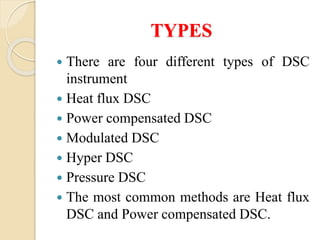

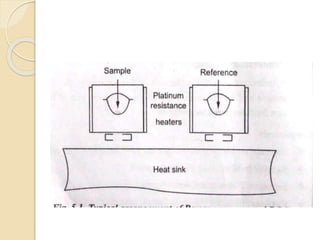

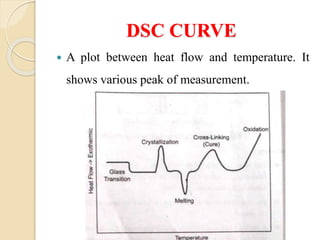

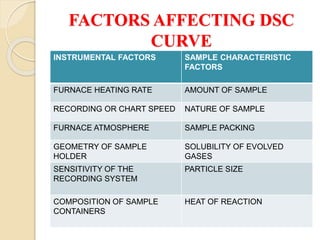

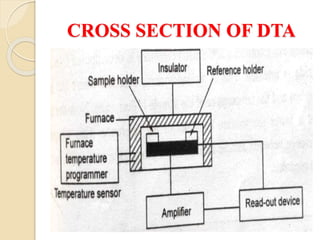

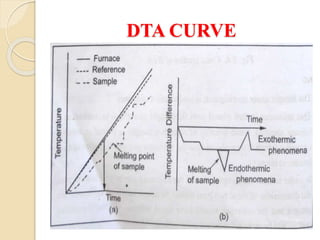

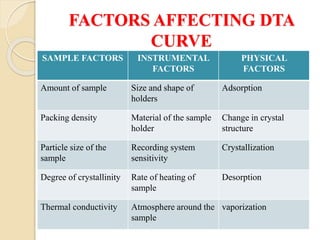

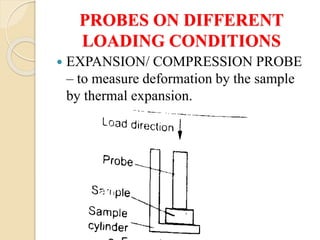

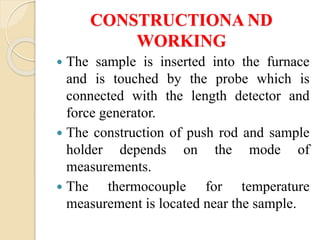

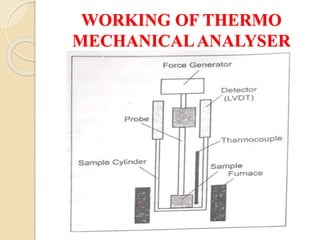

This document discusses various types of materials testing including mechanical, non-destructive, thermal, electrical, and corrosion testing. It focuses on thermal properties testing methods like thermal analysis, thermal testing, thermogravimetric analysis, differential scanning calorimetry, differential thermal analysis, and thermo-mechanical analysis. These techniques measure how a material's properties change with temperature and provide information on transitions, reactions, and dimensional stability. The principles, components, applications, and advantages of each technique are described over multiple sections.