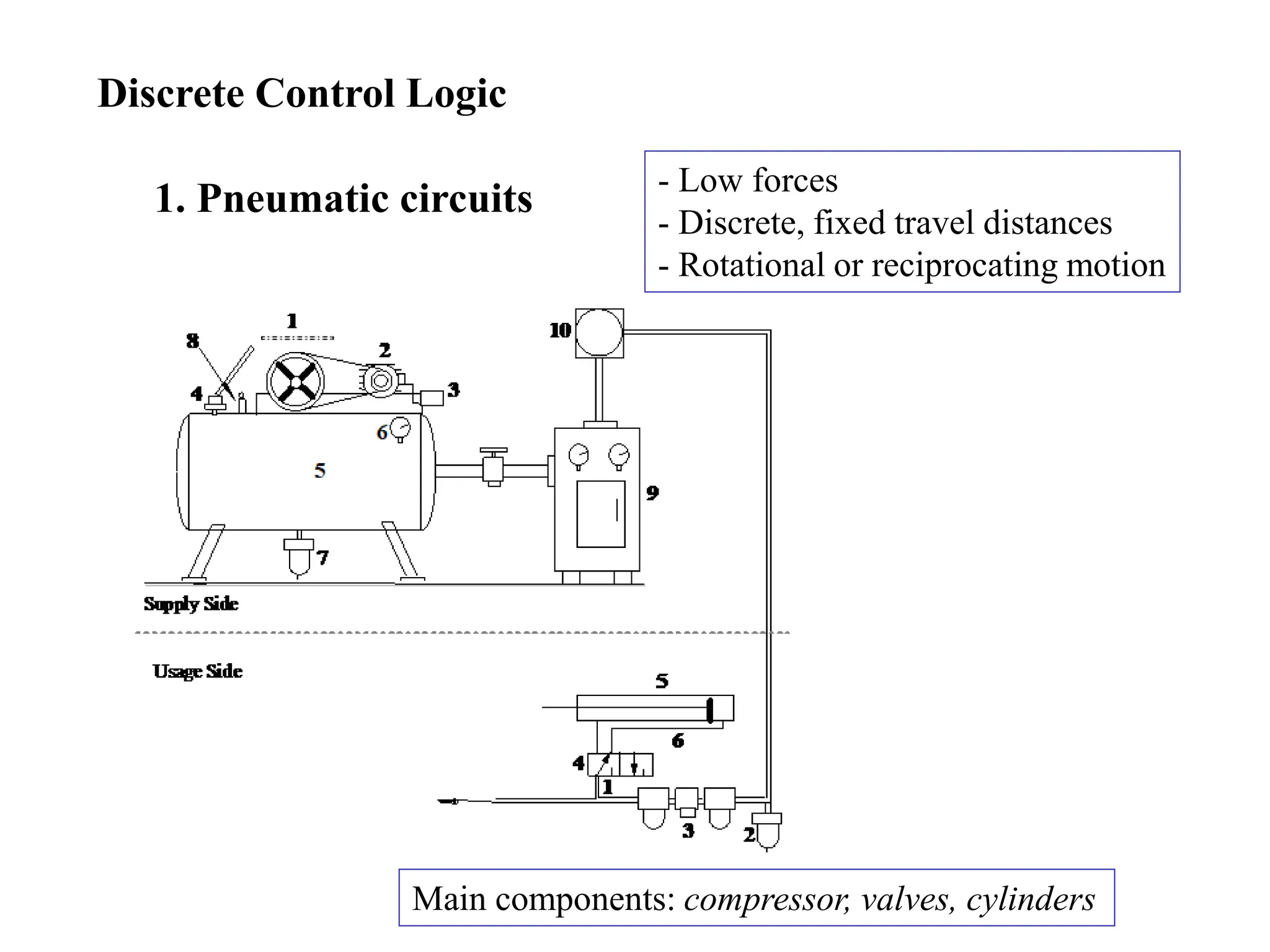

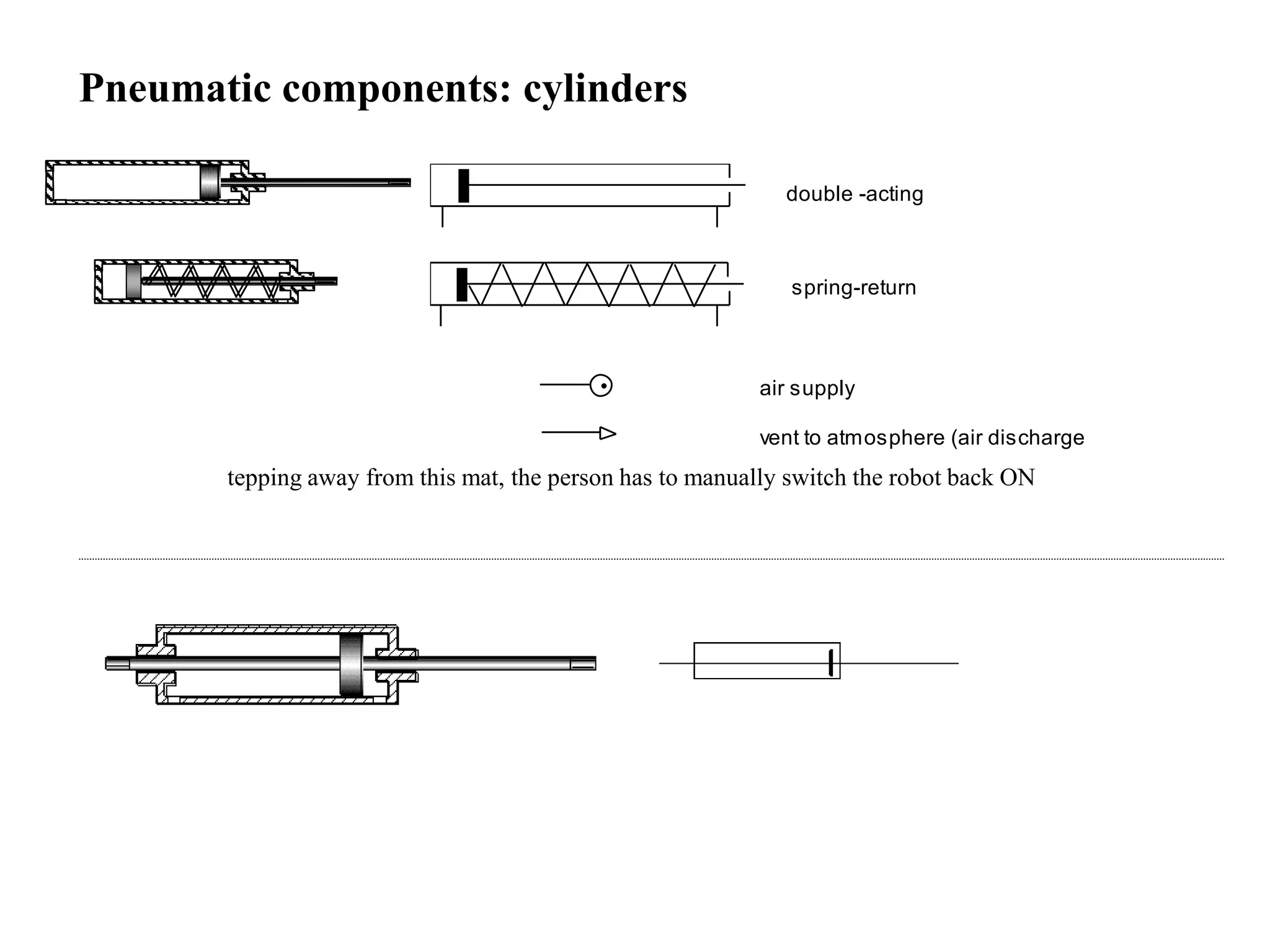

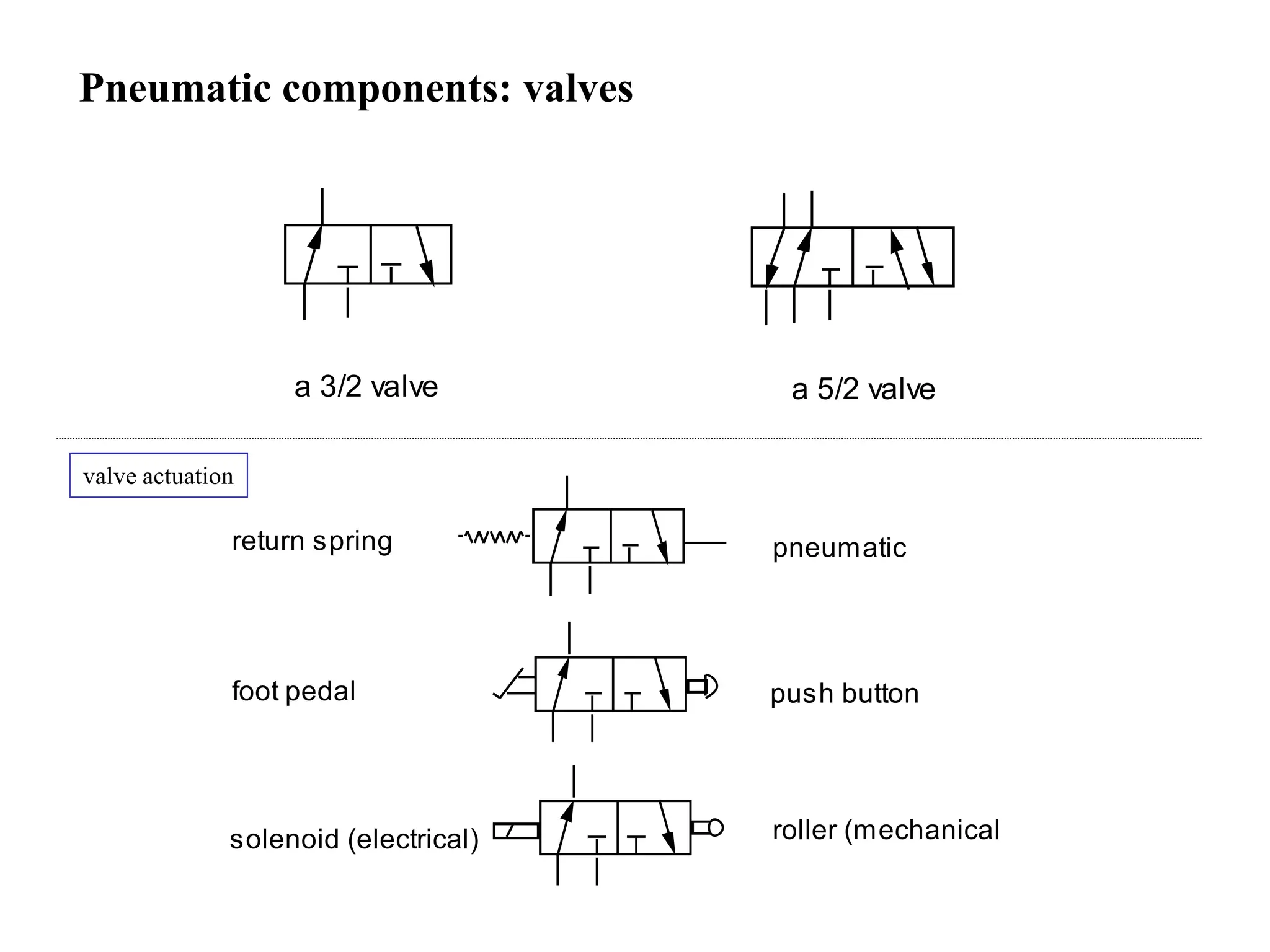

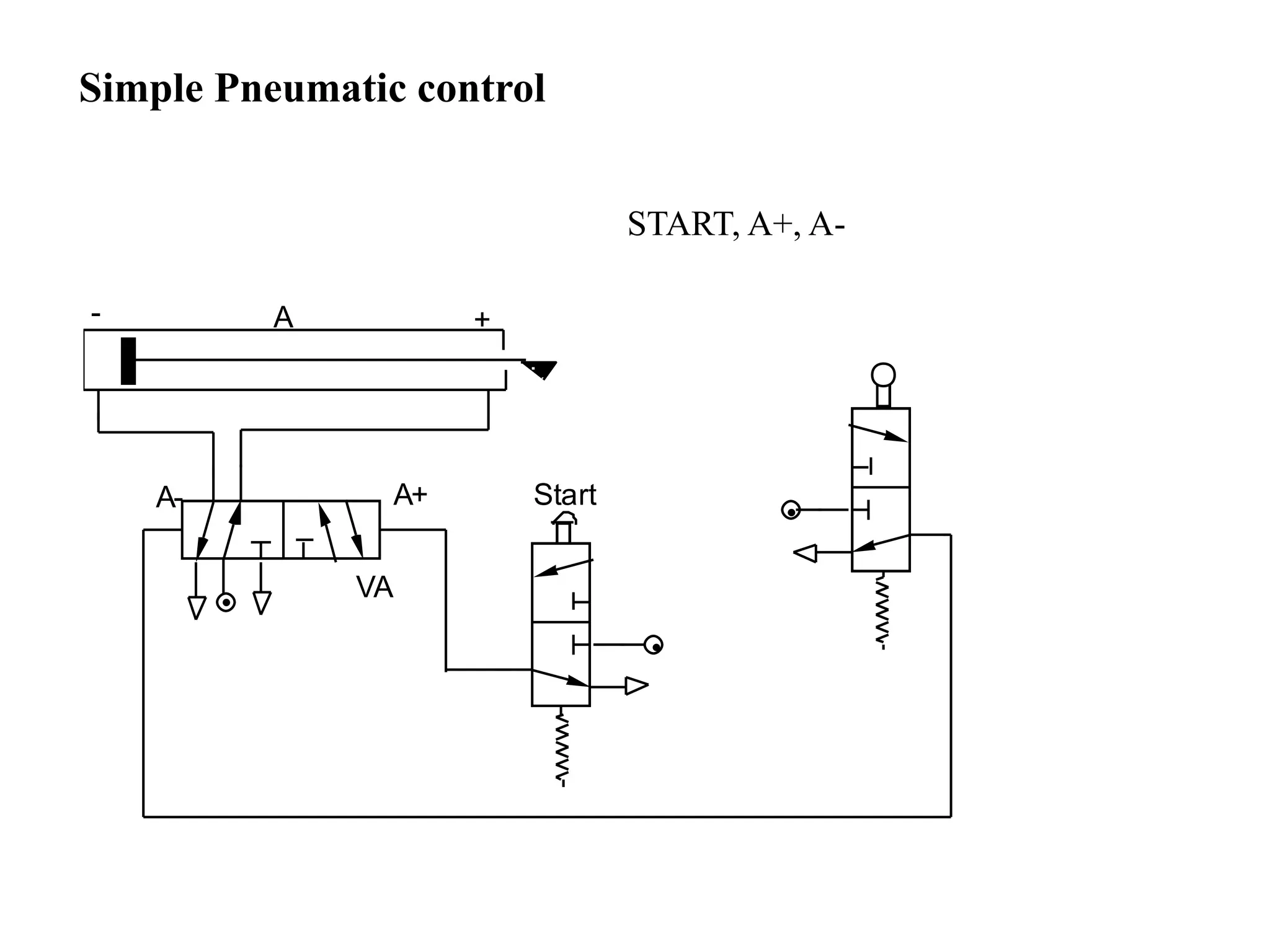

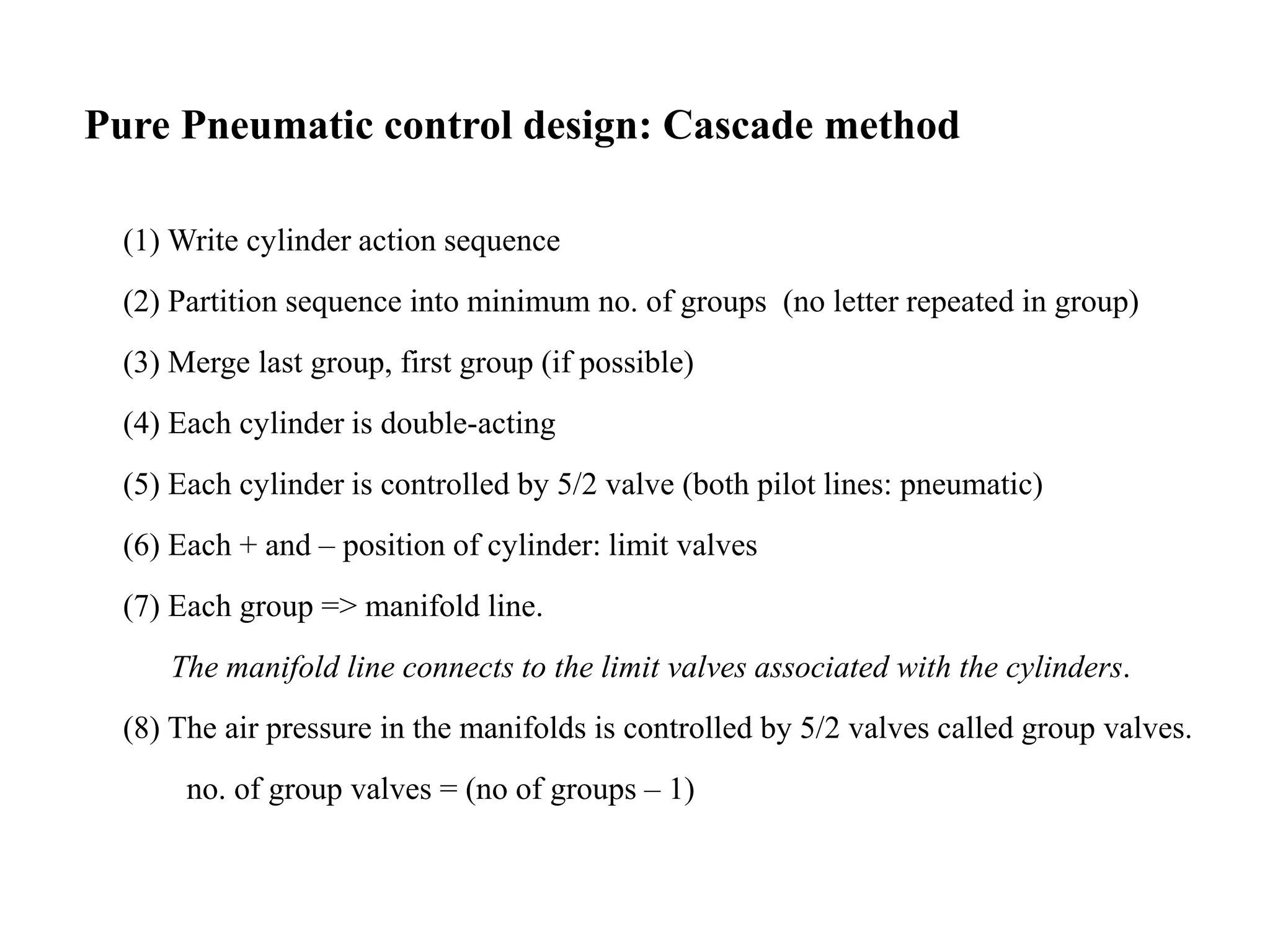

