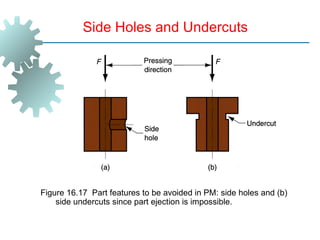

This document explores alternatives to conventional pressing and sintering in powder metallurgy (PM), highlighting methods like isostatic and hot pressing. It discusses materials suitable for PM, including elemental and pre-alloyed powders, as well as common products like gears and bearings, emphasizing the economic advantages and the importance of part design guidelines. The classification of PM parts according to design difficulty and considerations for geometry and processing limitations are also outlined.