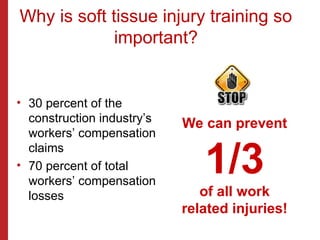

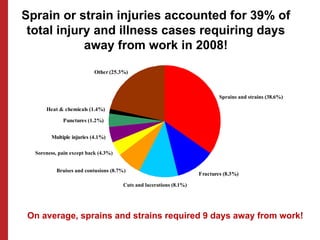

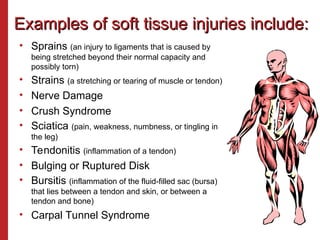

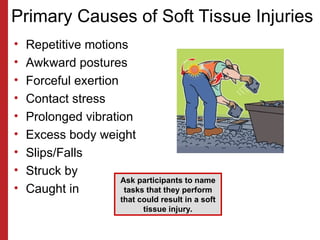

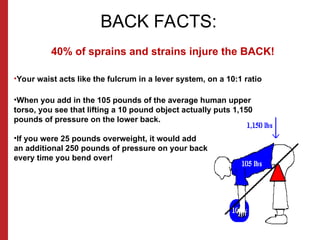

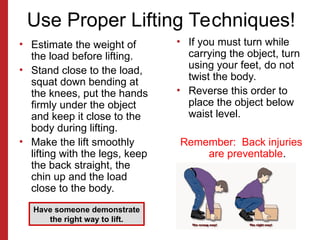

Soft tissue injuries, affecting muscles, tendons, and ligaments, are the most common injuries in the construction industry, accounting for a significant percentage of workers’ compensation claims. These injuries can often lead to long-term disability, and prevention strategies include awareness of body limitations, proper lifting techniques, and ergonomic practices. Training and proactive measures are essential to reduce the incidence of sprains and strains and to promote overall workplace safety.