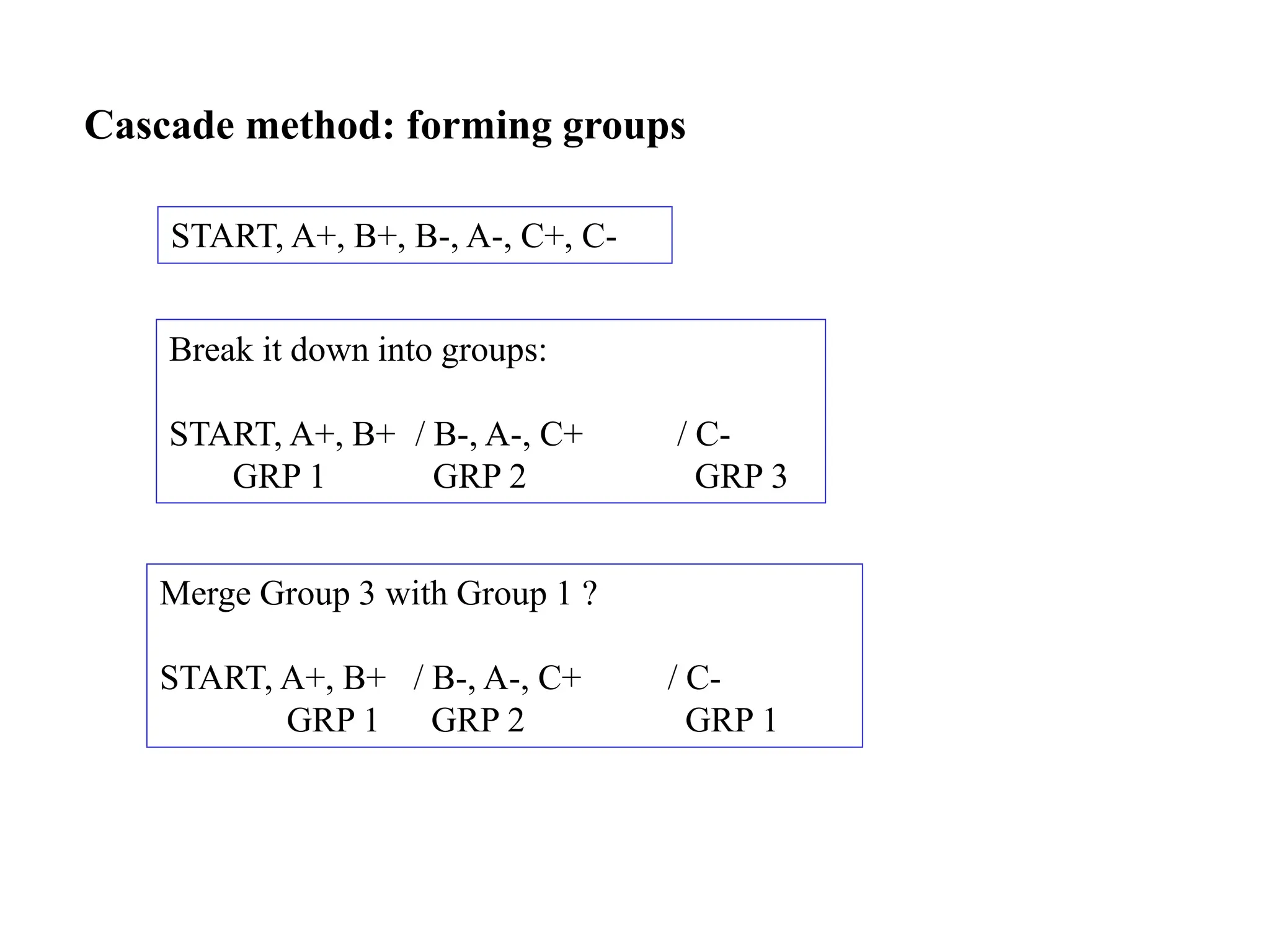

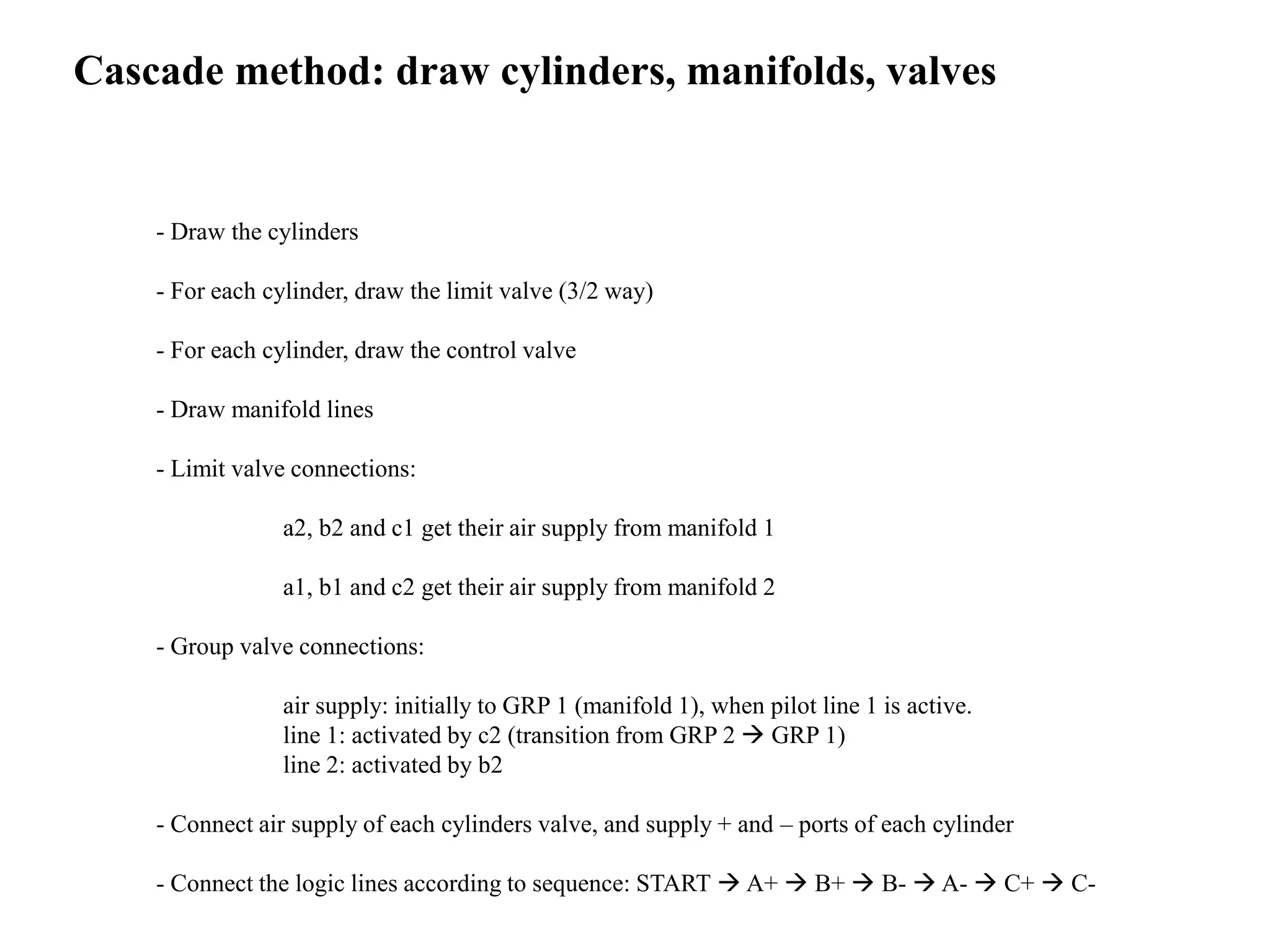

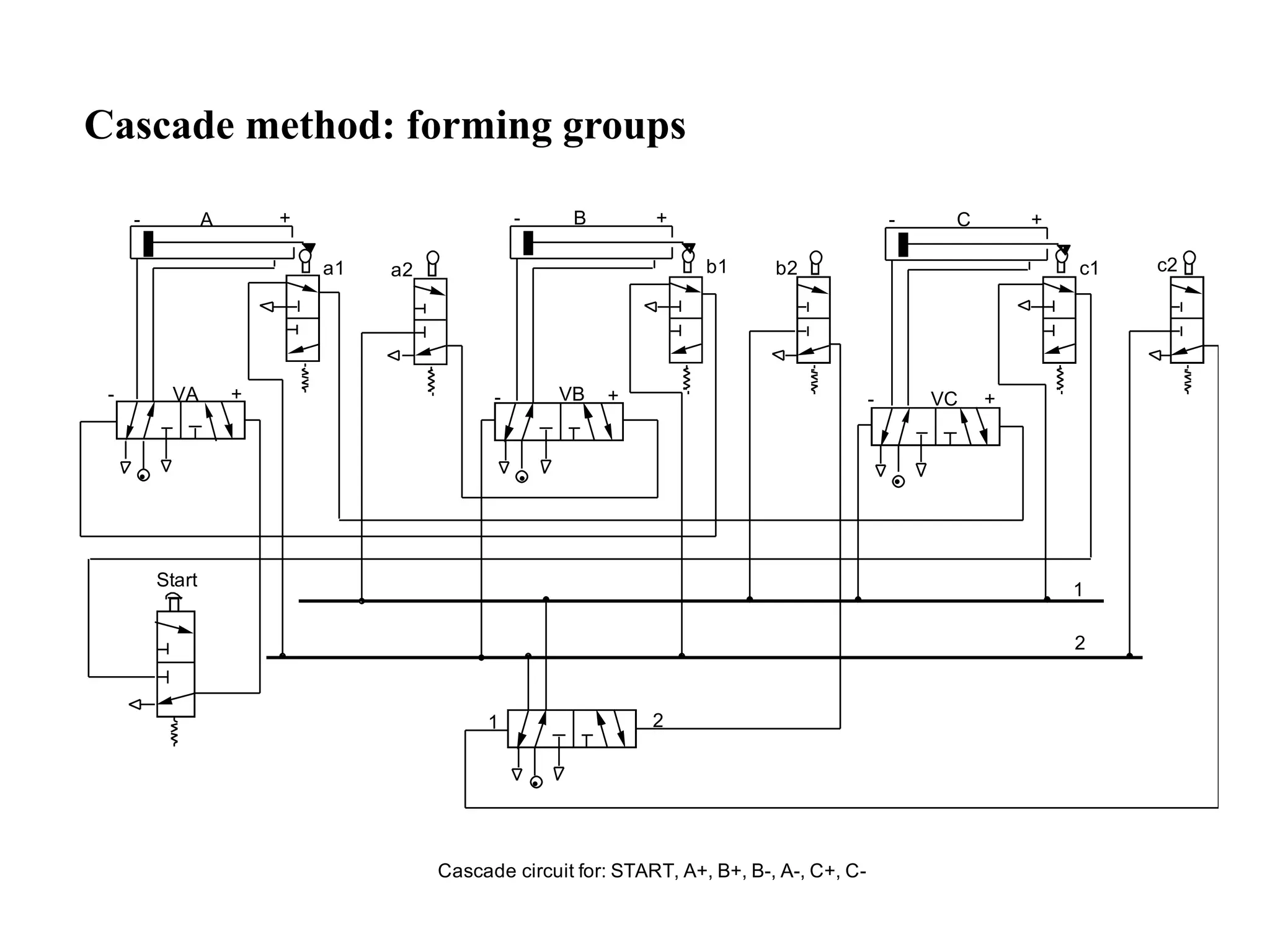

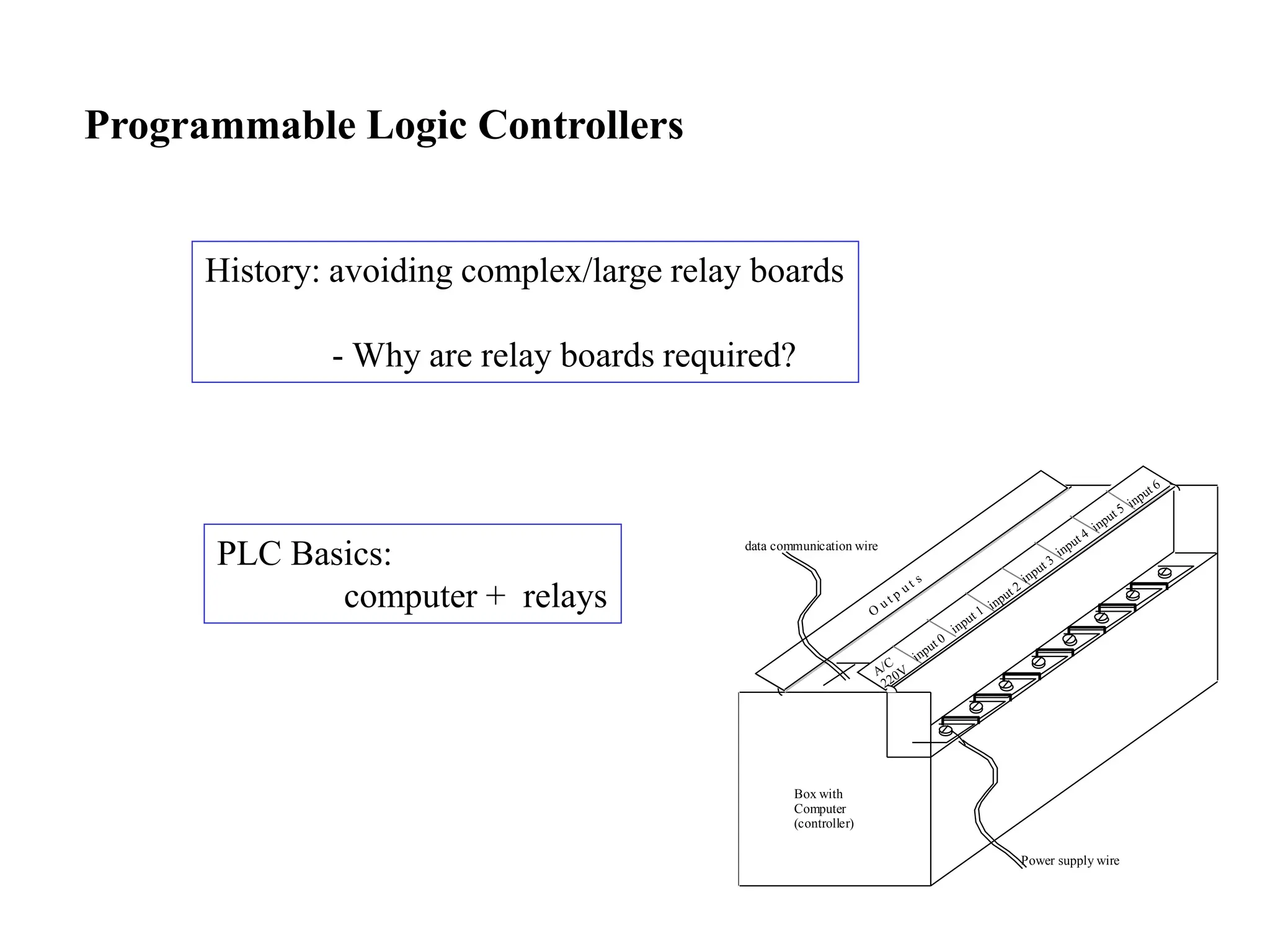

