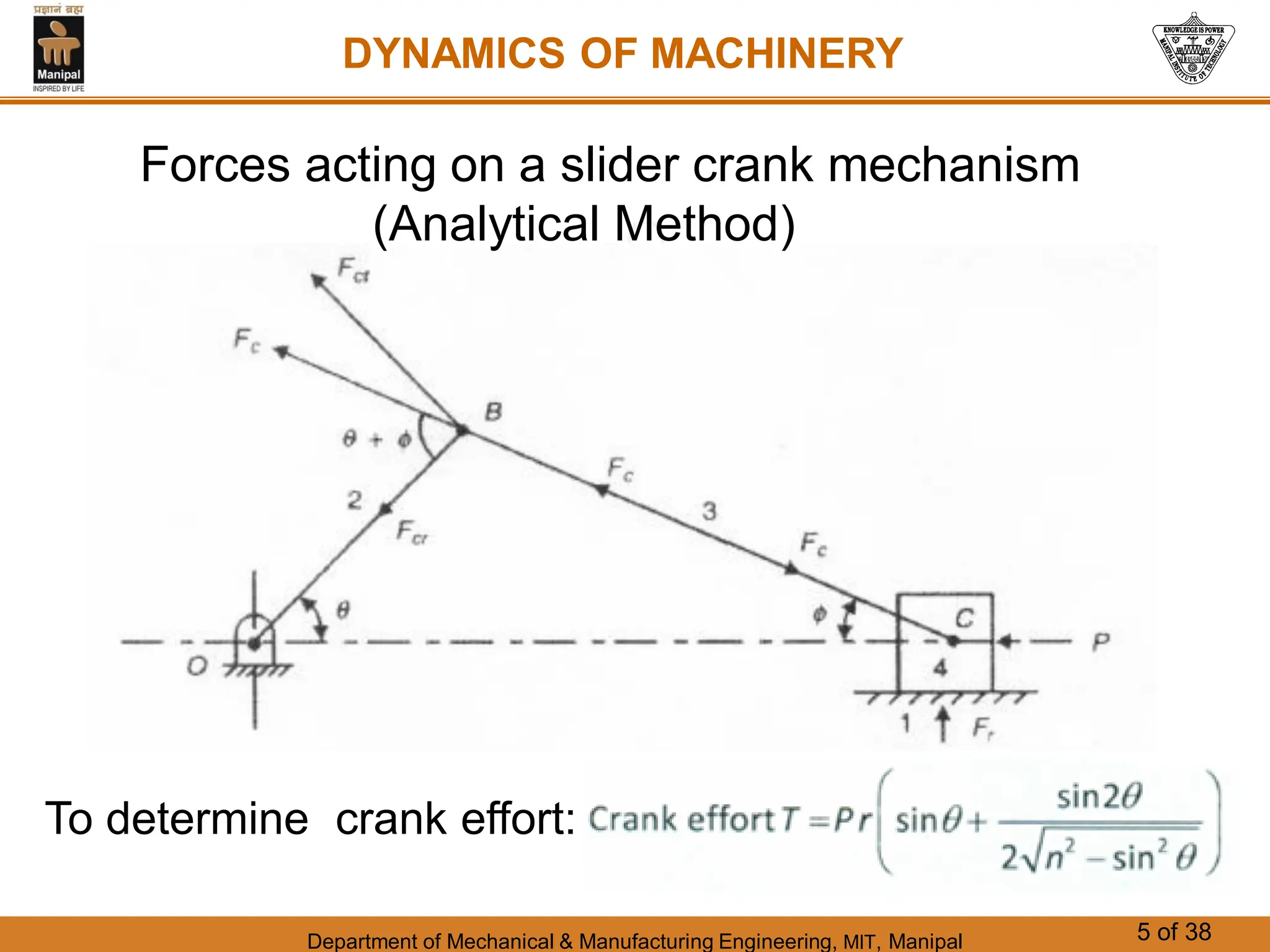

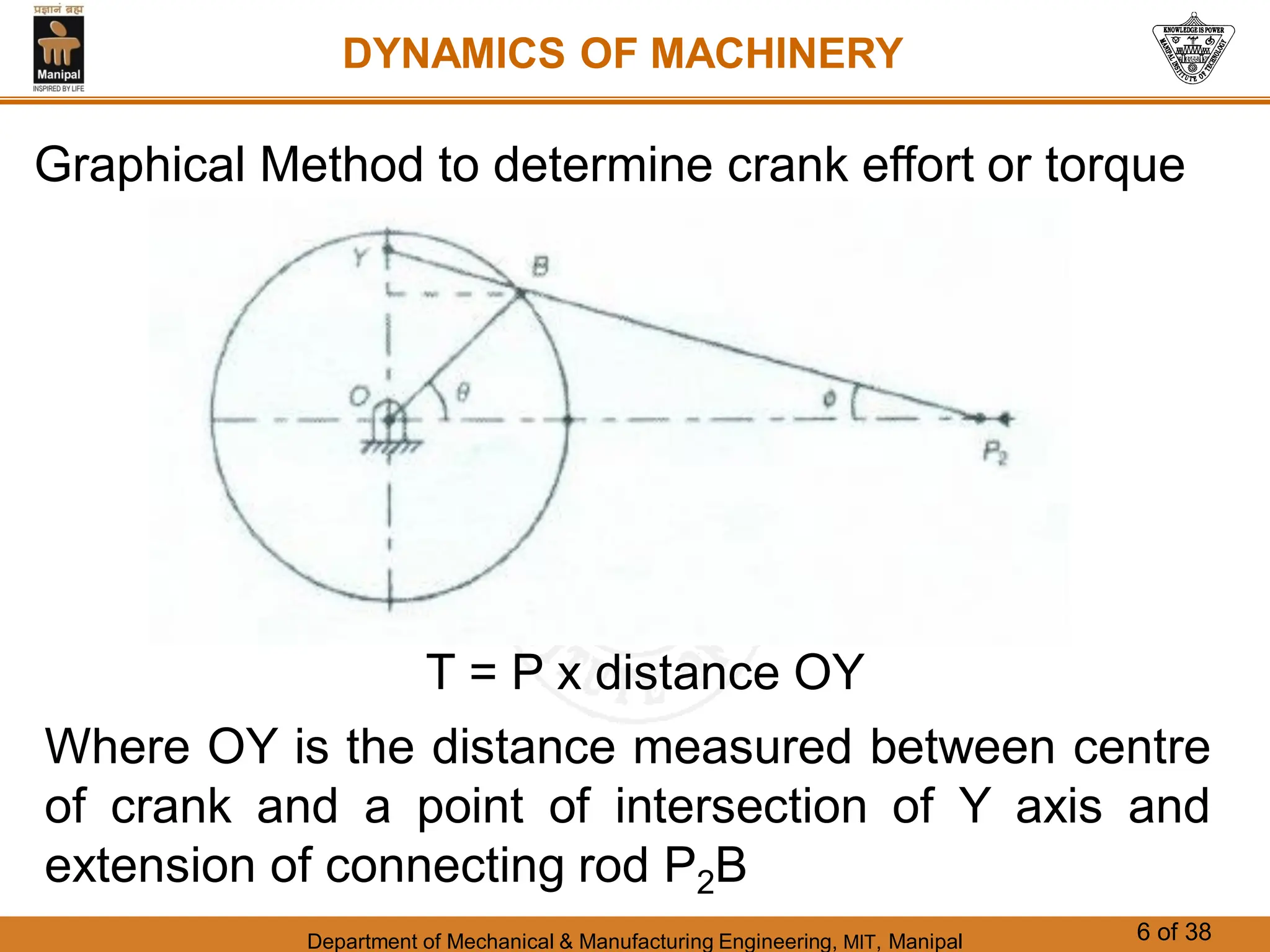

The document discusses inertia forces in internal combustion engines. It describes the three types of forces that act on the piston: gas force, inertia force, and the weight of the reciprocating mass. It explains how these forces affect the net piston effort. The document then discusses how to determine the crank effort using analytical and graphical methods based on the piston effort. It shows diagrams of variations in gas force, inertia force, piston effort, crank effort arm length, and the turning moment diagram. It also discusses flywheels, their purpose of absorbing energy fluctuations, types of flywheels, and coefficients related to energy and speed fluctuations.