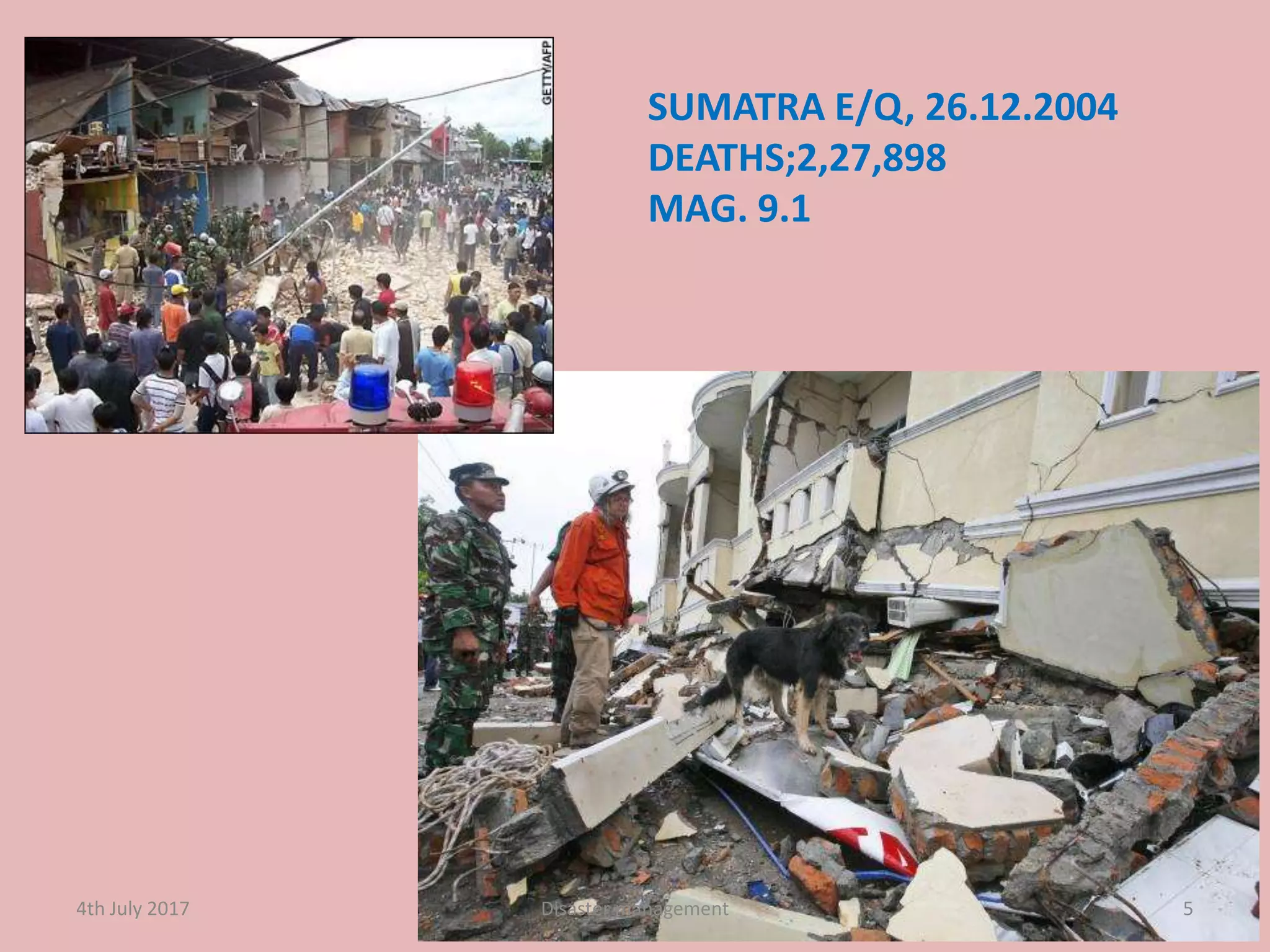

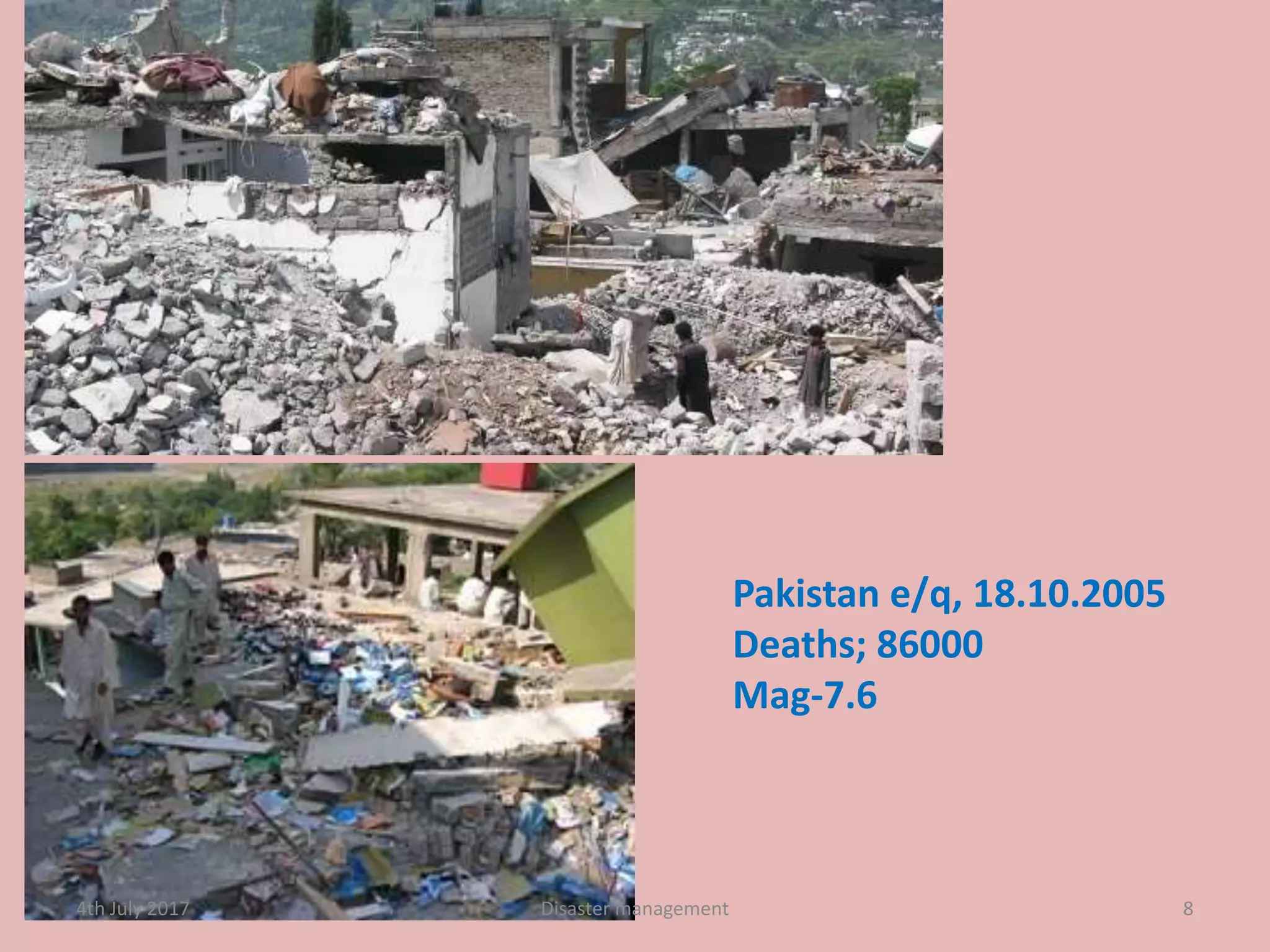

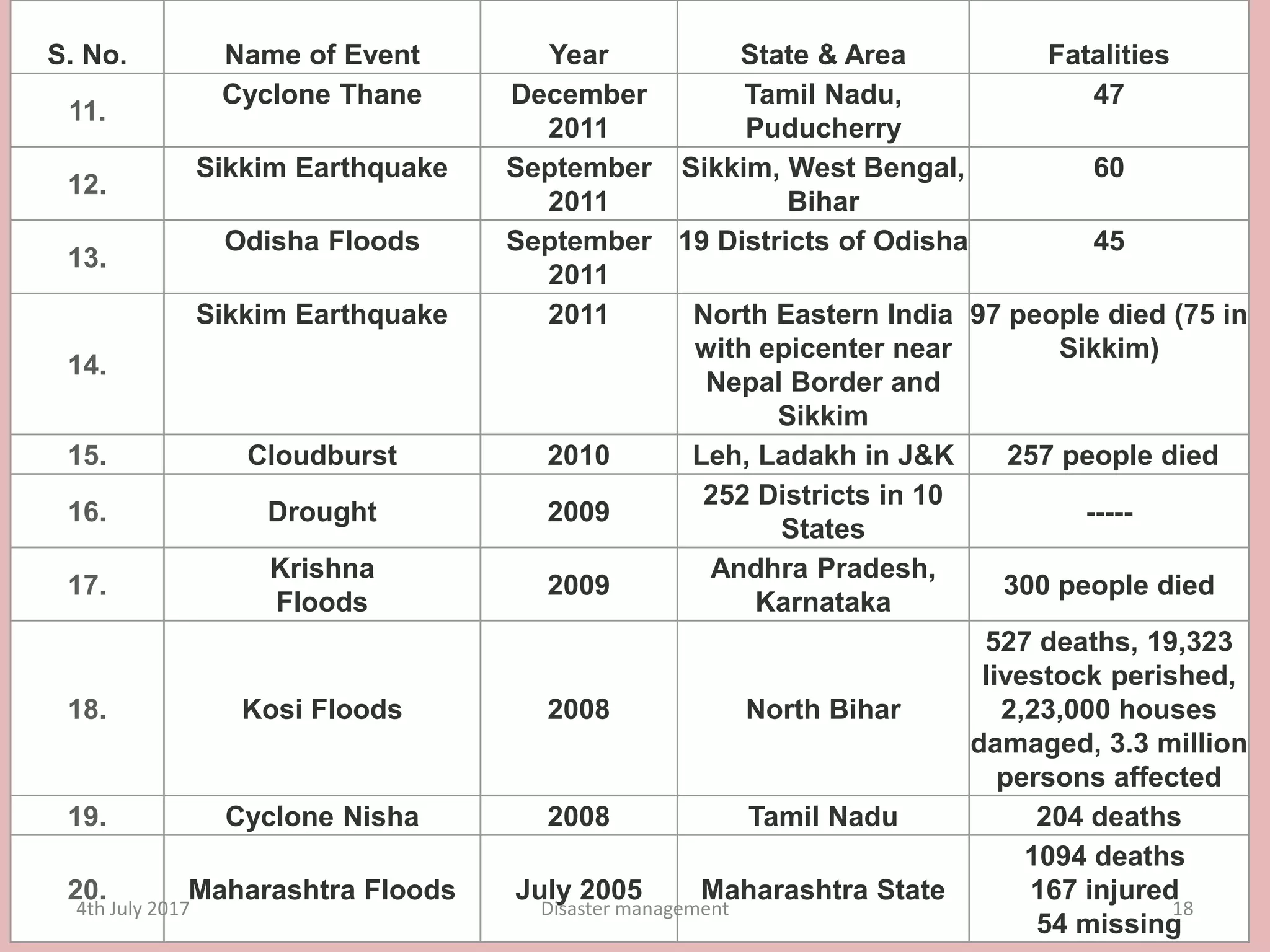

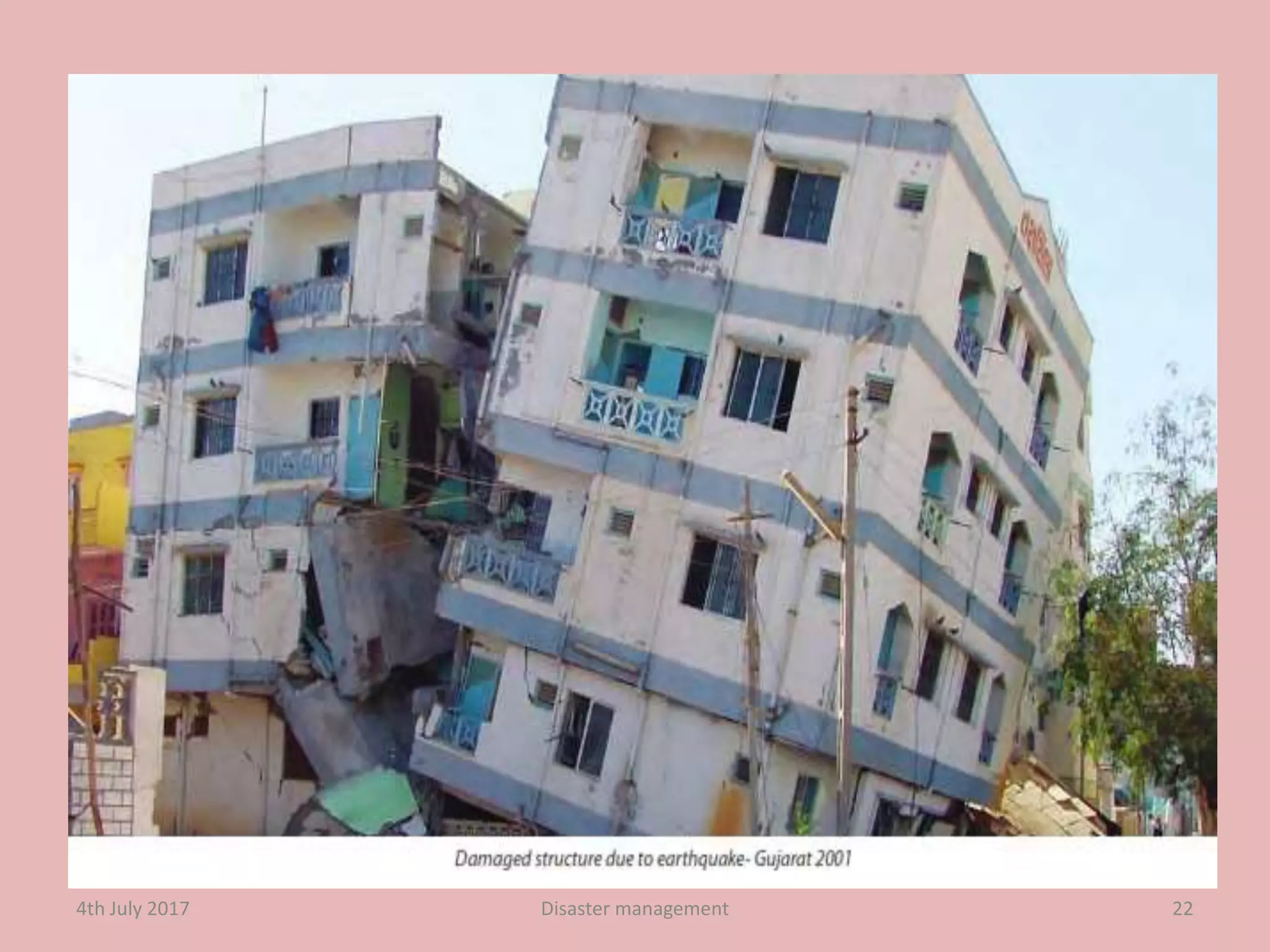

