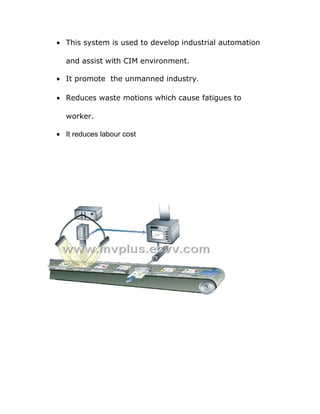

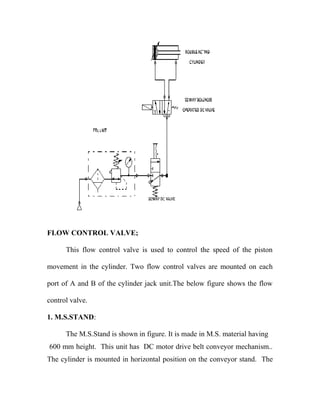

The document describes a project submitted for a diploma in mechanical engineering. It discusses developing an automatic inspection system for machining components using machine vision. The system would use a camera and image processing software to inspect parts on a conveyor belt for defects. Defective parts would be ejected by a pneumatic cylinder controlled by a microcontroller and computer system. The project aims to develop industrial automation and quality control by automatically checking parts throughout the manufacturing process.