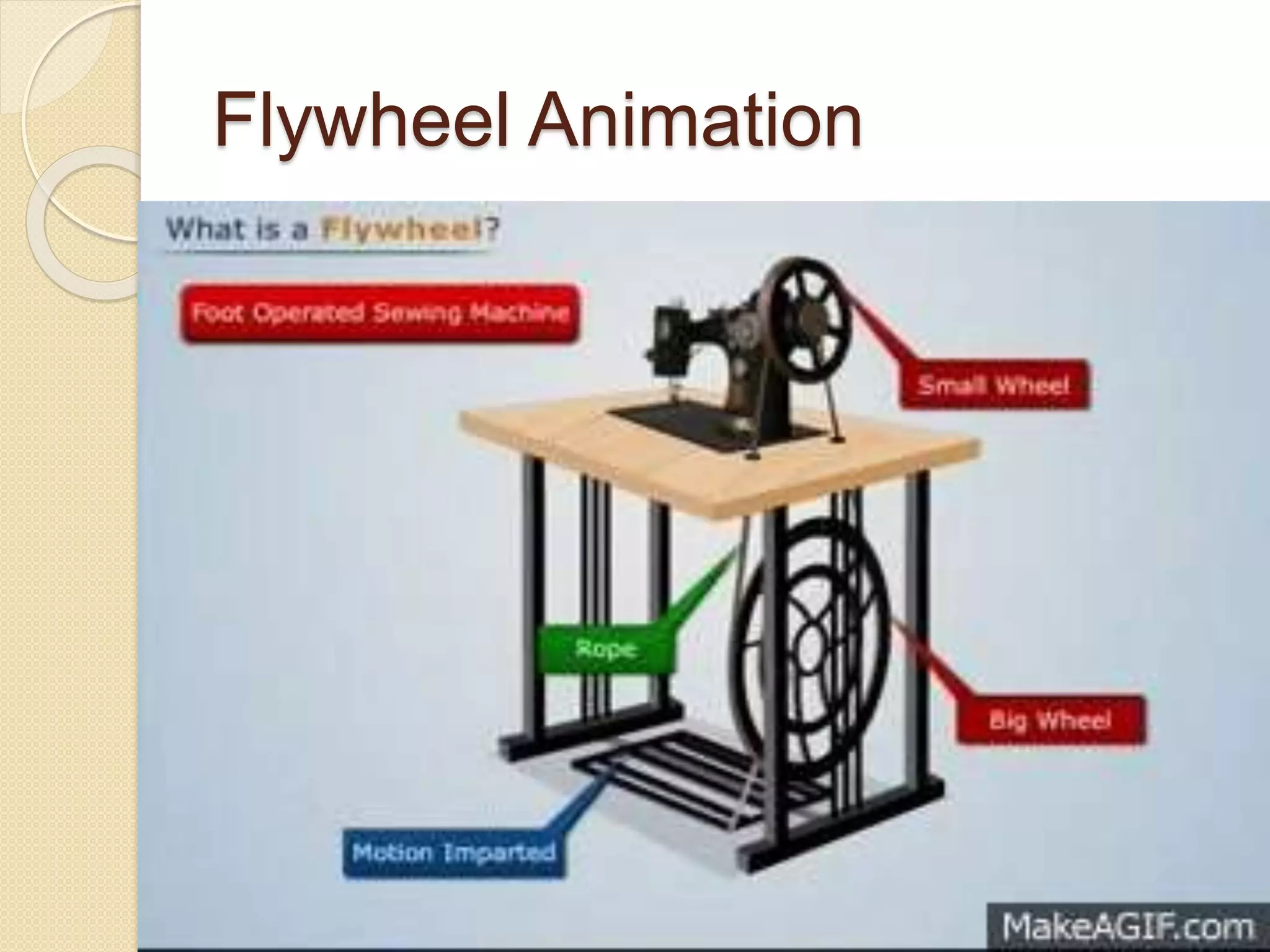

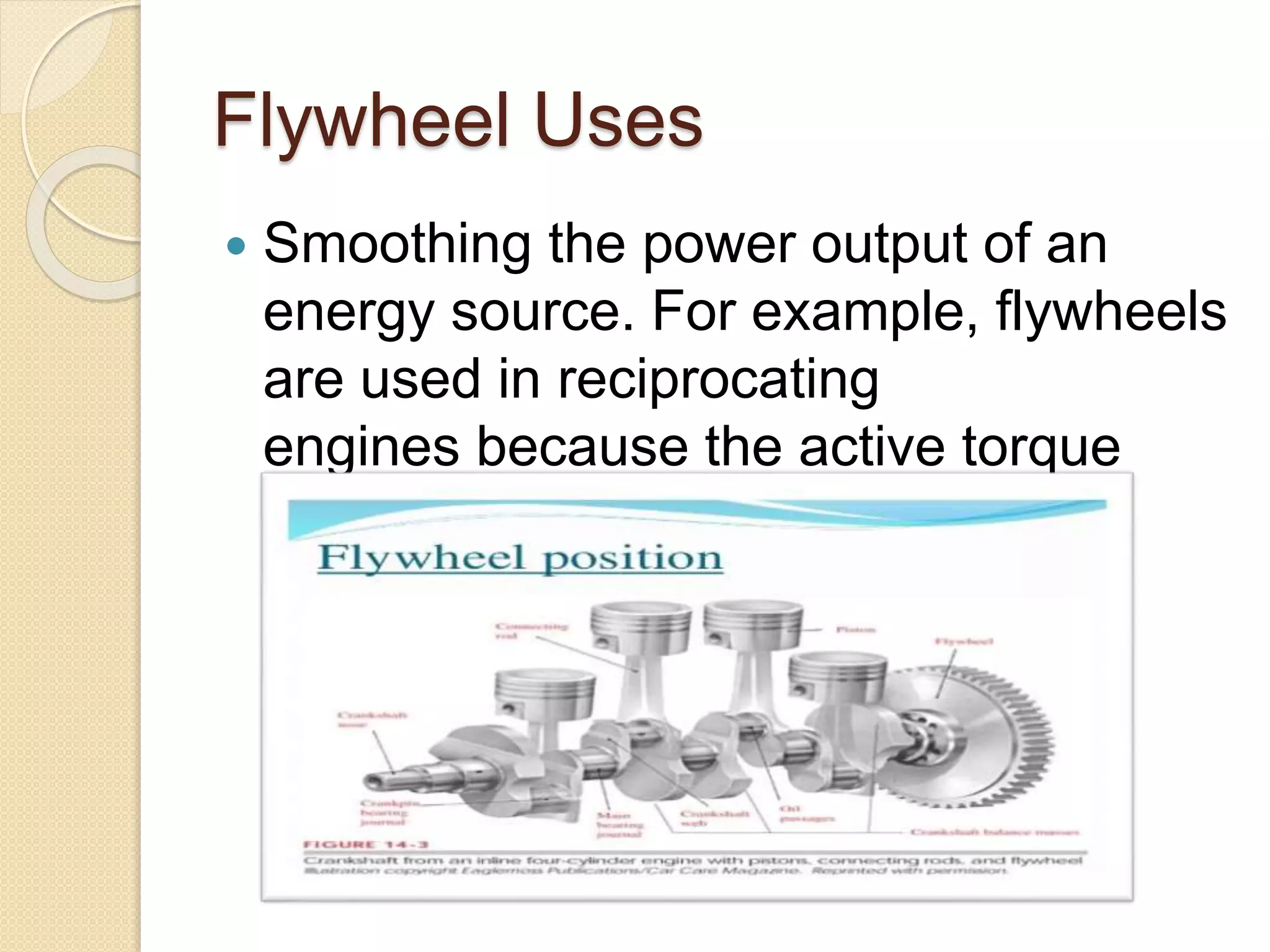

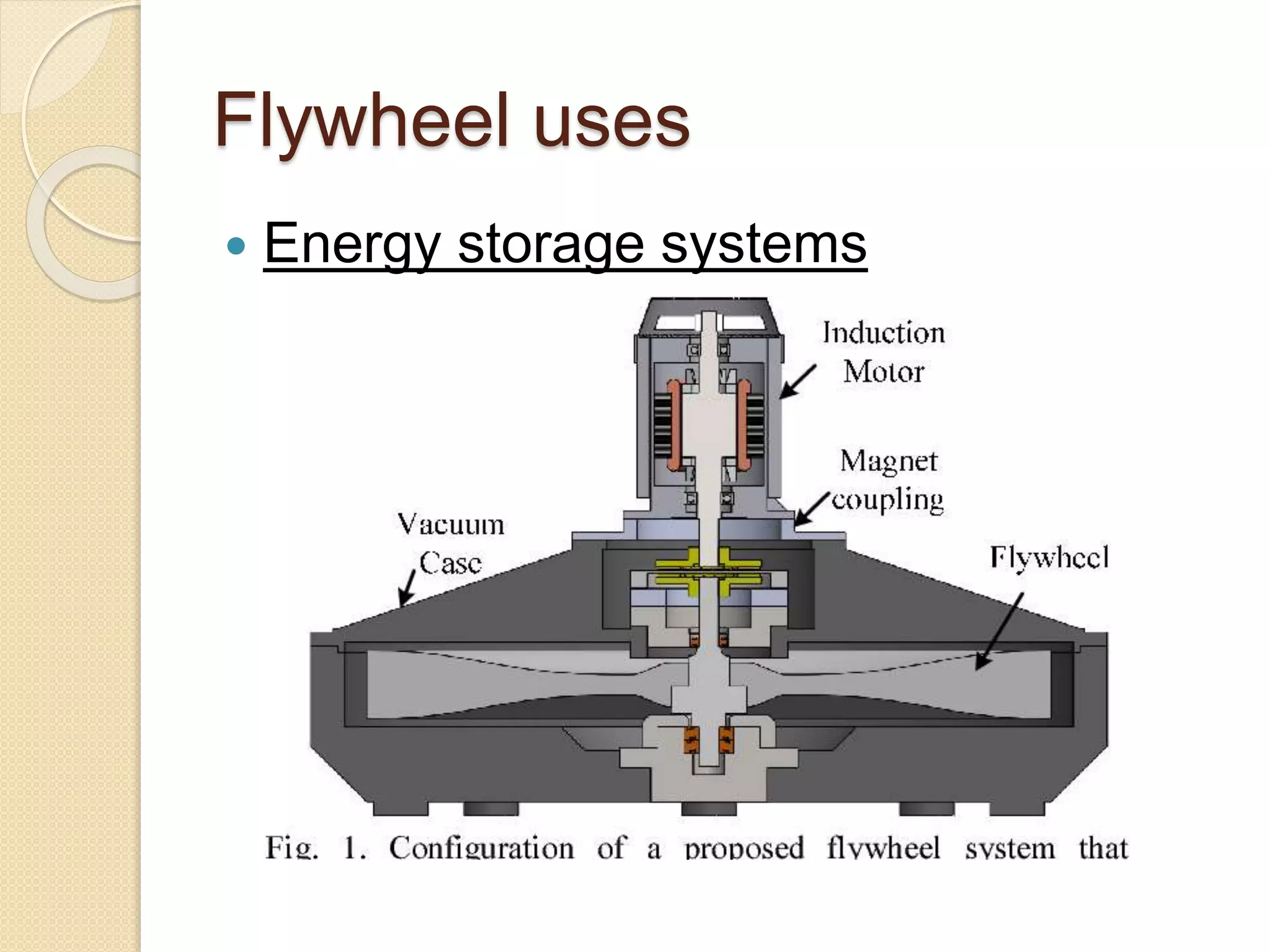

The document discusses the concept, design, and applications of flywheels, which are mechanical devices that store rotational energy. Flywheels are used to smooth power output in machines like engines and to supply intermittent energy pulses in various applications including power hammers and synchronous compensators. It also highlights the importance of the turning moment diagram in relation to engines and crankshafts.