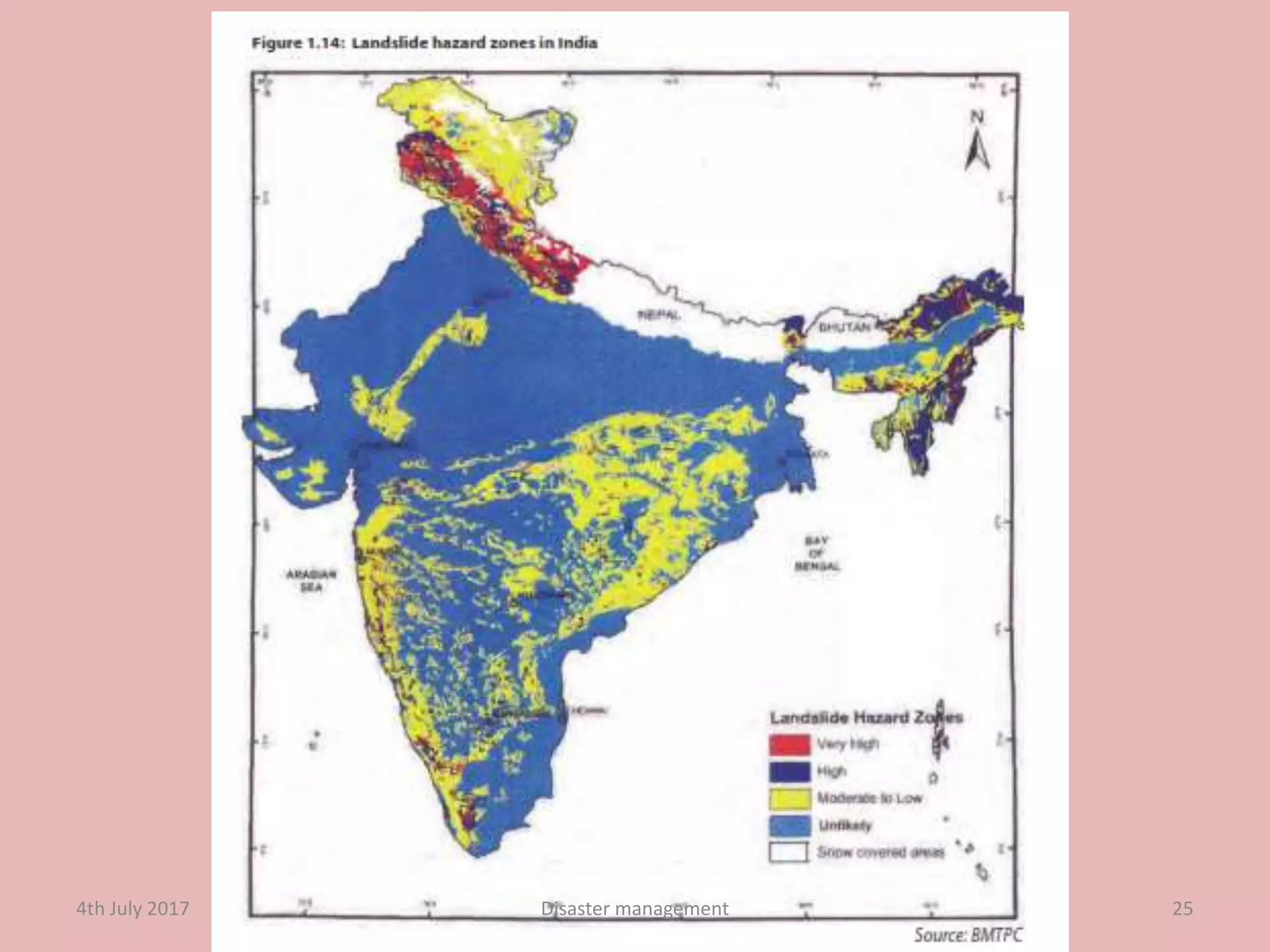

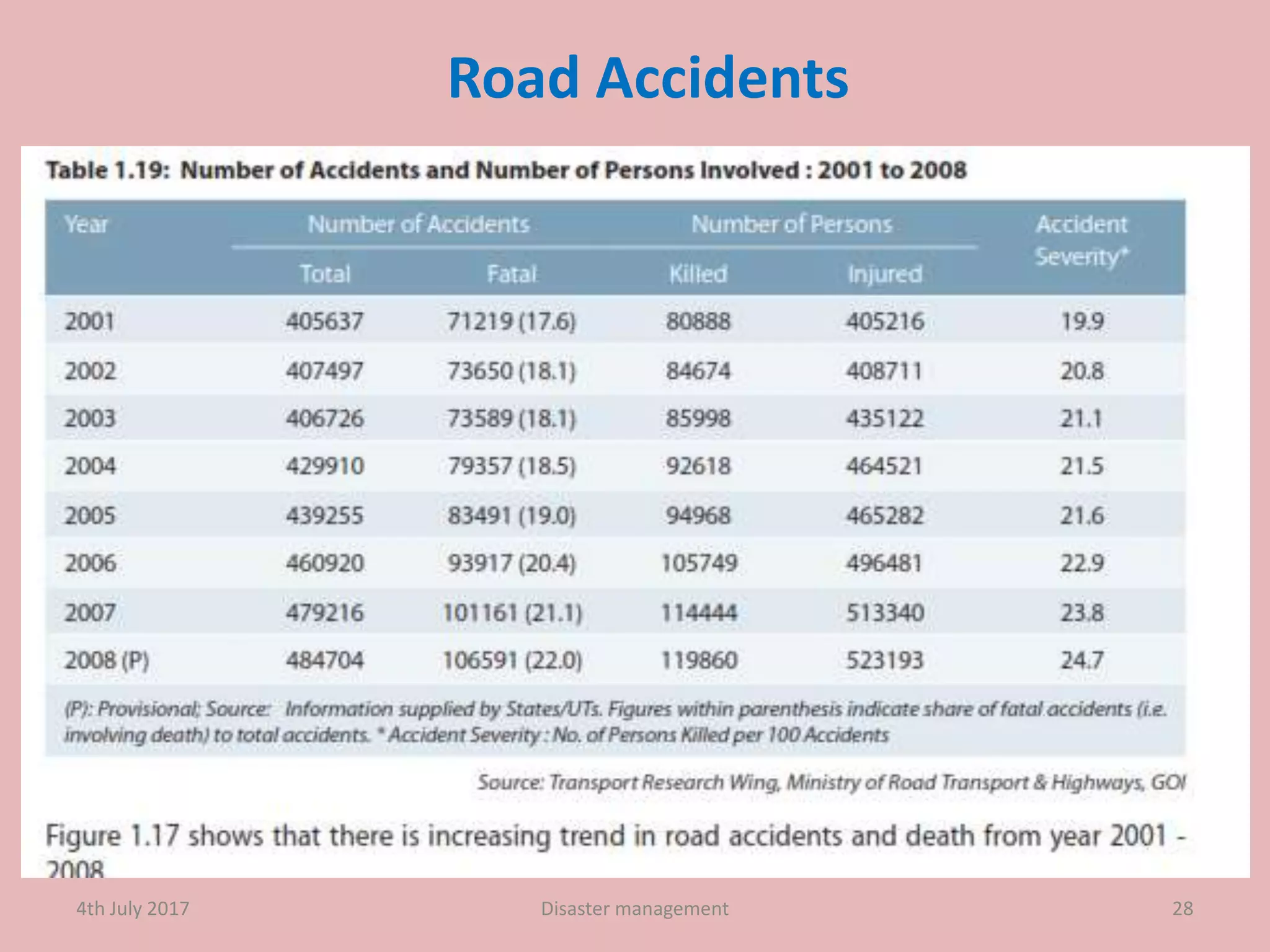

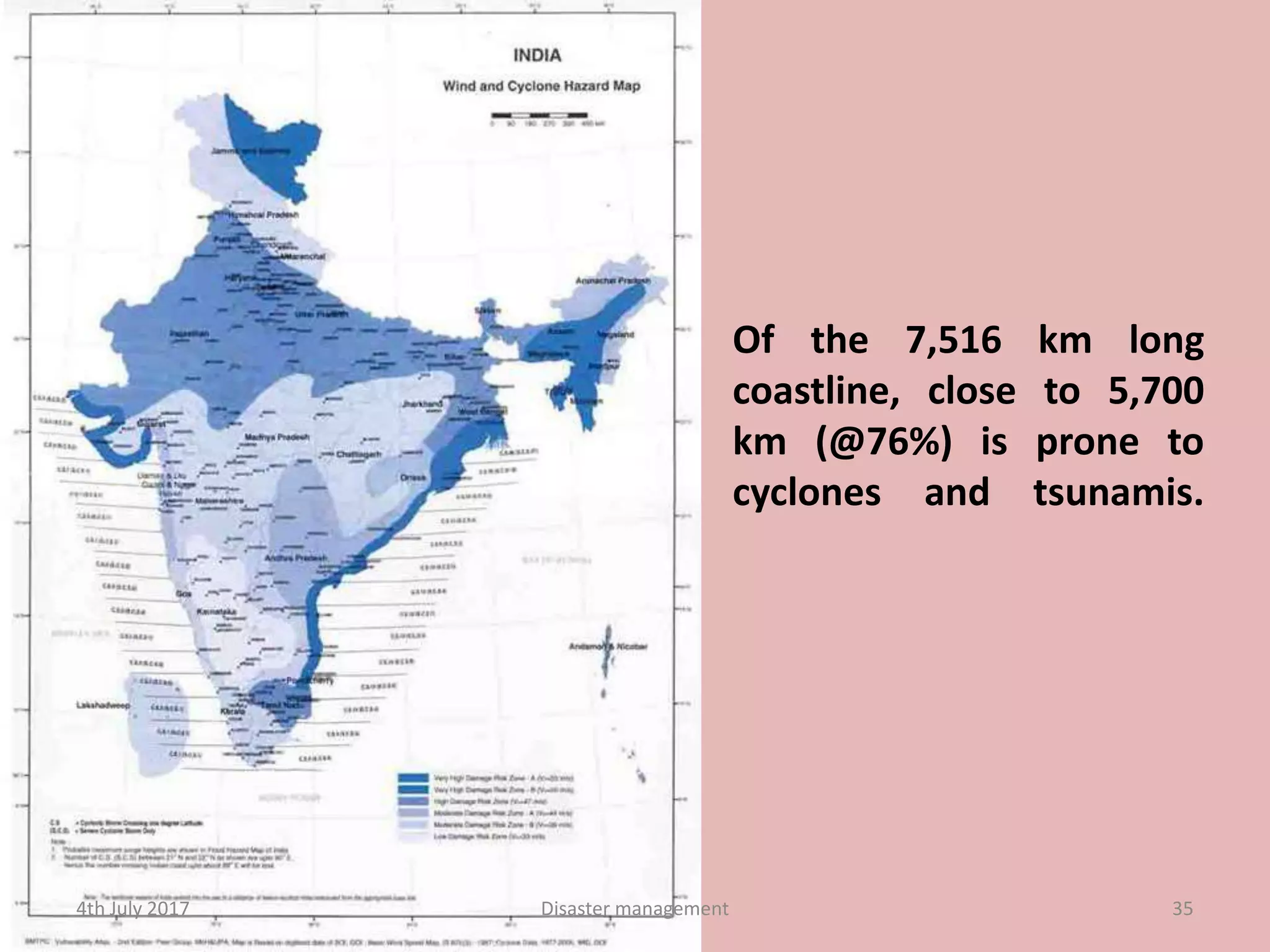

