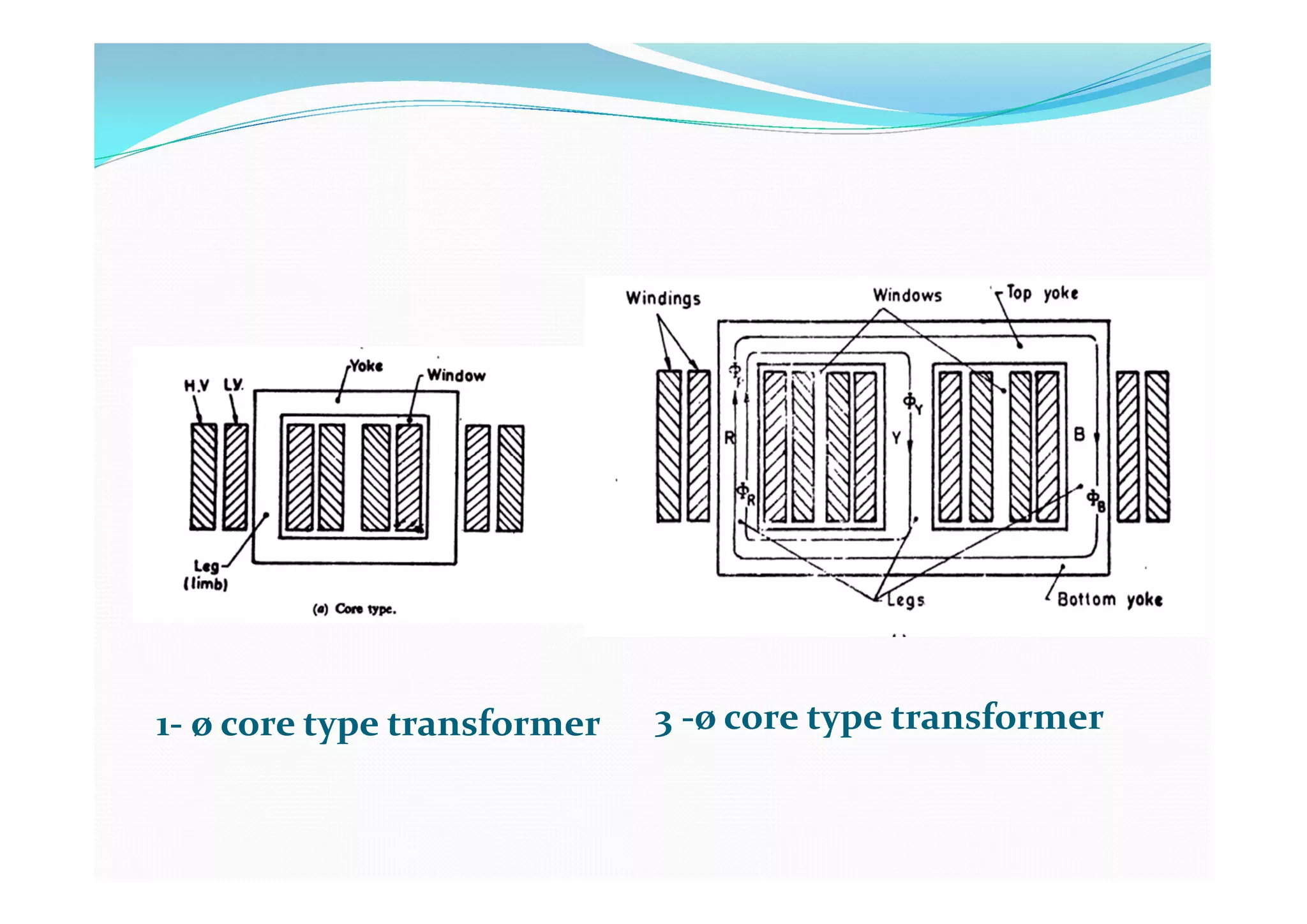

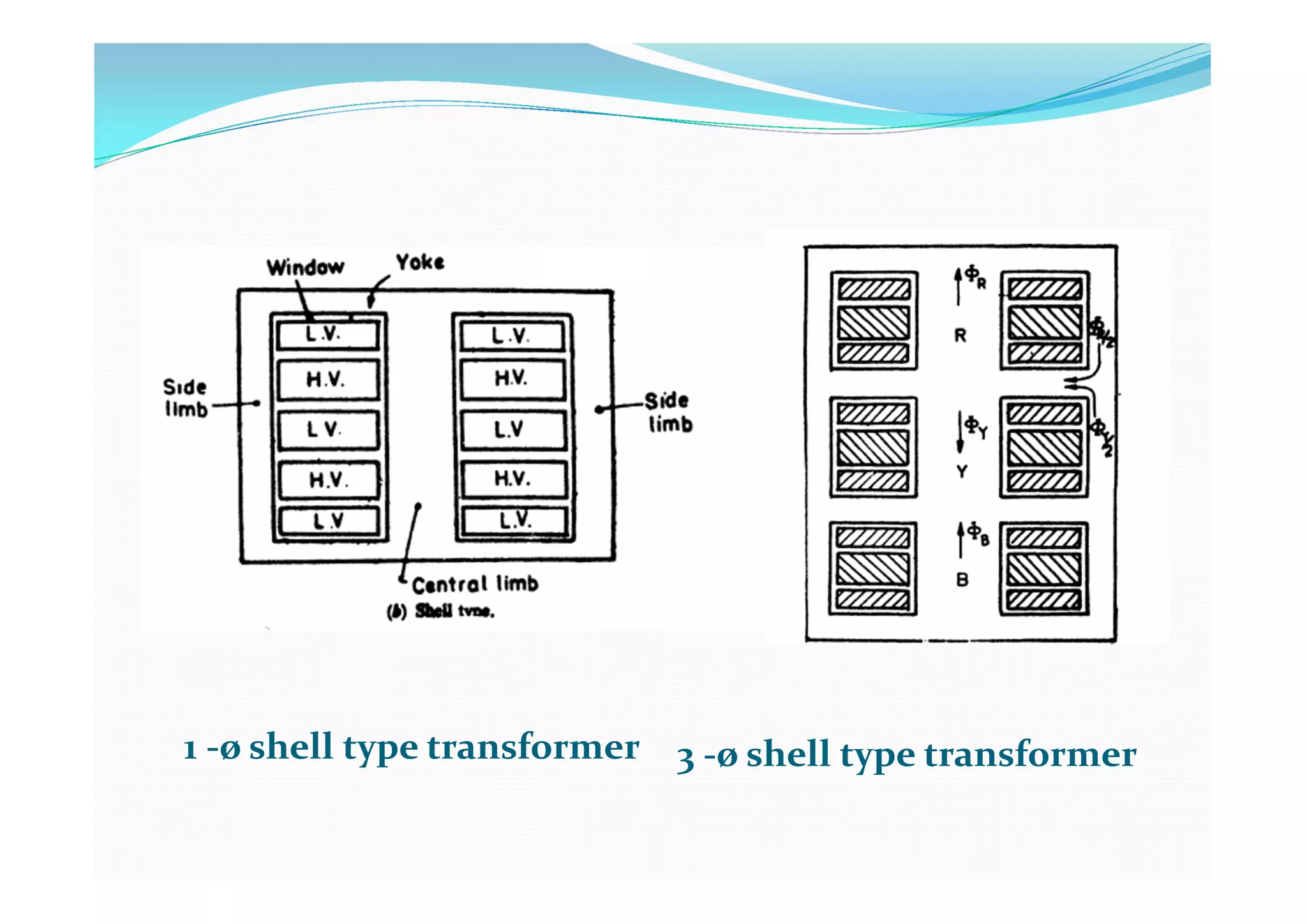

