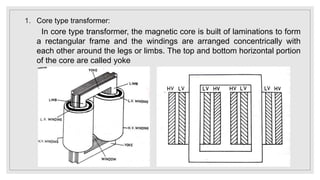

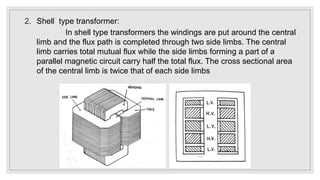

The document discusses different types and classifications of transformers. It begins by classifying transformers based on their construction as either core type or shell type. It then classifies transformers based on their application as either power transformers or distribution transformers. Power transformers are used in substations and generating stations above 200kVA rating, while distribution transformers step down voltage for distribution below 200kVA. Distribution transformers are designed for maximum efficiency at partial loads since they operate continuously with varying loads, while power transformers are designed for maximum efficiency at or near full load.