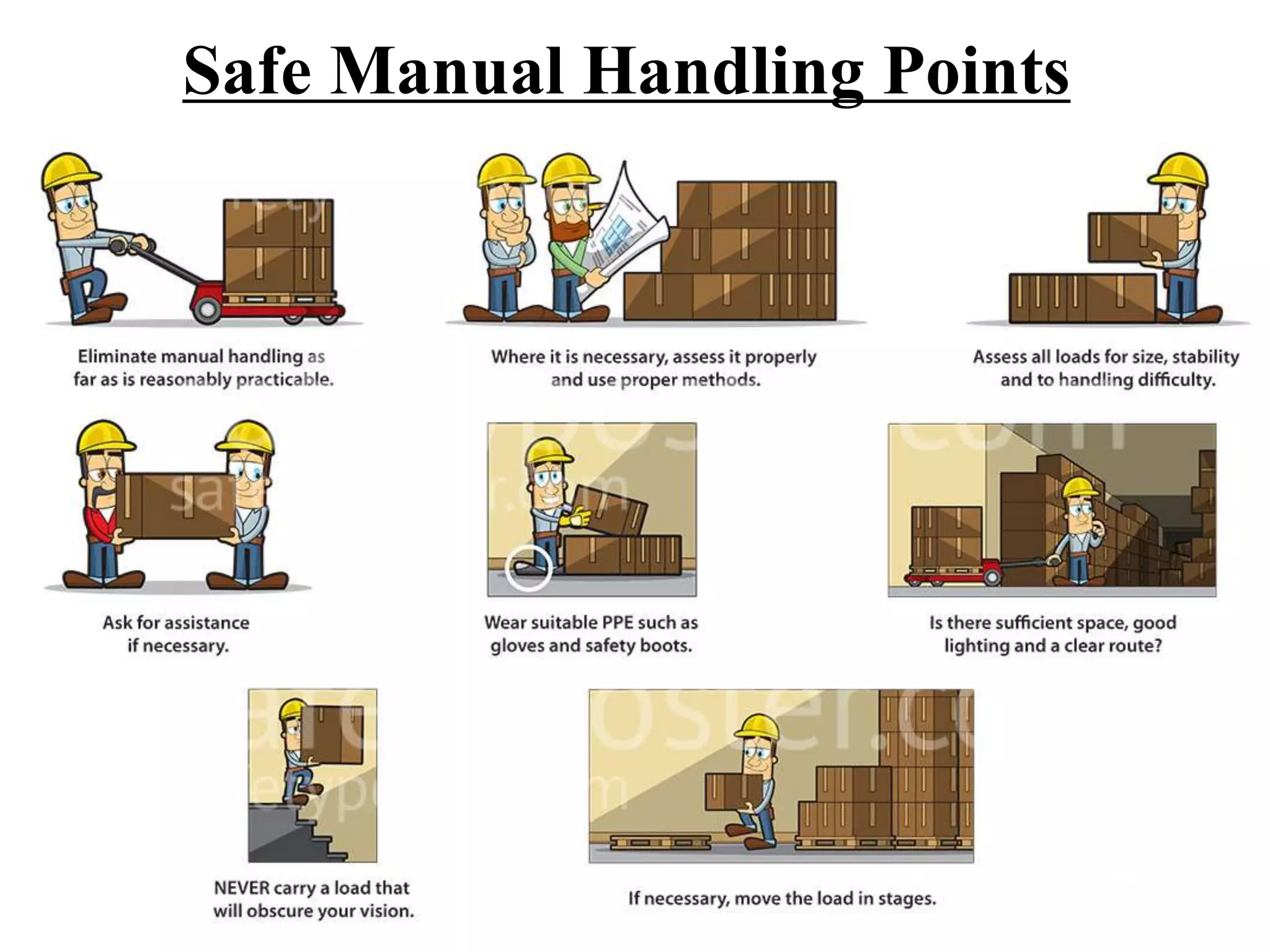

This document details the importance of proper manual handling techniques to prevent workplace injuries, particularly musculoskeletal disorders (MSDs). It outlines the factors that contribute to hazardous manual handling and provides risk assessment steps to mitigate these risks. Recommendations for safe practices include avoiding heavy lifting when possible, assessing individual capability, and maintaining proper posture.