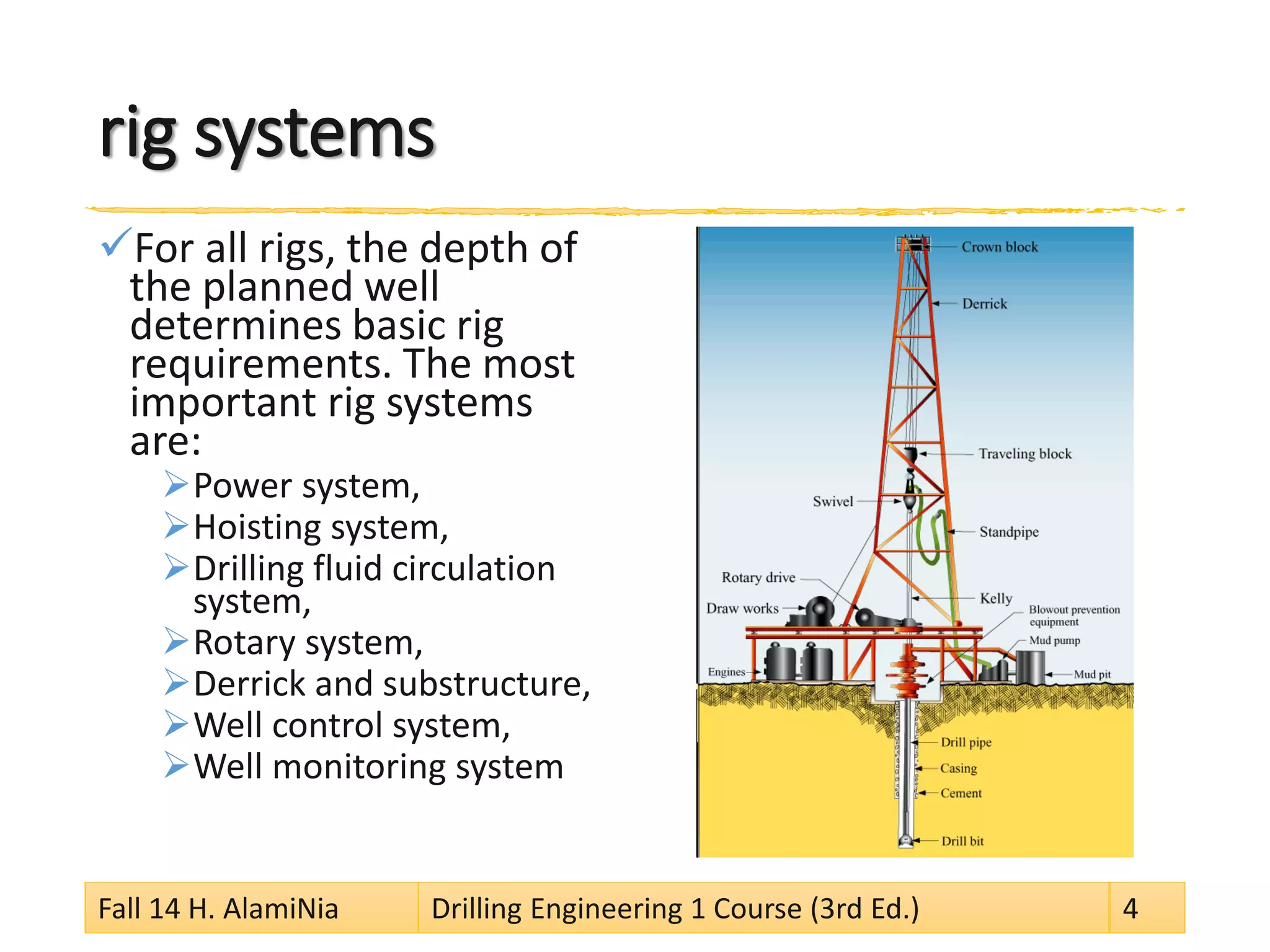

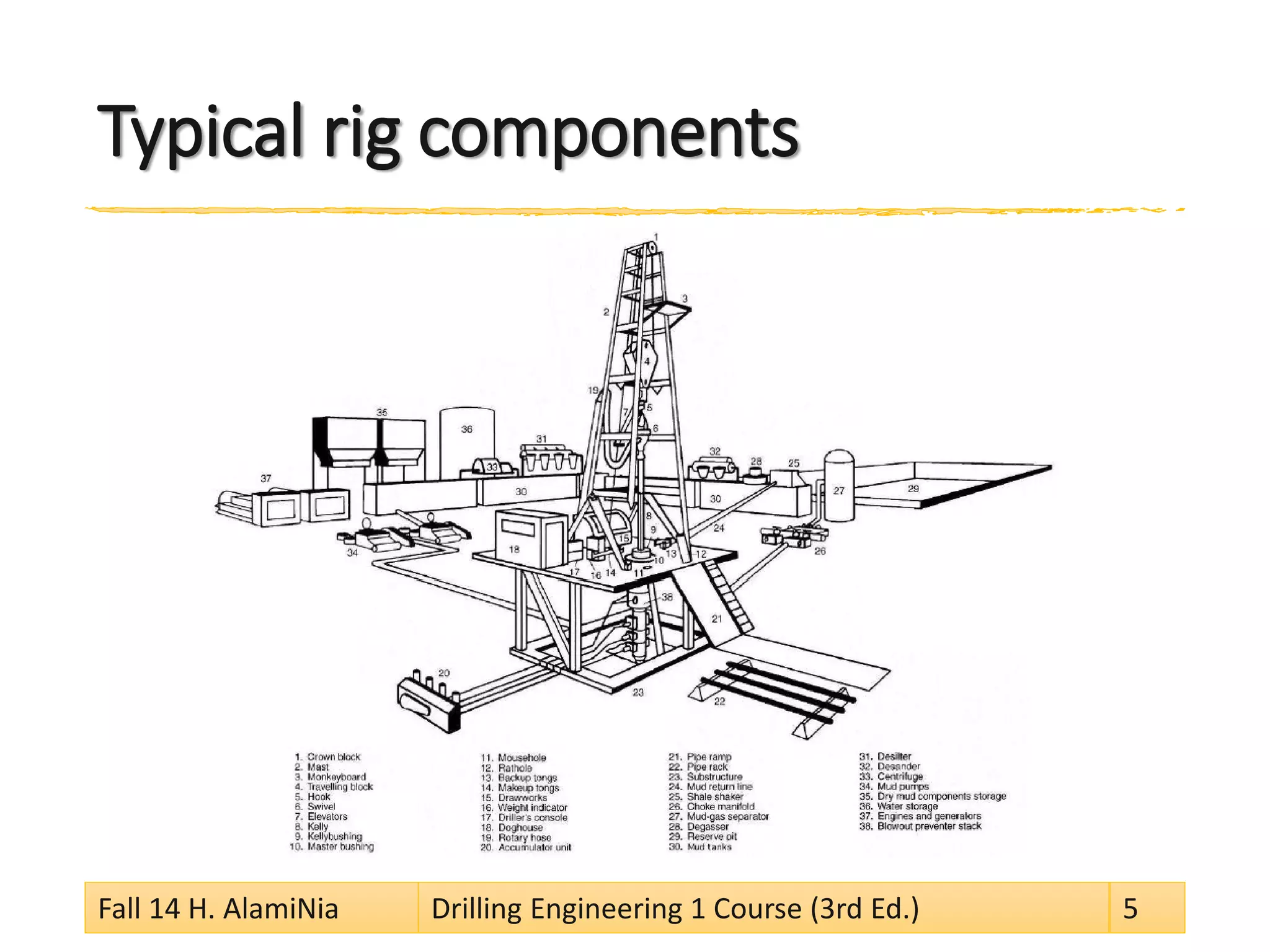

