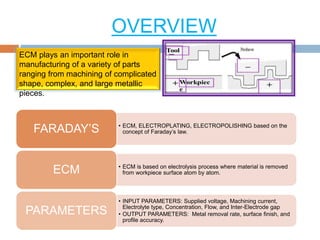

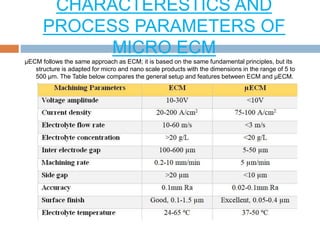

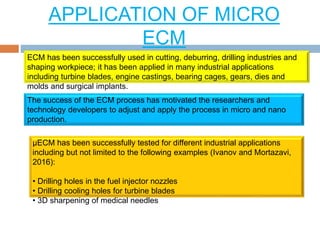

Micro electrochemical machining (Micro ECM) is a non-traditional machining process that uses electrolysis to remove material from a workpiece in micro-scale dimensions. It works by applying a voltage between a tool cathode and workpiece anode separated by an electrolyte, which causes the workpiece material to dissolve atom by atom according to Faraday's laws of electrolysis. Micro ECM has advantages over traditional machining for micro-scale applications and can machine complex micro-scale features with high precision and no thermal effects. Key parameters that affect the micro ECM process include inter-electrode gap, tool feed rate, electrolyte type and flow, and applied voltage.