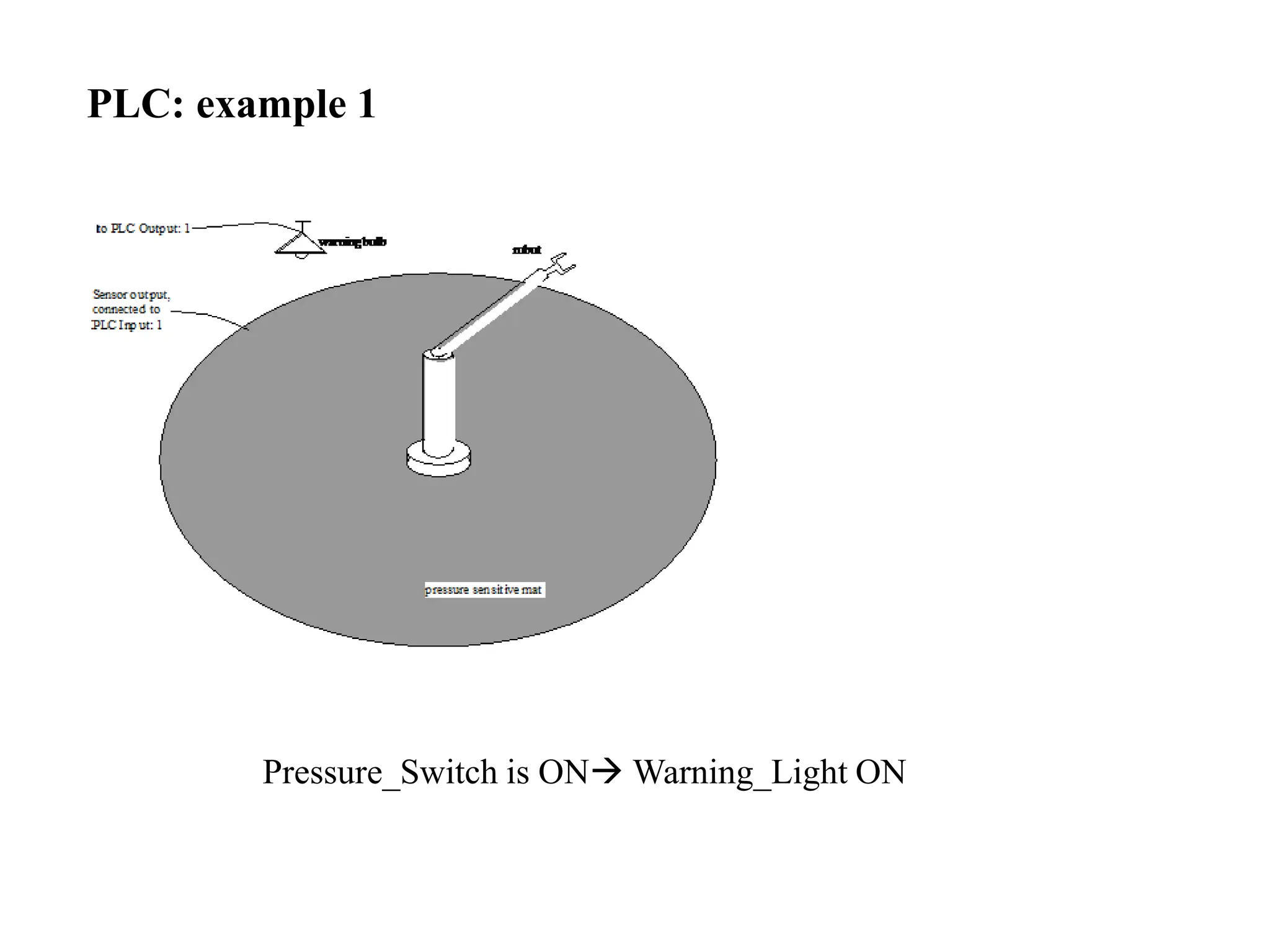

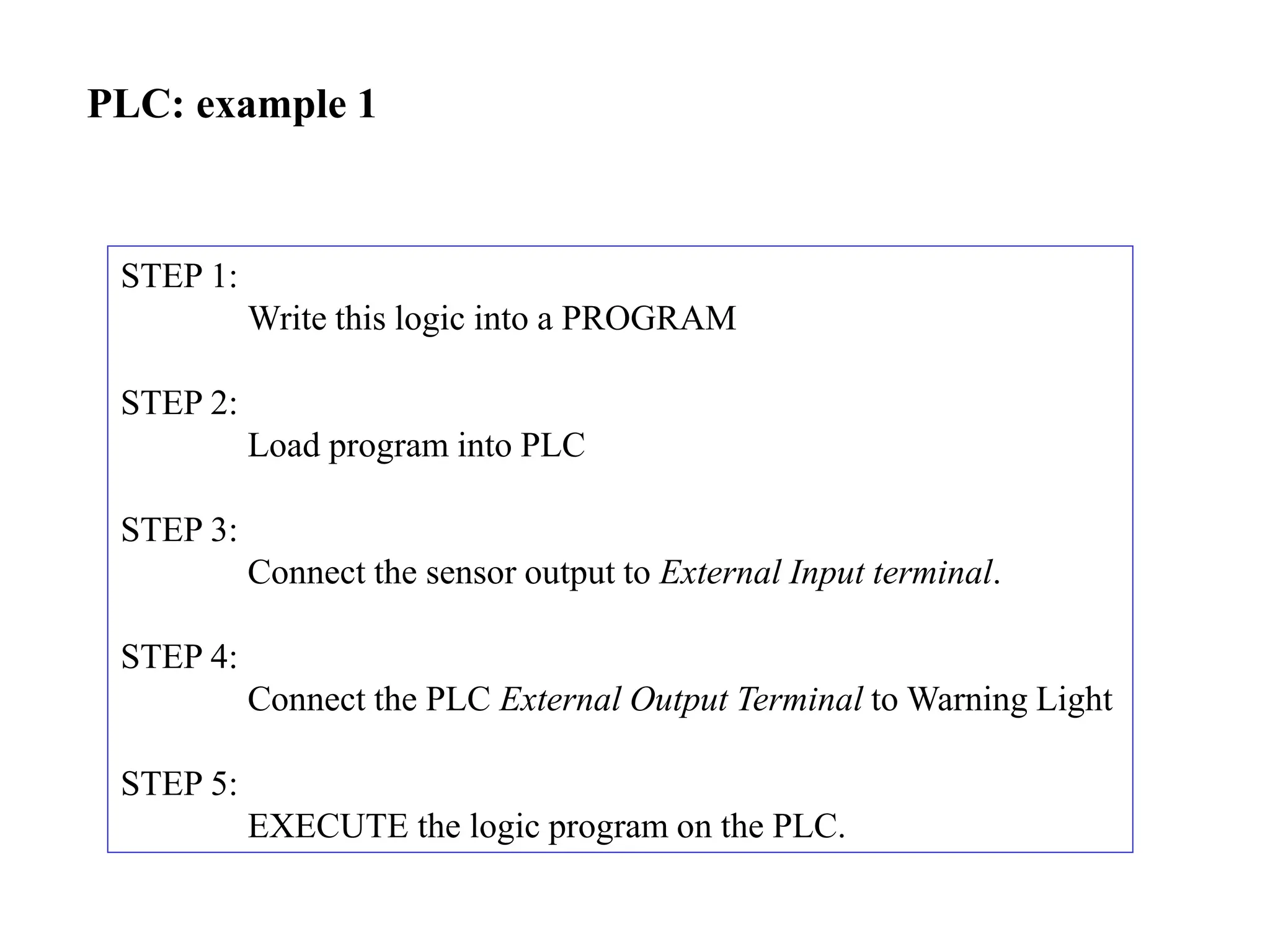

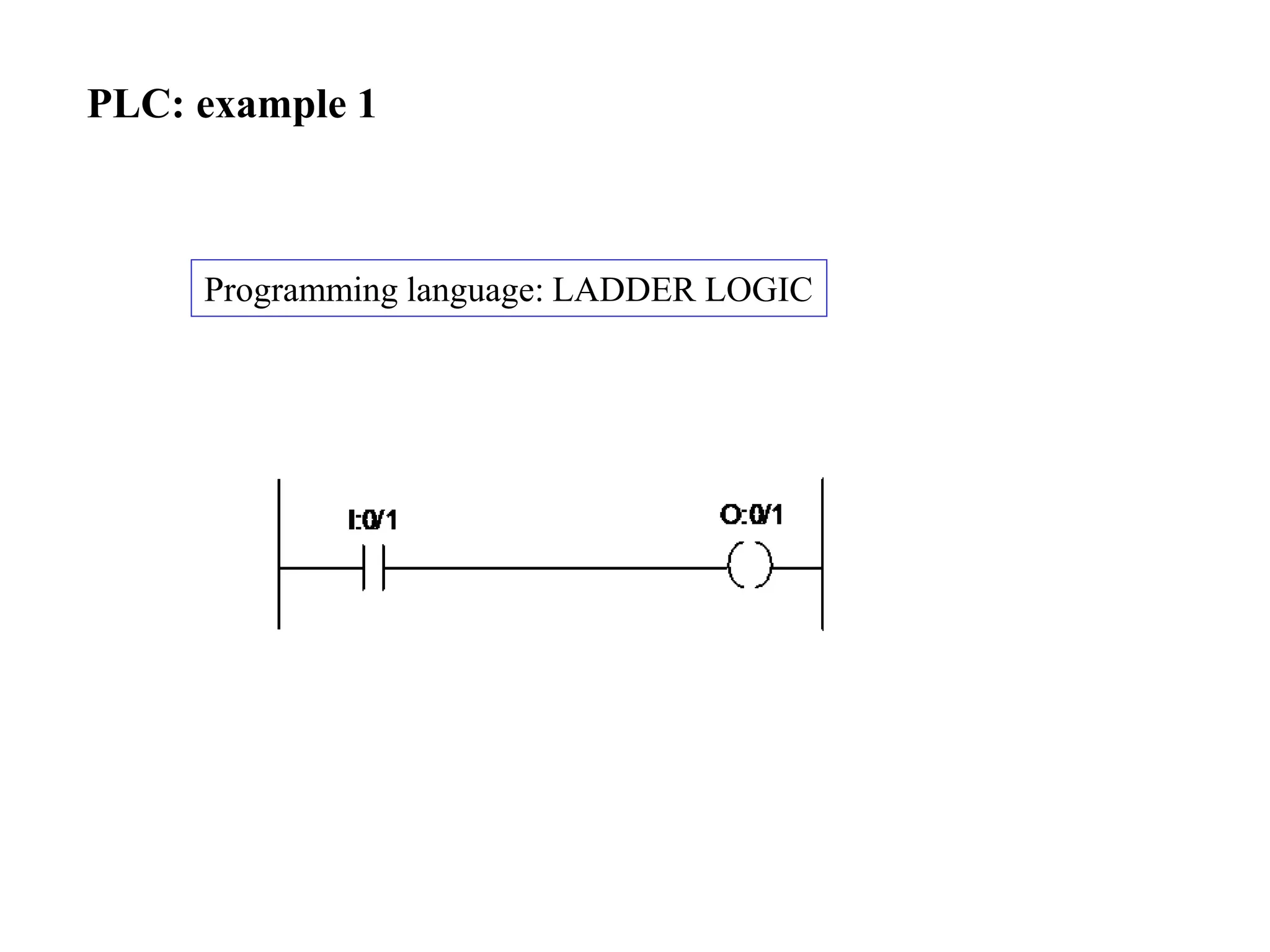

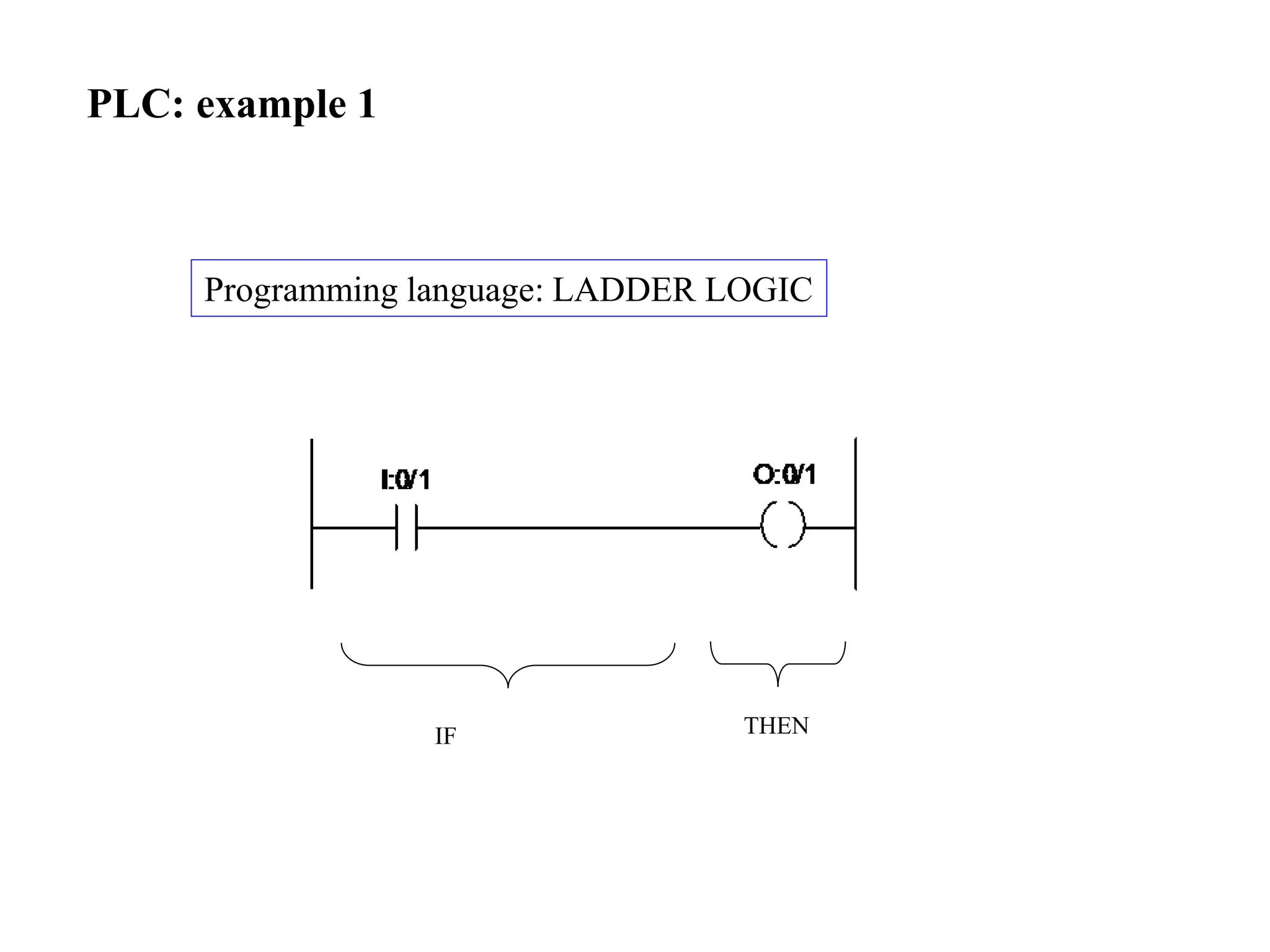

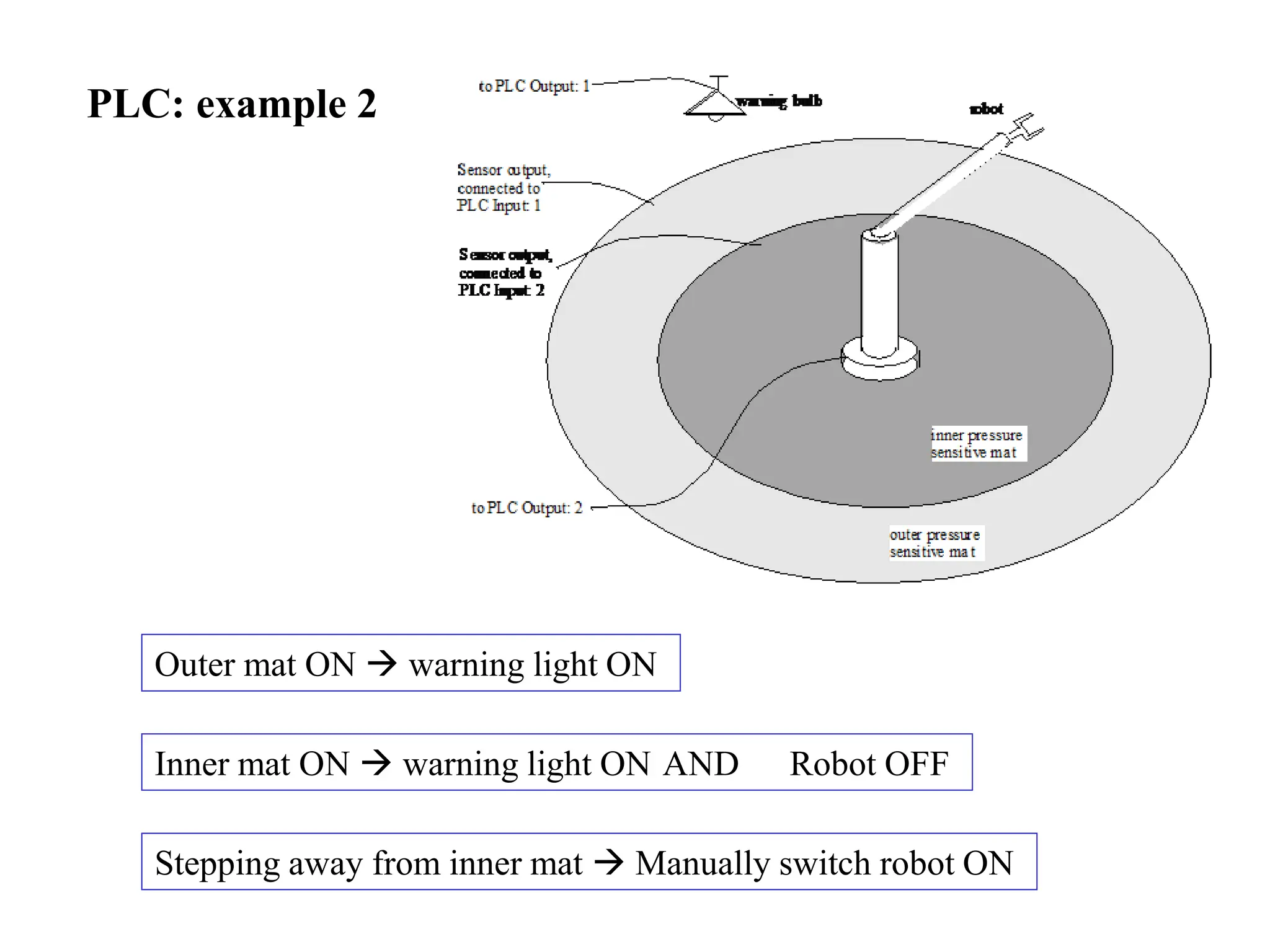

