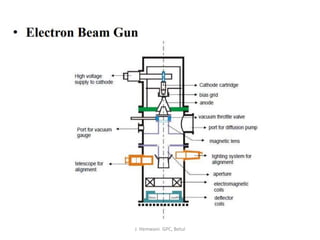

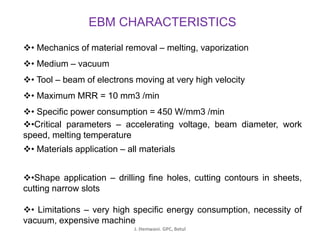

Electron beam machining (EBM) involves directing a high-velocity beam of electrons in a vacuum chamber to melt or vaporize material from a workpiece. The electron beam is generated in a gun and focused onto a small spot on the workpiece using magnetic coils. This localized heating allows for precise material removal with minimal heat effects. EBM can machine nearly any material and produces close tolerances, but requires expensive equipment and vacuum systems. Common applications include machining wire drawing dies and manufacturing semiconductor and optical components.