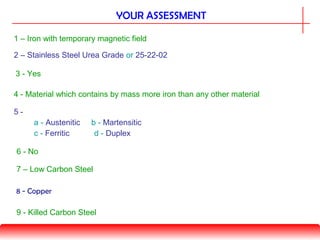

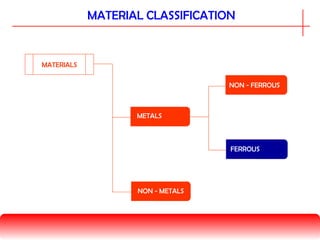

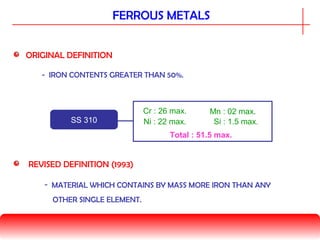

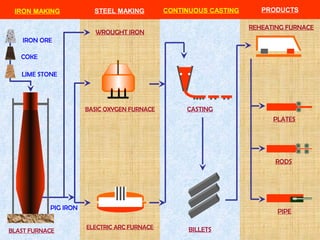

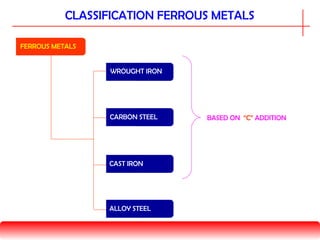

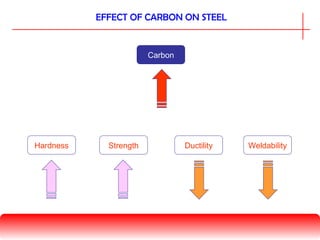

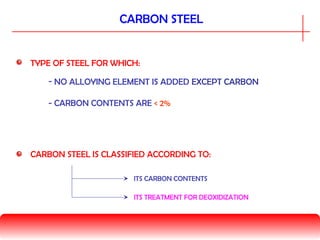

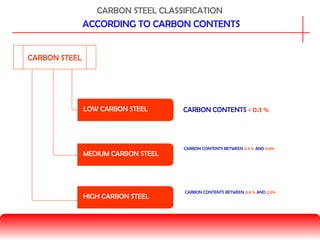

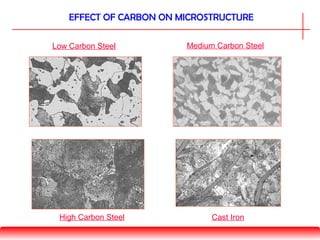

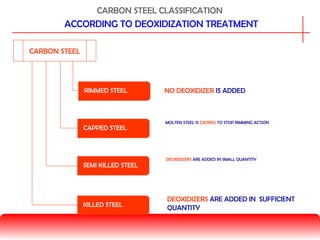

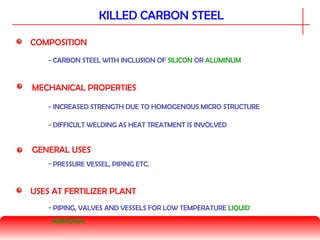

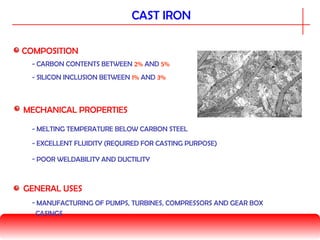

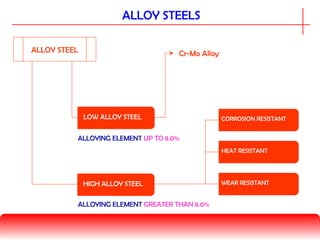

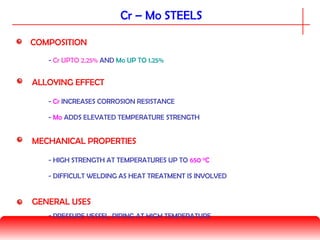

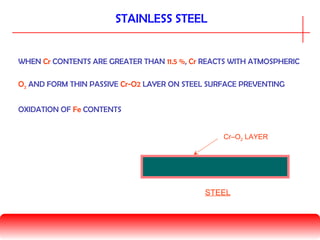

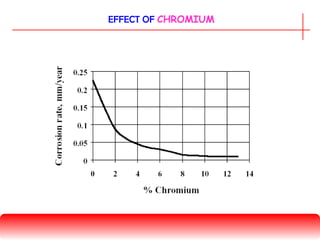

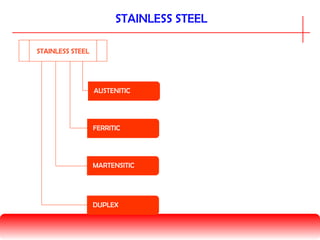

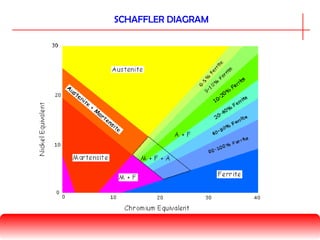