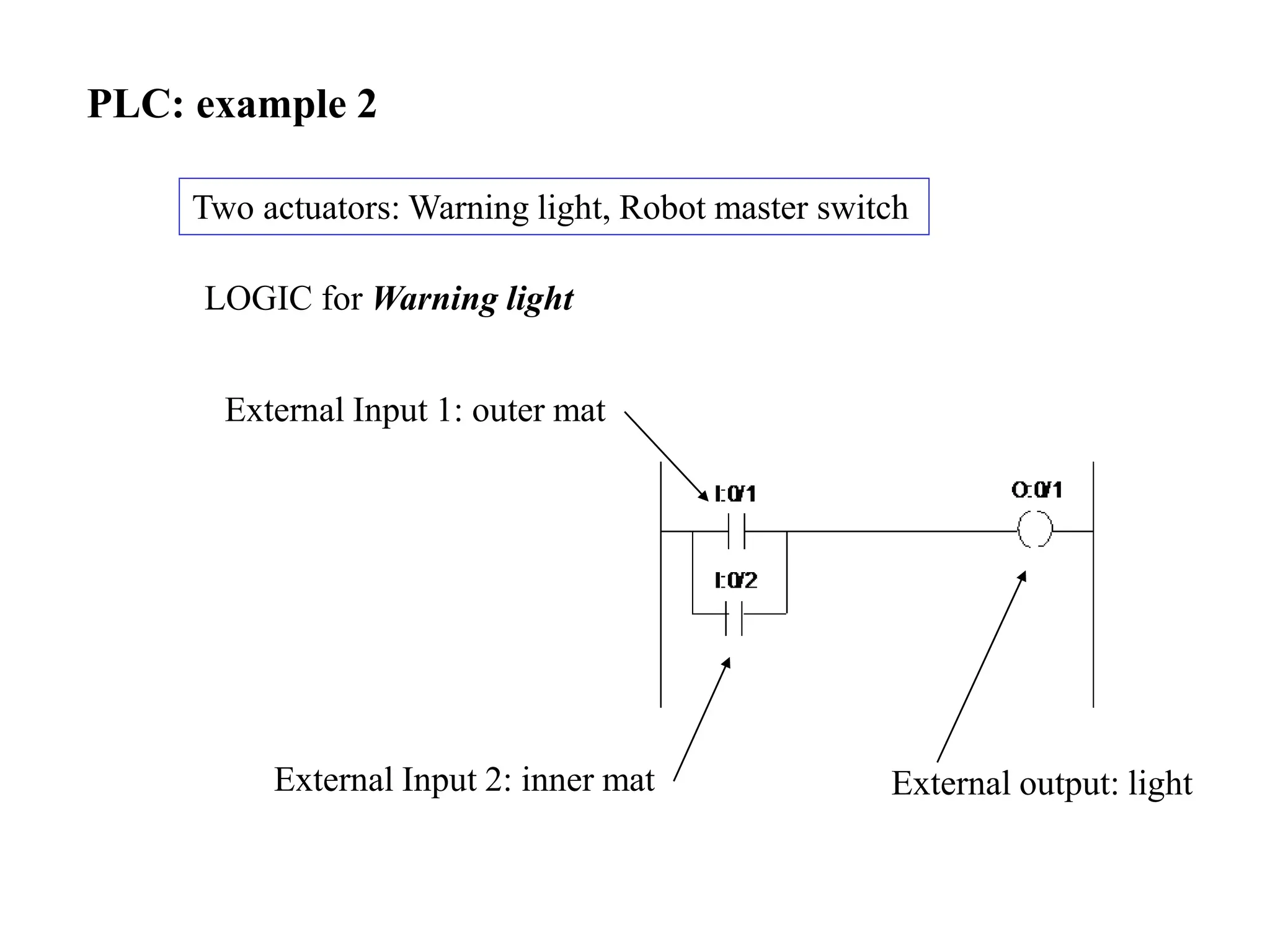

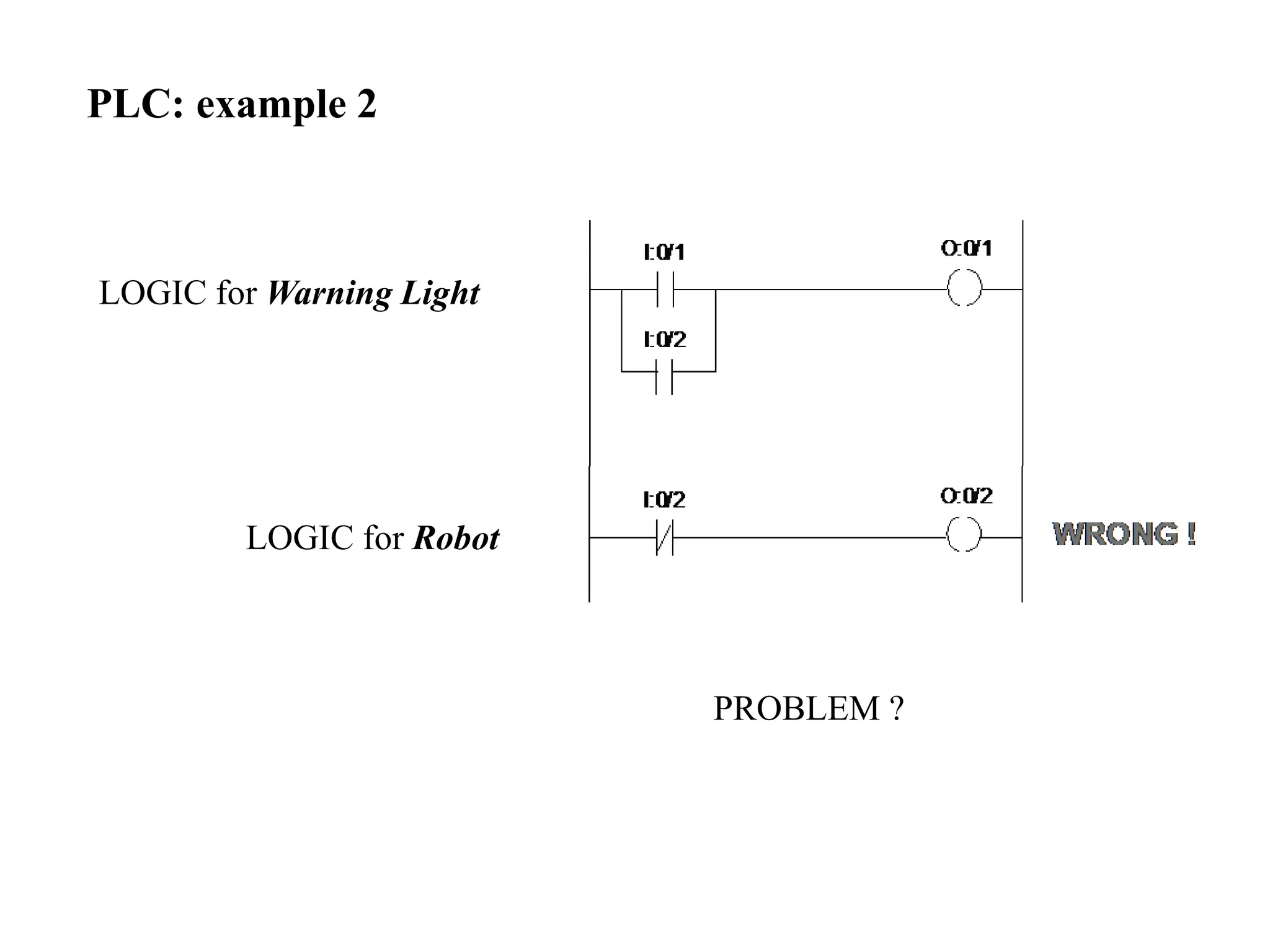

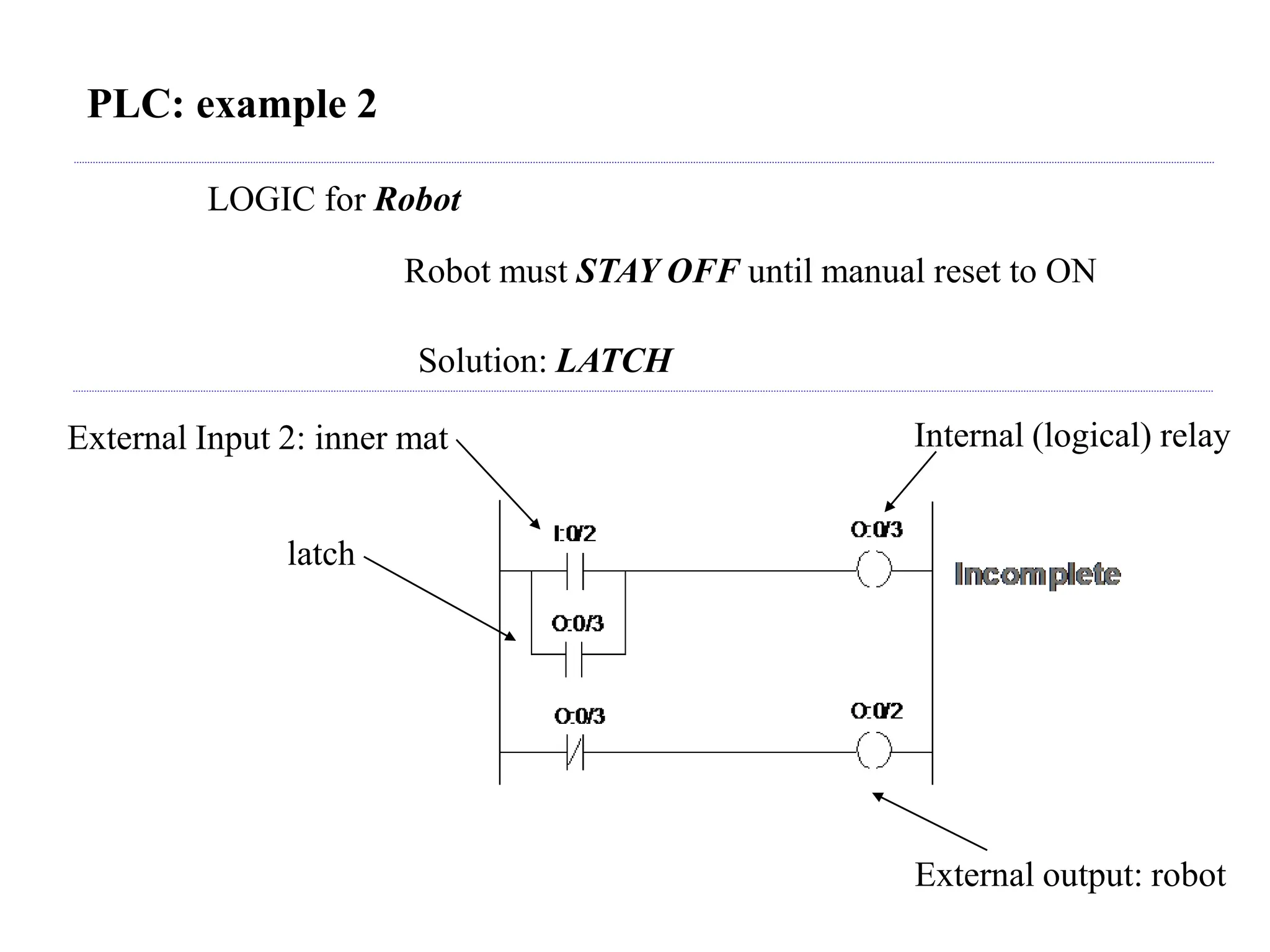

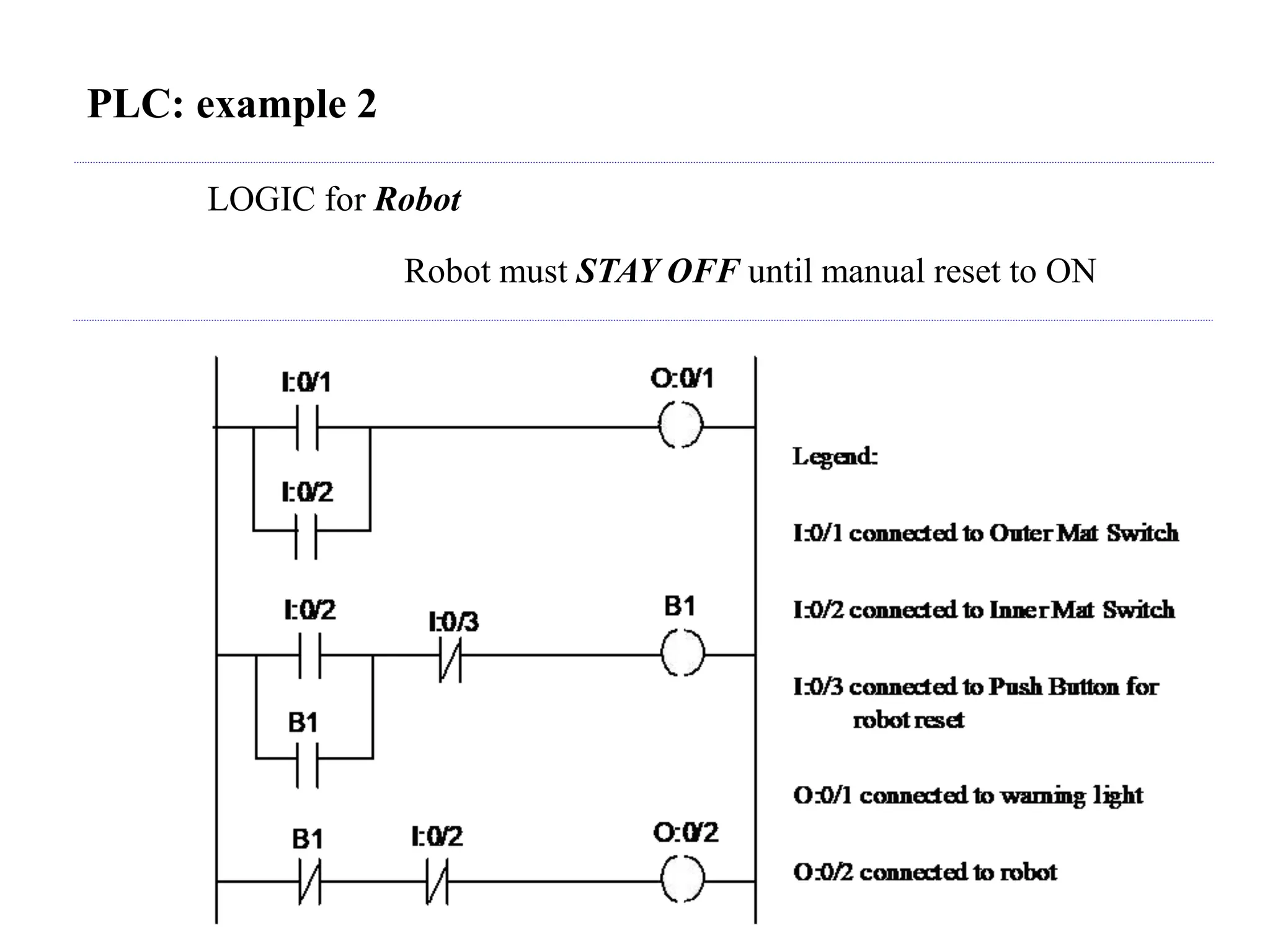