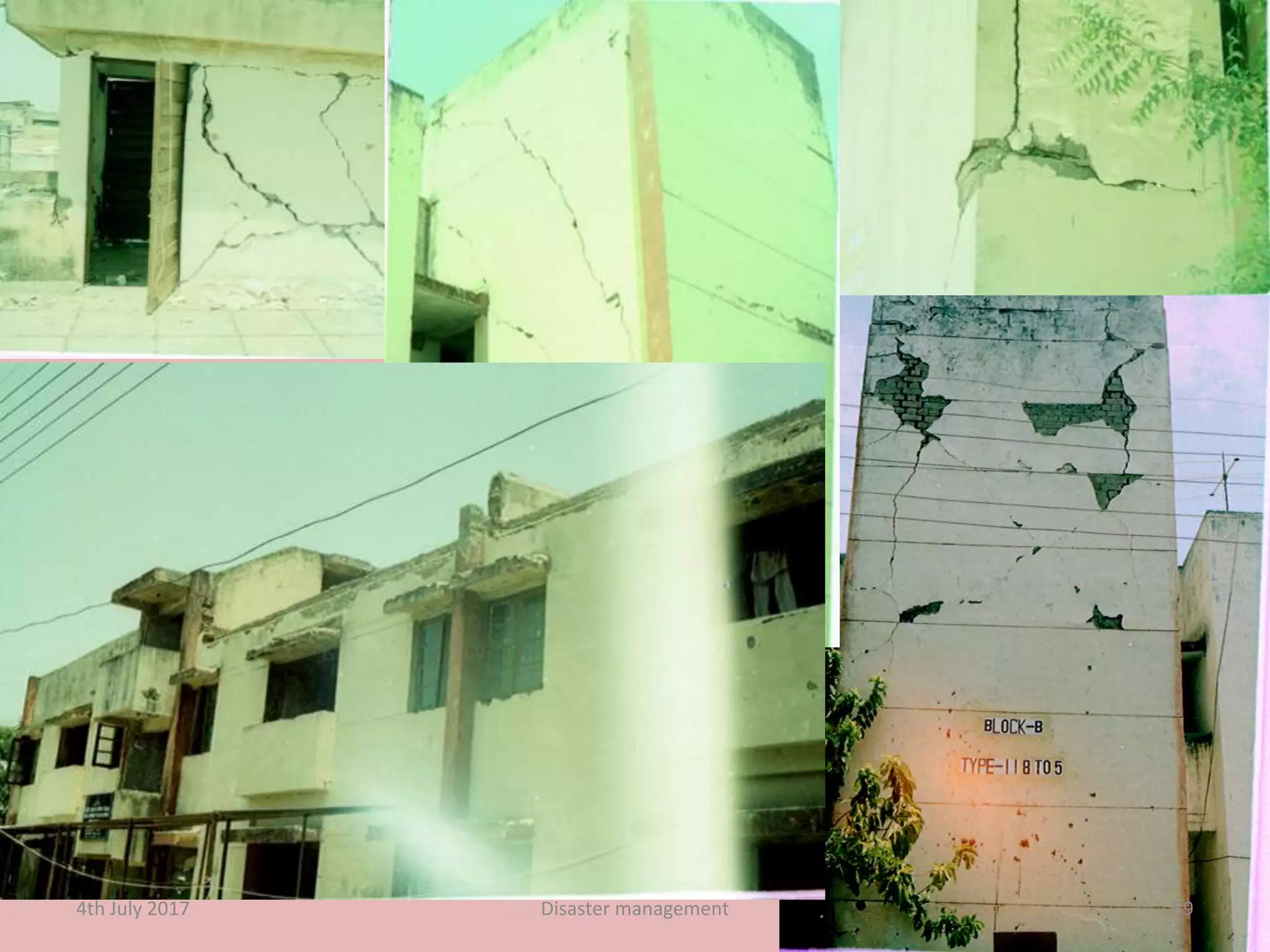

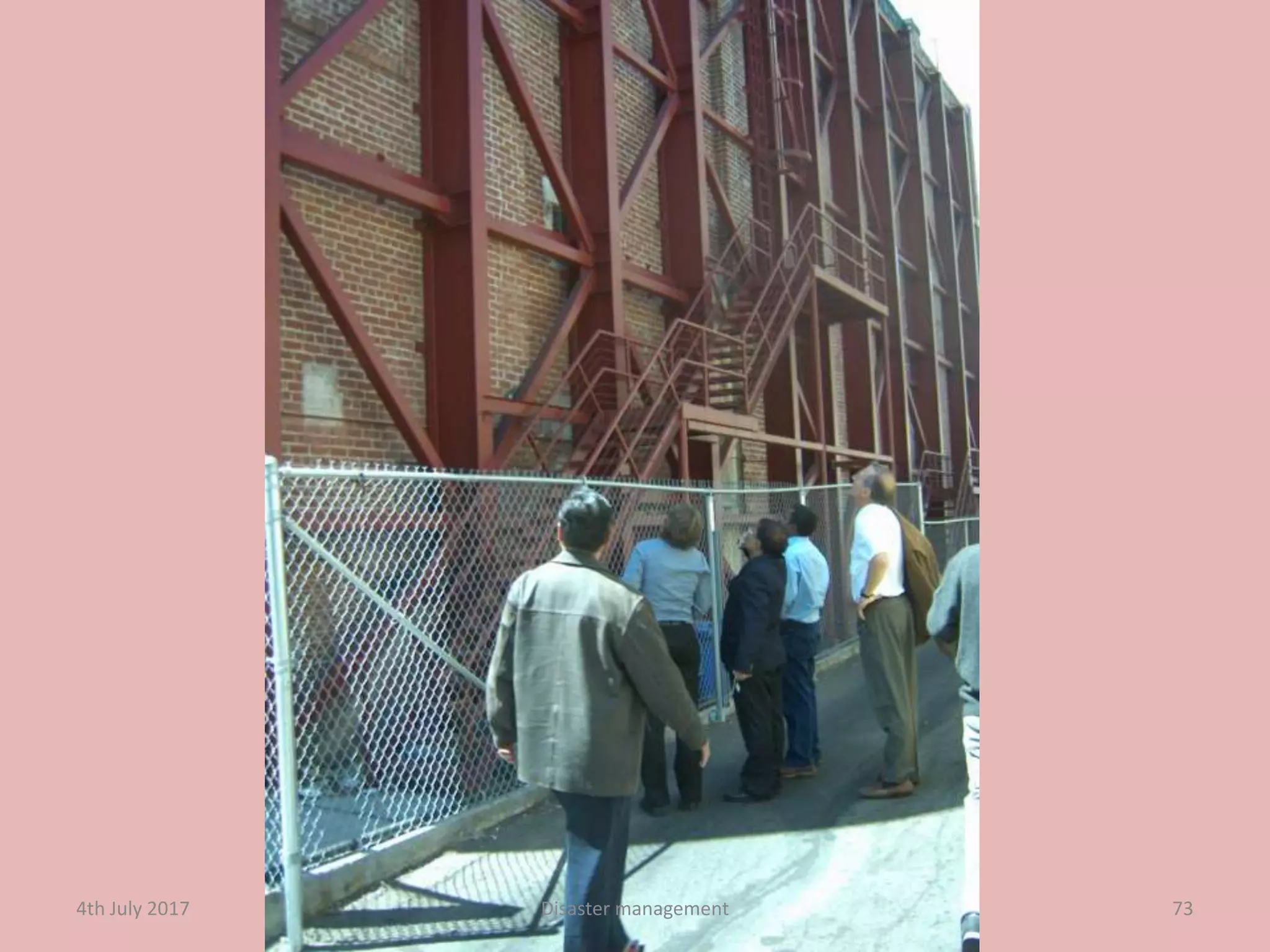

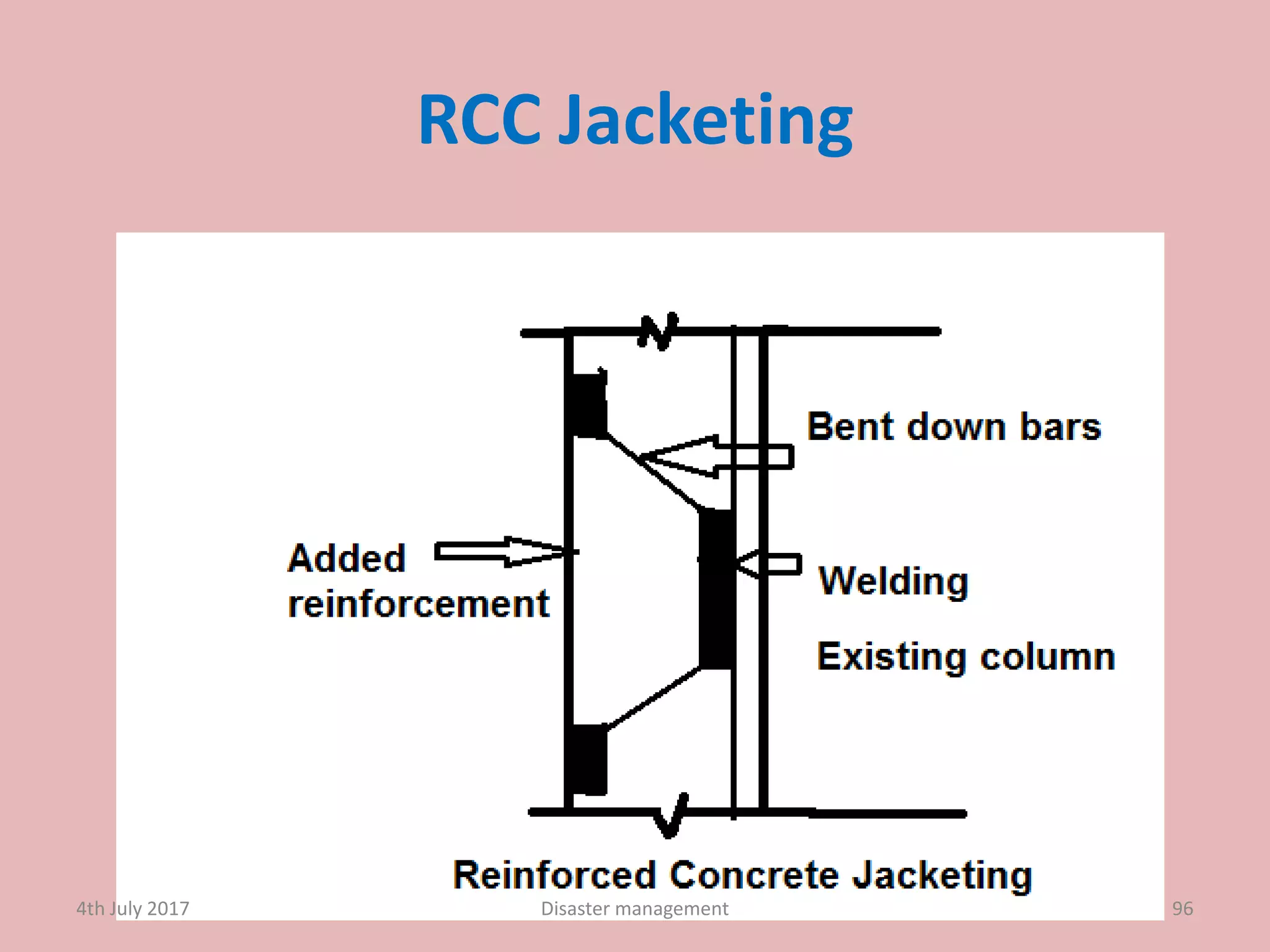

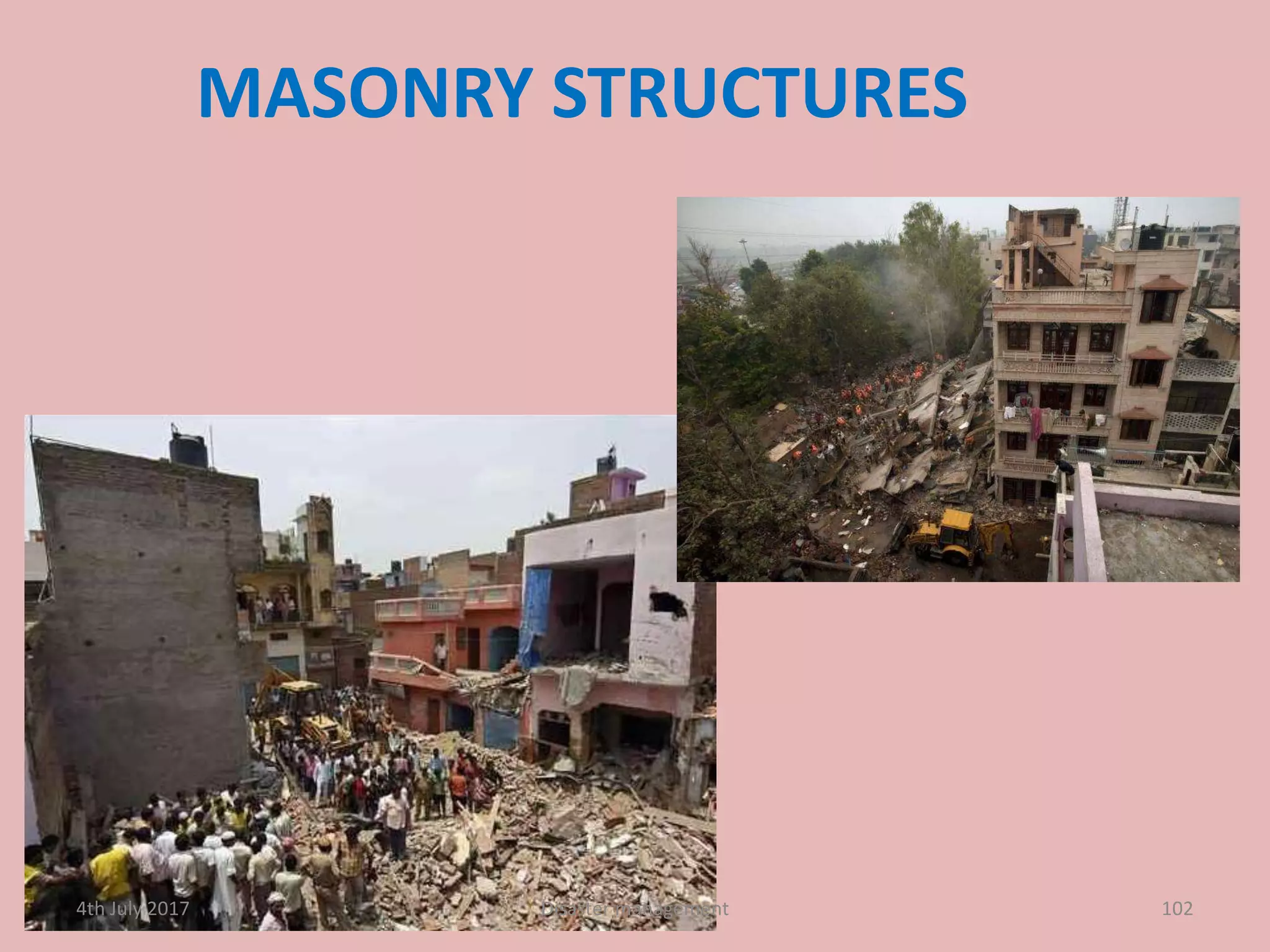

