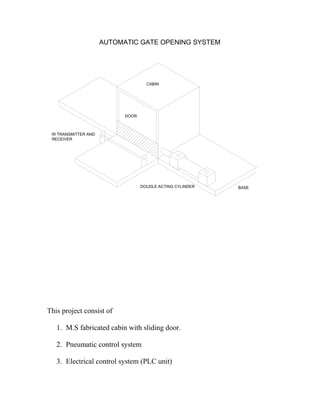

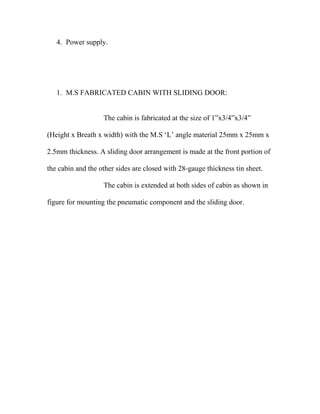

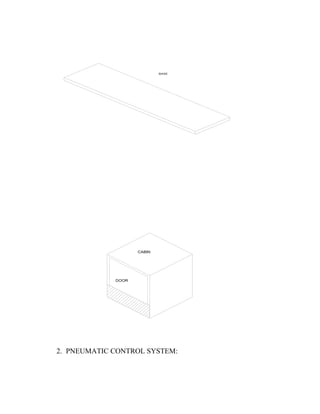

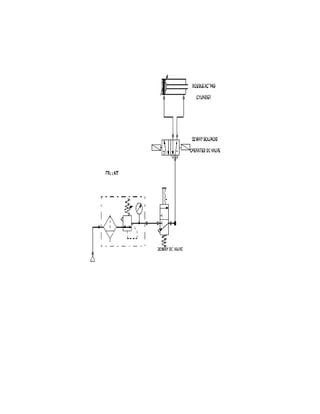

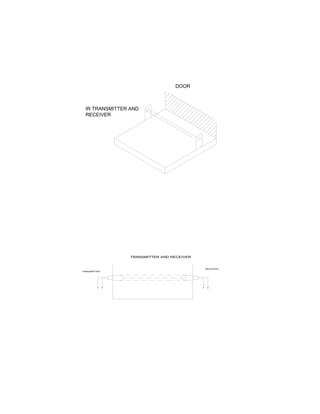

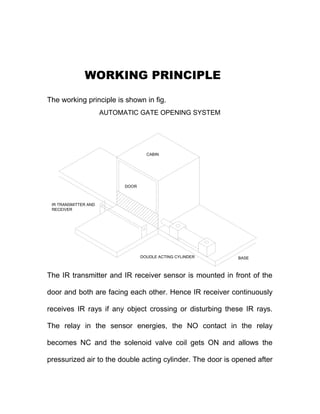

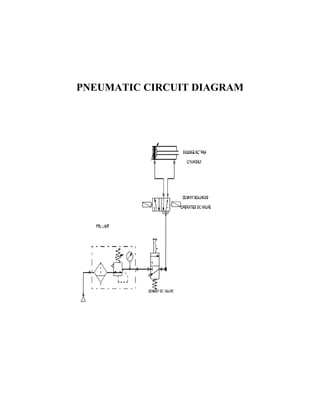

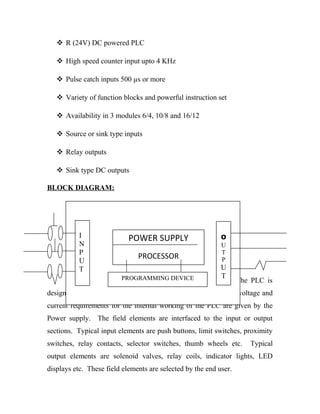

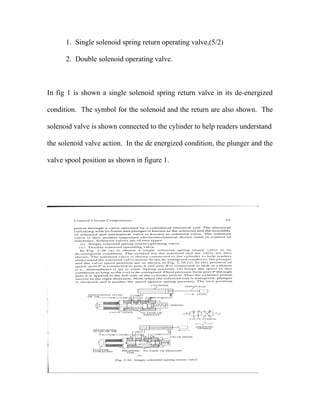

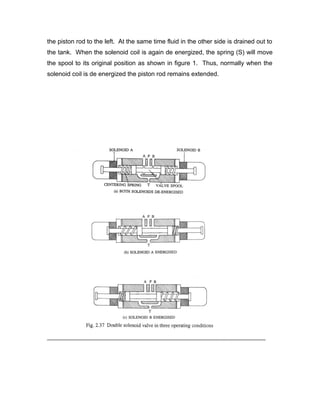

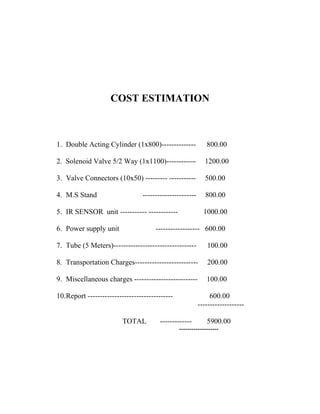

This document describes an automatic pneumatic controlled door and closing system using a programmable logic controller (PLC). A group of six students submitted the project to fulfill their diploma requirements. The system uses a double acting cylinder and 5/2 way solenoid valve controlled by an infrared sensor to automatically open and close a door. When an object is detected by the infrared sensor, it activates the solenoid valve which operates the cylinder to open the door.