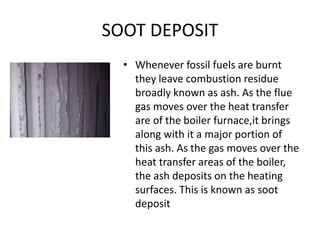

This document discusses soot blowers and the soot blowing process at the Sasan Ultra Mega Power Plant. It describes the types of soot deposits that form in boilers and the effects of deposition. It outlines the types of soot blowers used at Sasan UMPP, including wall blowers, long retractable soot blowers, and air heater blowers. The locations of the different soot blowers throughout the boiler are provided. Finally, the standard procedure for soot blowing the boilers is summarized in 6 steps.