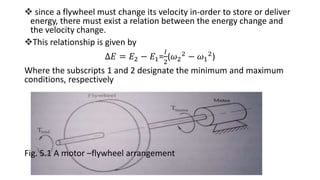

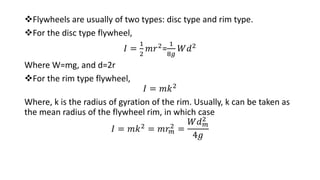

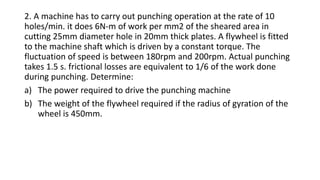

This document discusses flywheels and balancing of rotating masses. It defines a flywheel as an energy storage device that acts to smooth power transmission. Flywheels store excess energy from a motor and deliver it when needed. The kinetic energy of a flywheel depends on its moment of inertia and angular velocity. Flywheels are used to reduce torque fluctuations in machines like punch presses. The document also discusses balancing rotating masses to reduce vibrations by ensuring the system's center of gravity is at the axis of rotation.