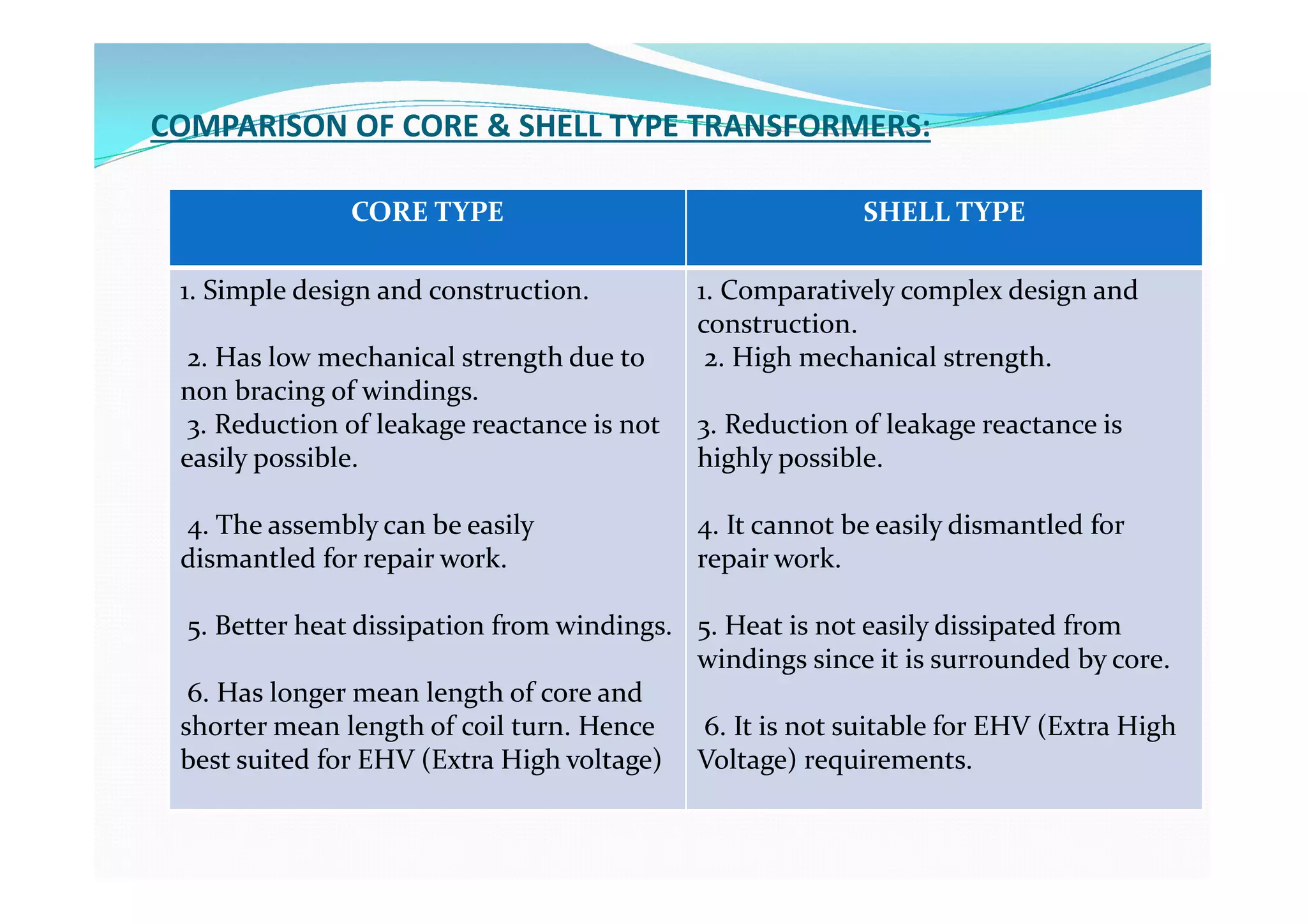

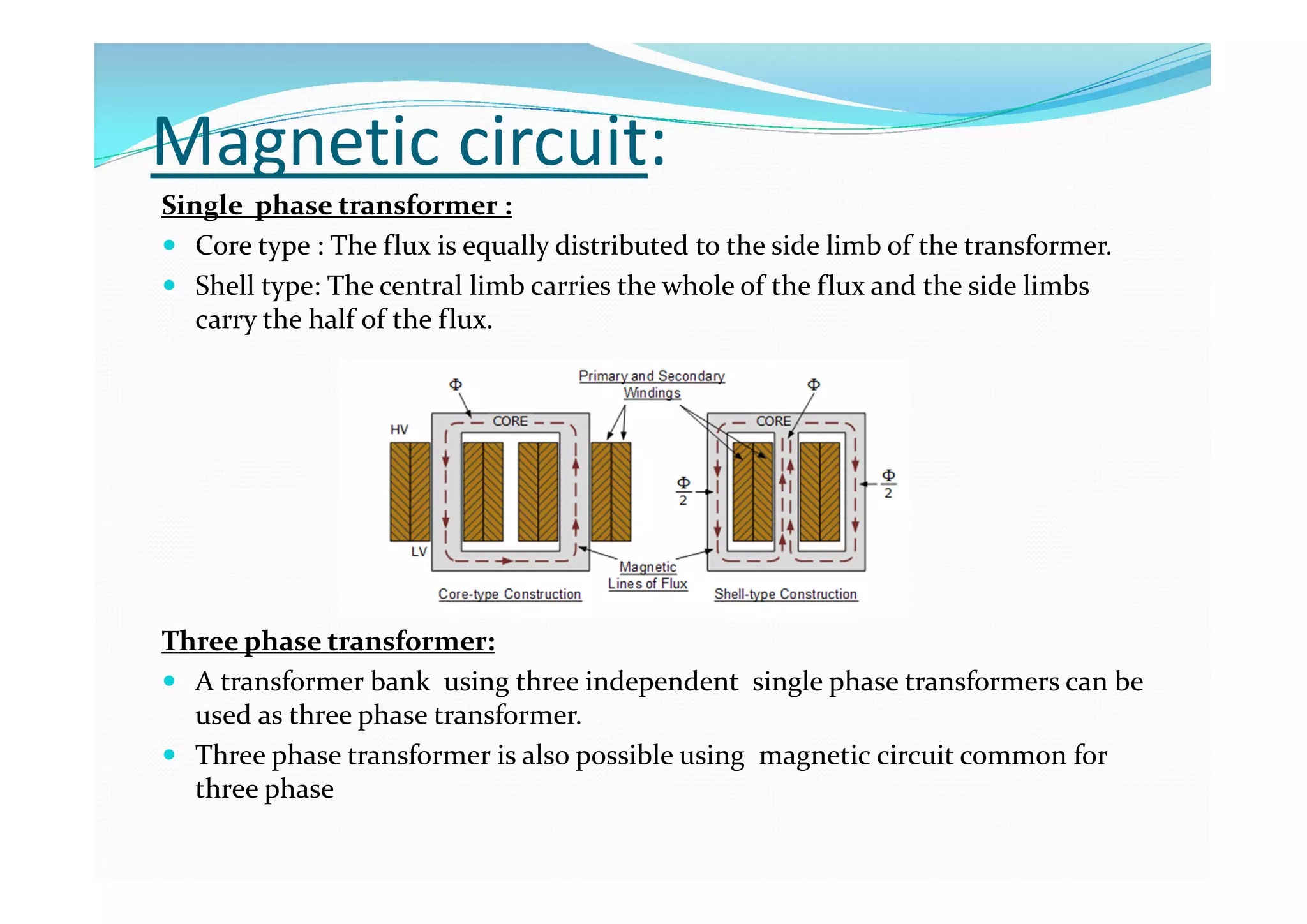

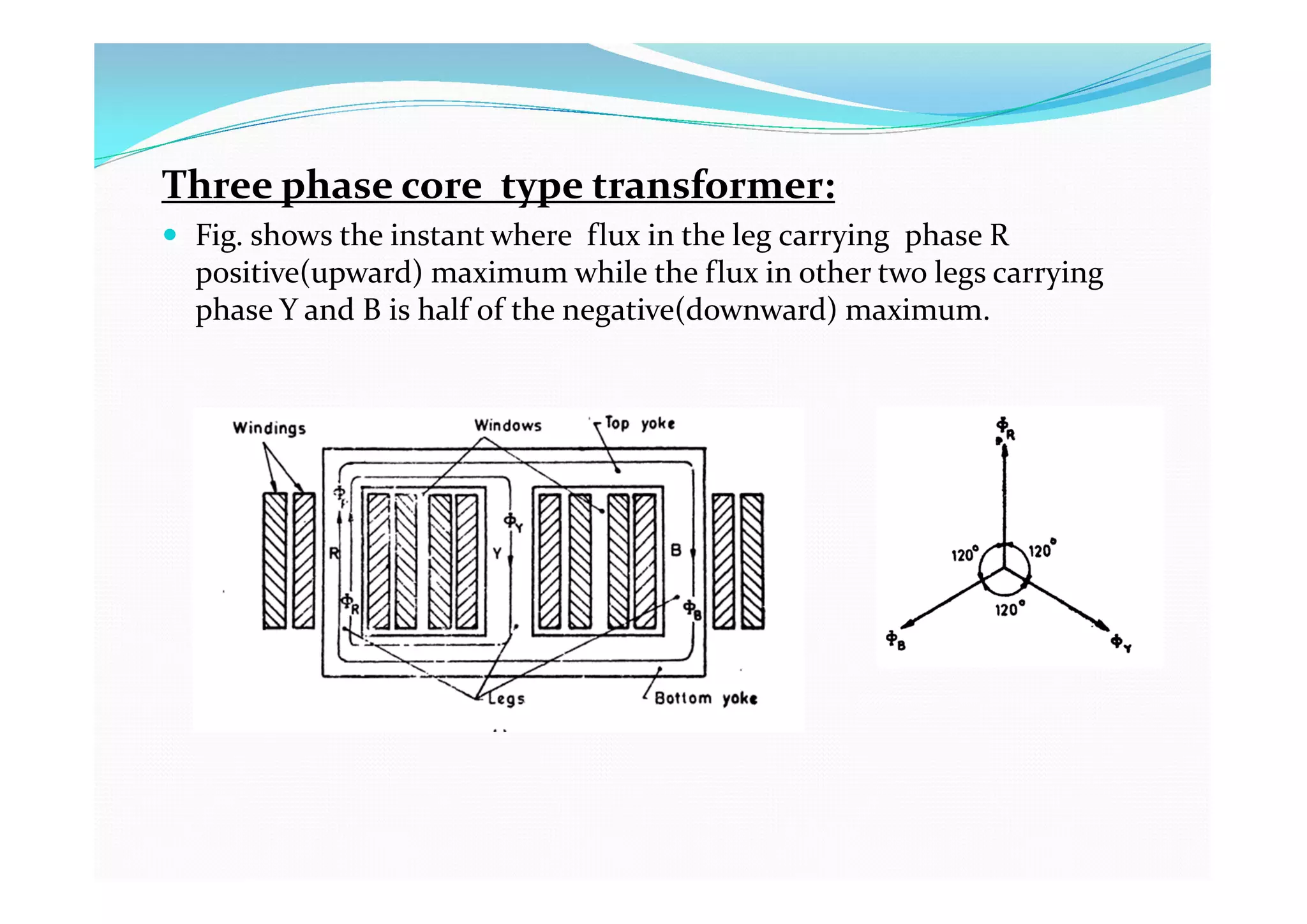

