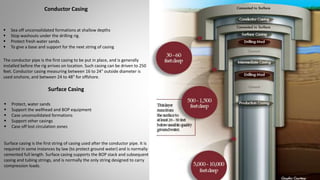

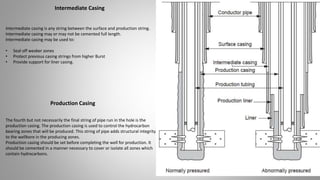

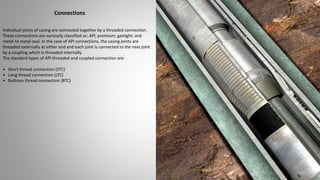

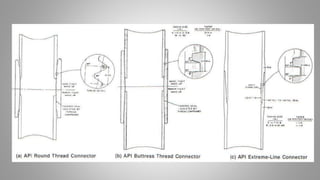

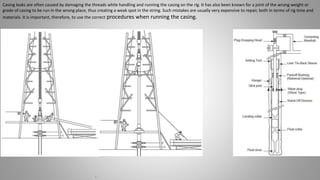

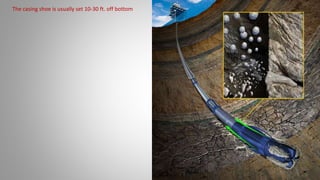

This document provides information about casing pipes used in oil and gas wells. It discusses the different types of casing including conductor casing, surface casing, intermediate casing, and production casing. Each type of casing serves a specific purpose like maintaining hole integrity, isolating pressure zones, and protecting groundwater. The document also covers casing connection types, sizing standards, recommended lengths, and potential causes of leaks.