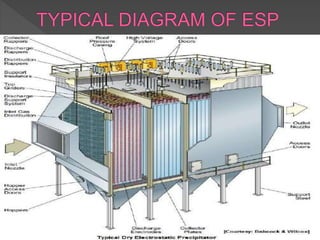

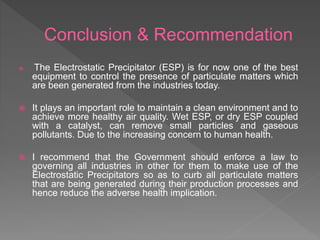

An electrostatic precipitator (ESP) is a vital pollution control device designed to remove impurities from gases, particularly in industrial settings. While it effectively manages large volumes of gas and has low operating costs, its high capital costs and space requirements limit its feasibility for small-scale industries. The document emphasizes the importance of regulatory enforcement for the use of ESPs to mitigate health risks associated with particulate matter emissions.