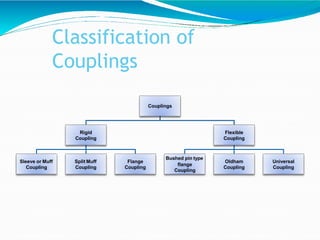

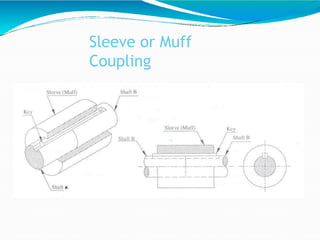

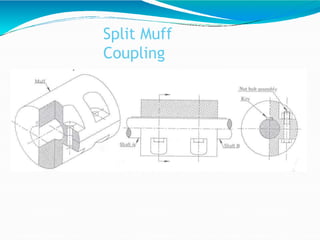

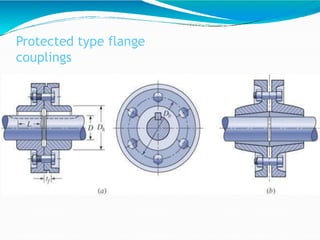

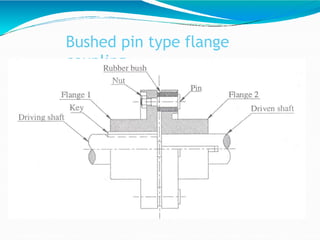

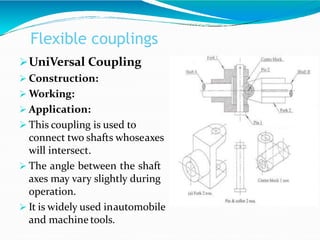

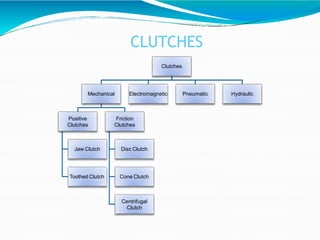

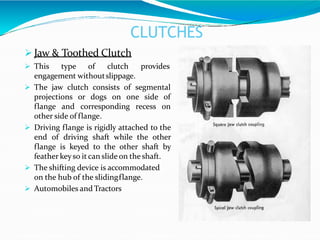

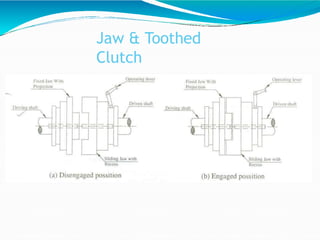

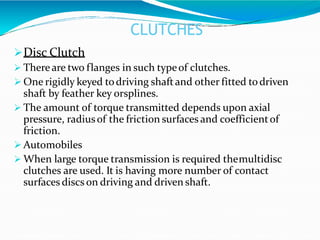

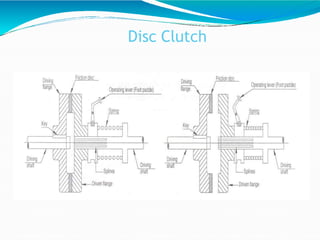

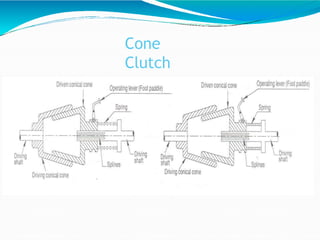

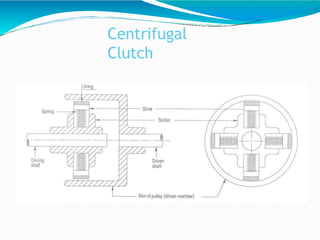

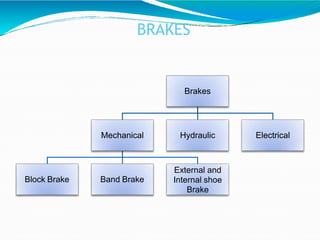

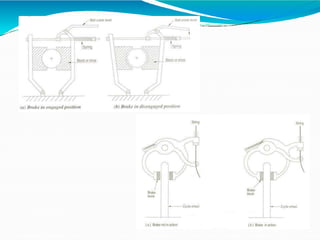

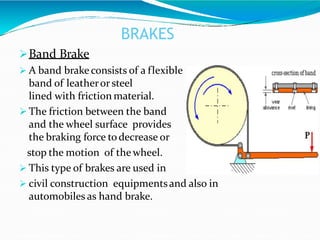

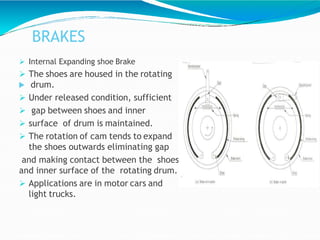

This document discusses various types of couplings, clutches, and brakes used for power transmission. It describes rigid couplings like sleeve couplings and flange couplings. Flexible couplings discussed include bushed pin flange couplings, Oldham couplings, and universal couplings. Clutches described are jaw, disc, cone, and centrifugal clutches. Finally, the document outlines different brake types including block, band, and internal expanding shoe brakes.