The document summarizes key aspects of welding design for manufacturability including:

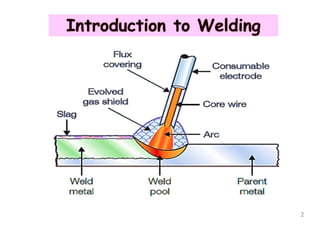

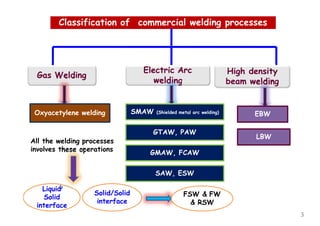

1. It classifies common welding processes and discusses factors like heat input, efficiency, and microstructural changes during welding.

2. It provides guidelines for designers like using fewer welded parts, ensuring proper joint fit-up and access, and specifying minimum weld sizes.

3. It discusses how to minimize distortion, residual stresses, and defects through techniques like multi-pass welding and preheating.