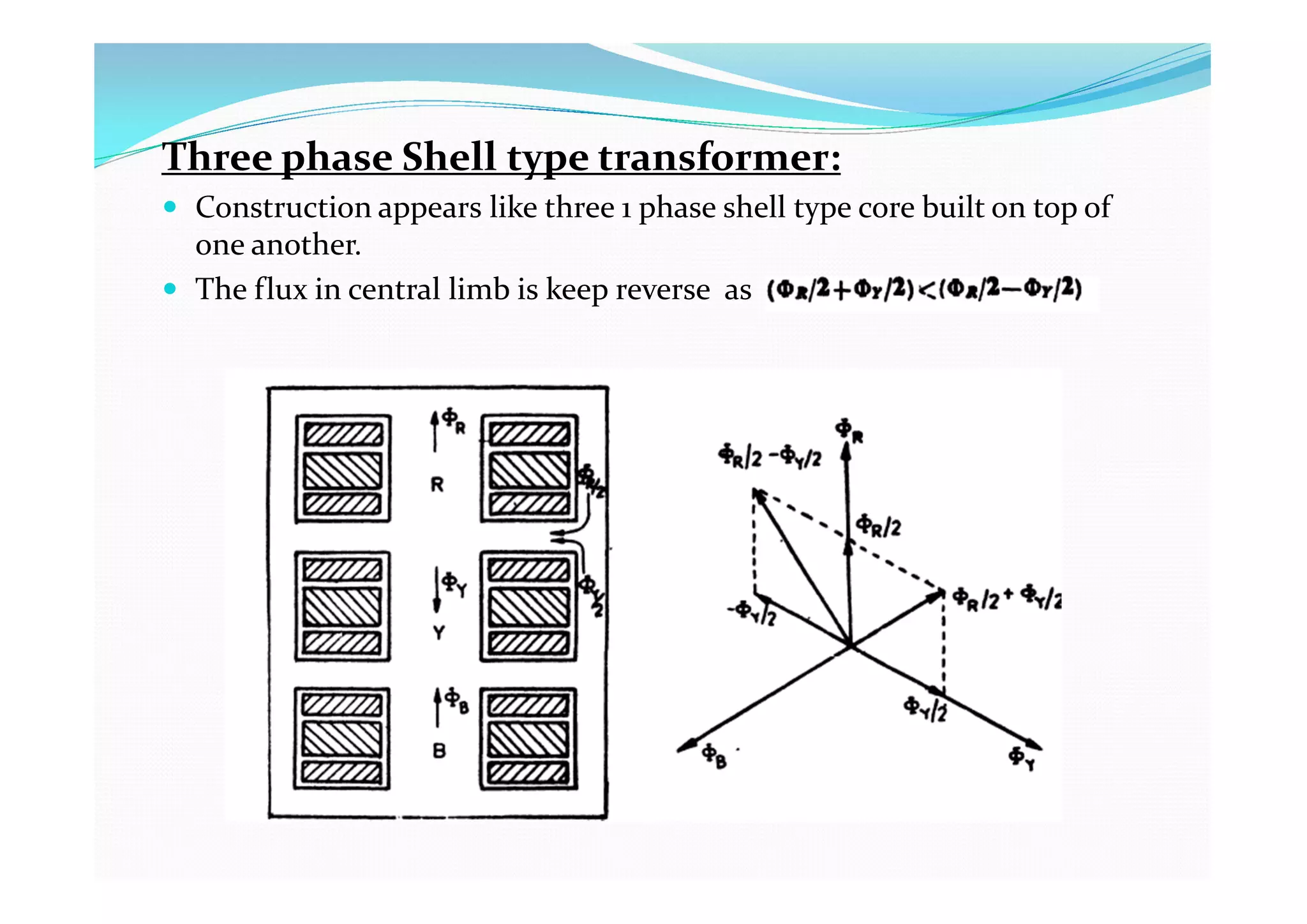

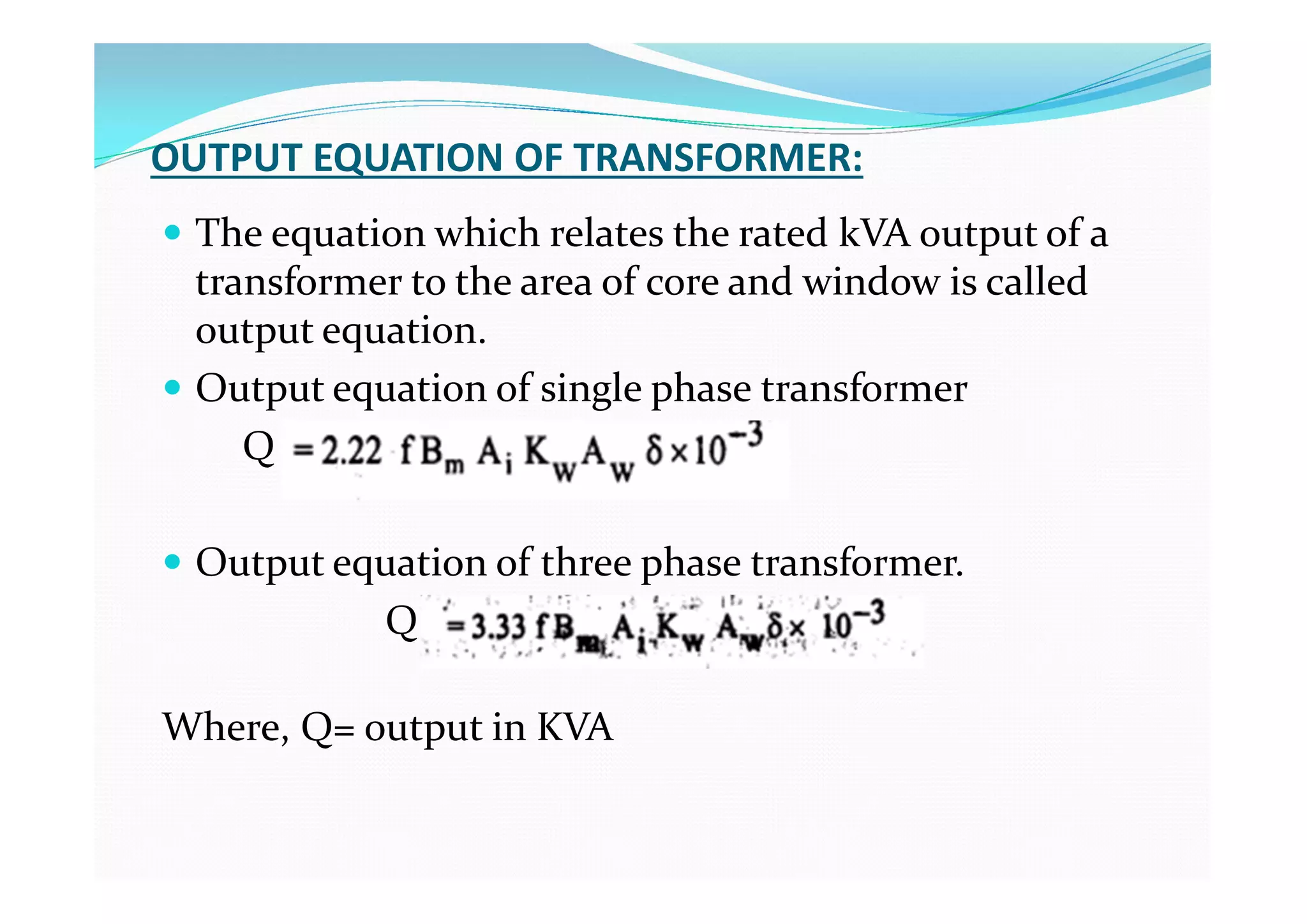

This document summarizes the key topics in the chapter on electrical transformer design and cost estimation. It describes the main types of transformers as core type and shell type, and their construction. Distribution transformers and power transformers are compared in terms of their typical ratings and applications. The specifications, magnetic circuit, and output equations of transformers are also outlined.