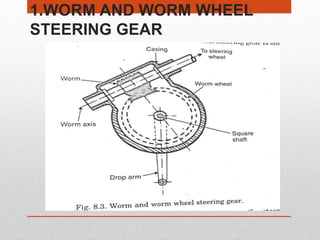

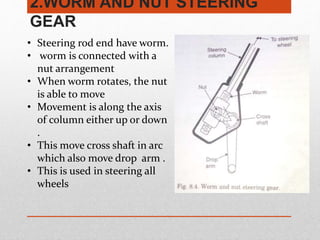

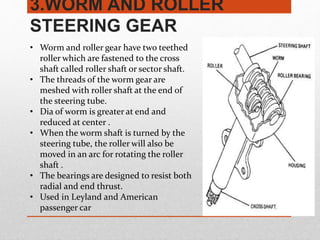

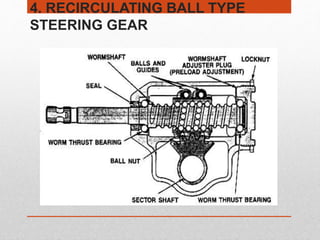

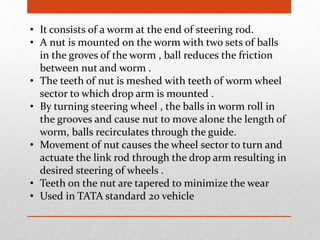

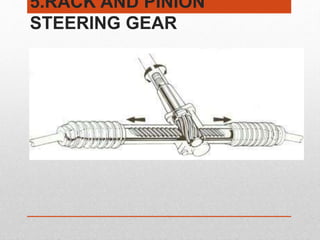

This document provides an overview of 5 common types of steering gearboxes: 1) worm and worm wheel, 2) worm and nut, 3) worm and roller, 4) recirculating ball type, and 5) rack and pinion. Each type is described in 1-2 paragraphs, outlining the key components and how rotation of the steering wheel is converted to linear motion to steer the wheels. The worm and worm wheel type is commonly used in tractors, while rack and pinion is popular for small cars due to its compact size but limited gear ratio. Recirculating ball type and worm and roller systems are used in various passenger vehicles.