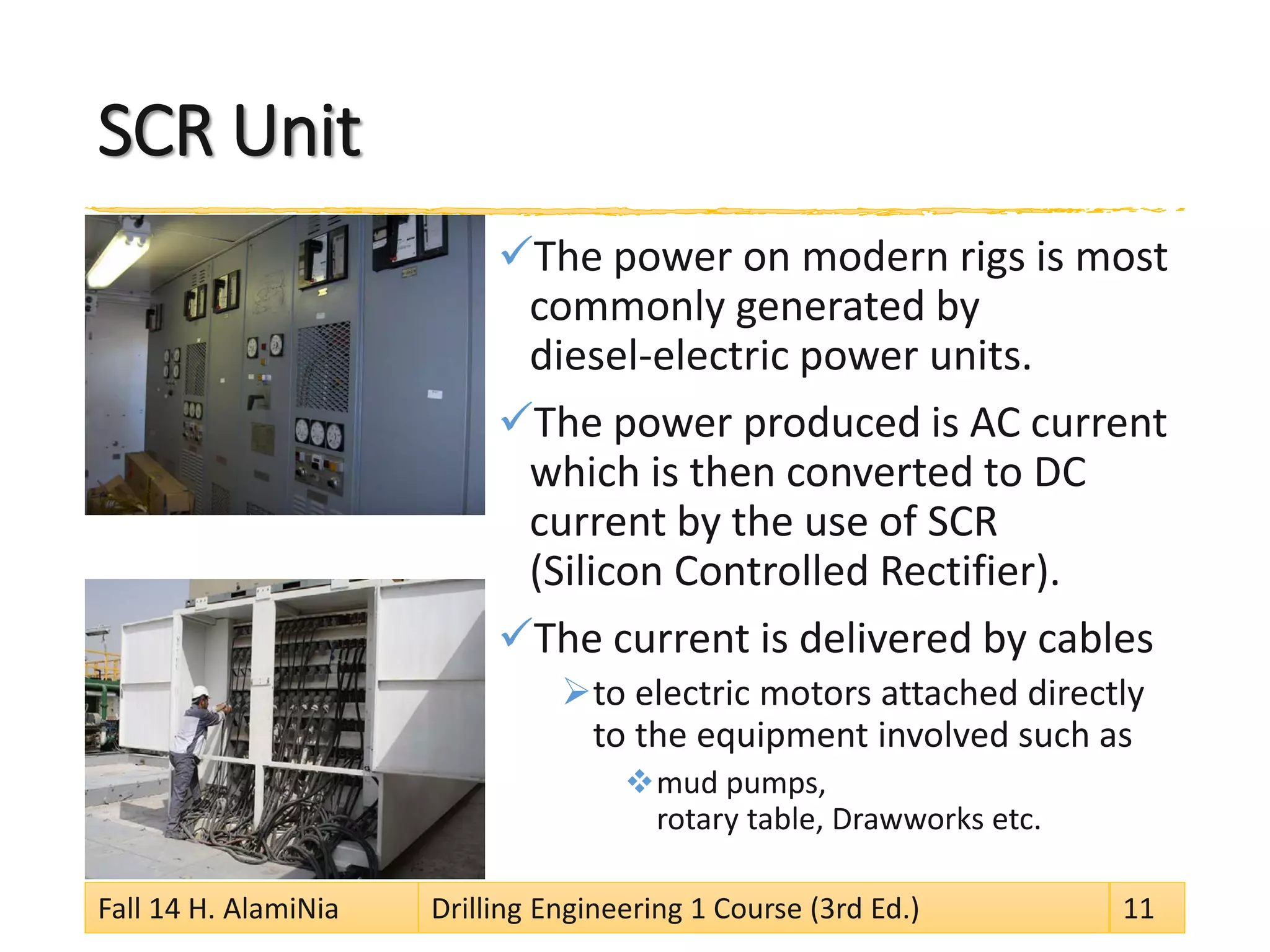

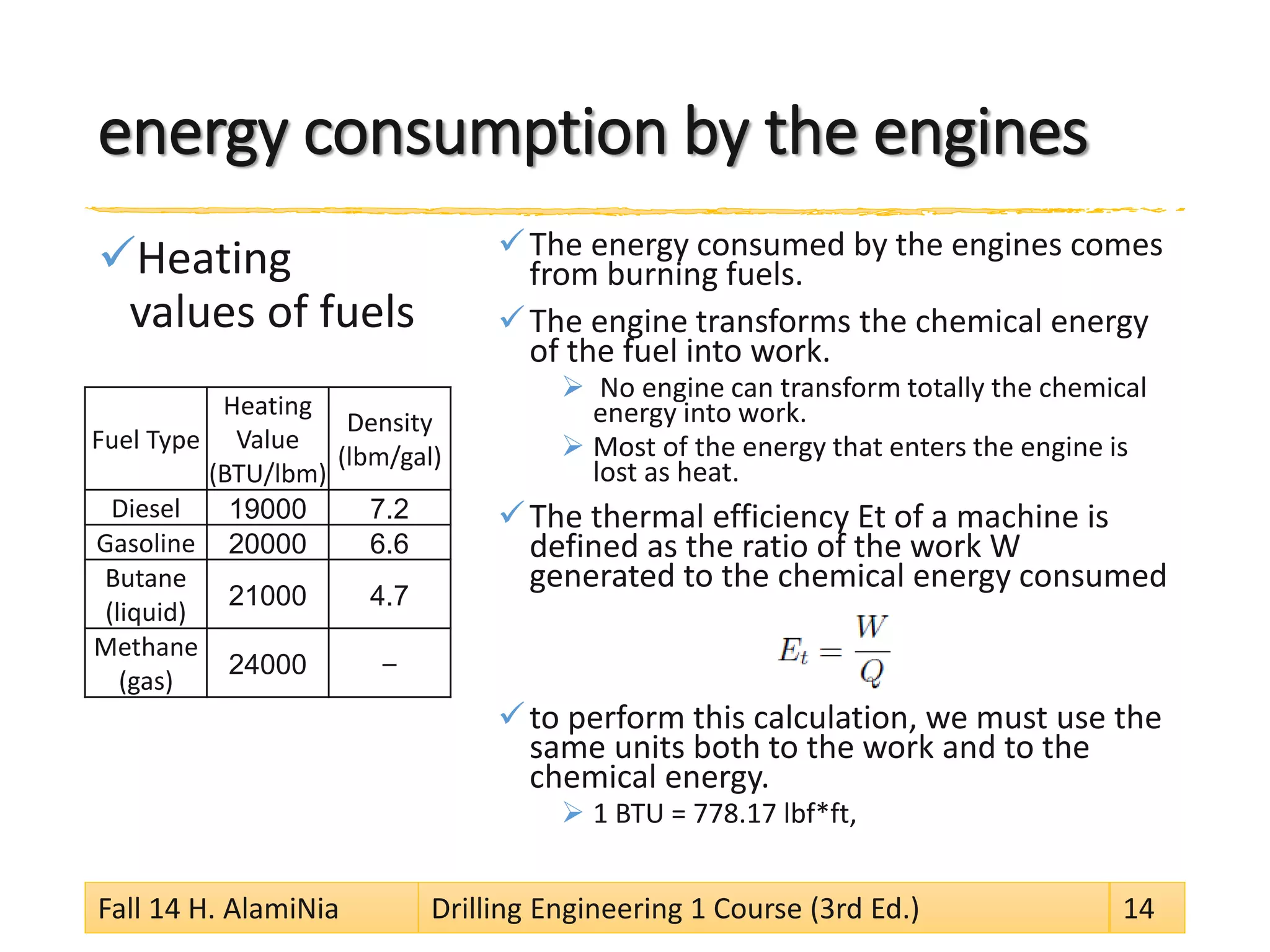

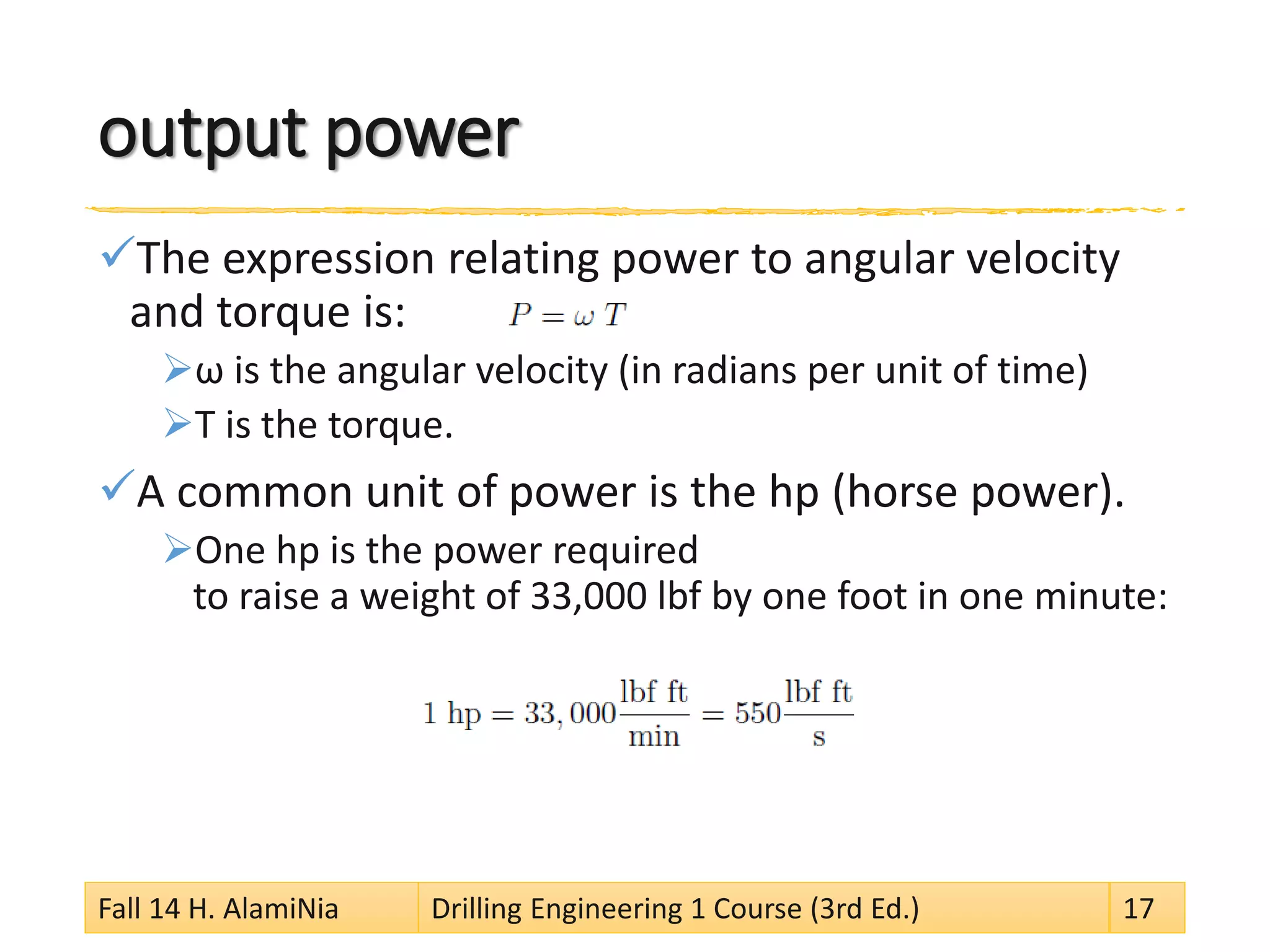

