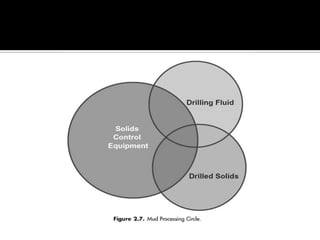

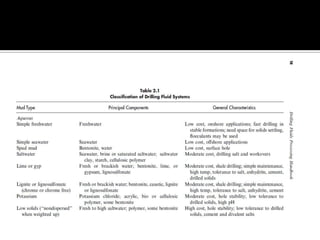

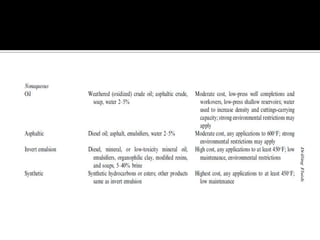

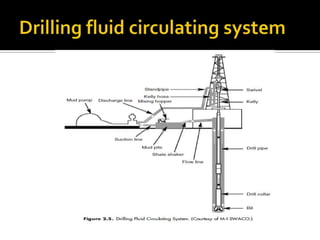

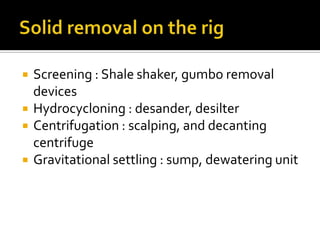

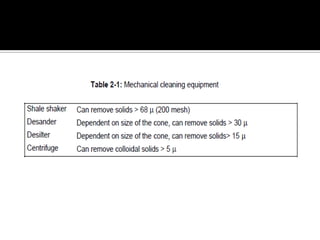

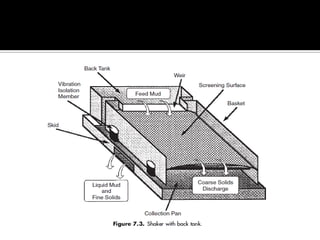

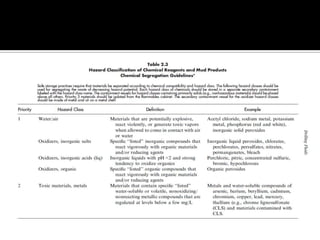

A drilling fluid, or mud, is circulated during drilling operations to carry cuttings to the surface, control formation pressure and maintain wellbore stability, cool and lubricate the drill bit, and minimize damage to the reservoir. There are three main types of drilling fluids: gaseous (such as air), aqueous (such as water-based muds containing clay or polymer), and non-aqueous (such as oil-based or synthetic-based muds). Cuttings are removed from the drilling fluid using various solids control equipment and processes at the surface. Working with drilling fluids requires safety precautions as some components can be hazardous if not properly handled.