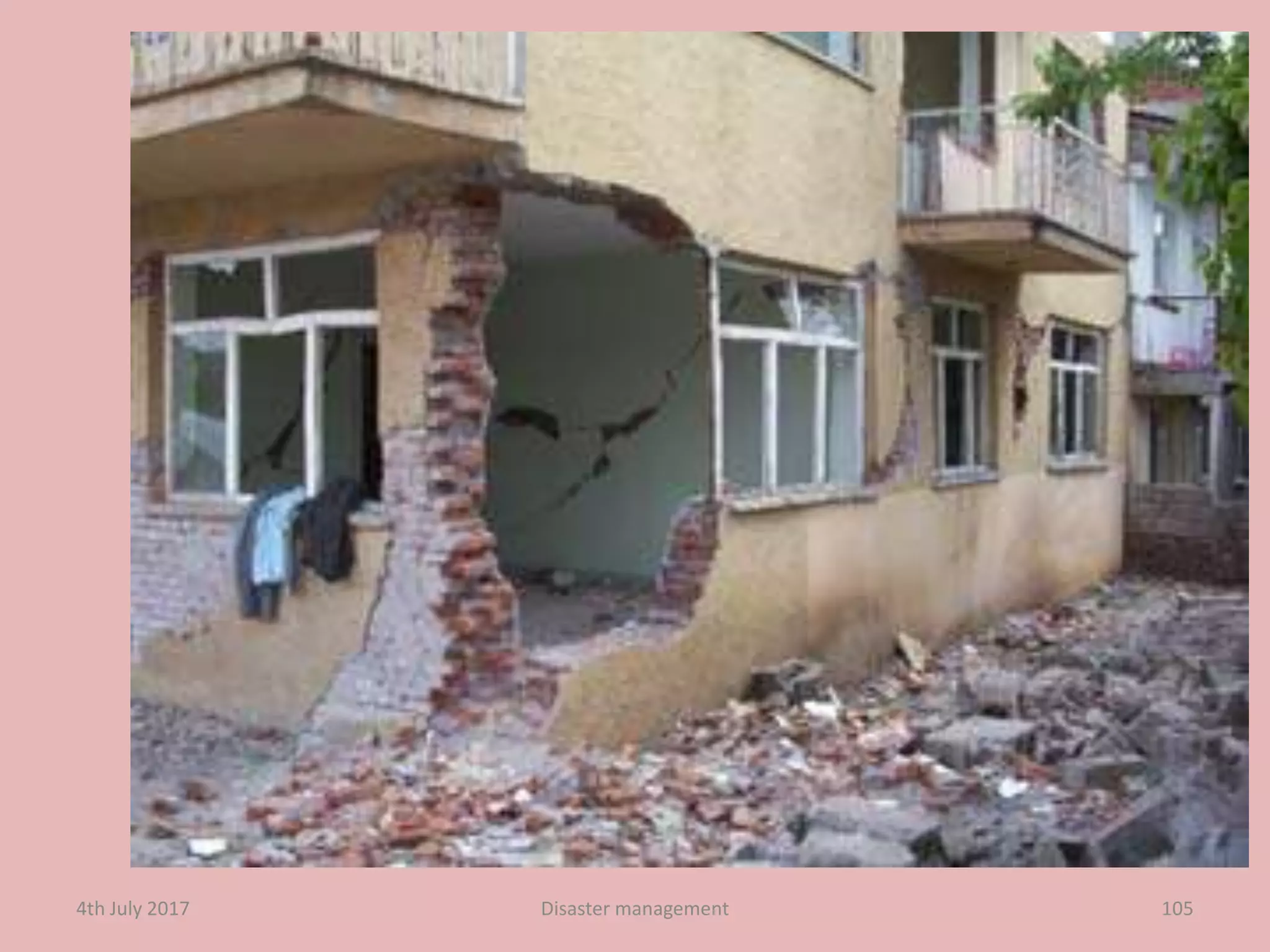

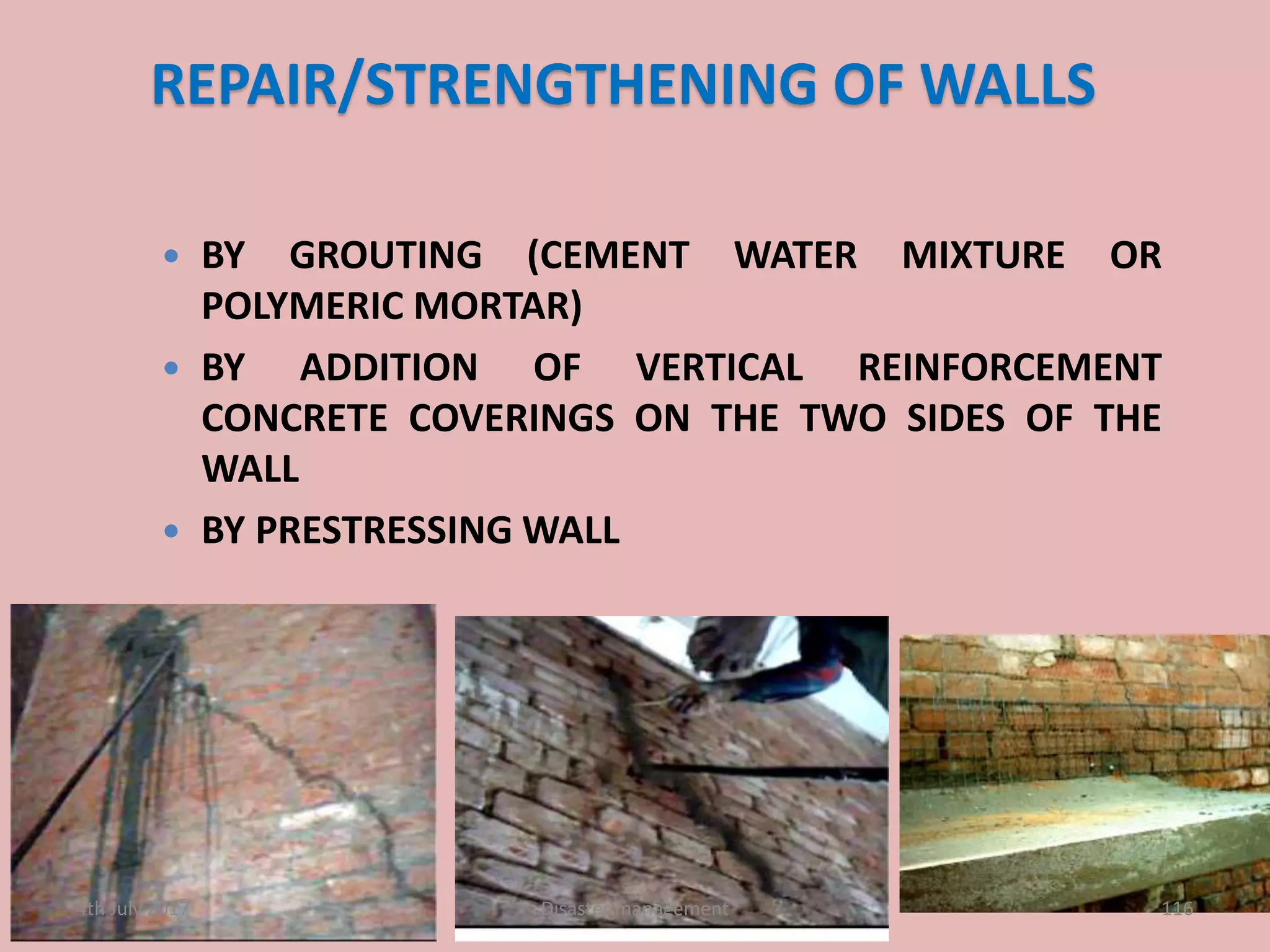

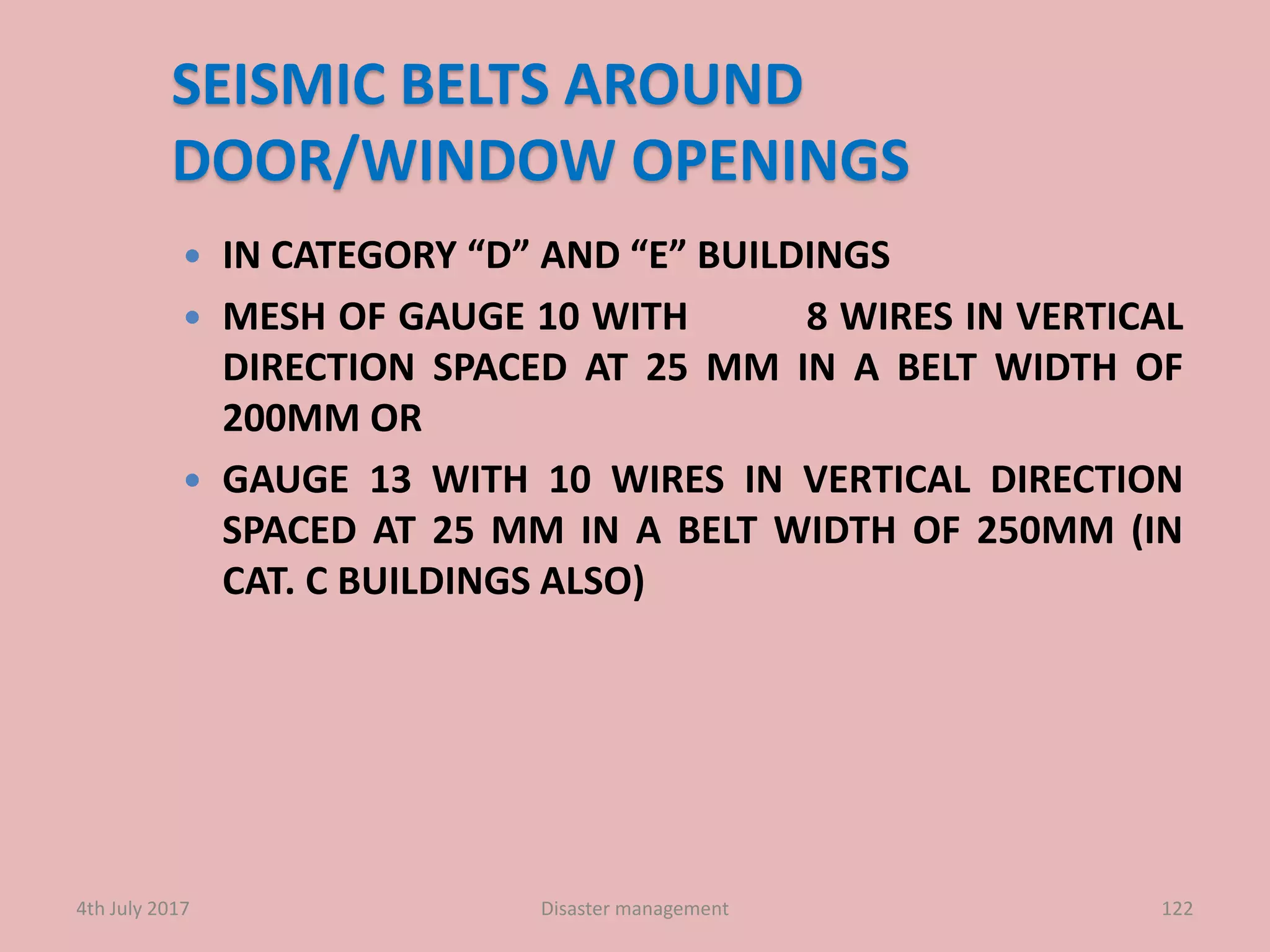

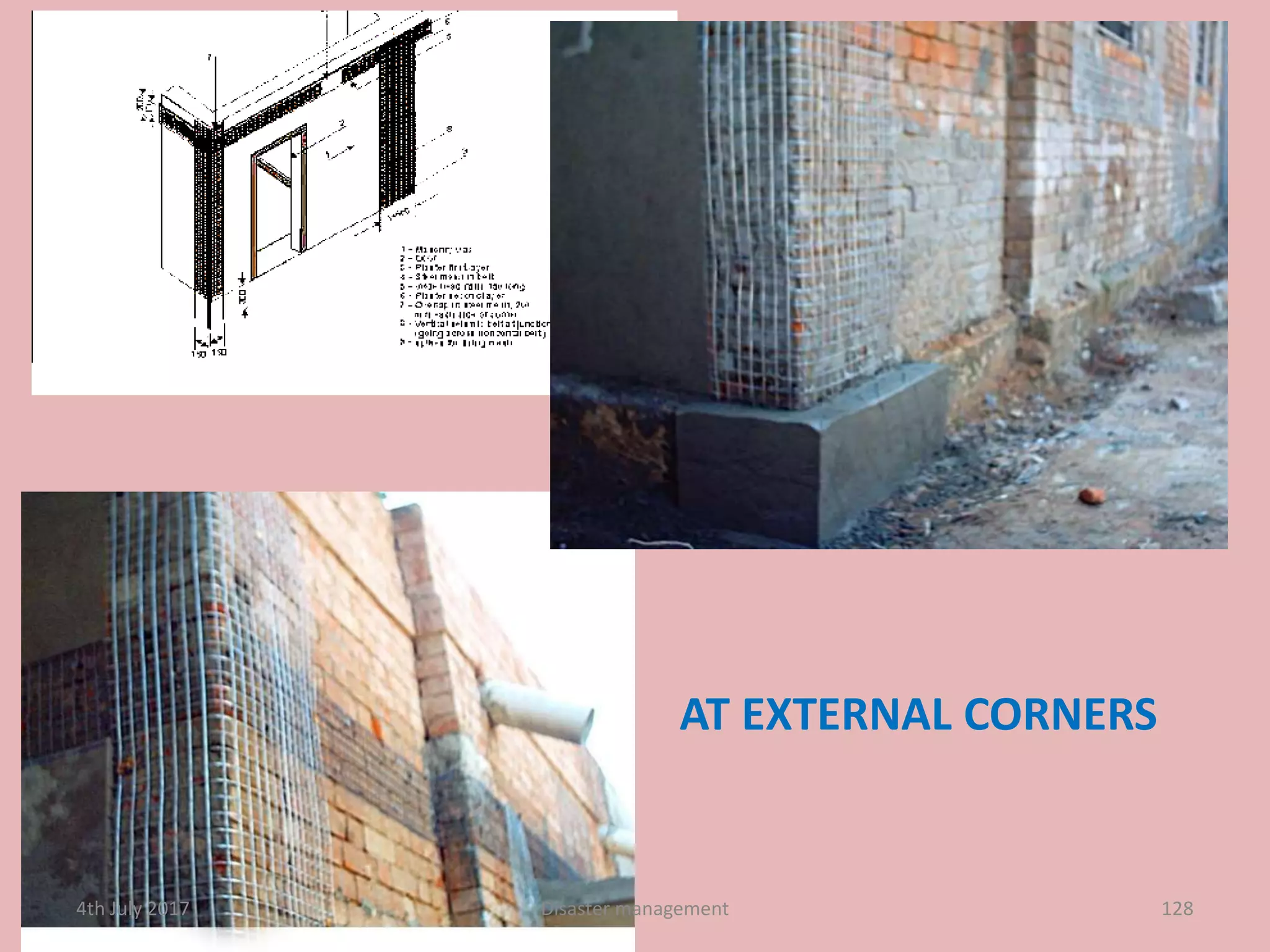