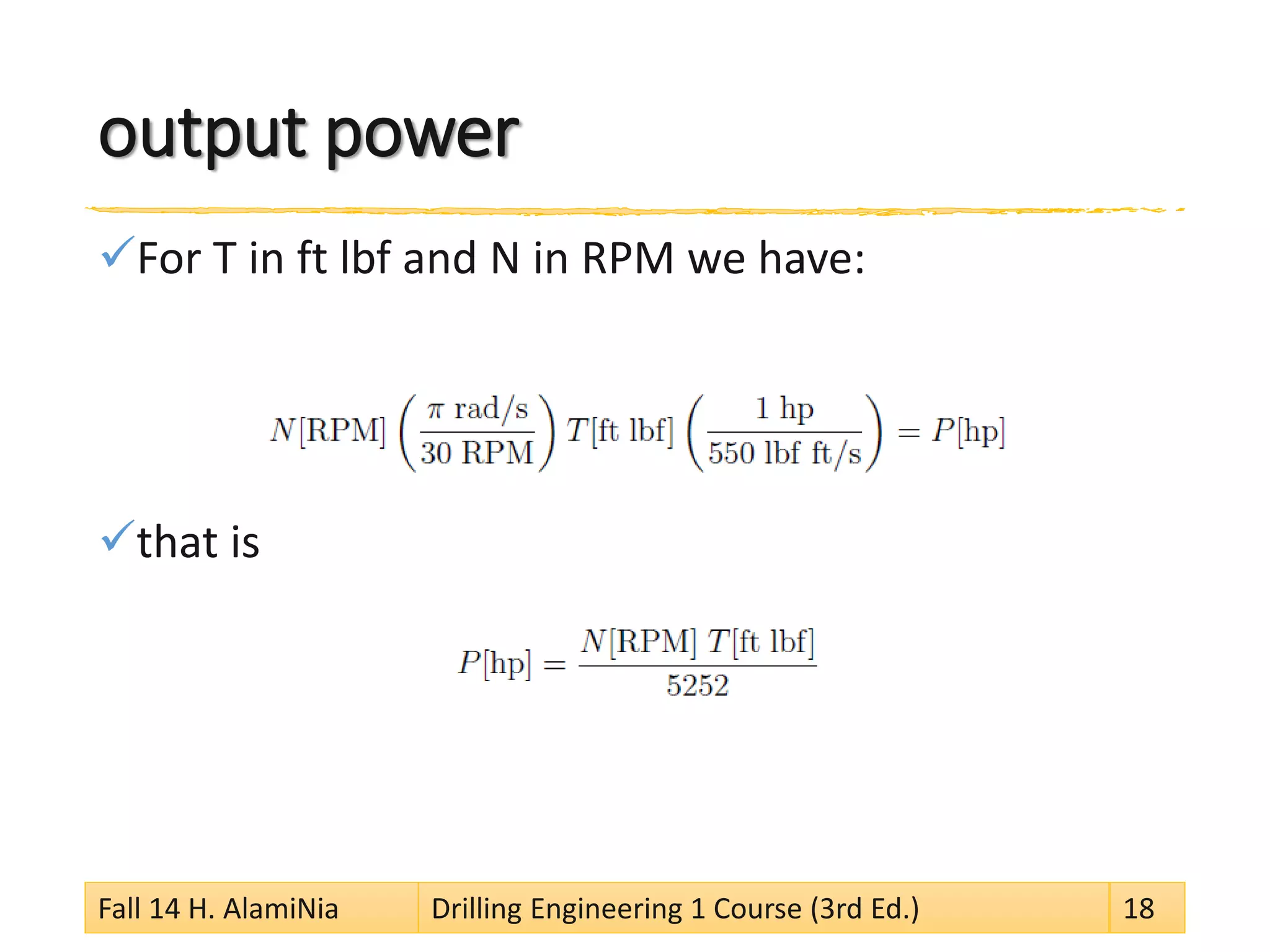

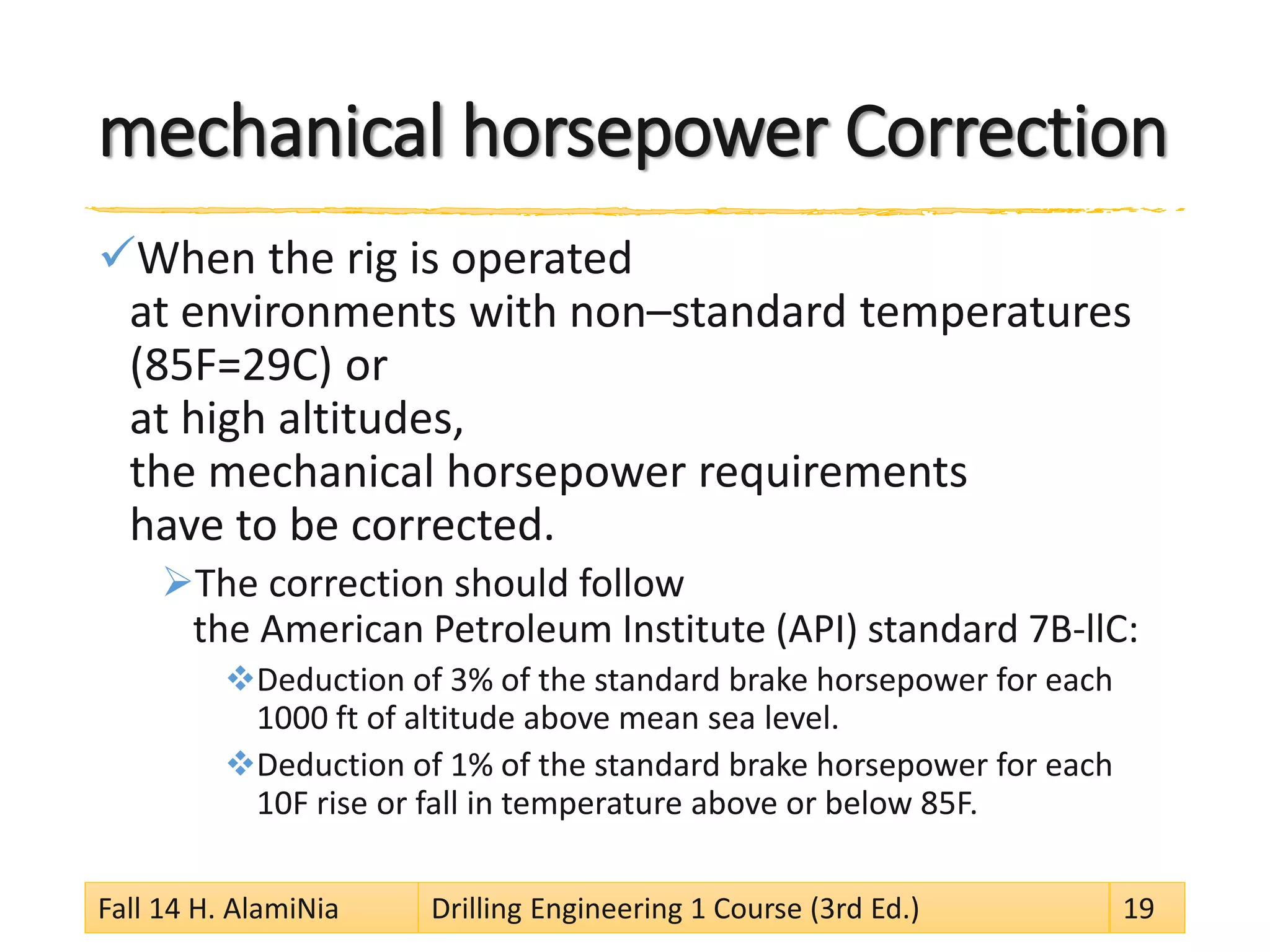

