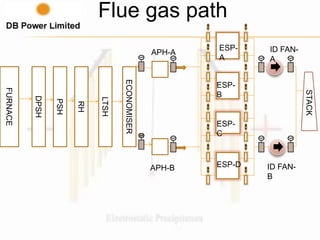

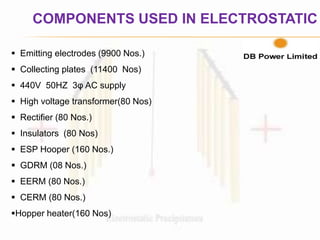

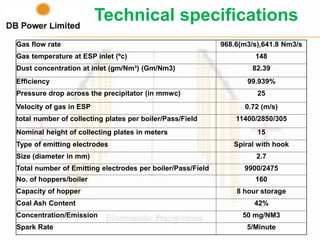

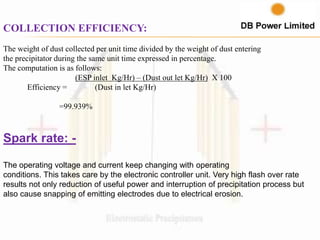

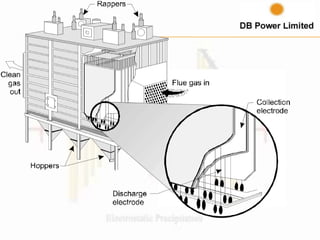

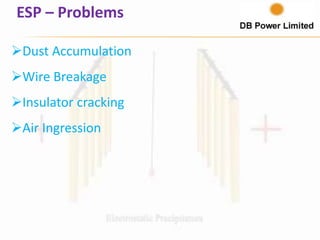

The document discusses electrostatic precipitators (ESPs) which remove dust particles from industrial emissions through electrostatic filtration.

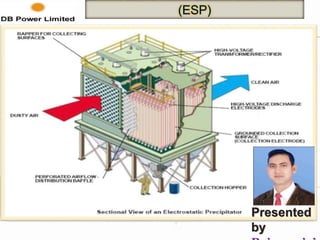

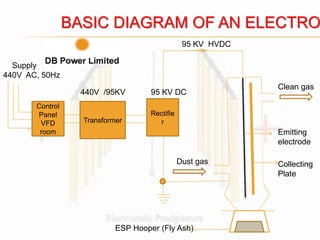

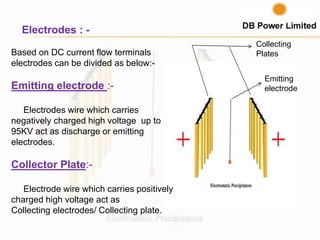

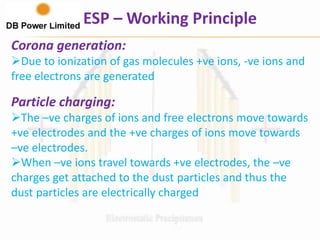

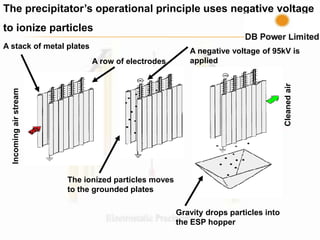

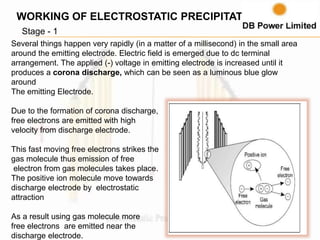

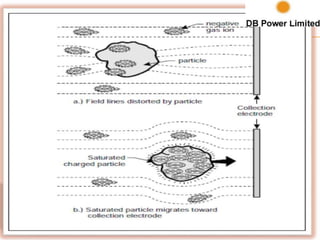

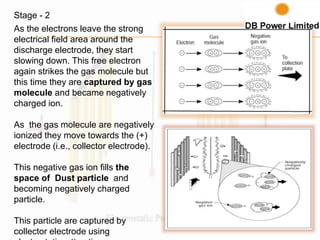

ESPs work by ionizing the dust particles in the flue gas stream and collecting them on oppositely charged plates. Negatively charged high voltage electrodes emit corona discharge which charges the dust particles positively. The particles are then attracted to and collected on grounded collecting plates.

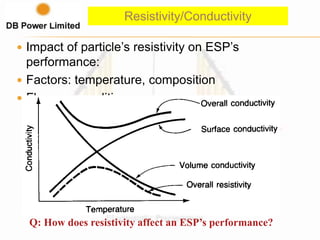

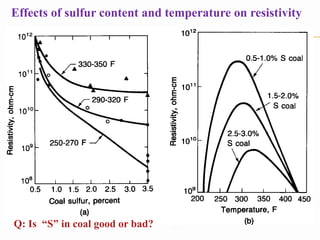

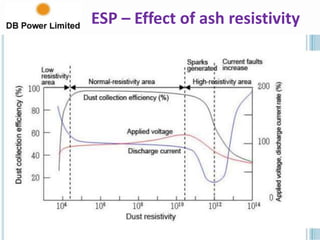

Key factors that impact ESP performance include gas temperature and composition, dust resistivity, specific collection area, and aspect ratio of the ESP unit. High resistivity dust like that containing sulfur is more difficult to collect efficiently. Temperature also affects dust resistivity and ESP operation.