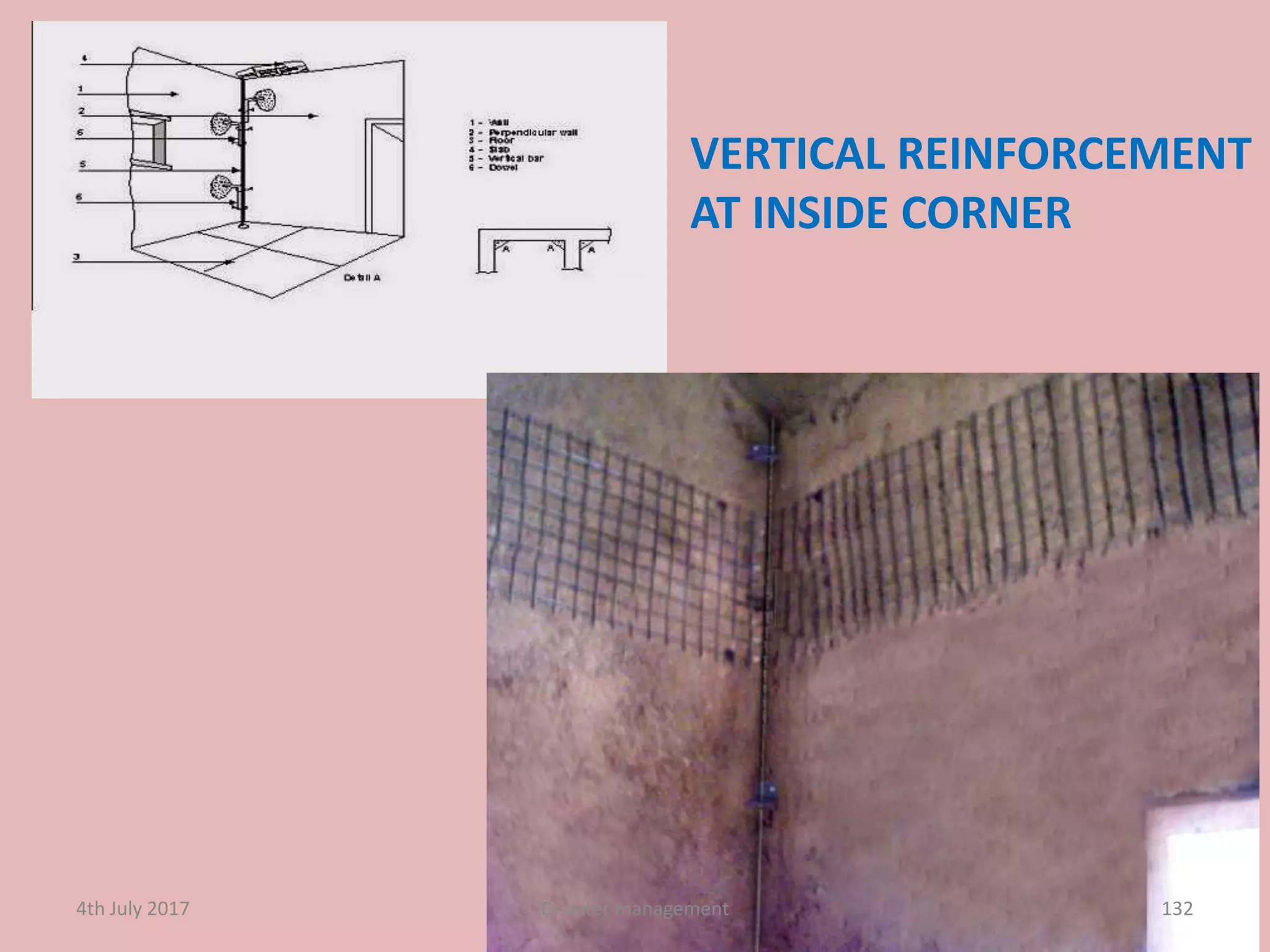

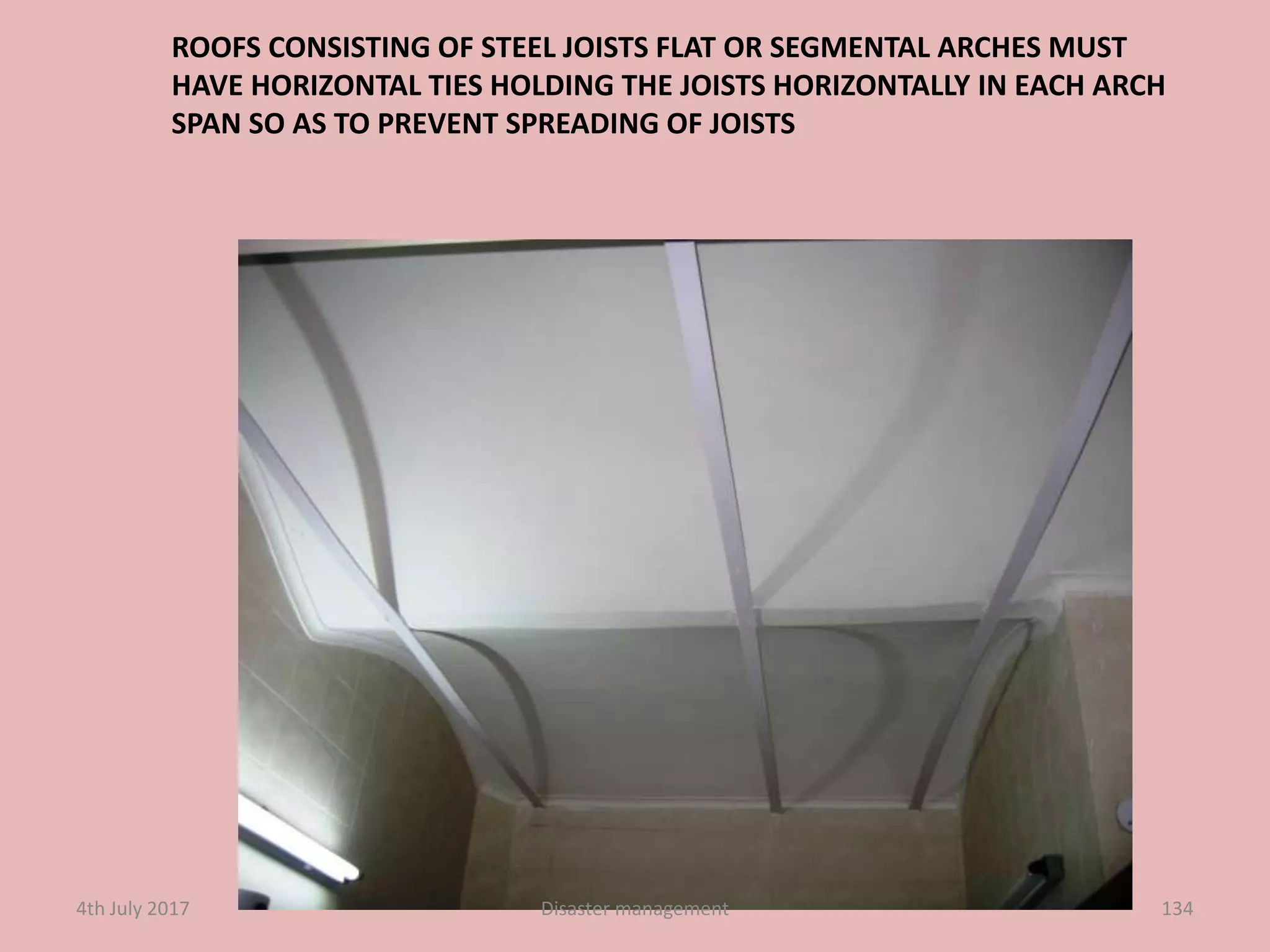

The document discusses disaster management focusing on natural and man-made disasters, with a detailed account of major historical events and their fatalities, particularly emphasizing earthquakes and their impacts. It outlines India's vulnerability to disasters and the establishment of a national framework for disaster management, including policies, responsibilities, and community-based approaches. Furthermore, it addresses the significance of retrofitting and rehabilitation of structures to enhance resilience against future disasters.