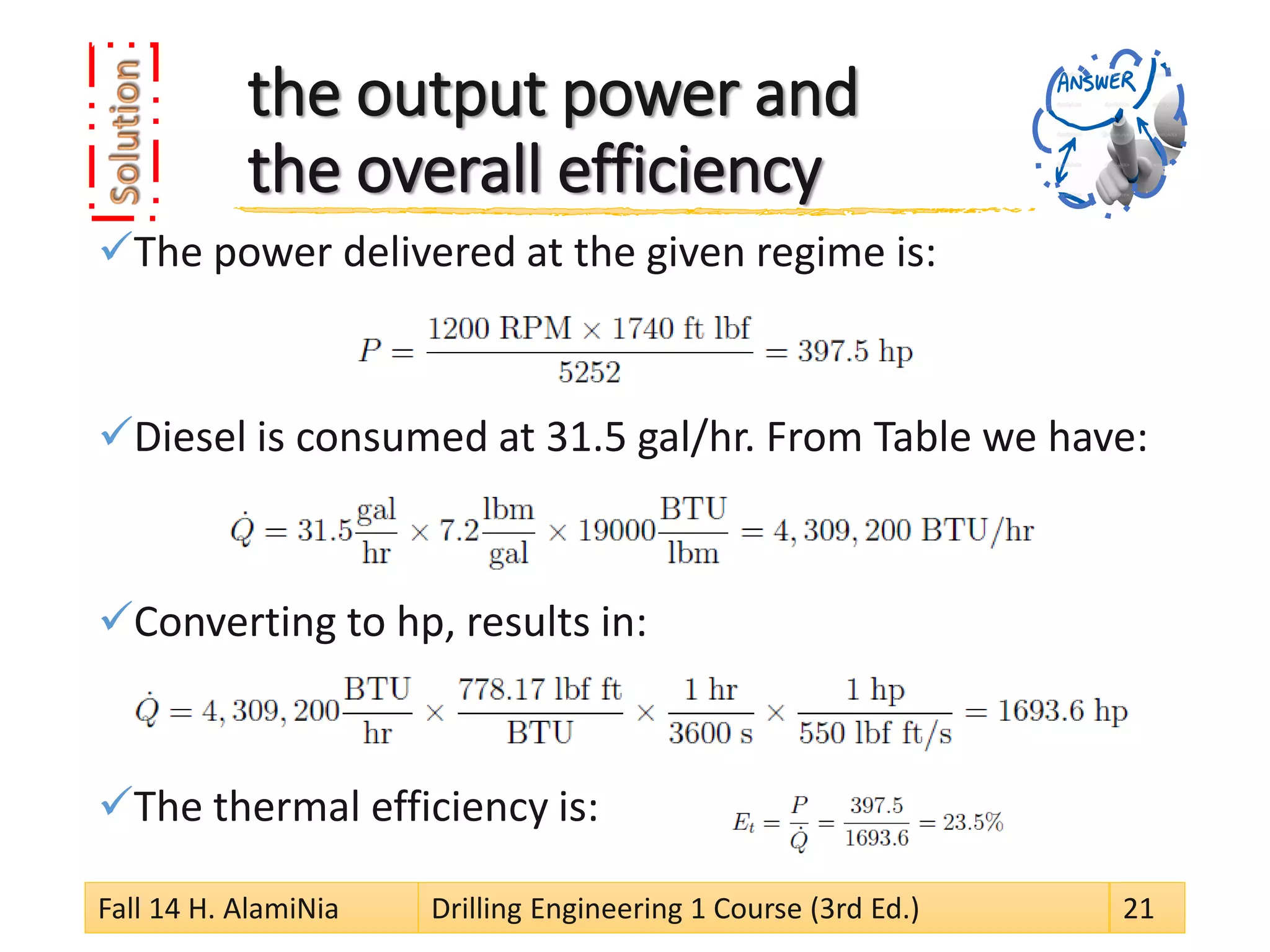

This document discusses the key systems of a rotary drilling rig, including the power system. It explains that the power system provides power to all other rig systems, including hoisting, circulation, and rotary systems. Diesel engines are typically used to power the drawworks and rotary table. The document discusses power requirements, classifications of power systems, power supply components, and calculations for determining output power and efficiency.