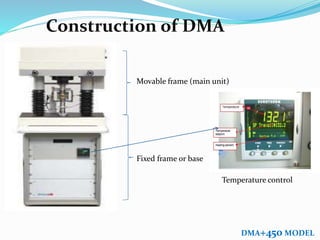

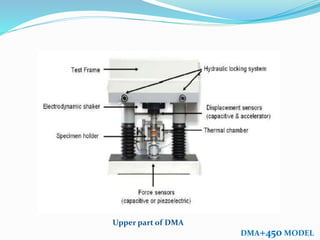

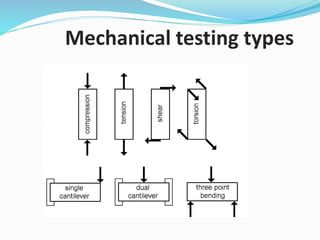

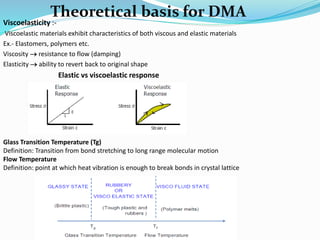

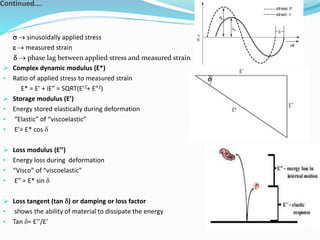

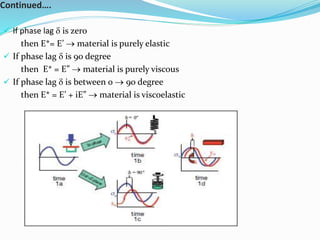

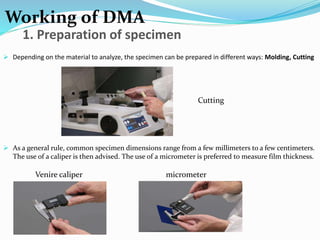

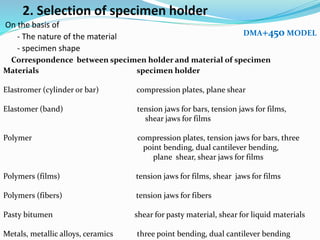

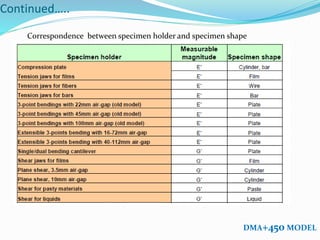

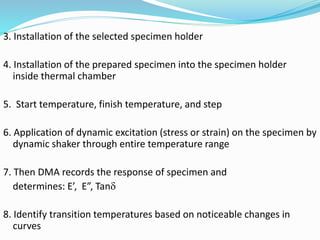

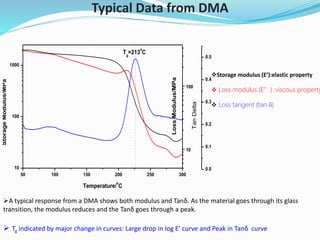

DMA is an instrument that applies a dynamic oscillating force to a material sample and analyzes the sample's response, determining changes in properties like modulus and loss factor from changes in temperature, time, frequency, force, and strain. It works by exerting a known oscillating excitation to a specimen and measuring the resulting strains and dynamic forces, from which mechanical properties like modulus and damping can be derived. A wide range of materials from polymers and composites to metals and biomaterials can be analyzed using different specimen holders and test types as the sample is subjected to a temperature range in the DMA's thermal chamber. The data obtained provides information on the material's transitions, like the glass transition temperature, indicated by changes in the storage