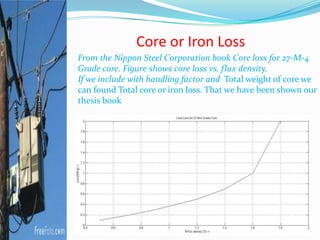

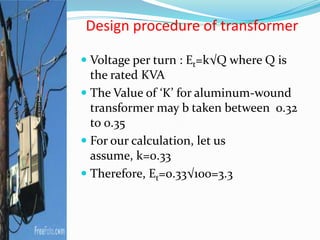

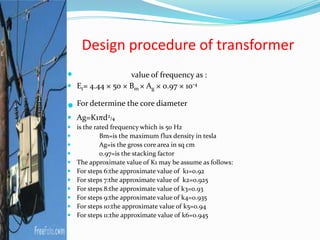

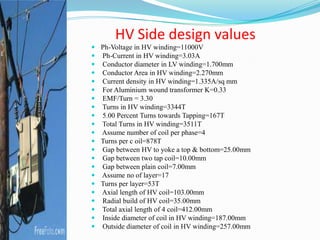

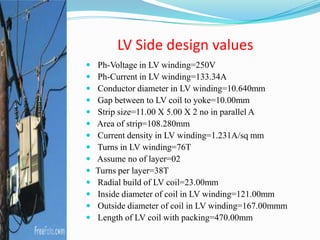

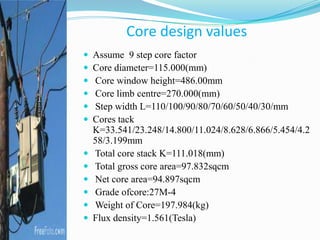

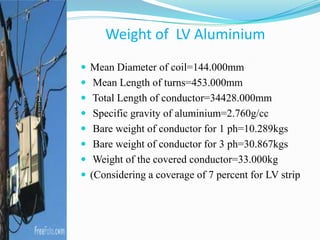

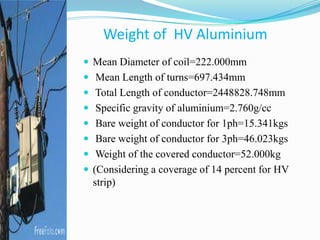

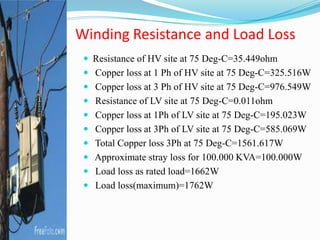

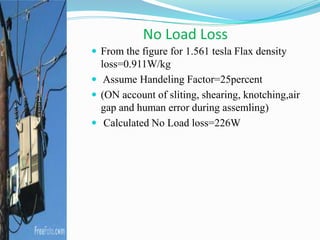

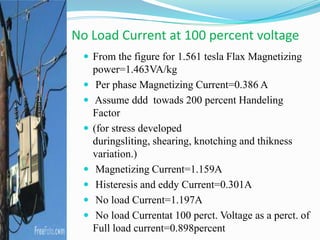

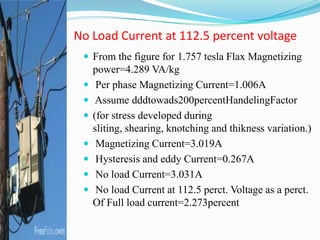

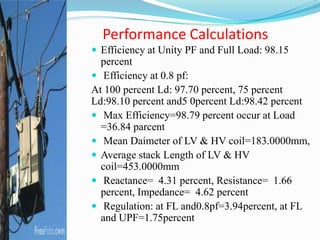

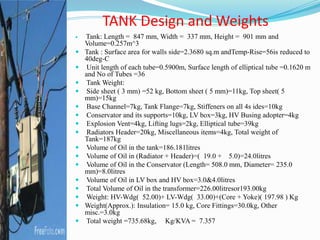

The document summarizes the design of a 100 KVA power transformer. It includes the design calculations for the high voltage and low voltage windings, core, tank, and other components. Key specifications calculated include 11,000/433V voltage ratings, 3344 turns for the high voltage winding, 76 turns for the low voltage winding, and a core size of 115mm diameter. Performance metrics like 98.15% efficiency at full load, 3.94% voltage regulation, and total losses of 1561.617W are provided. Dimensions for the transformer tank and cooling system are also listed.