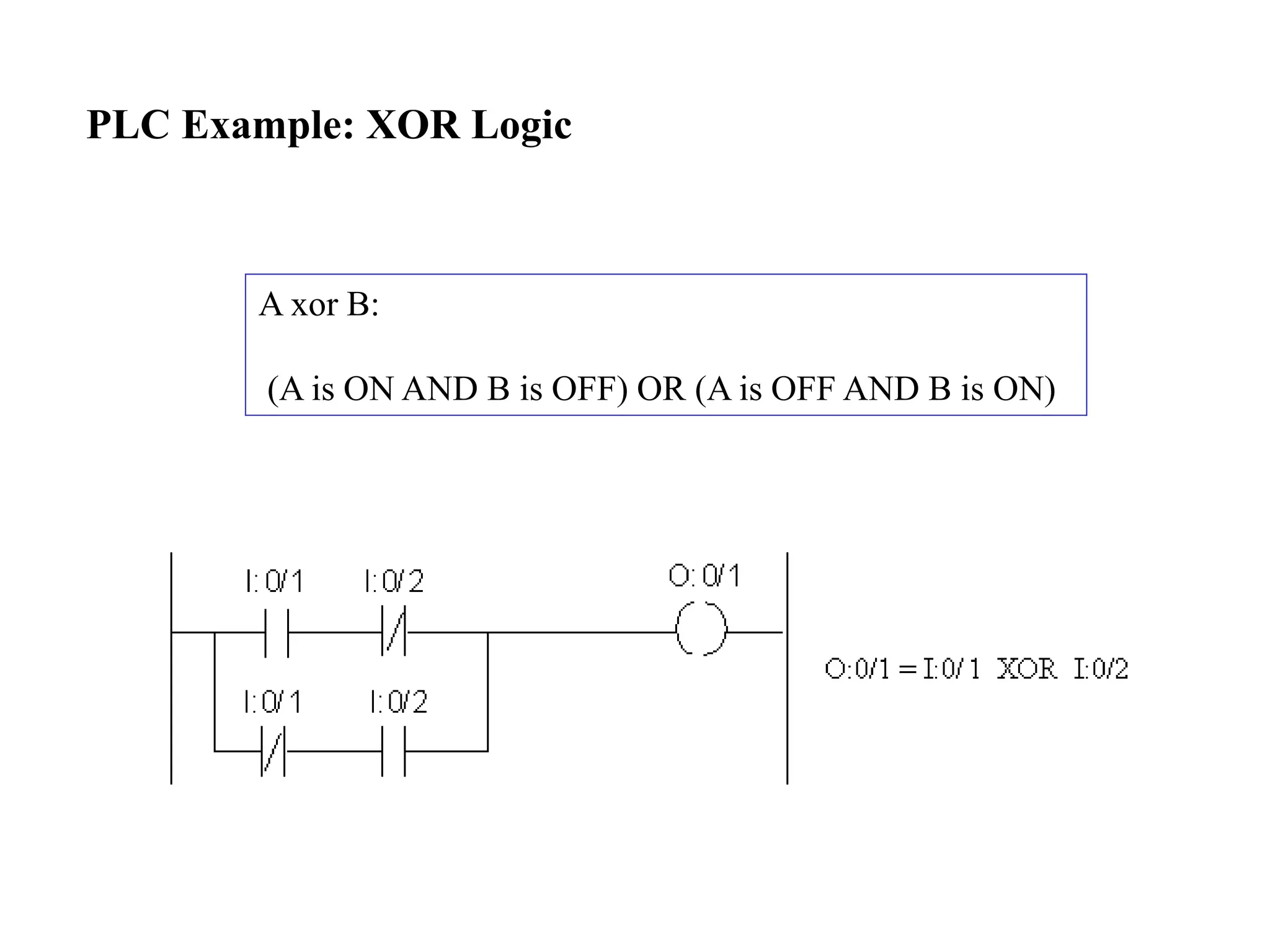

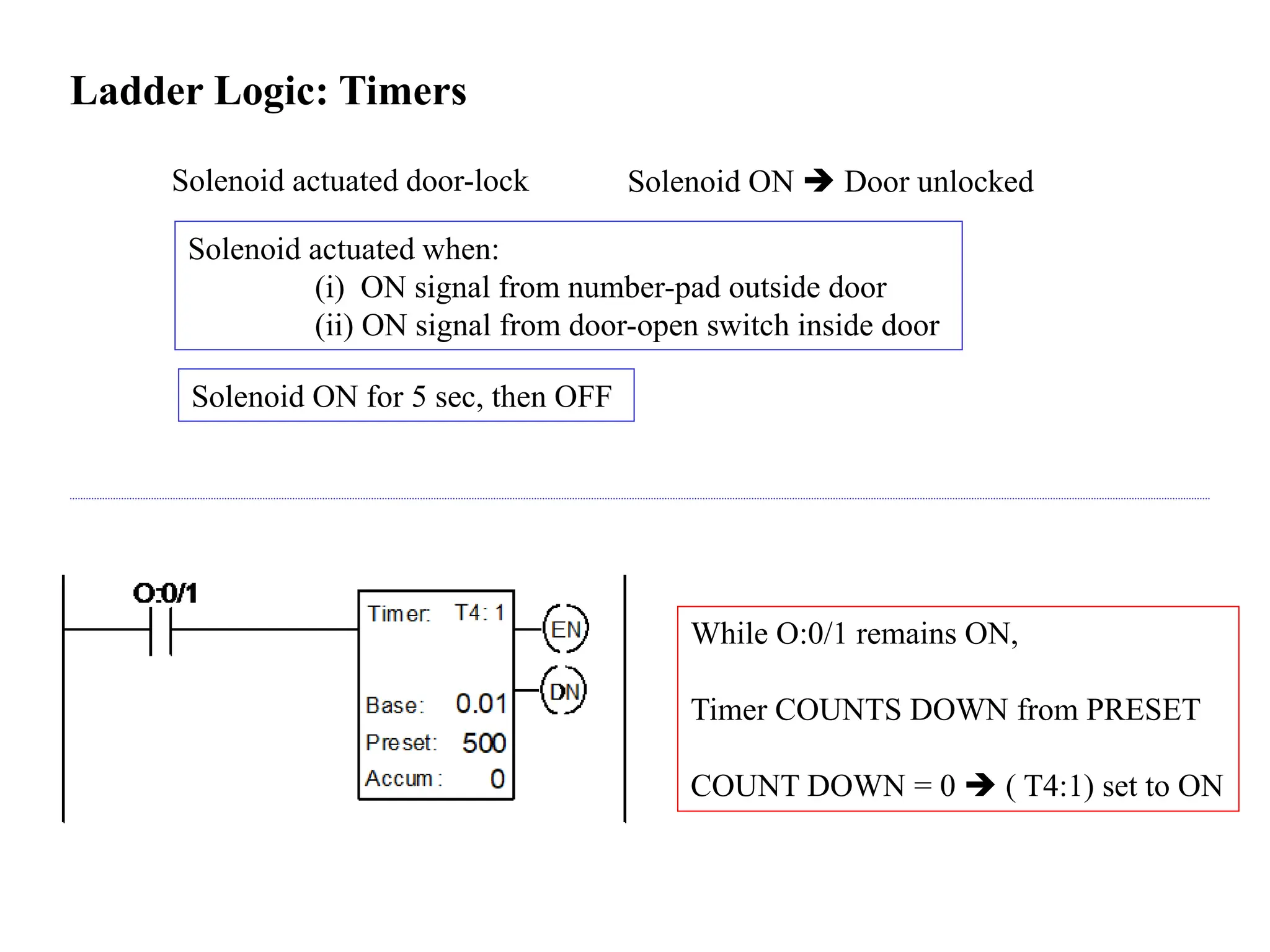

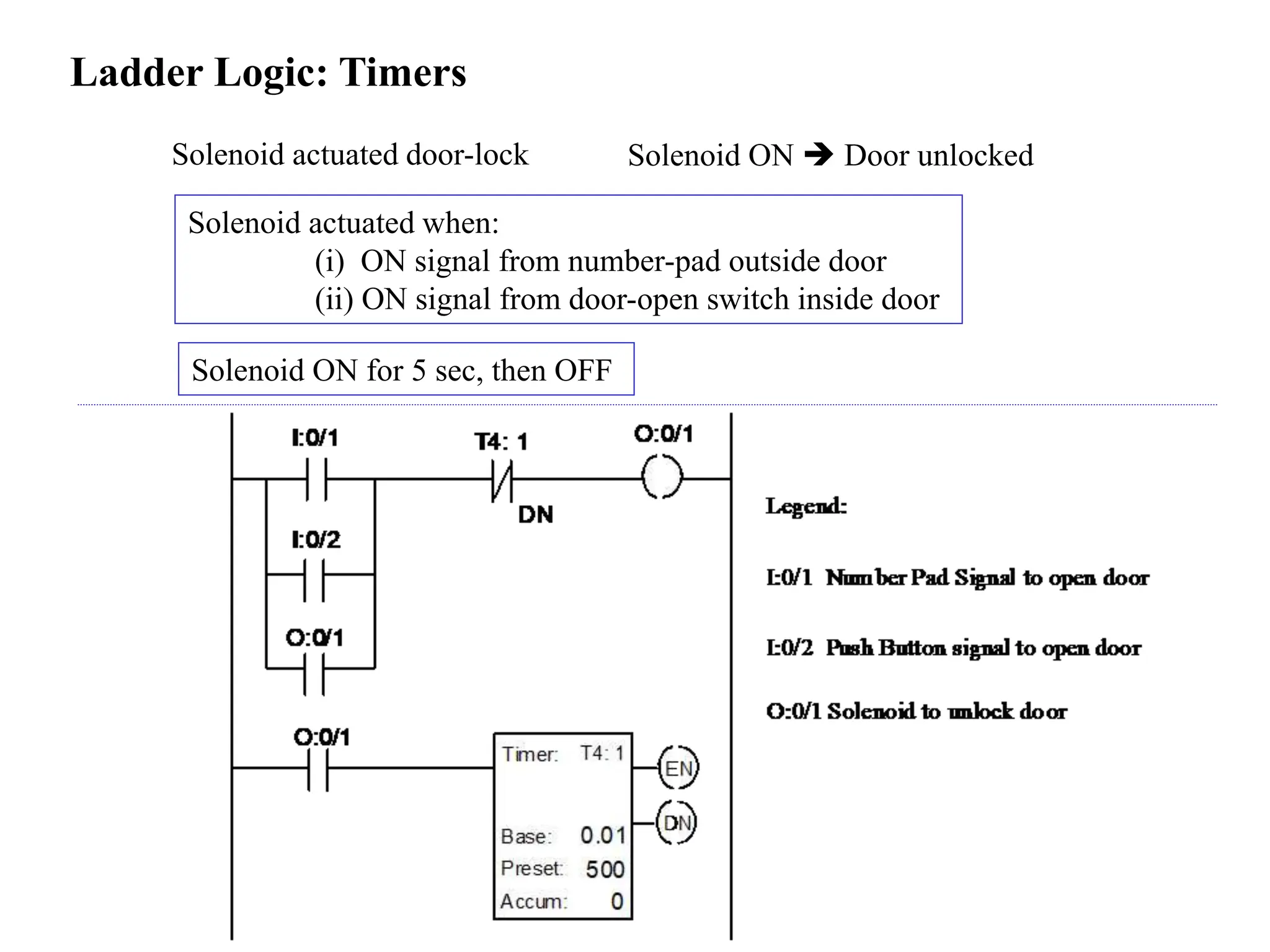

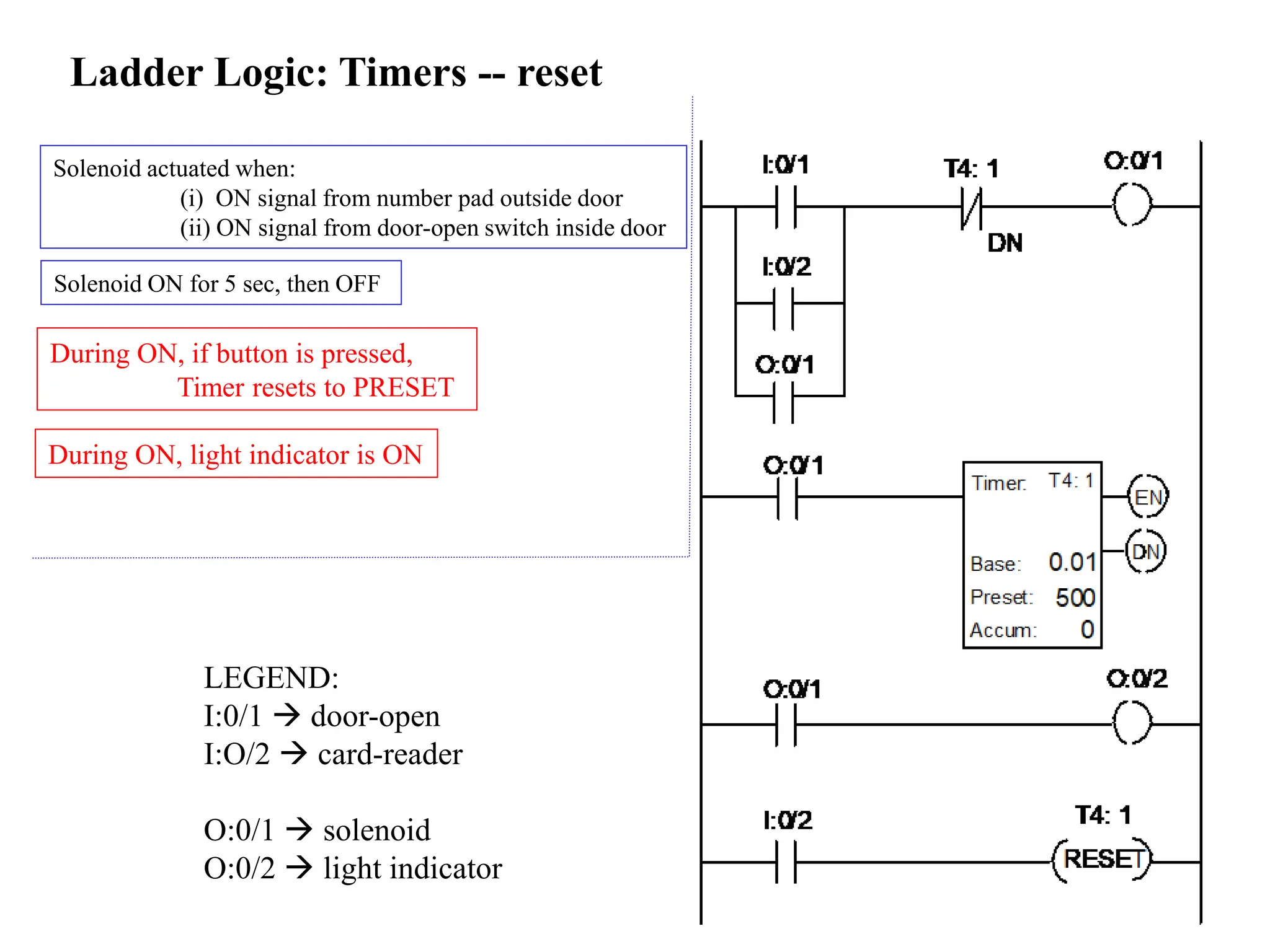

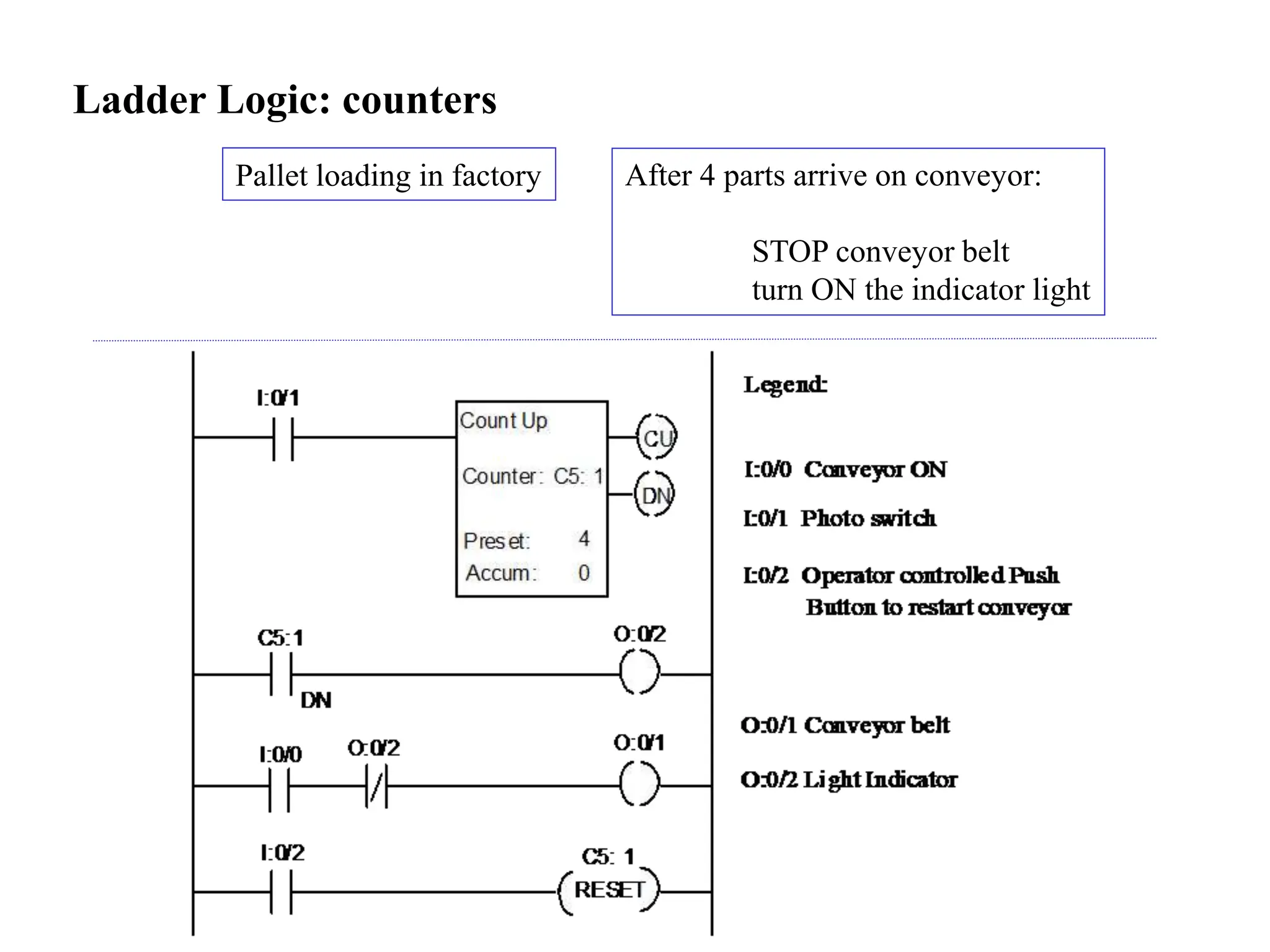

