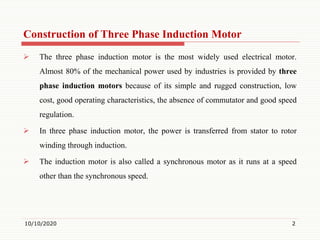

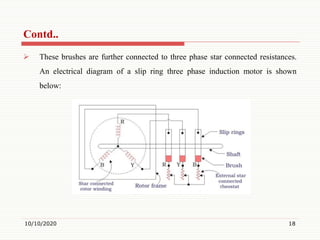

This document discusses the construction of three phase induction motors. It describes that induction motors have a stationary stator and a rotating rotor. The stator contains windings that produce a rotating magnetic field when powered by a three phase supply. There are two main types of rotors - squirrel cage and wound/slip ring. Squirrel cage rotors have aluminum or copper bars shorted by end rings, making their construction simple and robust. Wound rotors have windings and slip rings to allow adding external resistance for starting. The document provides details on the construction of stators, rotors, and operating principles of both types of three phase induction motors.