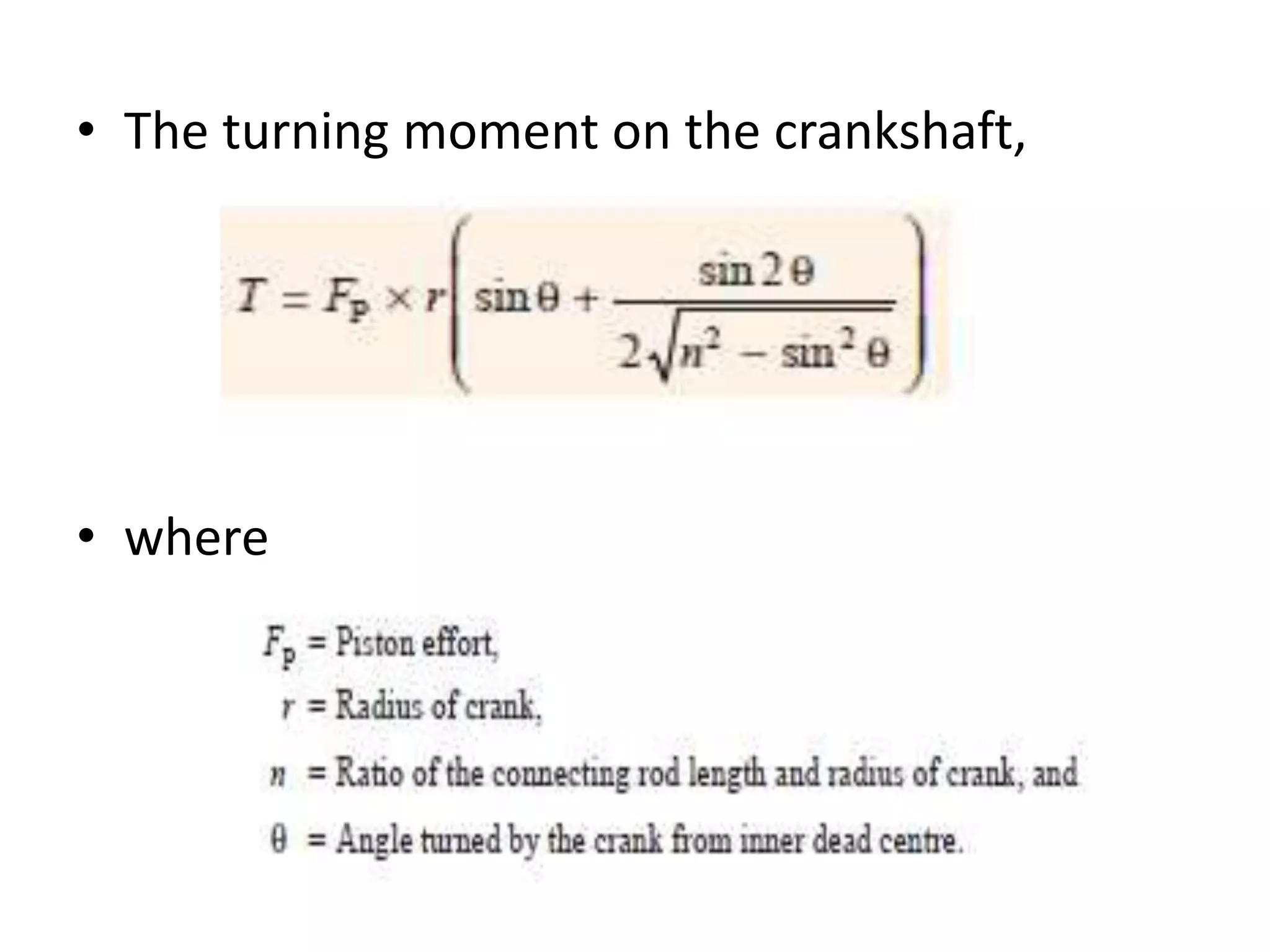

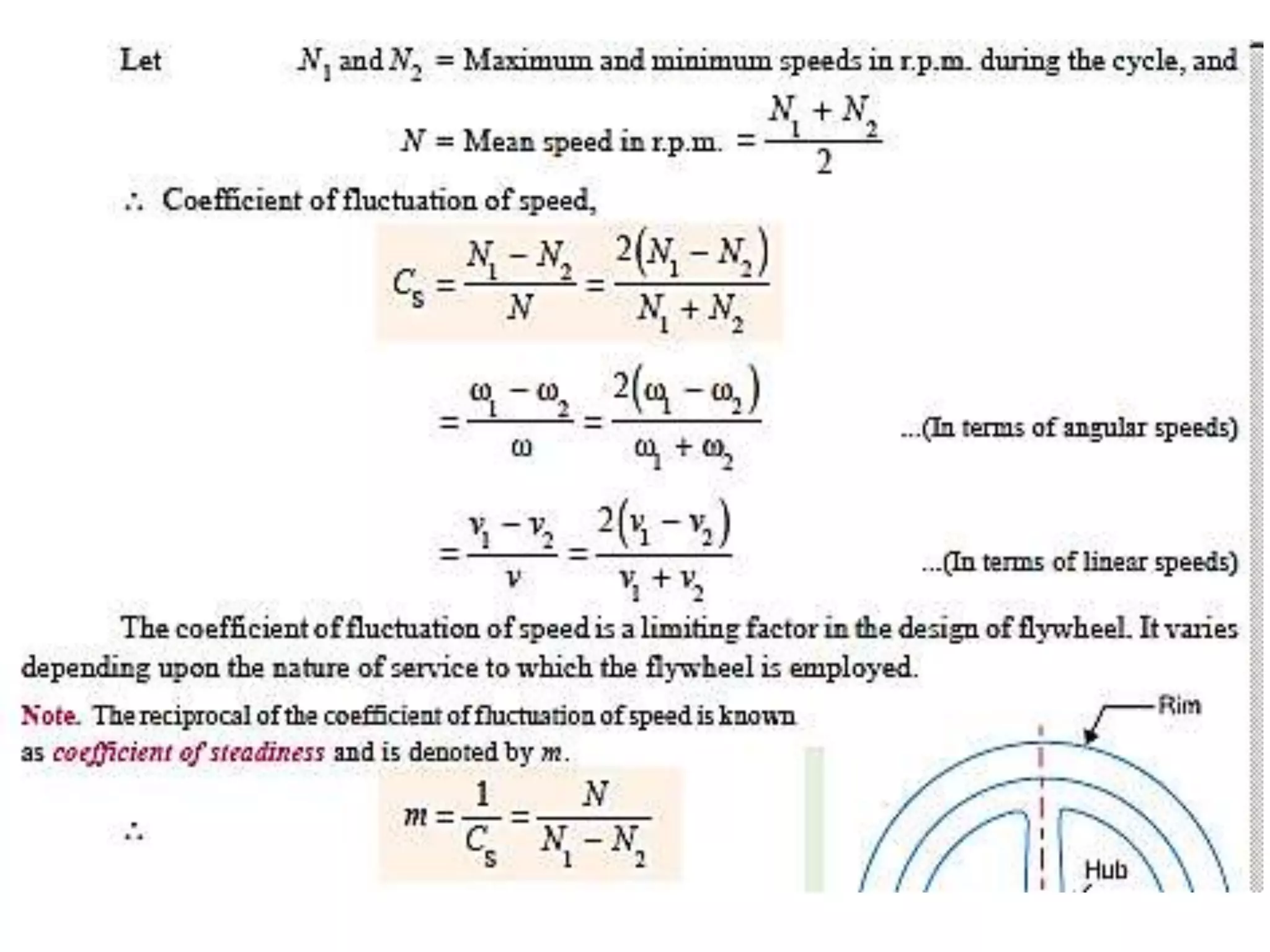

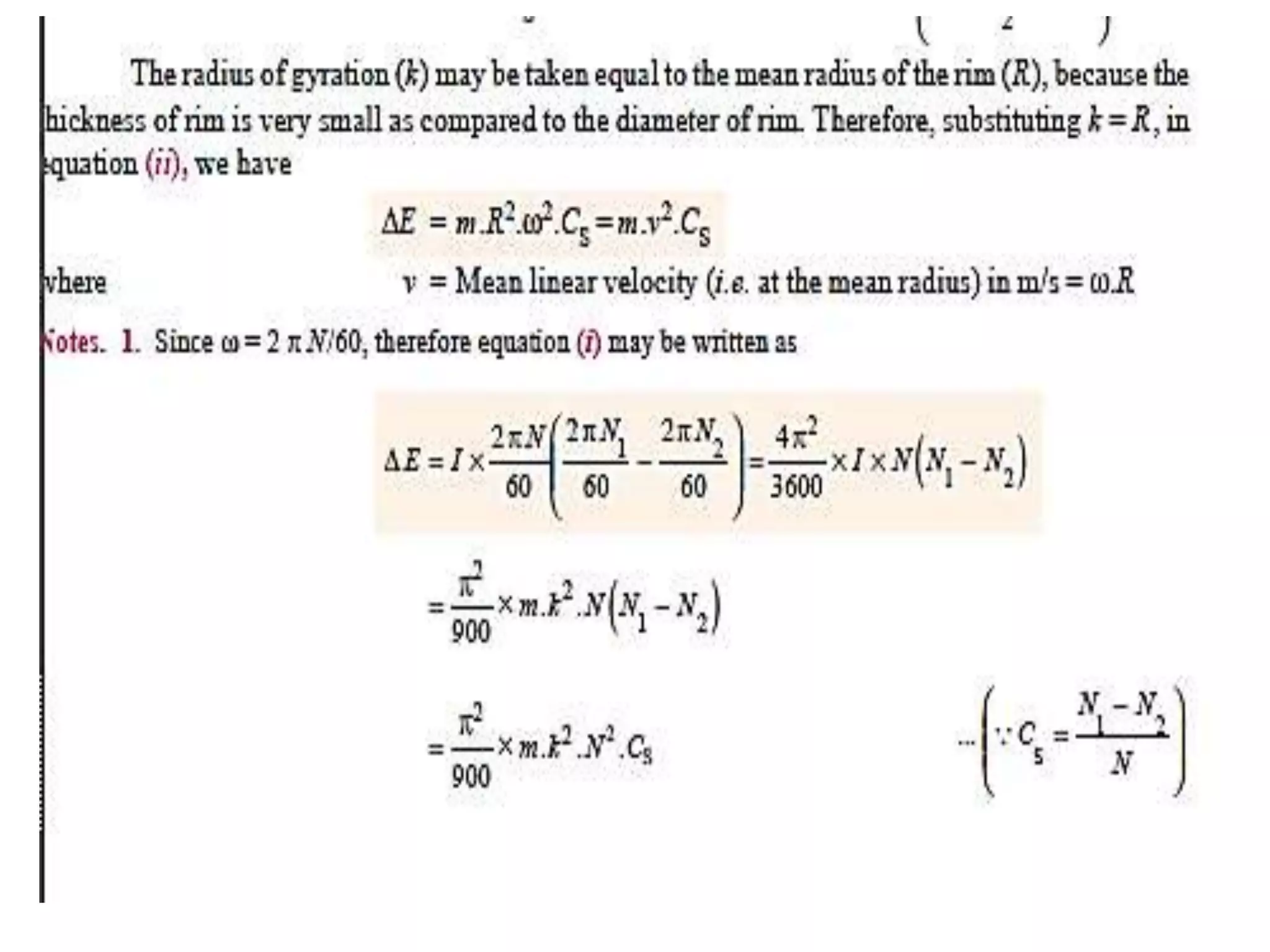

This document discusses turning moment diagrams and flywheels. It explains that a turning moment diagram is a graphical representation of the torque on the crankshaft at different crank angles. It shows the torque is highest at 90 degrees and lowest at 0 and 180 degrees. The area under the curve represents the work done per revolution. A flywheel stores energy when torque is high and releases it when torque is low, reducing fluctuations in speed. The ratio of maximum speed variation to mean speed is called the coefficient of fluctuation of speed. A flywheel controls speed variations caused by uneven engine torque over each operating cycle.