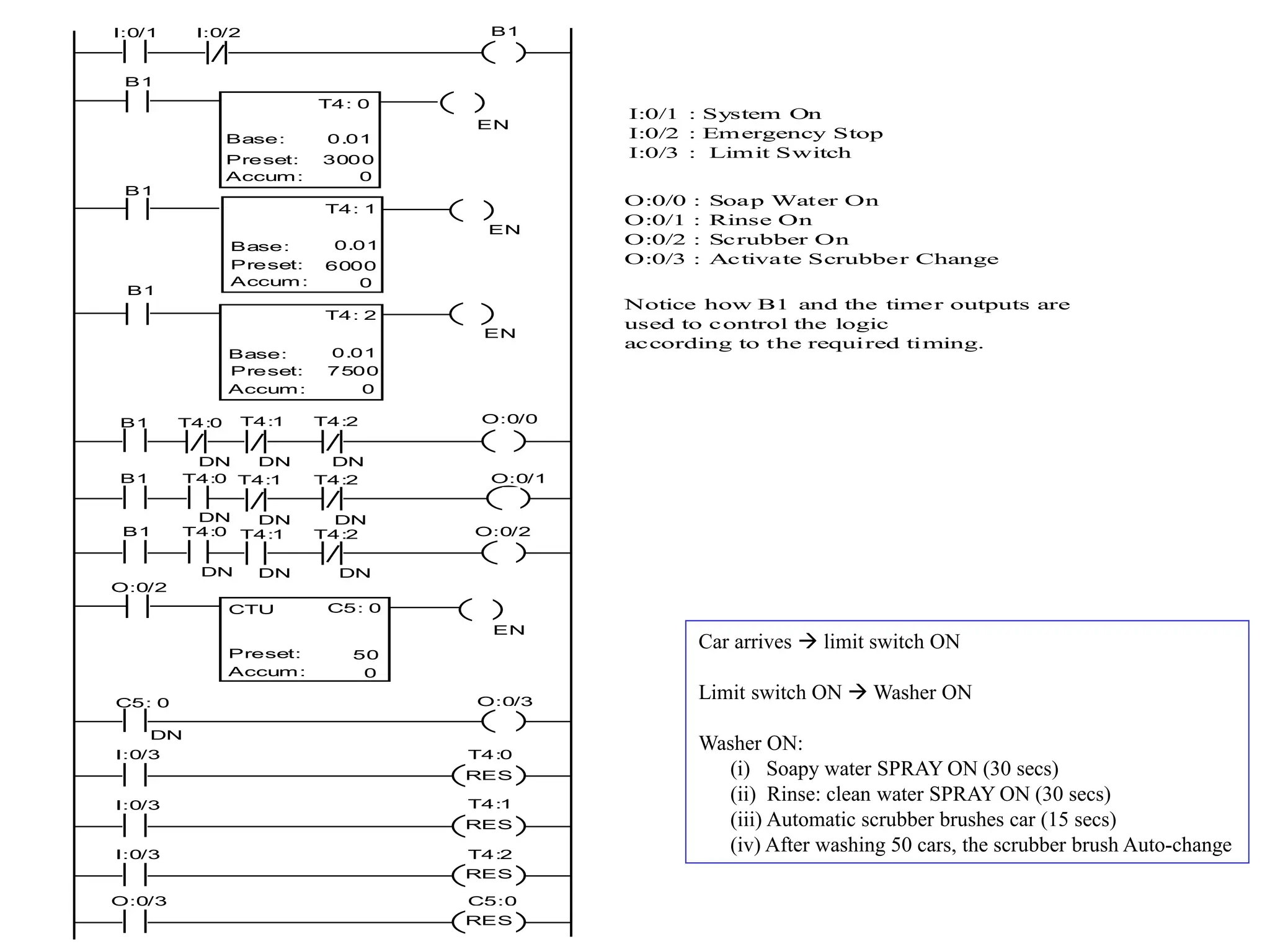

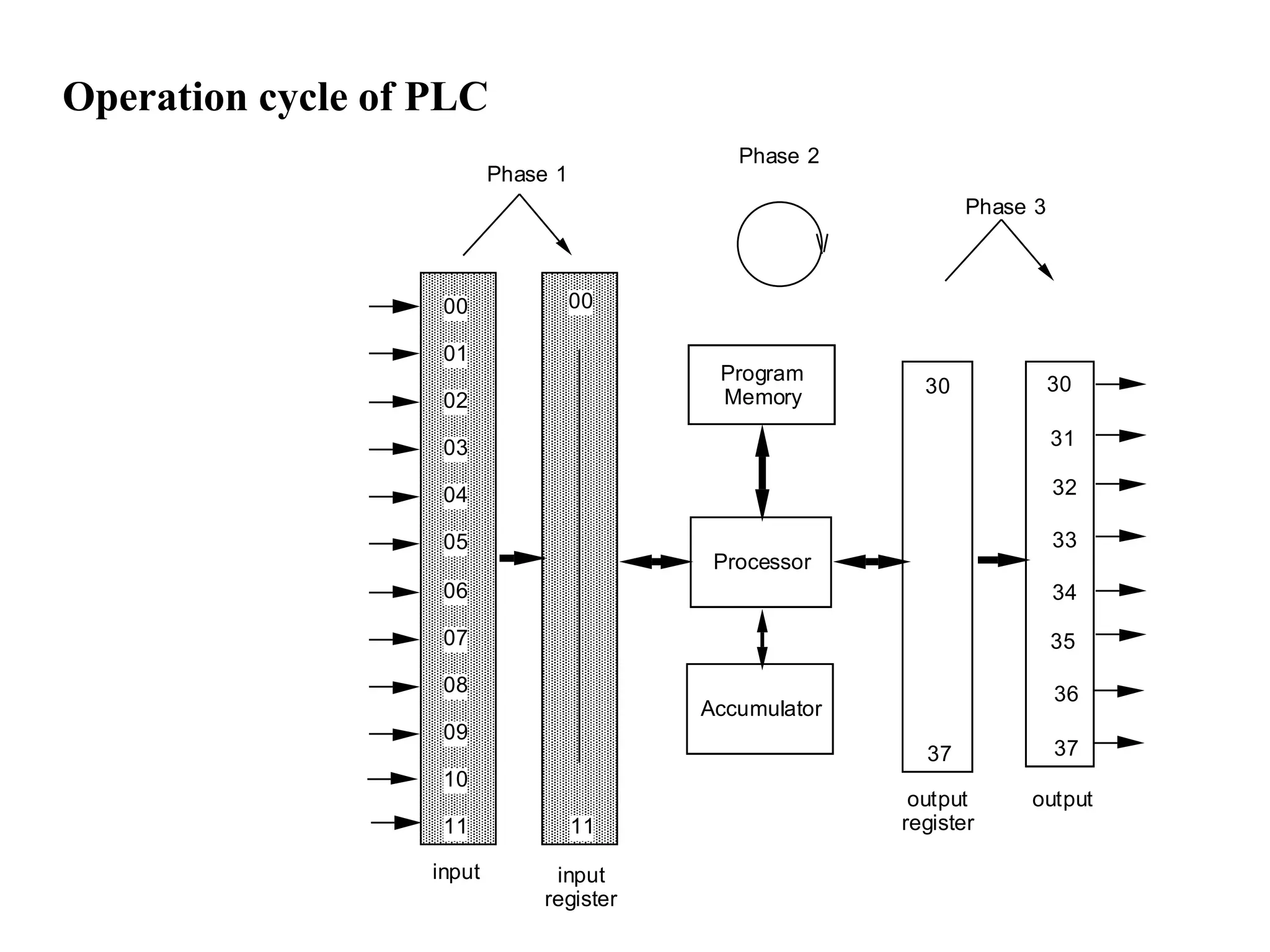

The document describes pneumatic control logic systems, detailing components such as valves, cylinders, and compressors utilized in various operations like punch presses. It explains the cascade method for designing pneumatic systems, as well as the basics and programming of programmable logic controllers (PLCs) for automation. Furthermore, it covers practical examples and logic techniques, including timers and counters for controlling processes like washing cars and operating door locks.