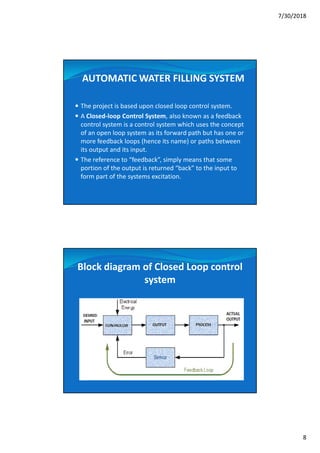

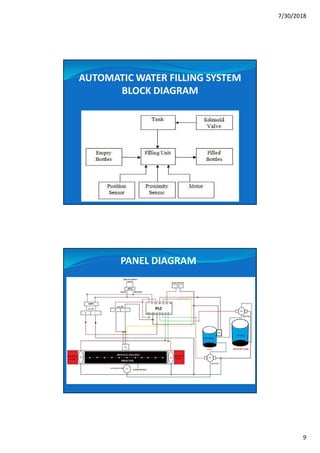

The document discusses the implementation of a PLC-based automatic water filling system, highlighting its objectives, types of automation, and operational principles. It details the components, wiring, and process flow, emphasizing the system's efficiency and applicability in various industries. The report concludes with a successful implementation and reflections on gained knowledge in automation.