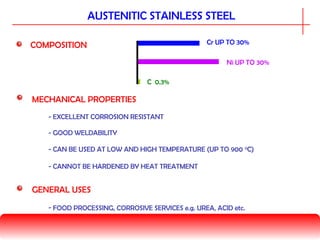

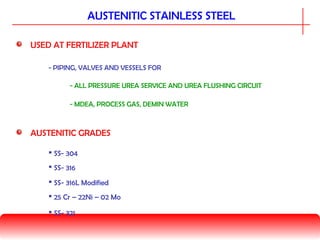

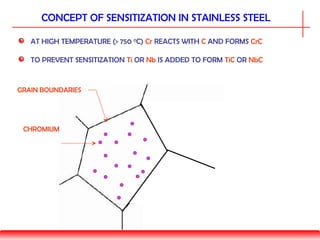

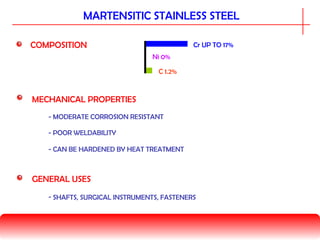

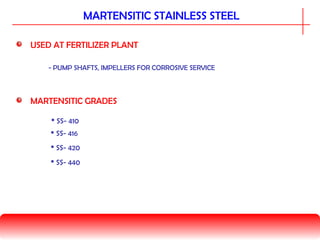

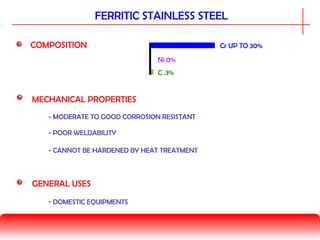

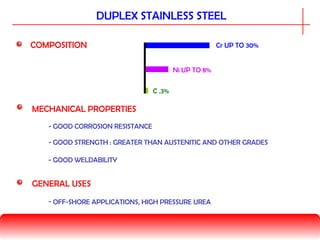

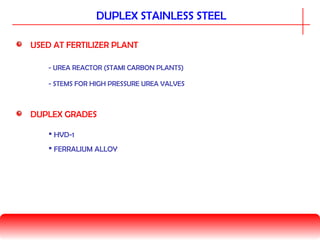

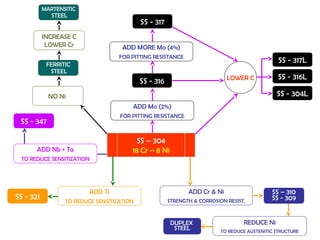

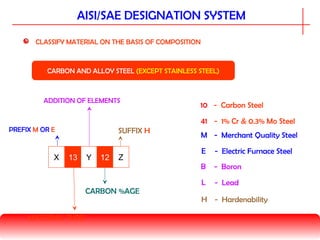

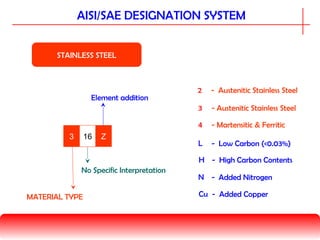

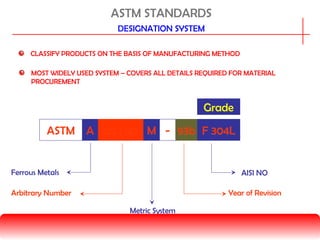

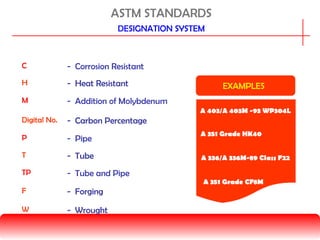

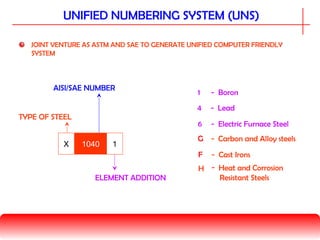

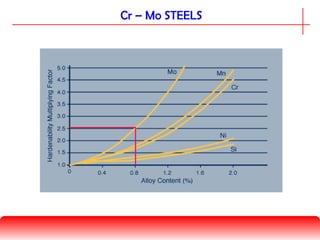

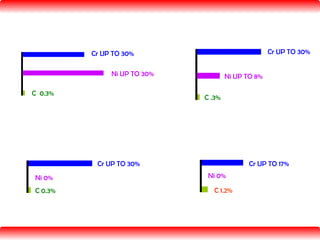

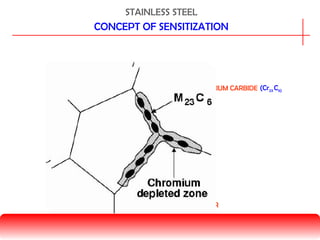

