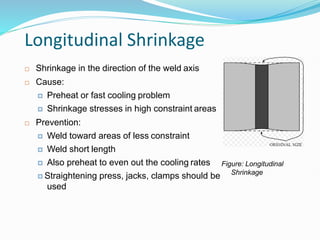

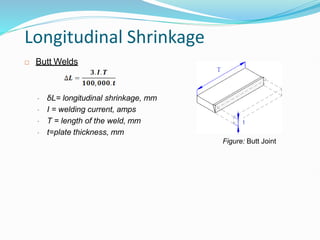

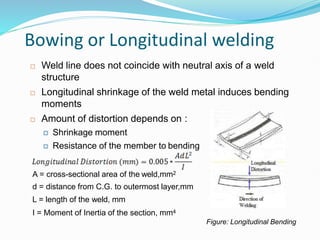

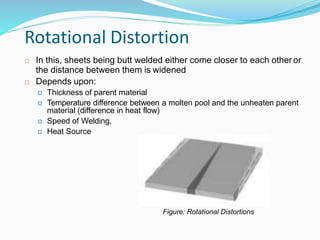

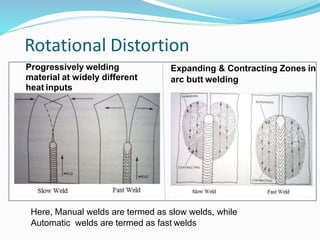

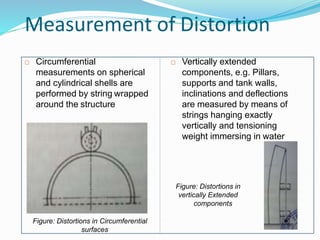

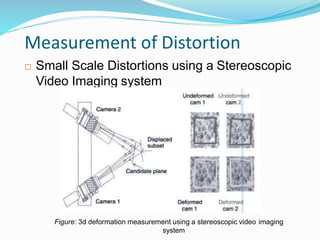

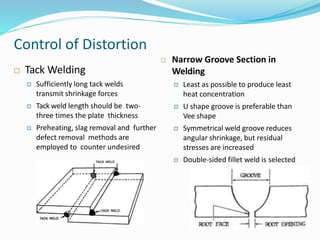

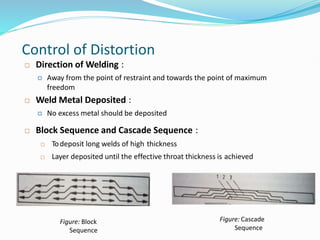

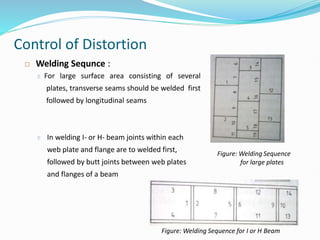

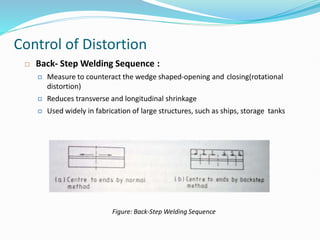

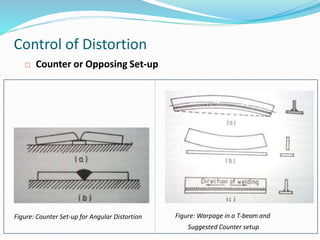

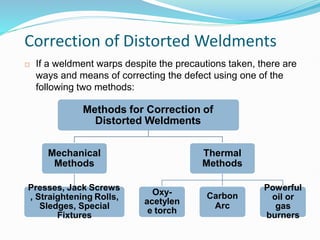

The document discusses the causes, effects, and control of distortion in welding, highlighting factors such as material properties and welding processes that contribute to unwanted physical changes in fabricated components. It covers various types of welding distortions including longitudinal and transverse shrinkage, angular distortion, and methods for measuring and correcting these distortions. Future advancements in distortion measurement using artificial neural networks and mechanized techniques are also mentioned.