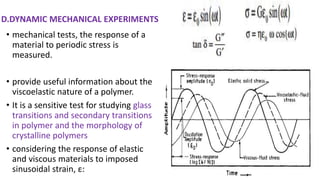

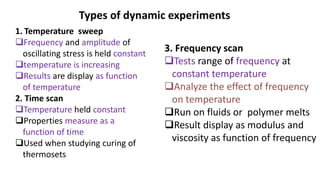

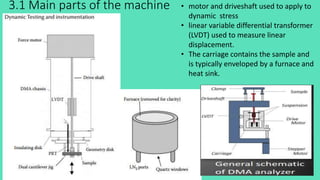

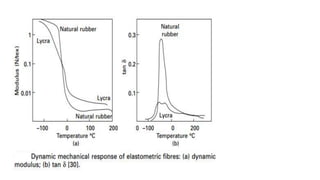

Dynamic mechanical analysis (DMA) is a technique that applies a periodic force to a material and measures the storage and loss modulus to characterize the viscoelastic properties. It can detect glass transition temperatures and other secondary transitions. The main components of a DMA machine include a motor to apply dynamic stress, an LVDT to measure strain, and a furnace. Samples are clamped and heated while a sinusoidal force is applied. The storage and loss modulus are calculated from the stress and strain measurements and plotted against temperature or time. DMA can be used to characterize polymers and fibers, determine the effects of composition, crystallinity, and orientation on transitions, and identify defects.