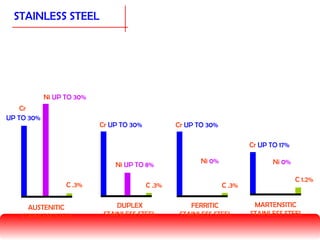

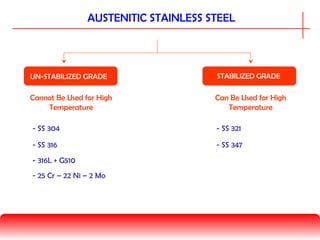

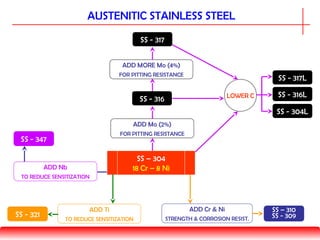

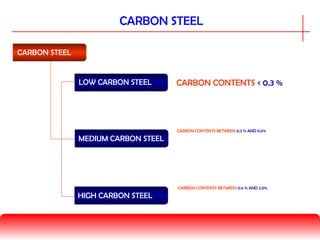

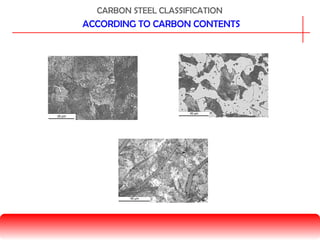

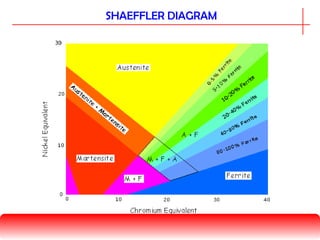

The document discusses various industrial and fertilizer materials. It covers the classification and properties of ferrous metals including carbon steel, alloy steels, cast iron and stainless steels. It describes the composition, mechanical properties and common uses of different grades of these materials. Specific grades used in fertilizer plants are also mentioned including Cr-Mo steels, austenitic stainless steels, and duplex stainless steels used in urea services and reactors.